Abstract

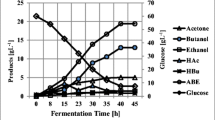

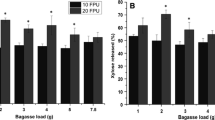

Due to the environmental concerns, the conversion of lignocellulosic waste can be the key to produce bioproducts and biofuels such as butanol. This study aimed to present and evaluate orange bagasse pellets (OBP) as a carbon source to produce butan-1-ol production via ABE fermentation using Clostridium beijerinckii. These bagasse pellets were characterized, holocellulose (18.99%), alfacellulose (5.37%), hemicellulose (13.62%), lignin (6.16%), pectin (7.21%), protein (3.14%), and was tested under three different pretreatments, which were the following: (a) ultrasound, (b) autohydrolysis, and (c) acid-diluted hydrolysis followed by enzymatic hydrolysis to verify an amount of fermentable total reducing sugars. ANOVA was used and pretreatments followed by enzymatic hydrolysis do not enhance a significant amount of available sugars compared to raw bagasse. The ABE fermentation was carried out in batch reactors at 37 °C under agitation of 160 rpm and anaerobic conditions, using OBP without treatment followed by enzymatic hydrolysis. Using a non-mutant microorganism, the fermentation achieved butyric acid yields of 3762.68 mg L−1 for control and 2488.82 mg L−1 for OBP and the butanol production was 63.86 mg L−1 and 196.80 mg L−1 for OBP and the control (glucose) assay, respectively. The results of this solvent’s production have shown that OBP has the potential for ABE fermentation and a promising feedstock.

Similar content being viewed by others

References

Matharu AS, de Melo EM, Houghton JA (2016) Opportunity for high value-added chemicals from food supply chain wastes. Bioresour Technol 215:123–130. https://doi.org/10.1016/j.biortech.2016.03.039

Liu Y, Heying E, Tanumihardjo SA (2012) History, global distribution, and nutritional importance of citrus fruits. Compr Rev Food Sci Food Saf 11:530–545. https://doi.org/10.1111/j.1541-4337.2012.00201.x

Zema DA, Calabrò PS, Folino A et al (2018) Valorisation of citrus processing waste: a review. Waste Manag 80:252–273. https://doi.org/10.1016/j.wasman.2018.09.024

Neves MF, Trombin VG (2017) Anuário da Citricultura 2017

Guilherme AA, Dantas PVF, Santos ES et al (2015) Evaluation od composition, characterization and enzymatic hydrolysis of pretreated sugar cane bagasse. Braz J Chem Eng 32:23–33

Pugazhendhi A, Mathimani T, Varjani S, Rene ER (2019) Biobutanol as a promising liquid fuel for the future—recent updates and perspectives. Fuel 253:637–646. https://doi.org/10.1016/j.fuel.2019.04.139

Qureshi N, Ezeji TC (2008) Butanol production by Clostridium beijerinckii. Part I: use of acid and enzyme hydrolyzed corn fiber. Biores Technol 9:5915–5922. https://doi.org/10.1016/j.biortech.2007.09.087

Mahapatra MK, Kumar A (2017) A short review on biobutanol, a second generation biofuel production from lignocellulosic biomass. J Clean Energy Technol 5:27–30. https://doi.org/10.18178/jocet.2017.5.1.338

Bellido C, Pinto ML, Coca M et al (2014) Acetone—butanol—ethanol (ABE) production by Clostridium beijerinckii from wheat straw hydrolysates: efficient use of penta and hexa carbohydrates. Bioresour Technol 167:198–205. https://doi.org/10.1016/j.biortech.2014.06.020

Algayyim SJM, Wendel AP, Yusaf T, Hamawand I (2018) Production and application of ABE as a biofuel. Renew Sustain Energy Rev 82:1195–1214. https://doi.org/10.1016/j.rser.2017.09.082

TAPPI (Technical Association of Pulp and Paper Industry) Standart Method T211 om-93 (1993)—Tappi Test Methods

NREL—National Renewable Energy Laboratory)—Laboratory Analytical Procedure (2018) Determination of total solids in biomass and total dissolved solid in liquid process samples

Nakashima GT, Adhmann ICS, Hansted ALS et al (2016) Materiais lignocelulósicos: caracterização e produção de briquetes. Revista Virtual de Química 9:150–162

Sudhakar DV, Maini SB (2000) Isolation and characterization of mango peel pectins. J Food Process Preserv 24:209–227

TAPPI (Technical Association of Pulp and Paper Industry) Standart Method T222 om-02 (2002)—Tappi Test Methods

