Abstract

The conversion to climate-stable, resilient and productive forests has resulted in an increasing share of mixed stands. Different growth conditions and silvicultural treatments lead to an increased scatter in strength compared to what is expected from monoculture experience. The study (i) quantified the magnitude of variation in strength of European beech timber from stands of different composition and (ii) showed the impact of grading on the characteristic strength value of timber coming from those stands. Strength grading models and machine settings for hardwood tensile classes on over 900 European beech (Fagus sylvatica L.) boards were derived. One model used only the dynamic modulus of elasticity (Edyn), and a more complex model used a knot value in addition. Afterwards, 407 boards from pure beech stands as well as mixed stands of beech with Douglas fir (Pseudotsuga menziesii (Mirb.) Franco), Norway spruce (Picea abies (L.) Karst.), sessile oak (Quercus petraea (Matt.) Liebl.), and Scots pine (Pinus sylvestris L.) were graded and analyzed for their material properties from tension tests parallel to grain. Although a variance components analysis attributed only 4.2% of the variation to mixture, the ungraded timber showed significant strength differences between the pure and the beech-pine stands (65.2 versus 46.6 MPa). The yield of the material graded to the highest class in a class combination was higher in pure beech stands. The required characteristic strength values were mostly met for boards from the pure stands; while boards from the beech-pine mixed stands hardly ever reached the required values. To reduce strength variation and guarantee reliable timber products, strength grading should consider the various growth situations in forests when sampling material for the derivation of settings.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Wood varies naturally in its properties. In recent years and across the entire forest chain, research projects have analyzed the influence of silvicultural treatment, forestry management strategies and site conditions on the physical and mechanical properties of timber. The studies focused mainly on some of the economically most important tree species: Sitka spruce (Brazier and Mobbs 1993; Moore et al. 2009b, a; Simic et al. 2018), radiata pine (Downes et al. 2002; Lasserre et al. 2009), Douglas fir (Barrett and Kellogg 1984; Krajnc et al. 2019), Pinus patula (Erasmus and Wessels 2020; Erasmus et al. 2020), Norway spruce (Høibø et al. 2014; Fischer et al. 2015, 2016), Scots pine (Høibø and Vestøl 2010; Auty et al. 2014), Japanese larch (Fujimoto and Koga 2009) or birch (Cameron et al. 1995) among others. To make the most use of the forest resource available regarding yields and mechanical properties, information on wood characteristic variation and sources of variation is essential (Moore et al. 2013), in particular how the wood properties vary on the different scales (stands, trees, boards). Variations in mechanical properties such as strength and stiffness have an impact on the definition of growth areas (Ridley-Ellis et al. 2016), on the modeling of wood properties (Giroud et al. 2017) and on the grading process (Ridley-Ellis et al. 2016). Understanding variations in wood characteristics, their causes, and the relevance of the observed scale (stand, tree, board) for the variation of the timber properties, provides essential insights for future forest management plans. As the entire grading process relies strongly on the standard, such knowledge on variation might support the standardization in timber industry, increase the reliability of the achieved mechanical properties and guarantee strength and stiffness. Datasets containing information on forest, tree, log, and board characteristics are required to quantify the variation in mechanical wood properties along the production chain (Moore et al. 2013; Fischer et al. 2016; Rais et al. 2022). Some studies could break down the total variation in mechanical properties into different levels via variance component analysis (VCA), i.e., using random-effects models and the overall mean of the dependent variable as fixed effect to estimate the amount of the variance components’ contribution to the total variability in the dependent variable (Schützenmeister and Piepho 2012). Moore et al. (2013) for Sitka spruce and Fischer et al. (2016) and Vestøl et al. (2016) for Norway spruce were able to assign approximately 80% of the total variation in strength values to within-stand differences; less than 20% was attributed to between-stand differences. In other investigations, mixed models with fixed and random effects were used. Fixed effects not only reduced the overall variance of the dependent variable that was explained, but they also shifted the proportion of variation explained by random effects. As a result, the findings on the variance components’ contribution of those investigations can only be interpreted as guidelines. For example, Rais et al. (2014) found that only 9% of the total variation in bending strength was attributed to between-stand variation—mainly due to initial spacing—, with the remaining 90% attributed to within-stand differences whereas in Moore et al. (2009a) thinning contributed to 10% of the total variation in bending strength.

