Abstract

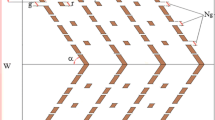

The most suitable approach to augment convective heat release rate is to fabricate the roughness underside of solar air heater (SAH) duct. This paper reveals an experimental effort made to augment the thermal performance of aligned gaps along with staggered element on SAH with minimum frictional consequence. The V-rib roughness namely aligned gaps in V-rib with staggered element roughness is evaluated with investigated range of parameters as relative rib height (e/Dh) 0.043, number of gaps (Ng) 2–5, relative gap breadth (g/e) 2–5, relative rib pitch (P/e) 10, relative staggered roughness pitch (P’/P) 0.4 and relative staggered rib length (r/g) 1. As per the selected mass flow rate Reynolds number varied from 4000 to 14,000. The result shows the augmentation in Nusselt number (Nu) value and friction factor (f) which is recorded as 2.16 times and 2.73 times respectively compared to flat plate surface. Performance of aligned gaps in V-rib with staggered element corresponding to studied geometrical parameters of roughness is compared with contemporary better performing V- rib geometry has also been done.

Similar content being viewed by others

Abbreviations

- Ap :

-

Area of absorber plate (m2)

- Aduct :

-

Flow cross sectional area of duct (m2)

- Ao :

-

Throat orifice plate area (m2)

- Cp :

-

Specific heat at constant pressure (J/kg K)

- Do :

-

Diameter of orifice plate (m)

- Dh :

-

Hydraulic diameter (m)

- e:

-

Circular wire diameter (m)

- g:

-

Gap breadth (m)

- G’:

-

Mass velocity of air (kg/s m2)

- H:

-

Height of duct (m)

- h:

-

Coefficient of heat transfer (W/m2 K)

- hw :

-

Heat transfer coefficient due to wind (W/m2 K)

- Δho :

-

Head difference across orifice plate (m)

- I:

-

Solar radiation intensity (W/m2)

- k:

-

Thermal conductivity of air (W/m K)

- Lf :

-

Test section length (m)

- m:

-

Mass flow rate of air (kg/s)

- P:

-

Roughness pitch (m)

- P’:

-

Staggered rib pitch (m)

- ΔPd :

-

Pressure drop across the duct (N/m2)

- ΔPo :

-

Pressure drop across orifice plate (N/m2)

- Qu1, Qu2 :

-

Rate of heat transfer (W)

- r:

-

Staggered rib size (m)

- s:

-

Inclination angle of collector (degree)

- Ta :

-

Atmospheric temperature of air (K)

- Tf :

-

Mean bulk air temperature (K)

- Ti:

-

Inlet air temperature (K)

- To :

-

Outlet air temperature (K)

- Tp :

-

Mean plate temperature (K)

- ΔT:

-

Temperature rise across duct (°C)

- Ub :

-

Bottom heat loss coefficient (W/m2 K)

- UL :

-

Overall heat loss coefficient (W/m2 K)

- Us :

-

Side heat loss coefficient (W/m2 K)

- Ut :

-

Top heat loss coefficient (W/m2 K)

- V:

-

Velocity of air (m/s)

- W:

-

Width of duct (m

- Cd :

-

Discharge coefficient

- e+ :

-

Roughness Reynolds number

- e/Dh :

-

Relative rib altitude

- f:

-

Friction factor of rough plate

- fapp :

-

Apparent friction factor

- fo :

-

Friction factor of circular duct

- Fp :

-

Plate efficiency factor

- FR :

-

Heat removal factor

- fs :

-

Friction factor of smooth plate

- ft :

-

Empirical factor

- G:

-

Heat transfer function

- g/e:

-

Relative gap breadth

- N:

-

Number of glass cover

- Ng :

-

Number of gaps

- Nu:

-

Nusselt number of rough plate

- Nus :

-

Nusselt number of smooth plate

- Pr:

-

Prandtl number

- P/e:

-

Relative pitch of ribs

- P’/P:

-

Relative position of staggered element

- Re:

-

Reynolds number

- r/g:

-

Relative length of staggered rib

- St:

-

Stanton number

- W/H:

-

Channel aspect ratio

- w’/w:

-

Relative gap location

- α:

-

Attack angle

- β:

-

Ratio of orifice diameter to pipe diameter

- ρair :

-

Air density (kg/m3)

- μ:

-

Dynamic viscosity (Ns/m2)

- σ:

-

Stefan Boltzmann constant

- εg :

-

Emissivity of glass cover

- εp :

-

Emissivity of absorber plate

- τα:

-

Transmissivity-absorptivity product

- ρm :

-

Manometer fluid density

- ηth :

-

Thermal efficiency

References

Prasad BN, Saini JS (1988) Effect of artificial roughness on heat transfer and friction factor in a solar air heater. Sol Energy 41:555–560

Sukhatme SP (1999) Solar energy, 4th edn. Tata McGram Hill Publishing Company Limited, New Delhi Fourth Reprint

Bhatti MS, Shah RK (1987) Turbulent and transition flow convective heat transfer. In: Kakac S, Shah RK, Aung W (eds) Handbook of single-phase convective heat transfer. Wiley, New York

Gupta D, Solanki SC, Saini JS (1993) Heat and fluid flow in rectangular solar air heater ducts having transverse rib roughness on absorber plates. Sol Energy 51(1):31–37

Sahu MM, Bhagoria JL (2005) Augmentation of heat transfer coefficient by using 90 broken transverse ribs on absorber plate of solar air heater. Renew Energy 30:2057–2073

Gupta D, Solanki SC, Saini JS (1997) Thermo-hydraulic performance of solar air heaters with roughened absorber plates. Sol Energy 61:33–42

Aharwal KR, Gandhi BK, Saini JS (2008) Experimental investigation on heat transfer enhancement due to a gap in an inclined continuous rib arrangement in a rectangular duct of solar air heater. Renew Energy 33(4):585–596

Aharwal KR, Gandhi BK, Saini JS (2009) Heat transfer and friction characteristics of solar air heater ducts having integral inclined discrete ribs on absorber plate. Int J Heat Mass Transf 52:5970–5977

Kumar TS, Mittal V, Thakur NS, Kumar A (2010) Second law analysis of a solar air heater having 60 inclined discrete rib roughness on absorber plate. Afr J Environ Sci Technol 4(13):913–929

Saini SK, Saini RP (2008) Development of correlations for Nusselt number and friction factor for solar air heater with roughened duct having arc-shaped wire as artificial roughness. Sol Energy 82(12):1118–1130

Hans VS, Gill RS, Singh S (2017) Heat transfer and friction factor correlations for a solar air heater duct roughened artificially with broken arc ribs. Exp Therm Fluid Sci 1(80):77–89

Gill RS, Hans VS, Singh S (2017) Investigations on thermo-hydraulic performance of broken arc rib in a rectangular duct of solar air heater. Int Commun Heat Mass Transf 1(88):20–27

Gill RS, Hans VS, Saini JS, Singh S (2017) Investigation on performance enhancement due to staggered piece in a broken arc rib roughened solar air heater duct. Renew Energy 1(104):148–162

Gill RS, Hans VS, Singh RP (2021) Optimization of artificial roughness parameters in a solar air heater duct roughened with hybrid ribs. Appl Therm Eng 191:116871

Singh AP (2014) Heat transfer and friction factor correlations for multiple arc shape roughness elements on the absorber plate used in solar air heaters. Exp Therm Fluid Sci 30(54):117–126

Singh AP, Varun, Siddhartha (2014) Effect of artificial roughness on heat transfer and friction characteristics having multiple arc shaped roughness element on the absorber plate. Sol Energy 105:479–493

Pandey NK, Bajpai VK (2016) Experimental investigation of heat transfer augmentation using multiple arcs with gap on absorber plate of solar air heater. Sol Energy 30(134):314–326

Varun, Saini RP, Singal SK (2008) Investigation of thermal performance of solar air heater having roughness elements as a combination of inclined and transverse ribs on the absorber plate. Renew Energy 33(6):1398–1405

Patnaik A, Saini RP, Singal SK (2009) Performance prediction of solar air heater having roughened duct provided with transverse and inclined ribs as artificial roughness. Renew Energy 34(12):2914–2922

Jaurker AR, Saini JS, Gandhi BK (2006) Heat transfer and friction characteristics of rectangular solar air heater duct using rib-grooved artificial roughness. Sol Energy 80(8):895–907

Saini RP, Verma J (2008) Heat transfer and friction factor correlations for a duct having dimple-shape artificial roughness for solar air heaters. Energy 33(8):1277–1287

