Abstract

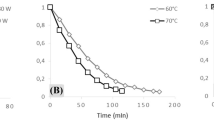

The aim of this study was to determine the drying characteristics, effective moisture diffusivity, colour, sensory properties and in-vitro bioaccessibility of phenolics and antioxidant capacity of blackthorn pestils dried with three different methods; hot air (60 and 70 °C), vacuum (60 and 70 °C with 20 and 30 kPa) and microwave (90 and 180 W) drying. Seven drying models were applied to the experimental data for the achievement of the most suitable thin layer model for drying curves. Depending on the statistical tests, The Page, Modified Page, Henderson and Pabis and Logarithmic models were found to be the most appropriate models to provide the drying characteristics of blackthorn pestils. Effective moisture diffusivity values obtained from Fick’s diffusion model were between 5.55 × 10−8 and 8.13 × 10−7 m2/s for vacuum drying at 60 °C–30 kPa and microwave drying at 180 W respectively. The colour values, a*, b*, Cab* and h° decreased while L* increased after drying. As a result of drying processes, total phenolic content and antioxidant capacity (DPPH, FRAP) of undigested and simulated gastric and intestinal digested samples showed a decrement compared to paste mixture.. After the simulated intestinal digestion the amount of total phenolic content and antioxidant capacity (DPPH, FRAP, CUPRAC) were increased significantly (p < 0.05). In conclusion, different drying methods affected the bioactive content and for sensorial analyses, hot air and vacuum dried samples were accepted by the panellists.

Similar content being viewed by others

References

Ramming DW, Cociu V (1990) Plums (Prunus). Acta Hortic 290:1–63. https://doi.org/10.17660/ActaHortic.1991.290.6

Radovanovic BC, Milenkovic Andelkovic AS, Radovanovic AB, Andelkovic MZ (2013) Antioxidant and antimicrobial activity of polyphenol extracts from wild berry fruits grown in Southeast Serbia. Trop J Pharm Res 12(5):813–819. https://doi.org/10.4314/tjpr.v12i5.23

Erturk Y, Ercisli S, Maghradze D, Orhan E, Agar G (2009) An assessment of genetic variability and relationships among wild-grown blackthorn (Prunus spinosa L.) plants based on RAPD markers. Genet Mol Res 8(4):1238–1244. https://doi.org/10.4238/vol8-4gmr641

Sikora E, Bieniek MI, Borczak B (2013) Composition and antioxidant properties of fresh and frozen stored blackthorn fruits (Prunus spinosa L.). Acta Sci Pol Technol Aliment 12:365–372

Çalışır S, Hacıseferoğulları H, Ozcan M, Arslan D (2005) Some nutritional and technological properties of wild plum (Prunus spp.) fruits in Turkey. J Food Eng 66:233–237. https://doi.org/10.1016/j.jfoodeng.2004.03.013

Barros L, Carvalho AM, Morais JS, Ferreira ICFR (2010) Strawberry-tree, blackthorn and rose fruits: detailed characterisation in nutrients and phytochemicals with antioxidant properties. Food Chem 120:247–254. https://doi.org/10.1016/j.foodchem.2009.10.016

Girones-Vilaplana A, Mena P, Moreno DA, Garcia-Viguera C (2013) Evaluation of sensorial phytochemical and biological properties of new isonic beverages enriched with lemon and berries during shelf life. J Sci Food Agric 94:1090–1100. https://doi.org/10.1002/jsfa.6370

Santos PHS, Silva MA (2008) Retention of vitamin C in drying processes of fruits and vegetables - a review. Dry Technol 26(12):1421–1437. https://doi.org/10.1080/07373930802458911

Ratti C (2001) Hot air and freeze-drying of high-calue foods: a review. J Food Eng 49(4):311–319. https://doi.org/10.1016/S0260-8774(00)00228-4

Babalis SJ, Belessiotis VG (2004) Influence of the drying conditions on the drying constants and moisture diffusivity during thin-layer drying of figs. J Food Eng 65:449–458. https://doi.org/10.1016/j.jfoodeng.2004.02.005

Ruiz NAQ, Demarchi SM, Giner SA (2011) Research on dehydrated fruit leathers: A review. In Proceedings of the 11th international congress on engineering and food. Athens, Greece

Tontul I, Topuz A (2017) Production of pomegranate fruit leather (pestil) using different hydrocolloid mixtures: an optimization study by mixture design. J Food Process Eng. https://doi.org/10.1111/jfpe.12657

Suna S, Tamer CE, Incedayi B, Ozcan Sinir G, Copur ÖU (2014) Impact of drying methods on physicochemical and sensory properties of apricot pestil. Indian J Tradit Knowl 13:47–55