For structural safety and for an economic use of structural timber, the strength either from bending or tension tests, stiffness and density of a population need to be assessed (Ridley-Ellis et al. 2016; Brunetti et al. 2021; Plos et al. 2022). These three properties are the so-called grade determining properties (GDPs) and are the ones used to assign timber population to a specific strength class (Ridley-Ellis et al. 2022). The strength classes of EN 338 comprise the timber design properties. For the GDP, those are fifth percentile of strength and density and mean modulus of elasticity. For softwoods, EN 338 introduces C-grades (based on bending testing) and T-grades (based on tension testing). Hardwoods such as poplar are handled as softwoods and classified in the C- and T-grades due to the similar physical and mechanical property profiles (EN 338). The same is true for chestnut which shows relatively low density compared to temperate hardwood species, such as ash, beech, and oak (Brunetti et al. 2013; Nocetti et al. 2016). For hardwoods, the EN 338 only lists bending strength classes, so called D-grades. Tensile strength classes for hardwoods were recently proposed by Kovryga et al. (2016, 2020). During the assignment, the characteristic values of the three GDPs are observed. The basis for the timber strength grading provides the measurement of the indicating properties (IPs). These properties comprise non-destructively measured wood properties and/or their combinations and are used to predict the GDPs. The boards’ IPs are mostly calculated by a (multiple) linear equation. Estimating its regression coefficients needs large dataset containing destructive data (strength) and non-destructive machine data. By means of the parametrized model, a single board’s strength can be predicted based on its machine data.

Machine strength grading is based on powerful predictors of wood quality; the non-destructive assessment of every piece of timber takes place at a faster rate with less risk of human errors than in visual grading (Ridley-Ellis et al. 2016). As already mentioned, the models for calculating the IPs and therefore the IPs themselves can be either based on a single parameter such as the knottiness, or on a combination of parameters and are the basis for the strength grading. EN 14081 assumes that IPs have a defined relationship to the GDPs within both a species and a grading region. The use of robust IPs in strength grading minimizes the unexplained variance of strength. In addition to the model's complexity, the class combination has an impact on the strength variance reduction inside a class (Rais et al. 2022). The IPs used, may describe up to 75% of the strength variation of some timber samples (Ranta-Maunus et al. 2011). The European machine-controlled system according to EN 14081 relies on so-called growth areas for which different models and settings are intended to minimize the uncertainty in the strength prediction. The present notion of growth areas is based on political national borders, without considering explicitly for existing inter-country differences in strength related to site characteristics (climate, soil), silviculture, or sawing pattern. The sample used to derive models and settings should be representative for the material to be graded in production in terms of origin, dimension and the wood quality (EN 14081–2).

The present investigation is dedicated to the silvicultural influence of the tree species mixture on the strength grading. Bending or tensile strength are often the limiting timber property in European strength grading, which is related to knot size and is in turn strongly influenced by silviculture (Gil-Moreno et al. 2019).

European beech (Fagus sylvatica L.) is the most common hardwood tree species in central Europe (Brus et al. 2012) and is the dominant tree species in most stands. It plays an important role in sustainable mixed stands (Pretzsch and Schütze 2021). For structural applications, there are promising products such as glued laminated timber (Pöhler et al. 2006). The current literature on the mechanical properties of beech timber comprises a variety of publications showing a broad range of possible mechanical property values. Westermayr et al. (2018) used a low-quality beech timber with characteristic properties matching the requirements of T-classes regarding the tensile strength (< 30 MPa). In contrast, Ehrhart et al. (2016) used high-quality beech lamellas to obtain characteristic tensile strength of 50 MPa. European beech is a very adaptive tree species in terms of stem and crown structure (Pretzsch 2019), but very little information is currently available on the source of the variation in the mechanical properties of European beech wood.

