Abstract

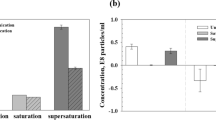

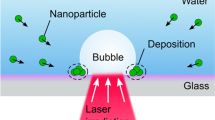

Previous studies have measured the sizes of bubbles in suspension during microwave irradiation to clarify the mechanism of bubble formation. Those results indicate that the particle number density and the dielectric constants of the particles and solvent are the most important factors determining bubble size during irradiation. The aim of this study is to determine whether bubble nucleation can be controlled by changing the microwave mode between continuous irradiation and the two-stage irradiation proposed in this study. The first irradiation of higher power rapidly accelerates bubble nucleation, whereupon the bubbles grow more slowly during the second irradiation of lower power. Because the absorbed microwave energy is distributed to the liquid–air interface of each highly suspended small bubble produced by the first irradiation, the absorbed energy per bubble decreases during the second irradiation. Finally, smaller bubbles are achieved at the target temperature. Because the bubble number density and size can be controlled by the rapid thermal response that is characteristic of microwaves, this method could be useful for preventing superheating and bumping during nano-particle synthesis.

Similar content being viewed by others

References

Cao H, Wan M, Qiao Y, Zhang S, Li R (2012) Spatial distribution of sonoluminescence and sonochemiluminescence generated by cavitation bubbles in 1.2 MHz focused ultrasound field. Ultrason Sonochem 19:257–263

Mizushima Y, Nagami Y, Nakamura Y, Saito T (2013) Interaction between acoustic cavitation bubbles and dispersed particles in a kHz-order-ultrasound-irradiated water. Chem Eng Sci 93:395–400

Martín M, Montes FJ, Galán MA (2008) Bubbling process in stirred tank reactors I: agitator effect on bubble size, formation and rising. Chem Eng Sci 63:3212–3222

Montante G, Horn D, Paglianti A (2008) Gas–liquid flow and bubble size distribution in stirred tanks. Chem Eng Sci 63:2107–2118

Seya PM, Desjouy C, J-C Béra CI (2015) Hysteresis of inertial cavitation activity induced by fluctuating bubble size distribution. Ultrason Sonochem 27:262–267

Asakuma Y, Munenaga T, Nakata R (2016) Observation of bubble formation behavior in water during microwave irradiation by DLS. Heat and Mass Transf 52:1833–1840

Asakuma Y, Nakata R, Saptoro A (2017) Bubble formation in water with magnetite nano-particles during microwave irradiation. Chem Eng Process: Process Intensif 119:101–105

Asakuma Y, Matsumura S, Saptoro A, Nakata R (2017) In-situ observation of nano-particle formation under different power of microwave irradiation. Cryst Res Technol 52:201700108

Asakuma Y, Matsumura S, Asada M, Phan C (2018) Microwave special effect through bubble and surface tension profiles of ethylene glycol aqueous solution. Int J Thermophys IJOT-D-16-00387, 39:21

Chen Q, Hu Z, Yao FY-D, Liang H (2016) Study of two-stage microwave extraction of essential oil and pectin from pomelo peels. LWT Food Sci Technol 66:538–545

Chen L, Qiu G, Peng B, Guo M, Zhang M (2015) (K0.5Na0.5)(Nb1−xTax)O3 ceramics with a higher d33: preparation from a two-stage microwave hydrothermal process. Ceram Int 41:13331–13340

Song Z, Yang Y, Zhou L, Liu L, Zhao X (2017) Gaseous products evolution during microwave pyrolysis of tire powders. Int J Hydrog Energy 42:18209–18215

Khachatourian AM, Golestani-Fard F, Sarpoolaky H, Vogt C, Toprak MS (2015) Microwave assisted synthesis of monodispersed Y2O3 and Y2O3:Eu3+ particles. Ceram Int 41:2006–2014

Hu S, Lu C, Wang W, Ding M, Xu Z (2013) Synthesis of monodisperse erbium aluminum garnet (EAG) nanoparticles via a microwave method. J Rare Earths 31:490–496

Horikoshi S, Osawa A, Sakamoto S, Serpone N (2013) Control of microwave-generated hot spots. Part IV. Control of hot spots on a heterogeneous microwave-absorber catalyst surface by a hybrid internal/external heating method. Chem Eng Process Process Intensif 69:52–56

Wang N, Wang P (2016) Study and application status of microwave in organic wastewater treatment – a review. Chem Eng J 283:193–214

De Bruyn M et al (2017) Subtle microwave-induced overheating effects in an industrial demethylation reaction and their direct use in the development of an innovative microwave reactor. J Am Chem Soc 139:5431–5436

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Asakuma, Y., Nakata, R. & Nishijima, S. New approach to achieving smaller bubbles with various microwave irradiation modes. Heat Mass Transfer 55, 3689–3696 (2019). https://doi.org/10.1007/s00231-019-02687-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-019-02687-x