Ozcan Sinir G, Ozkan Karabacak A, Tamer CE, Copur OU (2019) The effect of hot air, vacuum and microwave drying on drying characteristics, rehydration capacity, color, total phenolic content and antioxidant capacity of kumquat (Citrus japonica). Food Sci Technol (Campinas). https://doi.org/10.1590/fst.34417

Ozkan Karabacak A, Suna S, Tamer CE, Copur OU (2018) Effects of oven, microwave and vacuum drying on drying characteristics, colour, total phenolic content and antioxidant capacity of celery slices. Qual Assur Saf Crop 10(2):193–205. https://doi.org/10.3920/QAS2017.1197

Liu X, Qiu Z, Wang L, Cheng Y, Qu H, Chen Y (2009) Mathematical modelling for thin layer vacuum belt drying of Panax notoginseng extract. Energy Convers Manag 50:928–932. https://doi.org/10.1016/j.enconman.2008.12.032

Toğrul İT (2006) Suitable drying model for infrared drying of carrot. J Food Eng 77:610–619. https://doi.org/10.1016/j.jfoodeng.2005.07.020

Bhattacharya M, Srivastav PP, Mishra HN (2015) Thin-layer modeling of convective and microwave-convective drying of oyster mushroom (Pleurotus ostreatus). J Food Sci Technol 52(4):2013–2022. https://doi.org/10.1007/s13197-013-1209-2

Doymaz I (2006) Drying kinetics of black grapes treated with different solutions. J Food Eng 76:212–217. https://doi.org/10.1016/j.jfoodeng.2005.05.009

Evin D (2011) Microwave drying and moisture diffusivity of white mulberry: experimental and mathematical modelling. J Mech Sci Technol 25:2711–2718. https://doi.org/10.1007/s12206-011-0744-x

Ertekin C, Yaldiz O (2014) Drying of eggplant and selection of a suitable thin layer drying model. J Food Eng 63:349–359. https://doi.org/10.1016/j.jfoodeng.2003.08.007

Wang CY, Singh RP (1978) Use of variable equilibrium moisture content in modelling rice drying. Trans ASAE 11:668–672

Izli N, Tamer CE, Copur OU, Isık E, Yıldız B (2017) Drying model of sliced apple and effect of vacuum impregnation on its physicochemical properties. Phillipp Agric Scientist 100(3):315–323

Maskan M (2000) Microwave/air and microwave finish drying of banana. J Food Eng 44(2):71–78. https://doi.org/10.1016/S0260-8774(99)00167-3

Ozdemir M, Devres YO (1999) The thin layer drying characteristics of hazelnuts during roasting. J Food Eng 42:225–233. https://doi.org/10.1016/S0260-8774(99)00126-0

Sarsavadia PN, Sawhney RL, Pangavhane DR, Singh SP (1999) Drying behaviour of brined onion slices. J Food Eng 40:219–226. https://doi.org/10.1016/S0260-8774(99)00058-8

Yaldiz O, Ertekin C, Uzun HI (2001) Mathematical modelling of thin layer solar drying of sultana grapes. Energy 26:457–465. https://doi.org/10.1016/S0360-5442(01)00018-4

Maxwell JC (1881) Treatise on electricity and magnetism, vol 1, 2nd edn. Clarendon Press, Oxford

Wakao N, Smith JM (1962) Diffusion in catalyst pellets. Chem Eng Sci 17:825–834. https://doi.org/10.1016/0009-2509(62)87015-8

Weissberg HL (1963) Effective diffusion coefficient in porous media. J Appl Phys 34:2636–2639. https://doi.org/10.1063/1.1729783

Whitaker S (1999) The method of volume averaging. California, USA

Whitaker S (1998) Coupled transport in multiple systems: A theory of drying. In: Hartnett JP, Irvine TF (ed) Advances in heat transfer. California, USA, pp 1–104

Dadalı G, Apari DK, Ozbek B (2007) Estimation of effective moisture diffusivity of okra for microwave drying. Dry Technol 25:1445–1450. https://doi.org/10.1080/07373930701536767

Thuwapanichayanan R, Prachayawarakorn S, Kunwisawa J, Soponronnarit S (2011) Determination of effective moisture diffusivity and assessment of quality attributes of banana slices during drying. LWT Food Sci Technol. 44(6):1502–1510. https://doi.org/10.1016/j.lwt.2011.01.003

Doymaz I (2017) Microwave and infrared drying characteristics of mango slices. CBU Journal of Science 13(3):681–688. https://doi.org/10.18466/cbayarfbe.339337

Kaymak Ertekin F (2002) Drying and rehydrating kinetics of green and red peppers. J. Food Sci. 67(1):168–175. https://doi.org/10.1111/j.1365-2621.2002.tb11378.x