Previous research on European beech has found stiffness differences amongst 1907 boards originating from different species mixtures (Rais et al. 2020b). From the original sample, 407 boards representing pure and mixed stands were chosen for the current investigation. Destructive tests were used to see how the species mixing affects the timber strength. Not only strength differences were studied, but also whether grading can handle timber from varied forest managements and assure grade characteristic values.

-

(1) quantify the magnitude of variation in strength properties of European beech timber from stands with different tree species composition (pure stand versus mixed stand) and

-

(2) show the impact of machine strength grading on the characteristic strength value of timber coming from these different stands.

Material and methods

European beech boards from different mixture types

A sample of 407 boards was used for this study (Table 1). The sawn timber originated from 100 European beech (Fagus sylvatica L.) trees from 20 stands. All stands were located in two enterprises of the Bavarian State Forests (Bayerische Staatsforsten) in the Spessart, a low-mountain range located in Lower Franconia in the north of Bavaria, which is known for its extensive beech and oak forests. The stands were on average 125 years (y) old (standard deviation 32 y) and of good wood quality, as low-quality trees were removed in previous thinning interventions. Each tree and therefore each board could be assigned to one of the following mixture types: pure beech stands and mixed stands that included the tree species Douglas fir (Pseudotsuga menziesii [Mirb.] Franco), Norway spruce (Picea abies L. Karst.), Scots pine (Pinus sylvestris L.) and sessile oak (Quercus petraea (Matt.) L.), respectively. Apart from the mixing type, sources of variation were attempted to be minimized by sampling in the same region with similar soil conditions, climatic conditions, genetic material, altitude, and forest managements (ceteris-paribus-conditions): The sample contained only one cross-section, which is, however, relevant for production. The sampling area was located in one and the same area of about 300 km2 to keep the site conditions and silvicultural history as uniform as possible. With a coefficient of variation of 56% for the strength of the ungraded boards (Table 2), the data nevertheless revealed high variation, which was comparable to other data on European beech (Rais et al. 2021).

The sample in the current study was representatively drawn from an original dataset containing 1907 specimens, which contained two cross sections 50 × 150 × 4100 mm3 and 40 × 80 × 4100 mm3 as described by Rais et al. (2020b) . Because 50 × 150 mm2 is more typical for glued laminated timber where tensile strength is required in applications and influences the design, the current study's dataset only included boards from the bigger cross section. However, the subsample of 407 boards was chosen from the original sample (n = 1907) so that it was representative in terms of dynamic modulus of elasticity (Edyn) and contained at least one board per log and per tree.

Edyn-based machines are commonly used in strength grading because they are easy to operate and have a high throughput speed. More important, Edyn demonstrates a strong link to strength and stiffness. Edyn is calculated from wood density ρdyn, eigenfrequency EFdyn, length, and moisture content u. The board length was originally 4.1 m. For the tension testing according to EN408, the position where failure was expected to occur was determined visually and regarded as the critical section. Afterwards, board length was reduced to 2.4 m. As the boards were planed, the dimensions of the 407 boards were reduced from 50 × 150 × 4100 mm3 to 38 × 130 × 2400 mm3. Prior to testing, a non-destructive assessment of the boards was done measuring Edyn and the knot cluster value DAB defined in DIN 4074–5. The DAB takes into account all knots that appear in a moving window of 150 mm. The spread of all knots over the 150 mm window is related to the board’s width. The knots’ size (width) is measured parallel to the edge (Kovryga et al. 2019). Knot dimensions that overlap are considered only once. The DAB is a useful grading criterion for the mechanical properties of boards/planks and estimated the knot volume related to the board volume over 150 mm. Edyn values were corrected to a moisture content of 12% according to EN 384 (ΔEdyn Δu−1 = −1% %−1). Density ρdyn was calculated from the mass and the volume of the full board. The board mass in turn was determined using a scale. For volume determination, a measuring tape provided board length and a digital caliper provided board width and thickness.

