Abstract

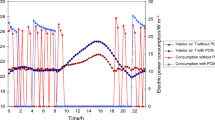

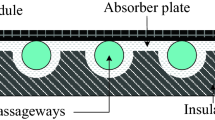

In this paper, thermal to electrical using waste heat recovery from a refrigeration system is utilized to generate electricity through a closed-loop heat sink thermoelectric generator (TEG) is presented. The concentric tube heat exchanger is used to take the waste heat from a refrigeration system to produce hot fluid for TEGs. The cold fluid is produced by a refrigeration system used for cooling the cold side. The hot and cold sides of the TEGs are coupled with heat sinks where hot and cold fluids flow through the heat sink channel to generate electricity. The effects of the fluid flow, and on/off modes of the refrigeration system, are investigated. It was found that the output voltage depends on the operating behavior of the refrigeration system, and operating time when on mode and off mode directly affects a hot fluid temperature fabrication. Applying fluid mass flow rate on the hot side and the cold side is very important that may cause the output voltage to be enhanced. The maximum temperature difference was obtained for the long-running refrigeration test mode. For on mode and off mode, the operating time of 10 minutes is the greatest to obtain the minimum and maximum temperature difference of 19.80°C and 13.10°C to get the maximum and the minimum output voltage of 9.80 V and 5.67 V. Besides, the cooling efficiency of the refrigeration system was increased and reduced power consumption by approximately 23% as integrated with the TEG system. Cooling capacity (Qc) and COP of the refrigeration system equipped with TEG increased by approximately 40% over traditional refrigeration system. Excess heat from the cooling system is recovered and converted into electricity. This is an energy-saving alternative that may help reduce the global warming crisis.

Similar content being viewed by others

Abbreviations

- T:

-

Temperature, [°C]

- TEG:

-

Thermoelectric generator

- HS:

-

Heat sink

- HEX:

-

Heat exchanger

- \(Q\) :

-

Heat transfer rate, [W]

- \(I\) :

-

Current, [A]

- \(V\) :

-

Voltage, [V]

- m:

-

Mass, [kg]

- \(\dot{m}\) :

-

Mass flow rate, [ms-1]

- \(\Delta t\) :

-

Total time, [s]

- \(\Delta T\) :

-

Temperature difference, [°C]

- COP:

-

Coefficient of performance

- \(C_{p}\) :

-

Specific heat, [kJkg-1 °C-1]

- \(T\) :

-

Temperature, [°C]

- W:

-

Work done by compressor, [W

- \(\rho\) :

-

Density, [kgm-3]

- \(\mathop V\limits^{ \circ }\) :

-

Volume flowrate, [kgm-3

- c:

-

Cold side of TEG

- cold:

-

Cooling load of water

- h:

-

Hot side

- in:

-

Inlet

- out:

-

Outlet

- TEG:

-

Thermoelectric generator

- min:

-

Minimum

- max:

-

Maximum

References

Jaziri N, Boughamoura A, Müller J, Mezghani B, Tounsi F, Ismail M (2020) A comprehensive review of Thermoelectric Generators: Technologies and common applications. Energy Reports 6:264–287

Liu Y, Shi Y, Li J, Guo X, Wang Y, Xiang Q, Guo S, Ze R, Zeng J, Xiang Y, Hao F (2020) Comprehensive performance prediction and power promotion for wearable thermoelectric generator with flexible encapsulation in practical application. Energ Conv Manag 220

Massaguer A, Pujol T, Comamala M, Massaguer E (2020) Feasibility study on a vehicular thermoelectric generator coupled to an exhaust gas heater to improve aftertreatment’s efficiency in cold-starts. Appl Ther Eng 167

Hiranandani K, Aravind B, Kishore VR, Kumar S (2020) Development of a numerical model for performance prediction of an integrated microcombustor-thermoelectric power generator. Energy 192

Li G, Zheng Y, Hu J, Guo W (2019) Experiments and a simplified theoretical model for a water-cooled, stove-powered thermoelectric generator. Energy 185:437–448

Li G, Zheng Y, Guo W, Zhu D, Tang Y (2020) Mesoscale combustor-powered thermoelectric generator: Experimental optimization and evaluation metrics. Appl Energ 272

