Abstract

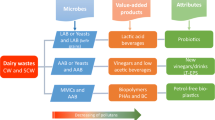

Whey, the main by-product of the cheese industry, is considered as an important pollutant due to its high chemical and biological oxygen demand. Whey, often considered as waste, has high nutritional value and can be used to obtain value-added products, although some of them need expensive enzymatic synthesis. An economical alternative to transform whey into valuable products is through bacterial or yeast fermentations and by accumulation during algae growth. Fermentative processes can be applied either to produce individual compounds or to formulate new foods and beverages. In the first case, a considerable amount of research has been directed to obtain biofuels able to replace those derived from petrol. In addition, the possibility of replacing petrol-derived plastics by biodegradable polymers synthesized during bacterial fermentation of whey has been sought. Further, the ability of different organisms to produce metabolites commonly used in the food and pharmaceutical industries (i.e., lactic acid, lactobionic acid, polysaccharides, etc.) using whey as growth substrate has been studied. On the other hand, new low-cost functional whey-based foods and beverages leveraging the high nutritional quality of whey have been formulated, highlighting the health-promoting effects of fermented whey-derived products. This review aims to gather the multiple uses of whey as sustainable raw material for the production of individual compounds, foods, and beverages by microbial fermentation. This is the first work to give an overview on the microbial transformation of whey as raw material into a large repertoire of industrially relevant foods and products.

Similar content being viewed by others

References

Abdelmoez W, Mustafa A (2014) Oleochemical industry future through biotechnology. J Oleo Sci 63:545–554

Abdel-Rahman MA, Tashiro Y, Sonomoto K (2013) Recent advances in lactic acid production by microbial fermentation processes. Biotechnol Adv 31:877–902

Adebola OO, Corcoran O, Morgan WA (2014) Synbiotics: the impact of potential prebiotics inulin, lactulose and lactobionic acid on the survival and growth of lactobacilli probiotics. J Funct Foods 10:75–84

Akaraonye E, Keshavarz T, Roy I (2010) Production of polyhydroxyalkanoates: the future green materials of choice (review). J Chem Technol Biotechnol 85:732–743

Alonso S, Rendueles M, Díaz M (2011) Efficient lactobionic acid production from whey by Pseudomonas taetrolens under pH-shift conditions. Bioresour Technol 102:9730–9736

Alonso S, Rendueles M, Díaz M (2013) Feeding strategies for enhanced lactobionic acid production from whey by Pseudomonas taetrolens. Bioresour Technol 134:134–142

Ariyanti D, Hadiyanto H (2013) Ethanol production from whey by Kluyveromyces marxianus in batch fermentation system: kinetics parameters estimation. Bull Chem React Eng Catal 7:179–184

Arora S, Jood S, Khetarpaul N (2011) Effect of germination and probiotic fermentation on nutrient profile of pearl millet based food blends. Br Food J113:470–481

Banat IM, Satpute SK, Cameotra SS, Patil R, Nyayanit NV (2014) Cost effective technologies and renewable substrates for biosurfactants’ production. Front Microbiol 5:1–18

Beaulieu J, Dubuc R, Beaudet N, Dupont C, Lemieux P (2007) Immunomodulation by a malleable matrix composed of fermented whey proteins and lactic acid bacteria. J Med Food 10:67–72

Boguta AM, Bringel F, Martinussen J, Jensen PR (2014) Screening of lactic acid bacteria for their potential as microbial cell factories for bioconversion of lignocellulosic feedstocks. Microb Cell Fact 13:1–16

Campeotto F, Suau A, Kapel N, Magne F, Viallon V, Ferraris L, Waligora-Dupriet A-J, Soulaines P, Leroux B, Kalach N, Dupont C, Butel M-J (2011) A fermented formula in pre-term infants: clinical tolerance, gut microbiota, down-regulation of faecal calprotectin and up-regulation of faecal secretory IgA. Br J Nutr 105:1843–1851

Cascone R (2008) Biobutanol—a replacement for bioethanol? Chem Eng Prog 104:4–9

Castro WF, Cruz AG, Bisinotto MS, Guerreiro LMR, Faria JAF, Bolini HMA, Cunha RL, Deliza R (2013) Development of probiotic dairy beverages: rheological properties and application of mathematical models in sensory evaluation. J Dairy Sci 96:16–25