The destructive tensile test was done in accordance with EN 408 and EN 384. For the tensile strength the free test length was set to nine times the nominal width of 130 mm with the critical section located within the tested range. The tensile strength values were adjusted to the reference width of 150 mm using the kh-factor as required by EN 384. The specimens were gripped by jaws on both endings. Static modulus of elasticity Et,0 was determined over five times the width. If possible, the Et,0 was determined in the linear range of the stress–strain diagram between 10% and 40% of the maximum stress. Following testing, density and moisture content were determined cutting a small specimen from each test piece in accordance with EN 408 and EN 13183–1 (oven dry method), respectively. Similar to Edyn, Et,0 values were corrected to a moisture content of 12% according to EN 384 (ΔEt,0 Δu−1 = −1% %−1). Density values were adjusted to a moisture content of 12% according to EN 384 (Δρ Δu−1 = \(+\)0.5% %−1). For a variance component analysis (VCA), a random-effects model was applied to divide the random variance into variances being attributable to the different levels (mixture type, stand, tree and board). A nested structure was assumed for the random effects in accordance with the experimental design:

where ft,0,ijkl was the measurement of the tensile strength of an individual board and μ was the overall mean. VCA was also conducted with Et,0,ijkl, Edyn,ijkl, and ρijkl. Parameters Mi, Sj(i) and Tk(ji) were nested random effects at (species) mixture, stand-in-mixture, tree-in-stand-in-mixture levels (Pinheiro and Bates 2000; Zuur et al. 2009). The random effects were assumed to be normally distributed with zero mean and constant variance. The symbol ɛl(kji) represented the independent and identically distributed random errors at board level.

Derivation of grading models and threshold values

There were neither models nor threshold values of strength classes (settings) for grading hardwood in tensile classes available at this time. As a result, we calculated both using European beech data from the wood database of the Professorship of Wood Technology (TU Munich). This dataset included 927 boards from four different projects (Table 2), whereas one project included the 407 boards already described and named sample D. The three other samples A, B, and C differed regarding their origin and cross section. Sample A originated from the forestry office Kirchheim (Baden-Wuerttemberg). The timber was cut from stems that could not be used for furniture production (Glos and Lederer 2000). An overall number of 104 and 115 boards with cross sections of 32 × 120 × 3080 mm3 and 32 × 160 × 3450 mm3 were available. Sample B consisted of beech lamellas from central Germany collected within a radius of 150 km around Creuzburg (Thuringia) as described in Westermayr et al. (2018, 2022). The dataset included 203 specimens with cross sections of 24 × 100 mm2 and 24 × 150 mm2 with 104 and 99 lamellas each and a length of approximately 3050 mm. Sample C is part of the ongoing project “Easy beech”, which is a continuation of the research by Westermayr et al. (2018). The cross section was 24 × 100 mm2. Both a simple and a more complex strength grading model were derived. The simple model Modelsimple used Edyn only, i.e., ft,0 = f(Edyn), and achieved a coefficient of determination r2 of 0.44; the complex model Modelcomplex combined Edyn and DAB, i.e., ft,0 = f(Edyn, DAB), and achieved a r2 of 0.64.

The setting for a strength class was the minimum threshold value that just fulfilled the requirements for tensile strength, tensile modulus of elasticity and density. Requirements for strength classes were not reduced by any of the factors given in the standard and the cost matrix was not applied. Individual strength classes or strength class combinations were optimized to maximize the yield of highest classes. Characteristic values were calculated according to the parametric approach of EN 14358. The tensile strength profiles (Table 3) for hardwood proposed by Kovryga et al. (2020) were applied. Those profiles comprise the relationships between the mechanical properties optimized for the tension test results of medium-density European hardwoods, such as ash and beech. Particularly, for the mentioned profiles, the proposed DT-classes exceed the limits of softwood T-classes regarding the characteristic tensile strength, which in cases of T-classes is set to maximum 30 MPa for T30. Although Kovryga et al. (2020) proposed to apply the use of T-classes for lower classes even for hardwoods, for consistency of the nomenclature used, only DT-classes were used here. In total, 16 strength class combinations were considered with either one or two strength classes for the boards to be assigned to. The following four strength class combinations including DT18 were analyzed: DT38/DT18/reject, DT42/DT18/reject, DT50/DT18/reject and DT18/reject. In analogy to DT18, strength class combinations were built with DT22, DT25 and DT28 as the lowest class, respectively. The free statistical software R was used for all statistical analysis (R Core Team 2019).