TAPPI (Technical Association of Pulp and Paper Industry) Standart Method T13 om-54 (1991)—Tappi Test Methods

TAPPI (Technical Association of Pulp and Paper Industry) Standart Method T257 m-85 (1985)—Tappi Test Methods

TAPPI (Technical Association of Pulp and Paper Industry) Standart Method T203 om-99 (1999)—Tappi Test Methods

Segal L, Creely JJ, Martin A, Conrad M (1958) Empirical method for estimating the degree of crystallinity of native cellulose using the x-ray diffractometer. Text Res J. https://doi.org/10.1177/004051755902901003

Amiri H, Karimi K (2015) Autohydrolysis: a promising pretreatment for the improvement of acetone, butanol, and ethanol production from woody materials. Chem Eng Sci 137:722–729. https://doi.org/10.1016/j.ces.2015.07.020

Li H, Xiong L, Chen X et al (2017) Enhanced enzymatic hydrolysis and acetone-butanol-ethanol fermentation of sugarcane bagasse by combined diluted acid with oxidate ammonolysis pretreatment. Bioresour Technol 228:257–263. https://doi.org/10.1016/j.biortech.2016.12.119

Maiti S, Gallastegui G, Suresh G et al (2018) Hydrolytic pre-treatment methods for enhanced biobutanol production from agro-industrial wastes. Bioresour Technol 249:673–683. https://doi.org/10.1016/j.biortech.2017.09.132

Sun JX, Sun XF, Zhao H, Sun RC (2004) Isolation and characterization of cellulose from sugarcane bagasse. Polym Degrad Stab 40:7384–7386. https://doi.org/10.1016/j.polymdegradstab.2004.02.008

Amiri H, Karimi K, Zilouei H (2014) Organosolv pretreatment of rice straw for efficient acetone, butanol, and ethanol production. Bioresour Technol 152:450–456. https://doi.org/10.1016/j.biortech.2013.11.038

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428. https://doi.org/10.1021/ac60147a030

Moradi F, Amiri H, Soleimanian-Zad S et al (2013) Improvement of acetone, butanol and ethanol production from rice straw by acid and alkaline pretreatments. Fuel 112:8–13. https://doi.org/10.1016/j.fuel.2013.05.011

Jafari Y, Amiri H, Karimi K (2016) Acetone pretreatment for improvement of acetone, butanol, and ethanol production from sweet sorghum bagasse. Appl Energy 168:216–225. https://doi.org/10.1016/j.apenergy.2016.01.090

Adorno MAT, Hirasawa JS, Varesche MBA (2014) Development and validation of two methods to quantify volatile acids (C2–C6) by GC/FID: headspace (automatic and manual) and liquid-liquid extraction (LLE). Am J Anal Chem 5:406–414

Zwietering MH, Jongenburger I, Rombouts FM, Van’t Riet K (1990) Modeling of the bacterial growth curve. Appl Environ Microbiol 56:1875–1881

Isikgor FH, Becer CR (2015) Lignocellulosic biomass: a sustainable platform for production of bio-based chemicals and polymers. Polym Chem. https://doi.org/10.1039/C5PY00263J

Satari B, Palhed J, Karimi K, Lundin M (2017) Process optimization for citrus waste biorefinery via simultaneous pectin extraction and pretreatment. BioResources 12:1706–1722

Pourbafrani M, Forgács G, Horváth IS et al (2010) Production of biofuels, limonene and pectin from citrus wastes. Bioresour Technol 101:4246–4250. https://doi.org/10.1016/j.biortech.2010.01.077

Lohrasbi M, Pourbafrani M, Niklasson C, Taherzadeh MJ (2010) Bioresource technology process design and economic analysis of a citrus waste biorefinery with biofuels and limonene as products. Bioresour Technol 101:7382–7388. https://doi.org/10.1016/j.biortech.2010.04.078

Arthington JD, Kunkle WE, Martin AM (2002) Citrus pulp for cattle. Vet Clin 18:317–326. https://doi.org/10.1016/S0749-0720(02)00023-3

Rivas-cantu RC, Jones KD, Mills PL (2013) A citrus waste-based biorefinery as a source of renewable energy: technical advances and analysis of engineering challenges. Waste Manag Res 31:413–420. https://doi.org/10.1177/0734242X13479432

Figuerola F, Hurtado ML, Estévez AM et al (2005) Food chemistry fibre concentrates from apple pomace and citrus peel as potential fibre sources for food enrichment. Food Chem 91:395–401. https://doi.org/10.1016/j.foodchem.2004.04.036