Bhushan B, Singh R (2011) Nusselt number and friction factor correlations for solar air heater duct having artificially roughened absorber plate. Sol Energy 85(5):1109–1118

Yadav S, Kaushal M (2013) Nusselt number and friction factor correlations for solar air heater duct having protrusions as roughness elements on absorber plate. Exp Therm Fluid Sci 31(44):34–41

Sethi M, Thakur NS, Varun (2012) Heat transfer and friction characteristics of dimple shaped roughness element arranged in angular fashion (arc) on the absorber plate of solar air heater. J Renew Sustain Energy 4:23112

Kumar A, Kumar R, Maithani R, Chauhan R, Sethi M, Kumari A, Kumar S, Kumar S (2017) Correlation development for Nusselt number and friction factor of a multiple type V-pattern dimpled obstacles solar air passage. Renew Energy 1(109):461–479

Srivastava A, Chhaparwal GK, Sharma RK (2020) Numerical and experimental investigation of different rib roughness in a solar air heater. Therm Sci Eng Prog 19:100576

Momin AME, Saini JS, Solanki SC (2002) Heat transfer and friction in solar air heater duct with V-shaped rib roughness on absorber plate. Int J Heat Mass Transf 45(16):3383–3396

Karwa R (2003) Experimental studies of augmented heat transfer and friction in asymmetrically heated rectangular ducts with ribs on the heated wall in transverse, inclined, V-continuous and V-discrete pattern. Int Commun Heat Mass Transf 30:241–250

Singh S, Chander S, Saini JS (2011) Heat transfer and friction factor correlations of solar air heater ducts artificially roughened with discrete V-down ribs. Energy 36(8):5053–5064

Singh S, Chander S, Saini JS (2012) Investigations on thermo-hydraulic performance due to flow-attack-angle in V-down rib with gap in a rectangular duct of solar air heater. Appl Energy 1(97):907–912

Singh S, Chander S, Saini JS (2011) Thermal and effective efficiency based analysis of discrete V-down rib-roughened solar air heaters. J Renew Sustain Energy 3:23107

Singh S, Chander S, Saini JS (2015) Thermo-hydraulic performance due to relative roughness pitch in V-down rib with gap in solar air heater duct—comparison with similar rib roughness geometries. Renew Sustain Energy Rev 1(43):1159–1166

Patil AK, Saini JS, Kumar K (2011) Effect of gap position in broken v-rib roughness combined with staggered rib on thermos-hydraulic performance of solar air heater. Green Energy 1:329–338

Patil AK, Saini JS, Kumar K (2012) Heat transfer and friction characteristics of solar air heater duct roughened by broken V-shape ribs combined with staggered rib piece. J Renew Sustain Energy 4:13115

Patil AK, Saini JS, Kumar K (2012) Nusselt number and Friction factor correlations for solar air heater duct with broken V-down ribs combined with staggered rib roughness. J Renew Sustain Energy 033122(4):1–17

Maithani R, Saini JS (2016) Heat transfer and friction factor correlations for a solar air heater duct roughened artificially with V-ribs with symmetrical gaps. Exp Therm Fluid Sci 70:220–227

Maithani R, Saini JS (2017) Performance evaluation of solar air heater having V-ribs with symmetrical gaps in a rectangular duct of solar air heater. Int J Ambient Energy 38(4):400–410

Deo NS, Chander S, Saini JS (2016) Performance analysis of solar air heater duct roughened with multigap V-down ribs combined with staggered ribs. Renew Energy 1(91):484–500

Jain PK, Lanjewar A (2019) Overview of V-RIB geometries in solar air heater and performance evaluation of a new V-RIB geometry. Renew Energy 1(133):77–90

Jain PK, Lanjewar A (2017) Effect of staggered rib length on performance of solar air heater using v-rib with symmetrical gap and staggered rib. ARPN J Eng Appl Sci 22:6291–6300

Jain PK, Lanjewar A, Rana KB, Meena ML (2020) Effect of fabricated V-rib roughness experimentally investigated in a rectangular channel of solar air heater: a comprehensive review. Environ Sci Pollut Res 12:1–37

A.S.H.R.A.E. (1977) Standard, method of testing to determine the thermal performance of solar collector, vols 93–97. ASHRAE, New York

Kline SJ, McClintock FA (1953) Describing uncertainties in single sample experiments. J Mech Eng 75:3–8