Results

Derivation of models and threshold values

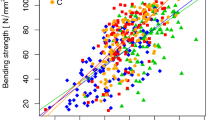

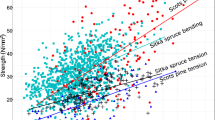

In Fig. 1, the strength ft,0 is plotted against the IPs. Regression lines and the coefficients of determination r2 for each sample A, B, and C are shown, whereas Sample D is subdivided into its five different sub-samples from different species mixtures. Independent of the strength class or class combination, the most critical GDP was characteristic strength value ft,0,k. The ρk overfulfilled the required characteristic values by 15% for Modelsimple and 12% for Modelcomplex, the Et,0,mean by 20% and 12%, respectively (Fig. 2). Figure 2 is based on 28 classes from the 16 strength class combinations studied.

Ratio between the achieved characteristic property value and the requirements for grading into 28 classes of different combinations is shown in boxplots with superimposed 1D jittered scatterplots. The tensile strength ft,0,k was the most critical GDP for the simple (a) and the complex (b) model. Figures in brackets show the coefficients of variation

Mechanical properties related to stand mixture

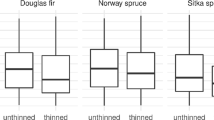

The majority of the total strength variation was not explained by differences between mixture types, stands, or trees and was therefore attributed to the board level (85.2%) based on the sample of 407 boards; 4.2% of the total variation were observed between different mixture types (Table 4). Of the variation in ft,0,ijkl, 1.1% was attributed to differences at the stand-in-mixture level and with 9.5% of the total variation in ft,0,ijkl attributed to differences at tree-in-stand-in-mixture level. The high proportion of 49.4% of the total variation in timber density attributed to the tree level is obvious. The tensile strength distributions ft,0 from pure and mixed stands differed significantly from one another (F-value of 2.7; p-value of 0.035). In particular, the European beech boards from pure stands had significantly higher strength values than from mixed stands with Douglas fir, oak or pine (post-hoc tests, Table 5). The differences in stiffness and density between mixture types were not significant.

The sample from pure stands achieved the highest characteristic strength values for the ungraded sawn timber, the sample from mixed beech-pine stands the lowest (Table 5).

A strength class DT50 could be set out for both models, i.e., the model based solely on the Edyn and the model based on knottiness and Edyn. The yield for DT50 using Modelsimple was 12.5% (51 of 407 boards); the majority with 20 boards came from the pure beech stands, the minority with two boards from the mixed beech-pine stands. As a result, based on the simple model, 24% of the boards from pure stands could be classified to DT50, whereas just 2% of the boards from beech-pine stands were (Fig. 3a). In comparison, the yield for DT50 using Modelcomplex was 24.3% (99 of 407 boards). A share of 44% of the boards from the pure stands was assigned to DT50 (Fig. 3b). Among all mixture types and independent of the model, the yields were similar for the low grade DT18 when grading only one class in one run. All yields were higher than 90% (Fig. 3).

Figure 4 shows the deviation from the strength requirement for the high-strength classes DT38, DT42 and DT50. Figure 4 focuses on the higher strength class of the considered class combinations, Fig. 5 and Fig. 6 on the second lower class. Apart from the boards from the beech-spruce mixture in DT50 (Modelcomplex), the random samples of all mixture types, classes and models met the strength requirements. The samples from the beech-oak and beech-pine stands had less than 20 boards in the high class, so that the characteristic strength value was not calculated.