Castro-Mayorga JL, Martínez-Abad A, Fabra MJ, Olivera C, Reis M, Lagarón JM (2014) Stabilization of antimicrobial silver nanoparticles by apolyhydroxyalkanoate obtained from mixed bacterial culture. Int J Biol Macromol. doi:10.1016/j.ijbiomac.2014.06.059

Chen H-J, Pan S-C, Shaw G-C (2009) Identification and characterization of a novel intracellular poly(3-hydroxybutyrate) depolymerase from Bacillus megaterium. Appl Environ Microbiol 75:5290–5299

Chia YN, Latusek MP, Holles JH (2008) Catalytic wet oxidation of lactose. Ind Eng Chem Res 47:4049–4055

Conti JP, Ceriani MC, Juliarena MA, Esteban EN (2012) Protein and peptide profile of a fluid base for functional beverages obtained by whey fermentation. Inf Technol 23:61–70

Das R, Sen D, Sarkar A, Bhattacharyya S, Bhattacharjee C (2011) A comparative study on the production of galacto-oligosaccharide from whey permeate in recycle membrane reactor and in enzymatic batch reactor. Ind Eng Chem Res 50:806–816

Davila-Vazquez G, de Leon-Rodriguez A, Alatriste-Mondragon F, Razo-Flores E (2011) The buffer composition impacts the hydrogen production and the microbial community composition in non-axenic cultures. Biomass Bioenergy 35:3174–3181

De Bassi LG, Ferreira GCC, Da Silva AS, Sivieri K, Aragon-Alegro LC, Costa MDR (2012) Evaluation of physicochemical, microbiological and sensorial characteristics of fermented milk beverages with buttermilk addition. Int J Dairy Technol 65:282–286

De Simone C, Picariello G, Mamone G, Stiuso P, Dicitore A, Vanacore D, Chianese L, Addeo F, Ferranti P (2009) Characterisation and cytomodulatory properties of peptides from Mozzarella di Bufala Campana cheese whey. J Pept Sci 15:251–258

Debowski M, Korzeniewska E, Filipkowska Z, Zielinski M, Kwiatkowski R (2014) Possibility of hydrogen production during cheese whey fermentation process by different strains of psychrophilic bacteria. Int J Hydrog Energy 39:1972–1978

Dragone G, Mussatto SI, Oliveira JM, Teixeira JA (2008) Alcoholic beverage from cheese whey: identification of volatile compounds. Bioenergy: Challenges and Opportunities International Conference and Exhibition on Bioenergy. Universidade do Minho, Guimarães

Du C, Sabirova J, Soetaert W, Lin SKC (2012) Polyhydroxyalkanoates production from low-cost sustainable raw materials. Curr Chem Biol 6:14–25

Duque AF, Oliveira CSS, Gouveia AR, CarmoI TD, Pardelha F, Ramos AM, Reis MAM (2014) Response of a three-stage process for PHA production by mixed microbial cultures to feedstock shift: impact on polymer composition. N Biotechnol 31:276–288

Endres HS, Siebert-Raths A (2011) End of life options for biopolymers. Engeneering Biopolymers: markets, manufacturing, properties and aplications. Chapter 5. Hanser, Munich

Espinosa-Gonzalez I, Parashar A, Bressler DC (2014) Heterotrophic growth and lipid accumulation of Chlorella protothecoides in whey permeate, a dairy by-product stream, for biofuel production. Bioresour Technol 155:170–176

Fakhravar S, Najafpour G, Heris SZ, Izadi M, Fakhravar A (2012) Fermentative lactic acid from deproteinized whey using Lactobacillus bulgaricus in batch culture. World Appl Sci J 17:1083–1086

Fernandes Castanha R, Adriano Pinto M, Salgado de Morais LA, Scramin S, Rosim Monteiro RT (2014) Optimization of lipids production by Cryptococcus laurentii 11 using cheese whey with molasses. Braz J Microbiol 45:379–387

Fernández C, Carracedo B, Martínez EJ, Gómez X, Morán A (2014) Application of a packed bed reactor for the production of hydrogen from cheese whey permeate: effect of organic loading rate. J Environ Sci Health A Tox Hazard Subst Environ Eng 49:210–217

Ferreira Rosa PR, Santos SC, Sakamoto IK, Amâncio Varesche MB, Silva EL (2014) Hydrogen production from cheese whey with ethanol-type fermentation: effect of hydraulic retention time on the microbial community composition. Bioresour Technol 16:10–19