Webb RL, Eckert ER, Goldstein R (1971) Heat transfer and friction in tubes with repeated-rib roughness. Int J Heat Mass Transf 14:601–617

Nikuradse J (1950) Laws of flow in rough pipes. NACA Technical Memorandum 1292, November

Dipprey DF, Sabersky RH (1963) Heat and momentum transfer in smooth and rough tubes at various prandtl numbers. Int J Heat Mass Transf 6(5):329–332

Klein SA (1975) Calculation of flat-plate collector loss coefficients. Sol Energy 17:79

McAdams WH (1954) Heat transmission. McGraw-Hill, New York

Karwa R, Solanki SC, Saini JS (2001) Thermo-hydraulic performance of solar air heaters having integral chamfered rib roughness on absorber plates. Energy 26(2):161–176

Acknowledgements

The authors are extremely grateful to Maulana Azad National Institute of Technology Bhopal for providing experimentation amenities to accomplish this research work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix 1: Uncertainty analysis

Appendix 1: Uncertainty analysis

If the parameters are calculated using certain reflected quantities as:

Then the uncertainty in ‘y’ is measured by:

where, δx1, δx2, δx3 ….. δxn are the uncertainties in measurement of x1, x2, x3…. xn, δy and \(\frac{\delta y}{y}\) are absolute uncertainty and relative uncertainty respectively.

The important parameters in present investigation are:

-

i.

Reynolds Number, \({\text{Re}} = \frac{{\rho_{a} VD_{h} }}{\mu }\)

-

ii.

Heat transfer coefficient,\(h = \frac{{mC_{p} \Delta T}}{{A_{p} \left( {T_{P} - T_{m} } \right)}}\)

-

iii.

Nusselt number, \(Nu = \frac{{hD_{h} }}{k}\)

-

iv.

Friction factor, \(f = \frac{{D_{h} \left( {\Delta P_{d} } \right)}}{{2L_{f} V^{2} \rho }}\)

Appendix Table 4 gives a detail of uncertainty interval of various measurements and equipment.

Appendix Table 5 gives the data related to dimensional parameters taken during present study.

Thermo-physical properties of air at Tf = 298.43, using correlations available are:

-

1.

Area of absorber plate (Ap):

$$A_{p} = W \times L$$$$\frac{{\delta A_{p} }}{{A_{p} }} = \left[ {\left( {\frac{{\delta A_{p} }}{\delta L} \times \delta L} \right)^{2} + \left( {\frac{{\delta A_{p} }}{\delta W} \times \delta W} \right)^{2} } \right]^{1/2}$$$$\frac{{\delta A_{p} }}{{A_{p} }} = \left[ {\left( {\frac{\delta L}{L}} \right)^{2} + \left( {\frac{\delta W}{W}} \right)^{2} } \right]^{1/2} = \left[ {\left( \frac{1}{1000} \right)^{2} + \left( {\frac{0.1}{{300}}} \right)^{2} } \right]^{1/2} = \, 1.054 \times 10^{ - 3} = \, 0.1054\%$$ -

2.

Area of flow (A):

$$A = W \times H$$$$\delta A = \left[ {\left( {\frac{\delta A}{{\delta W}} \times \delta W} \right)^{2} + \left( {\frac{\delta A}{{\delta H}} \times \delta H} \right)^{2} } \right]^{1/2}$$$$\frac{\delta A}{A} = \left[ {\left( {\frac{\delta W}{W}} \right)^{2} + \left( {\frac{\delta H}{H}} \right)^{2} } \right]^{1/2} = \left[ {\left( {\frac{0.1}{{300}}} \right)^{2} + \left( {\frac{0.1}{{25}}} \right)^{2} } \right]^{1/2} = \, 4.013 \times 10^{ - 3} = \, 0.4013\%$$ -

3.