Crank J (1975) The mathematics of diffusion, 2nd edn. Oxford University Press, London

Demiray E, Tulek Y (2014) Drying characteristics of garlic (Allium sativum L) slices in a convective hot air dryer. Heat Mass Transf 50:779–786. https://doi.org/10.1007/s00231-013-1286-9

Tütüncü MA, Labuza TP (1996) Effect of geometry on the effective moisture transfer diffusion coefficient. J Food Eng 30:433–447. https://doi.org/10.1016/S0260-8774(96)00028-3

Vega Gálvez A, Scala KD, Rodríguez K, Lemus-Mondaca R, Miranda M, López J, Perez-Won M (2009) Effect of air-drying temperature on physico-chemical properties, antioxidant capacity, colour and total phenolic content of red pepper (Capsicum annuum L. var. Hungarian). Food Chem 117:647–653. https://doi.org/10.1016/j.foodchem.2009.04.066

Karaaslan SN, Tuncer IK (2008) Development of a drying model for combined microwave-fan-assisted convection drying of spinach. Biosyst Eng 100:44–52. https://doi.org/10.1016/j.biosystemseng.2007.12.012

Vitali D, Vedrina Dragojevic I, Šebecic B (2009) Effects of incorporation of integral raw materials and dietary fibre on the selected nutritional and functional properties of biscuits. Food Chem 114:1462–1469. https://doi.org/10.1016/j.foodchem.2008.11.032

Minekus M, Alminger M, Alvito P, Ballance S, Bohn T, Bourlieu C, Carriere F, Boutrou R, Corredig M, Dupont D, Dufour C, Egger L, Golding M, Karakaya S, Kirkhus B, Feunteun SL, Lesmes U, Macierzanka A, Mackie A, Marze S, McClements DJ, Menard O, Recio I, Santos CN, Singh RP, Vegarud GE, Wickham MSJ, Weitschies W, Brodkorb A (2014) A standardised static in vitro digestion method suitable for food-an international consensus. Food Funct 5:1113–1124. https://doi.org/10.1039/c3fo60702j

Spanos GA, Wrolstad RE (1990) Influence of processing and storage on the phenolic composition of Thompson seedless grape juice. J Agric Food Chem 38:1565–1571. https://doi.org/10.1021/jf00097a030

Katalinic V, Milos M, Kulisic T, Jukic M (2006) Screening of 70 medicinal plant extracts for antioxidant capacity and total phenols. Food Chem 94(4):550–557. https://doi.org/10.1016/j.foodchem.2004.12.004

Benzie IFF, Strain JJ (1996) The ferric reducing ability of plasma (FRAP ) as a measure of “antioxidant power ”: the FRAP assay. Anal Biochem 239(1):70–76. https://doi.org/10.1006/abio.1996.0292

Apak R, Güçlü K, Özyürek M, Çelik SE (2008) Mechanism of antioxidant capacity assays and the CUPRAC (cupric ion reducing antioxidant capacity) assay. Microchim Acta 160:413–419. https://doi.org/10.1007/s00604-007-0777-0

Tamer CE, Yekeler FZ, Çopur ÖU, İncedayı B, Suna S (2016) A study of fortification of lemonade with herbal extracts. Food Sci Technol (Campinas) 37(1):45–51. https://doi.org/10.1590/1678-457x.06016

Swasdisevi T, Devahastin S, Sa-Adchom P, Soponronnarit S (2009) Mathematical modelling of combined far-infrared and vacuum drying banana slice. J Food Eng 92:100–106. https://doi.org/10.1016/j.jfoodeng.2008.10.030

Doymaz İ, Pala M (2002) Hot air drying characteristics of red pepper. J Food Eng 55:331–335. https://doi.org/10.1016/S0260-8774(02)00110-3

Giri SK, Prasad S (2007) Drying kinetics and rehydratin characterisitics of microwave-vacuum and convective hot-air dried mushrooms. J Food Eng 78:512–521. https://doi.org/10.1016/j.jfoodeng.2005.10.021

Orikasa T, Wu L, Shiina T, Tagawa A (2008) Drying characteristics of kiwifruit during hot air drying. J Food Eng 85:303–308. https://doi.org/10.1016/j.jfoodeng.2007.07.005

Wang Z, Sun J, Liao X, Chen F, Zhao G, Wu J, Hu X (2007) Mathematical modeling on hot air drying of thin layer apple pomace. Food Res Int 40:39–46. https://doi.org/10.1016/j.foodres.2006.07.017

Ghodake HM, Goswami TK, Chakraverty A (2006) Mathematical modelling of withering characteristics of tea leaves. Dry Technol 24:159–164. https://doi.org/10.1080/07373930600558979