Gabardo S, Rech R, Rosa CA, Záchia Ayub MA (2014) Dynamics of ethanol production from whey and whey permeate by immobilized strains of Kluyveromyces marxianus in batch and continuous bioreactors. Renew Energy 69:89–96

Ghaly AE, Kamal M, Correia LR (2005) Kinetic modelling of continuous submerged fermentation of cheese whey for single cell protein production. Bioresour Technol 96:1143–1152

Ghanshyambhai MR, Balakrishnan S, Aparnathi KD (2014) Standardization of the method for utilization of paneer whey in cultured buttermilk. J Food Sci Technol. doi:10.1007/s13197-014-1301-2

Gobinath D, Prapulla SG (2013) Permeabilized probiotic Lactobacillus plantarum as a source of β-galactosidase for the synthesis of prebiotic galactooligosaccharides. Biotechnol Lett 36:153–157

González MI, Álvarez S, Riera F, Alvarez R (2007) Economic evaluation of an integrated process for lactic acid production from ultrafiltered whey. J Food Eng 80:553–561

Granier A, Goulet O, Hoarau C (2013) Fermentation products: immunological effects on human and animal models. Pediatr Res 74:238–244

Green BA, Edison BL, Sigler ML (2008) Antiaging effects of topical lactobionic acid: results of a controlled usage study. Cosmet Dermatol 21:76–82

Guimarães PMR, Teixeira JA, Domingues L (2010) Fermentation of lactose to bio-ethanol by yeasts as part of integrated solutions for the valorisation of cheese whey (review). Biotechnol Adv 28:375–384

Gupta B, Revagade N, Hilborn J (2007) Poly(lactic acid) fiber: an overview. Prog Polym Sci 32:455–482

Gutiérrez L-F, Hamoudi S, Belkacemi K (2012) Lactobionic acid: a high value-added lactose derivative for food and pharmaceutical applications. Int Dairy J 26:103–111

Hadiyanto H, Ariyantia D, Ainia AP, Pinund DS (2014) Optimization of ethanol production from whey through fed-batch fermentation using Kluyveromyces marxianus. Energy Procedia 47:108–112

Hassan AN, Nelson BK (2012) Invited review: anaerobic fermentation of dairy food wastewater (review). J Dairy Sci 95:6188–6203

Hua L, Nordkvist M, Nielsen PM, Villadsen J (2007) Scale-up of enzymatic production of lactobionic acid using the rotary jet head system. Biotechnol Bioeng 97:842–849

Húngaro HM, Calil NO, Ferreira AS, Chandel AK, da Silva SS (2013) Fermentative production of ribonucleotides from whey by Kluyveromyces marxianus: effect of temperature and pH. J Food Sci Technol 50:958–964

Ikada Y, Tsuji H (2000) Biodegradable polyesters for medical and ecological applications. Macromol Rapid Commun 21:117–132

John RP, Nampoothiri KM, Pandey A (2006) Solid-state fermentation for l-lactic acid production from agro wastes using Lactobacillus delbrueckii. Process Biochem 41:759–763

Joosten HMLJ, Lardeau A (2004) Enhanced microbiological safety of acidified infant formulas tested in vitro. S Afr J Clin Nutr 17:87–92

Kapdan IK, Kargi F (2006) Bio-hydrogen production from waste materials. Enzyme Microb Technol 38:569–582

Karadag D, Köroğlu OE, Ozkaya B, Cakmakci M, Heaven S (2014) A review on fermentative hydrogen production from dairy industry wastewater (review). J Chem Technol Biotechnol 89:1627–1636

Keshavarz T, Roy I (2010) Polyhydroxyalkanoates: bioplastics with a green agenda. Curr Opin Microbiol 13:321–326

Khan NE, Myers JA, Tuerk AL, Curtis WR (2014) A process economic assessment of hydrocarbon biofuels production using chemoautotrophic organisms. Bioresour Technol 172:201–211

Koushki M, Jafari M, Azizi M (2012) Comparison of ethanol production from cheese whey permeate by two yeast strains. J Food Sci Technol 49:614–619

Koutinas M, Menelaou M, Nicolaou EN (2014) Development of a hybrid fermentation–enzymatic bioprocess for the production of ethyl lactate from dairy waste. Bioresour Technol 165:343–349