European beech timber from pure beech stands achieved the tensile strength requirement of classes DT18, DT22, DT25 and DT28 in almost each combination. Positive deviations in Fig. 5 and 6 indicate that the requirement has been exceeded, negative deviations indicate that it has not been met. In three combinations, the required characteristic tensile strength for the class with lower requirements in grade class combination was not fulfilled: by −2% for DT42/DT22 (Fig. 6b), by −2 for DT50/DT22 (Fig. 6b) and by −10% for DT50/DT25 (Fig. 6c). Because the higher-quality material was grouped in the top class, grading boards to two classes in one run reduced positive deviations in the class with lower requirements, if compared to the grading to the same lower class as a single class. The highest positive deviation was seen with Modelsimple for strength class DT28 in combination with DT50 (Fig. 5d), where the characteristic strength of boards from pure stands was 49% higher than required. On the other end of the spectrum, the characteristic strength of boards from beech-pine stands for DT28 in combination with DT50 (Fig. 5d) had the largest negative deviation, with the fifth percentile being 33% lower than necessary.

Seven times using Modelsimple and four times using Modelcomplex, the characteristic value of beech-pine stands missed the required strength value by more than 10%. Boards from beech-oak stands showed mainly negative deviations but only five combinations were lower than −10%: DT42/DT28 and DT38/DT28 based on Modelsimple and DT38/DT25, DT28 and DT25 based on Modelcomplex. Boards from beech-spruce stands did not deviate a lot. They never missed the requirement for a strength class by more than 10%; the lowest deviation was at DT50/DT25 when the benchmark for DT25 was missed by 8% (Modelcomplex). Boards from beech-Douglas fir stands only missed once the requirement for a class by more than 10% at DT38/DT25 with −11% (Modelsimple).

Deviations of the characteristic strength value from the required characteristic strength values for DT38, DT42 and DT50 using Modelsimple (left) and Modelcomplex (right). The bold figures next to the bars are the most positive and negative deviation among the mixture types for each combination, numbers in brackets are the number of boards. Bars are only illustrated if more than 20 boards were available. (Color online)

Deviations of the characteristic strength value from the required characteristic strength values for DT-classes DT18 (a), DT22 (b), DT25 (c) and DT28 (d) using Modelsimple. The bold figures next to the bars are the most positive and negative deviation among the mixture types for each combination, numbers in brackets are the number of boards. Bars are only illustrated if more than 20 boards were available. (Color online)

Deviations of the characteristic strength value from the required characteristic strength values for DT-classes DT18 (a), DT22 (b), DT25 (c) and DT28 (d) using Modelcomplex. The bold figures next to the bars are the most positive and negative deviation among the mixture types for each combination, numbers in brackets are the number of boards. Bars are only illustrated if more than 20 boards were available. (Color online)

Discussion

The VCA assigned the predominant part of the strength scatter to the board level; a smaller part was attributable to variations between trees, stands and mixture types (Table 4). Although only 4.2% of the total variation in strength could be attributed to between-mixture variation, an ANOVA revealed significant strength (ft,0) differences between mixture types. The ANOVA on stiffness (Et,0) did not show significant differences amongst mixture types. The p-value was with 0.079 slightly above the significance level of 0.05 (Table 5). In a related study, Rais et al. (2020b) applied a mixed model to describe a board's Edyn using year ring width, cambial age, axial position, and mixture type as explanatory variables. They found a significant (p-value 0.006) impact of mixture on stiffness. Their dataset with 1907 boards was more than four times as large, although the 407 specimens used in the present study were representatively selected from those boards. In the present study, stiffness was measured using both Et,0 and Edyn. Edyn reflects an average timber quality, whereas Et,0 (and ft,0) represents a local property of the weakest point of the board. The so-called length effect may influence the impact of mixture on timber quality indirectly (Rais and Van de Kuilen 2017) as it increases the strength variation at board level (Table 4). A general aspect becomes apparent by the analysis. It seems to be difficult to establish a general link between silvicultural practices and wood quality. Wood quality, here defined as good mechanical properties, is not only governed by the assessment level (standing tree, log, sawn timber), but also by the type of wood parameter that is measured, and the type of statistics chosen. Whether the selection was made along a site or a forest management gradient, whether the sampling included boards from the complete tree, or whether boards came from trees of various ages, may have an impact on the variation of wood properties. It is even more relevant for future research that intends to combine forest management and wood quality that any researcher analyzing mechanical timber properties should consider sampling and measuring in such a way that can contribute to a larger grading dataset at a later date (Ridley-Ellis et al. 2016) but is also robust for changes in methods to declare characteristic values for design purposes (Stapel and Van de Kuilen 2013, 2014).

