Abstract

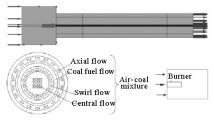

Numerical simulations using computational fluid dynamics (CFD) are performed to investigate the flame length characteristics in rotary kilns using probability density function (PDF) approach. A commercial CFD package (ANSYS-Fluent) is employed for this objective. A 2-D axisymmetric model is applied to study the effect of both operating and geometric parameters of rotary kiln on the characteristics of the flame length. Three types of gaseous fuel are used in the present work; methane (CH4), carbon monoxide (CO) and biogas (50 % CH4 + 50 % CO2). Preliminary comparison study of 2-D modeling outputs of free jet flames with available experimental data is carried out to choose and validate the proper turbulence model for the present numerical simulations. The results showed that the excess air number, diameter of kiln air entrance, radiation modeling consideration and fuel type have remarkable effects on the flame length characteristics. Numerical correlations for the rotary kiln flame length are presented in terms of the studied kiln operating and geometric parameters within acceptable error.

Similar content being viewed by others

Abbreviations

- A a,i :

-

Air entrance area (m2)

- C 2 , C 1ε :

-

Turbulence model constants

- D :

-

Diameter of kiln (m)

- d a,i :

-

Air entrance diameter (m)

- d o :

-

Fuel nozzle diameter (m)

- d p :

-

Primary air nozzle diameter (m)

- f :

-

Mixture fraction, f = ϕ/(ϕ + L)

- f a :

-

Axial mean mixture fraction

- F i :

-

External body force (N)

- f o :

-

Fuel mean mixture fraction

- f st :

-

Stoichiometric mean mixture fraction, f st = 1/(1 + L)

- G :

-

Incident radiation (W/m2)

- g i :

-

Gravitational acceleration (m/s2)

- I :

-

Turbulence intensity

- k :

-

Turbulent kinetic energy (m2/s2)

- L :

-

Stoichiometric air to fuel mass ratio (kgair/kgfuel)

- L f :

-

Overall confined jet flame length (m)

- p :

-

Pressure (Pa)

- q r :

-

Radiation heat flux (w/m2)

- R :

-

Radius of kiln (m)

- r a,i :

-

Radius of air entrance (m)

- Re DH :

-

Reynolds number based on hydraulic diameter

- T :

-

Local temperature (K)

- T a :

-

Axial temperature (K)

- T air :

-

Air temperature (K)

- T o :

-

Fuel temperature (K)

- u :

-

Mean axial velocity (m/s)

- u a :

-

Axial velocity of the mixture/flame (m/s)

- u i , u j :

-

Velocity components in x and y directions (m/s)

- u o :

-

Fuel velocity at the nozzle (m/s)

- u p :

-

Primary air velocity at the nozzle (m/s)

- v :

-

Mean radial velocity (m/s)

- w :

-

Mean tangential velocity (m/s)

- x :

-

Axial distance from burner (m)

- Z i :

-

Mass fraction of species i

- ε :

-

Turbulent dissipation rate (m2/s3)

- κ :

-

Absorption coefficient (1/m)

- λ :

-

Excess air number

- μ :

-

Dynamic viscosity (Pa.s)

- μ t :

-

Turbulent viscosity (kg/m.s)

- ν :

-

Kinematic viscosity (m2/s)

- ρ :

-

Density (kg/m3)

- ρ o :

-

Density of fuel (kg/m3)

- ρ st :

-

Stoichiometric density (density of combustion gas at stoichiometric mixture fraction) (kg/m3)

- σ:

-

Stefan-Boltzmann constant (5.669 × 10−8 W/m2K4)

- σε :

-

Turbulent Prandtl number for the turbulence kinetic energy dissipation rate

- σk :

-

Turbulent Prandtl number for the turbulence kinetic energy

- σt :

-

Turbulent Prandtl number, σ t = μ t c p /k t = 0.85

- τ i.j :

-

Stress tensor (Pa)

- ϕ :

-

Equivalence ratio, ϕ = (air/fuel) stoichiometric /(air/fuel) actual

- 2-D:

-

Two dimensional

- 3-D:

-

Three dimensional

- CFD:

-

Computational fluid dynamics

- CPU:

-

Central processing unit

- DLR:

-

Deutschland fur Lüft und Raumfahrt (German Aerospace Center)

- PDF:

-

Probability density function

- RANS:

-

Reynolds averaged Navier–Stokes

- RSM:

-

Reynolds stress model

- SWF:

-

Standard wall functions

- WSGGM:

-

Weighted sum of gray gases model

References

Boateng AA (2008) Rotary kilns transport phenomena and transport processes. ElsevierInc, Oxford

Jauhari R, Gray MR, Masliyah JH (1998) Gas–Solid mass transfer in a rotating drum. Can J Chem Eng 76(2):224–232

Georgallis M (2004) Mathematical modeling of lime kilns. Ph.D. Dissertation, The University of British Columbia, Vancouver, BC