Araiz M, Casi Á, Catalán L, Martínez Á, Astrain D (2020) Prospects of waste-heat recovery from a real industry using thermoelectric generators: Economic and power output analysis. Energ Conv Manag 205

Luo D, Wang R, Yu W, Zhou W (2020) A numerical study on the performance of a converging thermoelectric generator system used for waste heat recovery. Appl Energ 270

Aljaghtham M, Celik E (2020) Design optimization of oil pan thermoelectric generator to recover waste heat from internal combustion engines. Energy 200

Khalil H, Hassan H (2020) Enhancement of waste heat recovery from vertical chimney via thermoelectric generators by heat spreader. Process Safety and Environmental Protection 140:314–329

Wang CC, Hung CI, Chen WH (2012) Design of heat sink for improving the performance of thermoelectric generator using two-stage optimization. Energy 39(1):236–245

Zheng LJ, Kang HW (2022) A passive evaporative cooling heat sink method for enhancing low-grade waste heat recovery capacity of thermoelectric generators. Energ Conv Manag 251

Nuwayhid RY, Hamade R (2005) Design and testing of a locally made loop-type thermosyphonic heat sink for stove-top thermoelectric generators. Renewable Energy 30(7):1101–1116

Lokapure RB, Joshi JD (2012) Waste Heat Recovery through Air Conditioning System. Inte J Eng Res Dev 5:87–92

Khalil H, Hassan H (2019) Enhancement thermoelectric generators output power from heat recovery of chimneys by using flaps. J Power Sources 443

Rezania A, Rosendahl LA, Andreasen SJ (2012) Experimental investigation of thermoelectric power generation versus coolant pumping power in a microchannel heat sink. International Communications in Heat and Mass Transfer 39(8):1054–1058

Rezania A, Rosendahl LA (2012) Thermal effect of a thermoelectric generator on parallel microchannel heat sink. Energy 37:220–227

Rezania A, Rosendahl LA (2015) A comparison of micro-structured flat-plate and cross-cut heat sinks for thermoelectric generation application. Energy Conversion and Management 101:730–737

Wang C, Tang S, Liu X, Su GH, Tian W, Qiu S (2020) Experimental study on heat pipe thermoelectric generator for industrial high temperature waste heat recovery. Appl Therm Eng 175

Wiriyasart S, Naphon P (2021) Thermal to electrical closed-loop thermoelectric generator with compact heat sink modules. Int J Heat Mass Transf 164

Chen J, Li K, Liu C, Li M, Lv Y, Jia L, Jiang S (2017) Enhanced Efficiency of Thermoelectric Generator by Optimizing Mechanical and Electrical Structures. Energies 10

Li K, Garrison G, Moore M, Zhu Y, Liu C, Horne R, Petty S (2020) An expandable thermoelectric power generator and the experimental studies on power output. Int J Heat Mass Transf 160

Lee Wooram, Lee Jaeyoung (2018) Development of a compact thermoelectric generator consisting of printed circuit heat exchangers. Energy Conversion and Management 171:1302–1310

KULTHORN AE1390Y. Available at: http://kulthorn.co.th/rhvec/?viewid=1. Accessed 20 Sept 2022

KEYENCE FD-M50AY. Available at: https://www.keyence.ca/products/process/flow/fdm/models/fd-m50ay/. Accessed 9 Nov 2022

TEG1-199-1.4-0.5. Available at: https://www.amazon.com/BXQINLENX-TEG1-199-1-4-0-5-Thermoelectric-Generation-Peltier/dp/B011K7PYFC. Accessed 20 Sept 2022

Wisco-AI210 Available at: http://wisco.co.th/main/en/model/ai210_eng. Accessed 20 Sept 2022

Acknowledgment

The authors would like to express their appreciation to the Strategic Wisdom and Research Institute, Srinakharinwirot University (SWRI), and financial support from the faculty of Engineering, Srinakharinwirot University, through the research grant No. 172/2564 acknowledges.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wiriyasart, S., Kaewluan, S. & Naphon, P. Experimental study on waste heat recovery of refrigeration system for closed-loop heat sink thermoelectric generator. Heat Mass Transfer 59, 1019–1035 (2023). https://doi.org/10.1007/s00231-022-03317-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-022-03317-9