Kücükcetin A, Comak EM, Asci A, Demir M, Sik B (2012) Effect of casein to whey protein ratio of skim milk on the physical properties of a yoghurt drink, Ayran. Milchwissenschaft 67:274–276

Kume H, Okazaki K, Yamaji T, Sasaki H (2012) A newly designed enteral formula containing whey peptides and fermented milk product protects mice against concanavalin A-induced hepatitis by suppressing overproduction of inflammatory cytokines. Clin Nutr 31:283–289

Labuschagne IL, van Niekerk E, Lombard MJ (2012) Acidified infant formula explained. S Afr Fam Pract 55:354–356

Ling KC (2008) Agricultural economist. USDA Rural Development Research Report 214:1-20

Liu S-B, Qiao L-P, He H-L, Zhang Q, Chen X-L, Zhou W-Z, Zhou B-C, Zhang Y-Z (2011) Optimization of fermentation conditions and rheological properties of exopolysaccharide produced by deep-sea bacterium Zunongwangia profunda SM-A87. PLoS One 6(11):1–11

Lourens-Hattingh A, Viljoen BC (2001) Yogurt as probiotic carrier food. Int Dairy J11:1–17

Maity TK (2008) Development of healthy whey drink with Lactobacillus rhamnosus, Bifidobacterium bifidum and Propionibacterium freudenreichii subsp. shermanii. Mljekarstvo 58:315–325

Makendran R (2012) Enzymatic conversion of RNA from yeast extract to guanosine monophosphate (a flavoring agent). Department of Chemical and Biological Engineering Chalmers University of Technology, Göteborg

Marsh AJ, Hill C, Ross RP, Cotter PD (2014) Fermented beverages with health-promoting potential: past and future perspectives. Trends Food Sci Technol 38:113–124

Martínez Rodríguez AP, De Paula CD, Simanca Sotelo MM (2013) Fermented milk drink from cheese whey with added passion fruit pulp. Rev Téc Ing Univ Zulia 36:202–209

Mazzoli R, Bosco F, Mizrahi I, Bayer EA, Pessione E (2014) Towards lactic acid bacteria-based biorefineries. Biotechnol Adv 32:1216–1236

Menetrez MY (2012) An overview of algae biofuel production and potential environmental impact. Environ Sci Technol 46:7073–7085

Miyamoto Y, Ooi T, Kinoshita S (2000) Production of lactobionic acid from whey by Pseudomonas sp. LS13-1. Biotechnol Lett 22:427–430

Nwodo UU, Green E, Okoh AI (2012) Bacterial exopolysaccharides: functionality and prospects. Int J Mol Sci 13:14002–14015

Oh NS, Kwon HS, Lee HA, Joung JY, Lee JY, Lee KB, Shin YK, Baick SC, Park MR, Kim Y, Lee KW, Kim SH (2014) Preventive effect of fermented Maillard reaction products from milk proteins in cardiovascular health. J Dairy Sci 97:3300–3313

Panesar PS, Kennedy JF, Gandhi DN, Bunko K (2007) Bioutilisation of whey for lactic acid production. Food Chem 105:1–14

Panesar PS, Kennedy JF, Knill CJ, Kosseva M (2010) Production of L(+) lactic acid using Lactobacillus casei from whey. Braz Arch Biol Technol 53:219–226

Pantazaki AA, Papaneophytou CP, Pritsa AG, Liakopoulou-Kyriakides M, Kyriakidis DA (2009) Production of polyhydroxyalkanoates from whey by Thermus thermophilus HB8. Process Biochem 44:847–853

Pescuma M, Hébert EM, Mozzi F, Font de Valdez G (2008) Whey fermentation by thermophilic lactic acid bacteria: evolution of carbohydrates and protein content. Food Microbiol 25:442–451

Pescuma M, Hébert EM, Dalgalarrondo M, Haertle M, Mozzi F, Chobert J-M, Font de Valdez G (2009) Effect of exopolysaccharides on hydrolysis of β-lactoglobulin by Lactobacillus acidophilus CRL 636 in an in vitro gastric/pancreatic system. J Agric Food Chem 57:5571–5577

Pescuma M, Hébert EM, Mozzi F, Font de Valdez G (2010) Functional fermented whey-based beverage using lactic acid bacteria. Int J Food Microbiol 141:73–81

Pescuma M, Hébert EM, Rabesona H, Druet M, Choiset Y, Haertle T, Mozzi F, Font de Valdez G, Choberte J-M (2011) Proteolytic action of Lactobacillus delbrueckii subsp. bulgaricus CRL 656 reduces antigenic response to bovine β-lactoglobulin. Food Chem 27:487–492