Peray KE (1972) The rotary cement kiln. Chemical Publishing Co., New York

Manitius A, Kureyuz E, Kawecki W (1974) Mathematical model of the aluminium oxide rotary kiln. Ind Eng Chem Process Des Dev 13(2):132–142

Bui RT, Simard G, Charette A, Kocaefe Y, Perron J (1995) Mathematical modeling of the rotary coke calcining kiln. Can J Chem Eng 73(4):534–545

Smidth F, “Duoflex® Burner,” flsmidth (2015) http://www.flsmidth.com/en-US/Industries/Cement/Products/Pyroprocessing/ Duoflex+Burner/Duoflex+Burner. Accessed 10 April 2015

Rovaglio M, Manca D, Biardi G (1998) Dynamic modeling of waste incineration plants with rotary kilns: comparisons between experimental and simulation data. Chem Eng Sci 53(15):2727–2742

Abe I, Fukuhara T, Iwasaki S, Yasuda K, Nakagawa K, Iwata Y, Kominami H, Kera Y (2001) Development of a high density carbonaceous adsorbent from compressed wood. Carbon 39(10):1485–1490

Miguel GS, Fowler GD, Dall’Orso M, Sollars CJ (2002) Porosity and surface characteristics of activated carbons produced from waste tyre rubber. J Chem Technol Biotechnol 77(1):1–8

Ortiz OA, Sua’rez GI, Nelson A (2005) Dynamic simulation of a pilot rotary kiln for charcoal activation. Comput Chem Eng 29(8):1837–1848

Cook CA, Cundy VA (1995) Study of parameters influencing wall-to-bed heat transfer in low-temperature rotary desorbers. J Energy Resour Technol, Trans ASME 117(1):50–57

Rensch T (2001) Beitrag zum Prozess der thermischen Bodendekontamination im Drehrohrofen. Ph.D. Dissertation, The University of Magdeburg, Germany

Barr P (1986) Heat transfer processes in rotary kilns. Ph.D. Dissertation, The University of British Columbia, Vancouver, BC

Kolev D, Stefanov B, Borisov D, Choshnova D (2003) Method for numerical simulation and graphical presentation of the rate field in a physical model of flash smelting furnaces. J UCTM 38(4):1147–1154

Aloqaily A (2008) A study of aerodynamics in rotary kilns with two burners. Ph.D. Dissertation, The University of Toronto, Canada

Elattar HF, Stanev R, Specht E, Fouda A (2014) CFD simulation of confined non-premixed jet flames in rotary kilns for gaseous fuels. Comput Fluids 102(10):62–73

Elattar HF, Specht E, Fouda A, Bin-Mahfouz AS (2016) Study of parameters influencing fluid flow and wall hot spots in rotary kilns using CFD. Can J Chem Eng 94(2):355–367

Meier W, Barlow RS, Chen Y, Chen J (2000) Raman/rayleigh/lif measurements in a turbulent ch4/h2/n2 jet diffusion flame: experimental techniques and turbulence-chemistry interaction. Combust Flame 123(3):326–343

ANSYS, Inc. (2011) ANSYS FLUENT User’s guide. Ansys Inc, Canonsburg

Moles FD, Watson D, Lain PB (1973) The aerodynamics of the rotary cement kiln. J Inst Fuel 46:353–362

Shih TH, Liou WW, Shabbir A, Yang Z, Zhu J (1995) A new k-ɛ eddy viscosity model for high reynolds number turbulent flows. Comput Fluids 24(3):227–238

Poinsot T, Veynante D (2001) Theoretical and numerical combustion. R.T. Edwards, Inc, Philadelphia

Cheng P (1964) Two-dimensional radiating gas flow by a moment method. AIAA J 2:1662–1664

Siegel R, Howell JR (1992) Thermal radiation heat transfer. Hemisphere Publishing Corporation, Washington DC

Kim HK, Kim Y, Lee SM, Ahn KY (2007) Studies on combustion characteristics and flame length of turbulent oxy-fuel flames. Energy Fuels 21(3):1459–1467

Hawthorne WR, Weddell DS, Hottel HC (1949) Mixing and combustion in turbulent gas jets. Symp Combust Flame, Explos Phenom 1(3):266–288

Peters N (2000) Turbulent combustion. Cambridge University, Cambridge

Yang W, Blasiak W (2004) Chemical flame length and volume in liquified propane gas combustion using high-temperature and low-oxygen-concentration oxidizer. Energy Fuels 18(5):1329–1335

Elattar HF (2011) Flame simulation in rotary kilns using computational fluid dynamics, Ph.D. Dissertation, Magdeburg University, Germany

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Elattar, H.F., Specht, E., Fouda, A. et al. CFD modeling using PDF approach for investigating the flame length in rotary kilns. Heat Mass Transfer 52, 2635–2648 (2016). https://doi.org/10.1007/s00231-016-1768-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-016-1768-7