Abstract

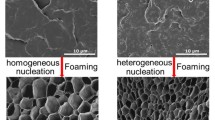

The objective of this study was to investigate the effect of supercritical carbon dioxide (scCO2) during continuous extrusion on controlling phase structure of polypropylene (PP)/polystyrene (PS) blends and the corresponding mechanical properties and foamability. Viscosity reduction of PP and PS was studied using a slit die rheometer attached to a tandem extrusion system. The scCO2 was injected at 2.0, 4.0 and 6.0 wt% to PP/PS blends during extrusion. It was found that a sharp decrease in the size of the dispersed phase was achieved with the injection of scCO2. The size of the minor phase for 75/25 PP-2/PS blend with 4.0 wt% scCO2 was significantly reduced to 50 nm, due to the viscosity ratio of PP-2 to PS close to one. The mechanical properties of the polymer blends were closely related to the phase structure, and better dispersion favored enhanced mechanical properties. Foamability of the PP/PS blends was also found to be closely dependent on phase morphology, and better dispersion endorsed uniform cell structure with smaller cell size and high cell densities.

Similar content being viewed by others

References

Jolfaei AF, Gavgani JN, Jalali A, Goharpey F (2015) Effect of organoclay and compatibilizers on microstructure, rheological and mechanical properties of dynamically vulcanized EPDM/PP elastomers. Polym Bull 72:1127–1144

Wang Y, Xiao Y, Zhang Q, Gao XL, Fu Q (2003) The morphology and mechanical properties of dynamic packing injection molded PP/PS blends. Polymer 44:1469–1480

Macaúbas PHP, Demarquette NR (2001) Morphologies and interfacial tensions of immiscible polypropylene/polystyrene blends modified with triblock copolymers. Polymer 42:2543–2554

Xanthos M (1988) Interfacial agents for multiphase polymer systems: recent advances. Polym Eng Sci 28:1392–1400

Gupta AK, Purwar SN (1985) Studies on binary and ternary blends of polypropylene with SEBS, PS, and HDPE. II. Tensile and impact properties. J Appl Polym Sci 30:1799–1814

Taylor GI (1999) The viscosity of a fluid containing small drops of another fluid. Proc R Soc Lond A Math 138:41–48

Yang K, Lee SH, Oh JM (1999) Effects of viscosity ratio and compatibilizers on the morphology and mechanical properties of polycarbonate/acrylonitrile-butadiene-styrene blends. Polym Eng Sci 39:1667–1677

Hietaoja PT, Holsti-miettinen RM, Seppälä JV, Ikkala OT (1994) The effect of viscosity ratio on the phase inversion of polyamide 66/polypropylene blends. J Appl Polym Sci 54:1613–1623

Favis BD, Chalifoux JP (1987) The effect of viscosity ratio on the morphology of polypropylene/polycarbonate blends during processing. Polym Eng Sci 27:1591–1600

Stone HA (1994) Dynamics of drop deformation and breakup in viscous fluids. Annu Rev Fluid Mech 26:65–102

Grace HP (1981) Dispersion phenomena in high viscosity immiscible fluid systems and application of static mixers as dispersion devices in such systems. Chem Eng Commun 14:225–277

Gerhardt LJ, Manke CW, Gulari E (1997) Rheology of polydimethylsiloxane swollen with supercritical carbon dioxide. J Polym Sci Part B Polym Phys 35:523–534

Garg A, Gulari E, Manke CW (1994) Thermodynamics of polymer melts swollen with supercritical gases. Macromolecules 27:5643–5653

Chiou JS, Barlow JW, Paul DR (1985) Plasticization of glassy-polymers by CO2. J Appl Polym Sci 30:2633–2642

Li HB, Lee LJ, Tomasko DL (2004) Effect of carbon dioxide on the interfacial tension of polymer melts. Ind Eng Chem Res 43:509–514

Elkovitch MD, Tomasko DL, Lee LJ (1999) Supercritical carbon dioxide assisted blending of polystyrene and poly(methyl methyacrylate). Polym Eng Sci 39:2075–2084

Elkovitch MD, Lee LJ, Tomasko DL (2000) Effect of supercritical carbon dioxide on morphology development during polymer blending. Polym Eng Sci 40:1850–1861

Elkovitch MD, Lee LJ, Tomasko DL (2001) Effect of supercritical carbon dioxide on PMMA/rubber and polystyrene/rubber blending: viscosity ratio and phase inversion. Polym Eng Sci 41:2108–2125