Hydraulic diameter (Dh):

$$D_{h} = \frac{4A}{P} = \frac{2WH}{{\left( {W + H} \right)}} = 2\left( {WH} \right)\left( {W + H} \right)^{ - 1}$$$$\frac{{\partial D_{h} }}{\partial H} = 2\left( {WH} \right)\left( { - 1} \right)\left( {W + H} \right)^{ - 2} + \left( {W + H} \right)^{ - 1} \left( {2W} \right)$$$$\begin{gathered} = \frac{ - 2WH}{{\left( {W + H} \right)^{2} }} + \frac{2W}{{W + H}}or\frac{2W}{{W + H}} - \frac{2WH}{{\left( {W + H} \right)^{2} }} = \frac{2 \times 300}{{\left( {300 + 25} \right)}} - \frac{2 \times 300 \times }{{\left( {300 + 25} \right)^{2} }} \hfill \\ = 1.84615 - 0.142012 = 1.704 \hfill \\ \end{gathered}$$$$= \frac{2 \times 25}{{\left( {300 + 25} \right)}} - \frac{2 \times 300 \times 25}{{\left( {300 + 25} \right)^{2} }} = 0.153846 - 0.142012 = 0.011834$$$$\frac{{\delta D_{h} }}{{D_{h} }} = \frac{{\left[ {\left( {\frac{{\delta D_{h} }}{\delta H}.\delta H} \right)^{2} + \left( {\frac{{\delta D_{h} }}{\delta W}.\delta W} \right)^{2} } \right]}}{{2\left( {WH} \right)\left( {W + H} \right)^{ - 1} }}^{1/2} = \frac{{\left[ {\left( {1.704 \times 0.1} \right)^{2} + \left( {0.011834 \times 0.1} \right)^{2} } \right]^{1/2} }}{{{{\left( {2 \times 300 \times 25} \right)} \mathord{\left/ {\vphantom {{\left( {2 \times 300 \times 25} \right)} {\left( {300 + 25} \right)}}} \right. \kern-\nulldelimiterspace} {\left( {300 + 25} \right)}}}} = 3.69 \times 10^{ - 3} = 0.369\%$$ -

4.

Area of orifice meter (Ao):

$$A_{o} = \frac{\pi }{4}d_{o}^{2}$$$$\frac{{\delta A_{o} }}{{\delta d_{o} }} = \frac{{2\pi d_{o} }}{4}$$$$\delta A_{o} = \left[ {\left( {\frac{{\delta A_{o} }}{{\delta d_{o} }} \times \delta d_{o} } \right)^{2} } \right]^{1/2} = \left[ {\left( {\frac{\pi }{2}d_{o} \times \delta d_{o} } \right)^{2} } \right]^{1/2}$$$$\delta A_{o} = \left( {\frac{\pi }{2}d_{o} \times \delta d_{o} } \right)$$$$\frac{{\delta A_{o} }}{{A_{o} }} = \frac{{\pi /2 \cdot d_{o} \cdot \delta d_{o} }}{{\pi /4 \cdot d_{o} }} = \frac{{2 \cdot \delta d_{o} }}{{d_{o} }} = \frac{2 \times 0.1}{{40.5}} = 4.9382 \times 10^{ - 3} = 0.49382\%$$ -

5.

Density of air (ρo):

$${\text{Density of air at T}}_{{\text{o}}} {, }\rho_{o} = \frac{{P_{atm} }}{{RT_{o} }}$$$$\frac{{\delta \rho_{o} }}{{\rho_{o} }} = \left[ {\left( {\frac{{\delta P_{atm} RT_{o} }}{{RT_{o} P_{atm} }}} \right)^{2} + \left( {\frac{{ - P_{atm} \delta T_{o} RT_{o} }}{{\left( {RT_{o} } \right)^{2} P_{atm} }}} \right)^{2} } \right]^{1/2}$$$$\frac{{\delta \rho_{o} }}{{\rho_{o} }} = \left[ {\left( {\frac{{\delta P_{atm} }}{{P_{atm} }}} \right)^{2} + \left( {\frac{{ - \delta T_{o} }}{{RT_{o} }}} \right)^{2} } \right]^{1/2} = \frac{{\delta \rho_{o} }}{{\rho_{o} }} = \left[ {\left( \frac{1}{760} \right)^{2} + \left( {\frac{ - 0.25}{{300.91}}} \right)^{2} } \right]^{1/2} = \, 1.556 \times 10^{ - 3} {\text{or }}0.1556\%$$$${\text{Density of air at Tm, (}}\rho_{{\text{a}}} {):}$$$$\frac{{\delta \rho_{a} }}{{\rho_{a} }} = \left[ {\left( {\frac{{\delta P_{a} }}{{P_{a} }}} \right)^{2} + \left( {\frac{{ - \delta T_{m} }}{{T_{m} }}} \right)^{2} } \right]^{1/2} = \frac{{\delta \rho_{a} }}{{\rho_{a} }} = \left[ {\left( \frac{1}{760} \right)^{2} + \left( {\frac{ - 0.25}{{298.43}}} \right)^{2} } \right]^{1/2} = { 1}.{559} \times {1}0^{{ - {3}}} {\text{or }}0.{1559}\%$$ -

6.