Gottumukkala LD, Haigh K, Görgens J (2017) Trends and advances in conversion of lignocellulosic biomass to biobutanol: microbes, bioprocesses and industrial viability. Renew Sustain Energy Rev 76:963–973. https://doi.org/10.1016/j.rser.2017.03.030

Abidi N, Cabrales L, Haigler CH (2014) Changes in the cell wall and cellulose content of developing cotton fibers investigated by FTIR spectroscopy. Carbohydr Polym 100:9–16. https://doi.org/10.1016/j.carbpol.2013.01.074

Xu F, Shi Y, Wang D (2017) X-ray scattering studies of lignocellulosic biomass: a review. Carbohydr Polym 94:904–917. https://doi.org/10.1016/j.carbpol.2013.02.008

Thygesen A, Oddershede J, Lilholt H et al (2005) On the determination of crystallinity and cellulose content in plant fibres. Cellulose 12:563–576. https://doi.org/10.1007/s10570-005-9001-8

Longaresi RH, De Menezes AJ, Pereira-da-silva MA et al (2019) The maize stem as a potential source of cellulose nanocrystal: cellulose characterization from its phenological growth stage dependence. Ind Crop Prod 133:232–240. https://doi.org/10.1016/j.indcrop.2019.02.046

García R, Pizarro C, Lavín AG, Bueno JL (2012) Characterization of Spanish biomass wastes for energy use. Bioresour Technol 103:249–258. https://doi.org/10.1016/j.biortech.2011.10.004

Pan X (2008) Role of functional groups in lignina inhibition of enzymatic hydrolysis of cellulose to glucose. Biobased Mater Bioenergy 2:25–32. https://doi.org/10.1166/jbmb.2008.005

Bellido C, Infante C, Coca M et al (2015) Efficient acetone-butanol-ethanol production by Clostridium beijerinckii from sugar beet pulp. Bioresour Technol 190:332–338. https://doi.org/10.1016/j.biortech.2015.04.082

Heluane H, Evans MR, Dagher SF (2011) Meta-analysis and functional validation of nutritional requirements of solventogenic clostridia growing under butanol stress conditions and coutilization of D -glucose and D -xylose. Appl Environ Microbiol 77:4473–4485. https://doi.org/10.1128/AEM.00116-11

Nimbalkar PR, Khedkar MA, Chavan PV, Bankar SB (2018) Biobutanol production using pea pod waste as substrate: impact of drying on sacchari fi cation and fermentation. Renew Energy 117:520–529. https://doi.org/10.1016/j.renene.2017.10.079

Paniagua-garcía AI, Hijosa-valsero M, Díez-antolínez R, Sánchez ME (2018) Enzymatic hydrolysis and detoxi fi cation of lignocellulosic biomass are not always necessary for ABE fermentation: the case of Panicum virgatum. Biomass Bioenergy 116:131–139. https://doi.org/10.1016/j.biombioe.2018.06.006

Ibrahim MF, Ramli N, Bahrin EK, Abd-aziz S (2017) Cellulosic biobutanol by Clostridia: challenges and improvements. Renew Sustain Energy Rev 79:1241–1254. https://doi.org/10.1016/j.rser.2017.05.184

Sabra W, Groeger C, Sharma PN, Zeng A-P (2014) Improved n-butanol production by a non-acetone producing Clostridium pasteurianum DMZ 525 in mixed substrate fermentation. Appl Microbiol Biotechnol 98:4267–4276. https://doi.org/10.1007/s00253-014-5588-8

Jin Q, Qureshi N, Wang H, Huang H (2019) Acetone-butanol-ethanol (ABE) fermentation of soluble and hydrolyzed sugars in apple pomace by Clostridium beijerinckii P260. Fuel 244:536–544. https://doi.org/10.1016/j.fuel.2019.01.177

Acknowledgements

The authors would like to thank Biomass and the Bioenergy Laboratory from UFSCar-Brazil for their assistance and providing equipments. The present work had no financial support by any funding organization.

Author information

Authors and Affiliations

Contributions

GFS and ICSD conceived the present idea. GFS carried out the experiments and wrote the manuscript with support from ICSD that supervised the project. JGPV, SLM, AJM, and MBAV contributed to analytical methods. GFS and TPD contributed to the final version of the manuscript. All authors made substantial contributions to concept this research.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

da Silva, G.F., Mathias, S.L., de Menezes, A.J. et al. Orange Bagasse Pellets as a Carbon Source for Biobutanol Production. Curr Microbiol 77, 4053–4062 (2020). https://doi.org/10.1007/s00284-020-02245-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00284-020-02245-3