Pescuma M, Hebert EM, Haertle T, Chobert J-M, Mozzi F, Font de Valdez G (2015) Lactobacillus delbrueckii subsp. bulgaricus CRL 454 cleaves allergenic peptides of β-lactoglobulin. Food Chem 170:407–414

Povolo S, Toffano P, Basaglia M, Casella S (2010) Polyhydroxyalkanoates production by engineered Cupriavidus necator from waste material containing lactose. Bioresour Technol 101:7902–7907

Prasad S, Srikanth K, Limaye AM, Sivaprakasam S (2014) Homo-fermentative production of D-lactic acid by Lactobacillus sp. employing casein whey permeate as a raw feed-stock. Biotechnol Lett 36:1303–1307

Prazeres AR, Carvalho F, Rivas J (2012) Cheese whey management: a review. J Environ Manag 110:48–68

Qureshi N, Friedl A, Maddox IS (2014) Butanol production from concentrated lactose/whey permeate: use of pervaporation membrane to recover and concentrate product. Appl Microbiol Biotechnol 98:9859–9867

Raganati F, Curth S, Götz P, Olivieri G, Marzocchella A (2012) Butanol production from lignocellulosic-based hexoses and pentoses by fermentation of Clostridium acetobutylicum. Chem Eng Trans 27:91–96

Raganati F, Olivieri G, Procentese A, Russo ME, Salatino P, Marzocchella A (2013) Butanol production by bioconversion of cheese whey in a continuous packed bed reactor. Bioresour Technol 138:259–265

Raman JK, Gnansounou E (2014) Ethanol and lignin production from Brazilian empty fruit bunch biomass. Bioresour Technol 172:241–248

Ranjana D, Dwaipayan S, Ankur S, Saurav B, Chiranjib B (2011) A comparative study on the production of galacto-oligosaccharide from whey permeate in recycle membrane reactor and in enzymatic batch reactor. Ind Eng Chem Res 50:806–816

Rasane P, Jha A, Kumar A, Sharma N (2014) Reduction in phytic acid content and enhancement of antioxidant properties of nutricereals by processing for developing a fermented baby food. J Food Sci Technol. doi:10.1007/s13197-014-1375-x

Romão BB, Batista FRX, Ferreira JS, Costa HCB, Resende MM, Cardoso VL (2014) Biohydrogen production through dark fermentation by a microbial consortium using whey permeate as substrate. Appl Biochem Biotechnol 172:3670–3685

Sabokbar N, Khodaiyan F (2014) Characterization of pomegranate juice and whey based novel beverage fermented by kefir grains. J Food Sci Technol. doi:10.1007/s13197-014-1412-9

Sachdeva A, Rawat S, Nagpal J (2014) Efficacy of fermented milk and whey proteins in Helicobacter pylori eradication: a review. World J Gastroenterol 20:724–737

Saeed M, Anjum FM, Khan MR, Khan MI, Nadeem M (2013) Isolation, characterization and utilization of starter cultures for the development of wheyghurt drink. Br Food J 115:1169–1186

Sangwan V, Tomar SK, Ali B, Singh RRB, Singh AK (2014) Production of β-galactosidase from Streptococcus thermophilus for galactooligosaccharides synthesis. J Food Sci Technol. doi:10.1007/s13197-014-1486-4

Schaller JP, Kuchan MJ, Thomas DL, Cordle CT, Winship TR, Buck RH, Baggs GE, Wheeler JG (2004) Effect of dietary ribonucleotides on infant immune status. Part 1: humoral responses. Pediatr Res 56:883–890

Schultz N, Chang L, Hauck A, Reuss M, Syldatk C (2006) Microbial production of single-cell protein from deproteinized whey concentrates. Appl Microbiol Biotechnol 69:515–520

Seiki N, Saito H (2012) Lactose as a source for lactulose and other functional lactose derivatives. Int Dairy J 22:110–115

Sharma KK, Schuhmann H, Schenk PM (2012) High lipid induction in microalgae for biodiesel production. Energies 5:1532–1553

Show KY, Lee DJ, Tay JH, Lin CY, Chang JS (2012) Biohydrogen production: current perspectives and the way forward. Int J Hydrog Energy 37:15616–15631