Toğrul İT, Pehlivan D (2003) Modelling of drying kinetics of single apricot. J Food Eng 58:23–32. https://doi.org/10.1016/S0260-8774(02)00329-1

Akgun NA, Doymaz I (2005) Modelling of olive cake thin-layer drying process. J Food Eng 68:455–461. https://doi.org/10.1016/j.jfoodeng.2004.06.023

Sharma GP, Prasad S (2004) Effective moisture diffusivity of garlic cloves undergoing microwave-convective drying. J Food Eng 65(4):609–617. https://doi.org/10.1016/j.jfoodeng.2004.02.027

Zogzas NP, Maroulis ZB, Marinos-Kouris D (1996) Moisture diffusivity data compilation in foodstuffs. Dry Technol 14(10):2225–2253. https://doi.org/10.1080/07373939608917205

Oberoi DPS, Sogi DS (2015) Drying kinetics, moisture diffusivity and lycopene retention of watermelon pomace in different dryers. J Food Sci Technol 52(11):7377–7384. https://doi.org/10.1007/s13197-015-1863-7

Darvishi H, Khoshtaghaza MH, Minaei S (2014) Drying kinetics and color change of lemon slices. Int Agrophys 28:1–6. https://doi.org/10.2478/intag-2013-0021

Demiray E, Seker A, Tulek Y (2016) Drying kinetics of onion (Allium cepa L.) slices with convective and microwave drying. Heat Mass Transf 53:1817–1827. https://doi.org/10.1007/s00231-016-1943-x

Ibarz A, Pagan J, Garza S (1999) Kinetic models for colour changes in pear puree during heating at relatively high temperatures. J Food Eng 39:415–422. https://doi.org/10.1016/S0260-8774(99)00032-1

Maskan M (2001) Kinetics of colour change of kiwifruits during hot air and microwave drying. J Food Eng 48:169–175. https://doi.org/10.1016/S0260-8774(00)00154-0

Gumusay OA, Borazan AA, Ercal N, Demirkol O (2015) Drying effects on the antioxidant properties of tomatoes and ginger. Food Chem 173:156–162. https://doi.org/10.1016/j.foodchem.2014.09.162

Kamiloglu S, Toydemir G, Boyacioglu D, Beekwilder J, Hall RD, Capanoglu E (2016) A review on the effect of drying on antioxidant potential of fruits and vegetables. Crit Rev Food Sci Nutr 56:110–129. https://doi.org/10.1080/10408398.2015.1045969

Kamiloglu S, Ozkan G, Isik H, Horoz O, Van Camp J, Capanoglu E (2017) Black carrot pomace as a source of polyphenols for enhancing the nutritional value of cake: an in vitro digestion study with a standardized static model. LWT Food Sci Technol 77:475–481. https://doi.org/10.1016/j.lwt.2016.12.002

Kamiloglu S, Demirci M, Selen S, Toydemir G, Boyacioglu D, Capanoglu E (2014) Home processing of tomatoes (Solanum lycopersicum): effects on in vitro bioaccessibility of total lycopene, phenolics, flavonoids, and antioxidant capacity. J Sci Food Agric 94:2225–2233. https://doi.org/10.1002/jsfa.6546

Nora CD, Muller CDR, de Bona GS, Rios ADO, Hertz PF, de Jong Jablonski A, Flores SH (2014) Effect of processing on the stability of bioactive compounds from red guava (Psidium cattleyanum Sabine) and Guabiju (Myrcianthes pungens). J Food Compos Anal 34:18–25. https://doi.org/10.1016/j.jfca.2014.01.006

Kamiloglu S, Capanoglu E (2014) Polyphenol content in figs (Ficus carica L.): effect of sun-drying. Int J Food Prop 18(3):521–535. https://doi.org/10.1080/10942912.2013.833522

Nicoli MC, Anese M, Parpinel M (1999) Influence of processing on the antioxidant properties of fruit and vegetables. Trends Food Sci Technol 10:94–100. https://doi.org/10.1016/S0924-2244(99)00023-0

Oliveira A, Pintado M (2015) Stability of polyphenols and carotenoids in strawberry and peach yoghurt throughout in vitro gastrointestinal digestion. Food Funct 6:1611–1619. https://doi.org/10.1039/c5fo00198f

Tagliazucchi D, Verzelloni E, Bertolini D, Conte A (2010) In vitro bio-accessibility and antioxidant activity of grape polyphenols. Food Chem 120:599–606. https://doi.org/10.1016/j.foodchem.2009.10.030

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Özkan Karabacak, A. Effects of different drying methods on drying characteristics, colour and in-vitro bioaccessibility of phenolics and antioxidant capacity of blackthorn pestil (leather). Heat Mass Transfer 55, 2739–2750 (2019). https://doi.org/10.1007/s00231-019-02611-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-019-02611-3