The dataset for the derivation of the initial machine settings included typical lamella dimensions with thickness ranging between 24 to 38 mm and width between 100 to 160 mm. The samples A, B, and C represented timber of low-medium quality material (Table 2). The sample D—containing the main dataset of this study—represented better quality, which can already be used for strength grading lamellas for glued laminated timber. The 407 boards were taken from old trees that remained in the stands due to their quality. In other words, the majority of trees with inferior stem and crown shape were already removed earlier by thinning. As a consequence, many boards were of good quality due to high cambial age. On the other side, all boards from logs were taken, in particular also boards close to the pith with a low cambial age. Boards from mixed stands with pine and oak increased the share of low quality timber in the sample. In total, a strength distribution of medium strength and of high variation was observed. In contrast, data recorded in other projects from Switzerland (Bacher 2014; Ehrhart 2019), Slovenia (Fortuna et al. 2018) or Germany (Frese and Riedler 2010) showed high-quality characteristics (see Rais et al. 2021, Table 1).

As it was not the main goal to compute models and settings here, threshold values were calculated straightforward with a simplified approach. Hence, threshold values derived based on the more complex approach according to EN 14081 might differ from the values derived here. The use of the cost matrix and sub-sampling method should tend to increase the threshold values, but the relative deviations found for different mixtures and combinations are likely to remain. Slightly different settings might cause some minor changes in the characteristic strength values due to the sensitivity of the 5th percentile on the strength distribution and the number of specimens. By choosing the parametric approach independent of the sample size, this effect was minimized as each mixture type contained approximately 80 boards before grading. According to EN 14358, the use of a parametric approach is mandatory for random samples smaller than 40.

For all combinations of DT-classes, the tensile strength was critical when deriving the threshold values. As the shape of the strength distribution between the mixture types changes, as may be observed on the arithmetic mean and variation in Table 5, yields and characteristic strength values are affected. The grade determining properties Et,0,mean and ρk were outperformed in all classes and combinations by on average 20% and 15% for Modelsimple and 12% and 12% for Modelcomplex (Fig. 2). As mentioned by Frühwald and Schickhofer (2005) and Kovryga et al. (2020), considering the high variation in characteristic density in European hardwood species, the separate declaration of density independent of the strength class assignment would be the best preferable option for more efficient utilization of the material properties. This also is in line with findings that density variations within a single species have a negligible effect on the load carrying capacity of timber joints made with that species, as shown for spruce, beech and ekki (Lophira alata) in Sandhaas and Van de Kuilen (2017). Comparing the ratios between assigned and required characteristic value of Et,0,mean based on Modelsimple and Modelcomplex (Fig. 2) showed that for one and the same wood species different ratios were possible depending on the grading method.

The reduction in timber strength variation for safe engineered timber structures requires a good grading model. Grading of beech timber with Edyn as a single predictor showed promising results to estimate bending strength (Brunetti et al. 2020) or stiffness and strength based on the log’s Edyn (Rais et al. 2020a; Plos et al. 2022). The tensile strength prediction values achieved were high compared to Ehrhart et al. (2018), who obtained an r2 value of only 0.16 for a high quality beech timber between strength and Edyn. The differences could be clearly attributed to the different qualities, as wood in the current analysis comprises a variety of qualities allowing a broad variation and covering a bigger scatter in properties. The knot cluster DAB together with Edyn showed a high correlation coefficient comparable to softwoods. The model showed similar regression coefficients across the different mixture types. The difference in the correlation coefficients could have its cause in the different coverage of wood qualities within the mixture types. In any case, strength class DT50 could be identified as feasible, especially for boards from pure beech forests. There seems to be the potential of producing high quality beech timber with a powerful grading model. Compared to Modelsimple, the grading with Modelcomplex, despite of only an increase of 6% in prediction accuracy, allowed to achieve significantly higher yields to the higher grades, particularly by over 10% higher yields to DT50. As shown in Fig. 5 and Fig. 6, the settings were more robust, leading to lower deviations from the desired quality (strength) level. A powerful strength prediction method was shown in Rais et al. (2021) based on a 3D interpolation of fiber deviation data from surface scans.