Mass flow rate (m):

$$m = C_{d} A_{o} \left[ {\frac{{2\rho_{o} (\Delta p)_{o} }}{{1 - \beta^{4} }}} \right]^{1/2}$$$$\frac{\delta \beta }{\beta } = \left[ {\left( {\frac{{\delta d_{i} }}{{d_{i} }}} \right)^{2} + \left( {\frac{{\delta d_{o} }}{{d_{o} }}} \right)^{2} } \right]^{1/2} = \frac{\delta \beta }{\beta } = \left[ {\left( {\frac{0.1}{{81}}} \right)^{2} + \left( {\frac{0.1}{{40.5}}} \right)^{2} } \right]^{1/2} = 0.00276$$$$\frac{\delta m}{m} = \left[ {\left( {\frac{{\delta C_{d} }}{{C_{d} }}} \right)^{2} + \left( {\frac{{\delta A_{o} }}{{A_{o} }}} \right)^{2} + \left( {\frac{{\delta \rho_{o} }}{{2\rho_{o} }}} \right)^{2} + \left( {\frac{{\delta (\Delta P)_{o} }}{{2(\Delta P)_{o} }}} \right)^{2} + \frac{1}{4}\left( {\frac{4\delta \beta }{\beta }} \right)^{2} } \right]^{1/2}$$$$\frac{\delta m}{m} = \left[ {\left( {0.015} \right)^{2} + \left( {0.004938} \right)^{2} + \left( {\frac{0.0015559}{2}} \right)^{2} + \left( {\frac{0.01}{{2 \times 12.8}}} \right)^{2} + \frac{1}{4}\left( {4 \times 0.00276} \right)^{2} } \right]^{1/2} = \, 0.0{\text{1675 or 1}}.{675}\%$$where δCd/Cd = 1.5% (from calibration chart of orifice meter).

-

7.

Velocity of air in the duct (V):

$${\text{V = }}\frac{{\text{m}}}{{{\uprho }_{{\text{a}}} {\text{WH}}}}$$$$\frac{\delta V}{V} = \left[ {\left( {\frac{\delta m}{m}} \right)^{2} + \left( {\frac{{\delta \rho_{a} }}{{\rho_{a} }}} \right)^{2} + \left( {\frac{\delta A}{A}} \right)^{2} } \right]^{1/2}$$$$\frac{\delta V}{V} = \left[ {\left( {0.016764} \right)^{2} + \left( {0.001559} \right)^{2} + \left( {0.004013} \right)^{2} } \right]^{1/2} = \, 0.0{\text{172 or 1}}.{72}\%$$ -

8.

Useful heat gain (Qu):

$$Q_{u} = mC_{P} \left( {T_{o} - T_{i} } \right) = mC_{P} \left( {\Delta T} \right)$$$$\frac{{\delta Q_{u} }}{{Q_{u} }} = \left[ {\left( {\frac{\delta m}{m}} \right)^{2} + \left( {\frac{{\delta C_{P} }}{{C_{P} }}} \right)^{2} + \left( {\frac{{\delta \left( {\Delta T} \right)}}{\Delta T}} \right)^{2} } \right]^{1/2}$$The uncertainty in δCp = 0.1, δμ = 0.001 × 10–5, δk = 0.00001 and δPr = 0.001

$$\Delta T = T_{o} - T_{i}$$$$\delta \left( {\Delta T} \right) = \left[ {\left( {\frac{\delta \Delta T}{{\delta T_{o} }}.\delta T_{o} } \right)^{2} + \left( {\frac{\delta \Delta T}{{\delta T_{i} }}.\delta T_{i} } \right)^{2} } \right]^{1/2} = \left[ {\left( {1 \times 0.25} \right)^{2} + \left( {1 \times 0.25} \right)^{2} } \right]^{1/2} = 0.353^{^\circ } {\text{C}}$$$$\left( {\frac{\delta \Delta T}{{\Delta T}}} \right) = \left( {\frac{0.353}{{4.96}}} \right)$$$$\frac{{\delta Q_{u} }}{{Q_{u} }} = \left[ {\left( {0.016764} \right)^{2} + \left( {\frac{0.1}{{1006.29}}} \right)^{2} + \left( {\frac{0.353}{{4.96}}} \right)^{2} } \right]^{1/2} = \, 0.0{\text{73116 or 7}}.{311}\%$$ -

9.