Smithers GW (2008) Whey and whey proteins—from ‘gutter-to-gold’. Int Dairy J 18:695–704

Södergårda A, Stolta M (2002) Properties of lactic acid based polymers and their correlation with composition. Prog Polym Sci 27:1123–1163

Soukoulis C, Yonekura L, Gan HH, Behboudi-Jobbehdar S, Parmenter C, Fisk I (2014) Probiotic edible films as a new strategy for developing functional bakery products: the case of pan bread. Food Hydrocoll 39:231–242

Subrota H, Shilpa V, Brij S, Vandna K, Surajit M (2013) Antioxidative activity and polyphenol content in fermented soymilk supplemented with WPC-70 by probiotic Lactobacilli. Int Food Res Journal 20:2125–2131

Sudesh K, Abe H, Doi Y (2000) Synthesis, structure and properties of polyhydroxyalkanoates: biological polyesters. Prog Polym Sci 25:1503–1555

Sun M-L, Liu S-B, Qiao L-P, Chen X-L, Pang X, Shi M, Zhang X-Y, Qin Q-L, Zhou B-C, Zhang Y-Z, Xie B-B (2014) A novel exopolysaccharide from deep-sea bacterium Zunongwangia profunda SM-A87: low-cost fermentation, moisture retention, and antioxidant activities. Appl Microbiol Biotechnol 98:7437–7445

Uchida M, Mogami O, Matsueda K (2007) Characteristic of milk whey culture with Propionibacterium freudenreichii ET-3 and its application to the inflammatory bowel disease therapy. Inflammopharmacology 15:105–108

Ujor V, Bharathidasan AK, Cornish K, Ezeji TC (2014) Evaluation of industrial dairy waste (milk dust powder) for acetone–butanol–ethanol production by solventogenic Clostridium species. Springer Plus 3(387):1–10

Ust’ak S, Havrland B, Muñoz JOJ, Fernández EC, Lachman J (2007) Experimental verification of various methods for biological hydrogen production. Int J Hydrog Energy 32:1736–1741

Vardar-Schara G, Maeda T, Wood TK (2008) Metabolically engineered bacteria for producing hydrogen via fermentation. Microb Biotechnol 1:107–125

Vink ETH, Rábago KR, Glassner DA, Gruber PR (2003) Applications of life cycle assessment to NatureWorksTM polylactide (PLA) production. Polym Degrad Stab 80:403–419

Wang ZT, Ullrich N, Joo S, Waffenschmidt S, Goodenough U (2009) Algal lipid bodies: stress induction, purification, and biochemical characterization in wild-type and starchless Chlamydomonas reinhardtii. Eukaryot Cell 8:1856–1868

Yadav JSS, Bezawada J, Ajila CM, Yan S, Tyagi RD, Surampalli RY (2014) Mixed culture of Kluyveromyces marxianus and Candida krusei for single-cell protein production and organic load removal from whey. Bioresour Technol 164:119–127

Yu Y, Tangey M, Aass HC, Mitchel WJ (2007) Analysis of the mechanism and regulation of lactose transport and metabolism in Clostridium acetobutylicum ATCC 824. Appl Environ Microbiol 73:1842–1850

Zabed H, Faruq G, Sahu JN, Azirun MS, Hashim R, Boyce NA (2014) Bioethanol production from fermentable sugar juice. Sci World J 2014:957102. doi:10.1155/2014/957102

Zhao ZW, Pan DD, Wu Z, Sun YY, Guo YX, Zeng XQ (2014) Antialcoholic liver activity of whey fermented by Lactobacillus casei isolated from koumiss. J Dairy Sci 97:4062–4071

Zhou F, Wu Z, Chen C, Han J, Ai L, Guo B (2014) Exopolysaccharides produced by Rhizobium radiobacter S10 in whey and their rheological properties. Food Hydrocoll 36:362–368

Acknowledgments

The authors thank CONICET (PIP0062) and FONCyT (Préstamo BID PICT 2008-933 and Préstamo BID PICT 2012-2538) for financial support.

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical statement

The authors state that principles of ethical and professional conduct have been followed in this research and in the preparation of this article.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pescuma, M., de Valdez, G.F. & Mozzi, F. Whey-derived valuable products obtained by microbial fermentation. Appl Microbiol Biotechnol 99, 6183–6196 (2015). https://doi.org/10.1007/s00253-015-6766-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-015-6766-z