Abstract

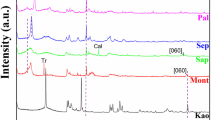

In this study, zeolite Y was synthesized from sodium silicate, aluminum hydroxide, sodium hydroxide and distilled water under hydrothermal method. The Box–Behnken design was used as a response surface method considering seven factors affecting the crystallization of zeolite to determine the number of experiments. The linear, square and interaction effects of the factors were investigated. The factors consist of four factors for the gel composition, including the molar value of Si, Al, Na and H2O and three factors for the synthesis conditions, including aging time, crystallization time and temperature. The XRD patterns of the synthesized samples were compared with the XRD pattern of standard zeolite Y. Among the samples, sample 50 with the highest intensity and maximum total area of 14 peaks, was selected as the reference sample and it was used to determine the relative crystallinity percentage of the remaining samples. Based on the results of the experiments, it was concluded that changes in the gel composition have a more significant effect on the response in comparison with changes in the synthesis conditions. In addition, optimization of the obtained model was carried out and a zeolite with higher relative crystallinity than the standard zeolite Y was synthesized. At the optimal point, zeolite Y was synthesized with a relative crystallinity of 117.5%. The composition of the gel was 0.59 SiO2: 0.0563 Al2O3: 0.4266 Na2O: 12.376 H2O. The total synthesis time was 30 h.

Similar content being viewed by others

References

Akhoundzadeh H, Taghizadeh M, Pajaie HS (2018) Synthesis of highly selective and stable mesoporous Ni–Ce/SAPO-34 nanocatalyst for methanol-to-olefin reaction: Role of polar aprotic N, N-Dimethylformamide. Solvent Particuol 40:113–122

Bortolatto LB et al (2017) Synthesis and characterization of Y zeolites from alternative silicon and aluminium sources. Microporous Mesoporous Mater 248:214–221

Breck DW (1974) Zeolite molecular sieves. Wiley, New York, pp 313–320

Cejka J et al (2007) Introduction to zeolite molecular sieves. Elsevier

Cerutti MLN et al (2019) Copper-exchanged Y zeolites for gasoline deep-desulfurization. Adsorption 25(8):1595–1609

Chen M et al (2020a) Renewable P-type zeolite for superior absorption of heavy metals: Isotherms, kinetics, and mechanism. Sci Total Environ 726:138535

Chen C-T et al (2020b) Understanding the nucleation and crystal growth of zeolites: a case study on the crystallization of ZSM-5 from a hydrogel system under ultrasonication. J Phys Chem C 124(21):11516–11524

DA (2013) Standard Test method for determination of relative X-ray diffraction intensities of faujasite-type zeolite-containing materials. ASTM International West Conshohocken

Dean A et al (2015) Handbook of design and analysis of experiments, vol 7. CRC Press, Berlin

Dias da Silva P et al (2019) Adsorptive desulfurization of liquid fuels at elevated temperatures using metal exchanged zeolite Y. Ind Eng Chem Res 58(42):19623–19632

Garcia G et al (2016) Synthesis of zeolite Y from diatomite as silica source. Microporous Mesoporous Mater 219:29–37

Grand J, Awala H, Mintova S (2016) Mechanism of zeolites crystal growth: new findings and open questions. CrystEngComm 18(5):650–664

Hiroshi O, Yoshimasa A, Hiroshi U (1969) The Acidic Nature of Synthetic Zeolites: Acid Strength and Its Correlation with the Catalytic Activity. Bull Chem Soc Jpn 42(9):2449–2453

Huang Y et al (2010) Synthesis of hierarchical porous zeolite NaY particles with controllable particle sizes. Microporous Mesoporous Mater 127(3):167–175

Julbe A, Drobek M (2016a) Zeolite X-type. In: Drioli E, Giorno L (eds) Encyclopedia of membranes. Springer, Berlin