Lee M, Tzoganakis C (2000) Effects of supercritical CO2 on the viscosity and morphology of polymer blends. Adv Polym Technol 19:300–311

Wang K, Wu F, Zhai WT, Zheng WG (2013) Effect of polytetrafluoroethylene on the foaming behaviors of linear polypropylene in continuous extrusion. J Appl Polym Sci 129:2253–2260

Areerat S, Nagata T, Ohshima M (2002) Measurement and prediction of LDPE/CO2 solution viscosity. Polym Eng Sci 42:2234–2245

Lee M, Park CB, Tzoganakis C (1999) Measurements and modeling of PS/supercritical CO2 solution viscosities. Polym Eng Sci 39:99–109

Ladin D, Park CB, Park SS, Naguib HE, Cha SW (2001) Study of shear and extensional viscosities of biodegradable PBS/CO2 solutions. J Cell Plast 37:109–148

Laun HM (1983) Polymer melt rheology with a slit die. Rheol Acta 22:171–185

Macosko CW (1994) Rheology—principles, measurements, and applications. VCH Publishers, New York

Dealy JM, Wissbrun KF (1989) Melt rheology and its role in plastics processing. Van Nostrand Reinhold, New York

Sato Y, Yurugi M, Fujiwara K, Takishima S, Masuoka H (1996) Solubilities of carbon dioxide and nitrogen in polystyrene under high temperature and pressure. Fluid Phase Equilib 125:129–138

Sato Y, Fujiwara K, Takikawa T, Sumarno Takishima S, Masuoka H (1999) Solubilities and diffusion coefficients of carbon dioxide and nitrogen in polypropylene, high-density polyethylene, and polystyrene under high pressures and temperatures. Fluid Phase Equilib 162:261–276

Lee JK, Han CD (2000) Evolution of polymer blend morphology during compounding in a twin-screw extruder. Polymer 41:1799–1815

Radonjič G, Musil V, Šmit I (1998) Compatibilization of polypropylene/polystyrene blends with poly(styrene-b-butadiene-b-styrene) block copolymer. J Appl Polym Sci 69:2625–2639

Favis BD, Therrien D (1991) Factors influencing structure formation and phase size in an immiscible polymer blend of polycarbonate and polypropylene prepared by twin-screw extrusion. Polymer 32:1474–1481

Paul DR, Newman S (1978) Polymer blends. Academic Press, New York

Bains M, Balke ST, Reck D, Horn J (1994) The compatibility of linear low density polyethylene-polypropylene blends: viscosity ratio plots. Polym Eng Sci 34:1260–1268

Pang YY, Dong X, Zhao Y, Han CC, Wang DJ (2007) Time evolution of phase structure and corresponding mechanical properties of iPP/PEOc blends in the late-stage phase separation and crystallization. Polymer 48:6395–6403

Pang YY, Dong X, Zhao Y, Han CC, Wang DJ (2011) Phase separation induced morphology evolution and corresponding impact fracture behavior of iPP/PEOc blends. J Appl Polym Sci 121:445–453

Zhai WT, Wang HY, Yu J, Dong JY, He JS (2008) Foaming behavior of polypropylene/polystyrene blends enhanced by improved interfacial compatibility. J Polym Sci Part B Polym Phys 46:1641–1651

Hu SF, Zhu XB, Hu W, Yan L, Cai C (2013) Crystallization behaviors and foaming properties of diatomite-filled polypropylene composites. Polym Bull 70:517–533

Wang J, Zhai WT, Ling JQ, Shen B, Zheng WG, Park CB (2011) Ultrasonic irradiation enhanced cell nucleation in microcellular poly(lactic acid): a novel approach to reduce cell size distribution and increase foam expansion. Ind Eng Chem Res 50:13840–13847

Huang HX, Xu HF (2011) Preparation of microcellular polypropylene/polystyrene blend foams with tunable cell structure. Polym Adv Technol 22:822–829

Acknowledgments

Financial supports from National Natural Science Foundation of China (51473181), Natural Science Foundation of Zhejiang Province (LQ14E030006) and Natural Science Foundation of Ningbo (2014A610131) are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wang, K., Wang, S., Wu, F. et al. Supercritical CO2 in controlling phase morphology of polypropylene/polystyrene blends and the corresponding mechanical properties and foamability. Polym. Bull. 73, 941–957 (2016). https://doi.org/10.1007/s00289-015-1528-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-015-1528-8