Heat transfer coefficient (h):

$$h = \frac{{Q_{u} }}{{A_{p} \left( {T_{P} - T_{m} } \right)}} = \frac{{Q_{u} }}{{A_{p} \Delta T_{1} }}$$$$\frac{\delta h}{h} = \left[ {\left( {\frac{{\delta Q_{u} }}{{Q_{u} }}} \right)^{2} + \left( {\frac{{\delta A_{p} }}{{A_{p} }}} \right)^{2} + \left( {\frac{{\delta \left( {\Delta T_{1} } \right)}}{{\Delta T_{1} }}} \right)^{2} } \right]^{1/2} = \left[ {\left( {0.073116} \right)^{2} + \left( {0.001054} \right)^{2} + \left( {\frac{0.353}{{14.4}}} \right)^{2} } \right]^{1/2} = \, 0.0{\text{7711 or 7}}.{711}\%$$ -

10.

Nusselt number (Nu):

$$Nu = \frac{{hD_{h} }}{k}$$$$\frac{\delta Nu}{{Nu}} = \left[ {\left( {\frac{\delta h}{h}} \right)^{2} + \left( {\frac{{\delta D_{h} }}{{D_{h} }}} \right)^{2} + \left( {\frac{\delta k}{k}} \right)^{2} } \right]^{1/2} = \left[ {\left( {0.07712} \right)^{2} + \left( {0.00369} \right)^{2} + \left( {\frac{0.00001}{{0.026109}}} \right)^{2} } \right]^{1/2} = \, 0.0772 \, or \, 7.72\%$$ -

11.

Reynolds number (Re):

$${\text{Re}} = \frac{{\rho_{a} VD_{h} }}{\mu }$$$$\frac{{\delta {\text{Re}} }}{{\text{Re}}} = \left[ {\left( {\frac{{\delta \rho_{a} }}{{\rho_{a} }}} \right)^{2} + \left( {\frac{\delta V}{V}} \right)^{2} + \left( {\frac{{\delta D_{h} }}{{D_{h} }}} \right)^{2} + \left( {\frac{\delta \mu }{\mu }} \right)^{2} } \right]^{1/2} = \left[ {\left( {0.001559} \right)^{2} + \left( {0.01732} \right)^{2} + \left( {0.00369} \right)^{2} + \left( {\frac{{0.001 \times 10^{ - 5} }}{{1.8346 \times 10^{ - 5} }}} \right)^{2} } \right]^{1/2} = \, 0.01776 \, or \, 1.77\%$$ -

12.

Friction factor (f):

$$f = \frac{{D_{h} \left( {\Delta P_{d} } \right)}}{{2L_{f} V^{2} \rho }}$$$$\begin{aligned} \frac{\delta f}{f} & = \left[ {\left( {\frac{{\delta D_{h} }}{{D_{h} }}} \right)^{2} + \left( {\frac{{\delta \left( {\Delta P} \right)_{d} }}{{\left( {\Delta P} \right)_{d} }}} \right)^{2} + \left( {\frac{\delta L}{L}} \right)^{2} + \left( {\frac{2\delta V}{V}} \right)^{2} + \left( {\frac{{\delta \rho_{a} }}{{\rho_{a} }}} \right)^{2} } \right]^{1/2} \\ & = \left[ {\left( {0.00369} \right)^{2} + \left( {\frac{0.1}{{28.8}}} \right)^{2} + \left( \frac{1}{1000} \right)^{2} + \left( {2 \times 0.01732} \right)^{2} + \left( {0.001559} \right)^{2} } \right]^{1/2} \\ & = 0.035 \, or \, 3.50\% \\ \end{aligned}$$

Rights and permissions

About this article

Cite this article

Jain, P.K., Lanjewar, A. Experimental study of thermal augmentation in solar air heater roughened with aligned gaps in V-rib roughness with staggered element geometry. Heat Mass Transfer 58, 531–559 (2022). https://doi.org/10.1007/s00231-021-03118-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-021-03118-6