Julbe A, Drobek M (2016b) Zeolite Y type. In: Drioli E, Giorno L (eds) Encyclopedia of membranes. Springer,Berlin Heidelberg, Berlin, pp 2060–2061

Kacirek H, Lechert H (1975) Growth of the zeolite type NaY. J Phys Chem 79(15):1589–1593

Kacirek H, Lechert H (1976) Rates of crystallization and a model for the growth of sodium-Y zeolites. J Phys Chem 80(12):1291–1296

Kim YC et al (2009) Influencing factors on rapid crystallization of high silica nano-sized zeolite Y without organic template under atmospheric pressure. J Porous Mater 16(3):299–306

Kostinko JA (1983) Factors influencing the synthesis of zeolites A, X, and Y, G. D. Stucky and F. G. Dwyer, Eds., ACS Symposium Series 218, American Chemical Society, Washington, DC, USA pp. 3–19

Li Q et al (2010) Influence of synthesis parameters on the crystallinity and Si/Al ratio of NaY zeolite synthesized from kaolin. Pet Sci 7(3):403–409

Liu Z, et al (2016) A simple method of preparation of high silica zeolite Y and its performance in the catalytic cracking of cumene. J Nanotechnol

Louwen JN et al (2020) Role of rare earth ions in the prevention of dealumination of zeolite Y for fluid cracking catalysts. J Phys Chem C 124(8):4626–4636

Lutz W (2014) Zeolite Y: synthesis, modification, and properties—a case revisited. Adv Mater Sci Eng 2014(1):1–20

Ma B, Lothenbach B (2020) Synthesis, characterization, and thermodynamic study of selected Na-based zeolites. Cem Concr Res 135:106111

Montgomery DC (2017) Design and analysis of experiments. Wiley

Oyinade A, Kovo AS, Hill P (2016) Synthesis, characterization and ion exchange isotherm of zeolite Y using Box-Behnken design. Adv Powder Technol 27(2):750–755

Patterson A (1939) The Scherrer formula for X-ray particle size determination. Phys Rev 56(10):978

Reiprich B et al (2020) Layer-like FAU-type zeolites: A comparative view on different preparation routes. Front Chem Sci Eng 14(2):127–142

Sellaoui L et al (2021) Trapping of Ag+, Cu2+, and Co2+ by faujasite zeolite Y: New interpretations of the adsorption mechanism via DFT and statistical modeling investigation. Chem Eng J 420:127712

Soheili S, Pour AN, Mohammadi A (2021) SAPO-34 synthesis by combinations of structure-directing agents: experimental and Monte Carlo simulations studies. Microporous Mesoporous Mater 317:111003

Sulaiman KO, Sajid M, Alhooshani K (2020) Application of porous membrane bag enclosed alkaline treated Y-Zeolite for removal of heavy metal ions from water. Microchem J 152:104289

Tang T et al (2017) Organic template-free synthesis of zeolite Y nanoparticle assemblies and their application in the catalysis of the Ritter reaction. RSC Adv 7(13):7711–7717

Tian F et al (2014) Enhanced adsorption desulfurization performance over hierarchically structured zeolite Y. Fuel Process Technol 128:176–182

Xie M et al (2019) Enhanced catalytic performance of the FCC catalyst with an alumina matrix modified by the zeolite Y structure-directing agent. Ind Eng Chem Res 58(14):5455–5463

Acknowledgements

The authors of this work appreciate the financial support of the Ferdowsi University of Mashhad Research Council, Mashhad, Iran (Grant No. 3/51517).

Author information

Authors and Affiliations

Contributions

MRRT, MP, MK, AN and AM wrote the main manuscript text. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ranjbar Toroghi, M.R., Panahi, M., Karimi, M. et al. Development of the crystallinity model and investigation of the effective factors on the crystallinity of zeolite Y using the response surface method. Phys Chem Minerals 50, 26 (2023). https://doi.org/10.1007/s00269-023-01251-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00269-023-01251-8