The analysis showed that especially beech lamellas from the mixed beech-pine stands were different from lamellae from the pure beech stands exhibiting lower yields, but also lower characteristic strength values of graded wood. The results pointed out that the silvicultural origin of trees reflected the characteristic strength values. For pure beech stands, this resulted in a higher strength class assignment. Furthermore, the differences were more pronounced if the grading model was rather simple including only one single strength predictor such as Edyn. This appeared to be reasonable, as the quality differences attributed to the observable biological or structural characteristics, such as knots, remained undiscovered and overlapping effects of silvicultural treatment remained undetected. With the original sampling plan applied here, these differences could be clearly attributed.

Knowing the effects of the specific silvicultural treatments (Pretzsch et al. 2021) in the past and at present for European beech, but also for other less studied species, is an important step to efficient material utilization. It can serve as a guideline for the forestry management, or for sawmill management to attribute standing trees to the desired quality correctly. By adjusting the material supply, a more efficient material production chain and utilization can be achieved. The origin of timber, the variation within a single log (radial or longitudinal) or silvicultural treatments, all contribute to the variation in mechanical properties observed in a single sawmill, which can be particularly high (Ranta-Maunus and Turk 2010; Kovryga et al. 2017). The high variation is counteracted by temporally and/or spatially distributed sampling to obtain a representative dataset for the determination of characteristic values. However, such a procedure does not account for the initial reasons for the different wood qualities. As shown here, and despite the fact that logs were of similar dimension and age, considerable differences in mechanical properties arise from simple wood species mixture in the forest, and can be rather large especially for the highest grade. Such variation should be accounted for in case of initial settings derivation for grading machines, as it would allow to determine reliable settings, attributed to the known quality differences, without relying on coincidence. The different mixtures should be accounted for to the same extent as the wood from this mixture is actually used for sawn timber production.

Conclusion

The mixture effect on European beech (Fagus sylvatica L.) timber was studied with a structured experimental design, i.e., with timber sawn from logs coming from the different mixtures and other factors were ceteris paribus. This could be achieved by producing timber from logs of similar age/size, same position of timber inside the log and wood coming from the same area with very similar site conditions. On the basis of the research, the following could be concluded:

-

(1)

Mixture of beech with other wood species affected the mechanical properties. The differences were observed on the mean and characteristic values of grade determining properties of both ungraded and graded timber. In the current paper, beech boards coming from the pure stand showed the highest mechanical property values and highest yields to the highest class.

-

(2)

The mixture effect was less evident for the strength class with lower requirements in case of grading to two classes in one run compared to grading to the same class in one run.

-

(3)

For the grading with Modelcomplex comprising Edyn and DAB, the differences between the mixtures regarding the mechanical properties were less evident compared to a model based on Edyn only.

-

(4)

The prediction model using Edyn and DAB showed a high r2 value of more than 0.6 (for all wood qualities used in this study originating from different forest stands) and allowed an assignment of beech timber to strength classes of up to DT50 with considerable yields.

-

(5)

The ratios between the ft,0,k and Et,0,mean match the profiles (ratios) of tensile strength classes for medium-density hardwoods (DT-classes) proposed by Kovryga et al. (2020).

Data availability

The datasets generated during the current study are not publicly available due to confidentiality but are available from the corresponding author on reasonable request.

References

Auty D, Achim A, Macdonald E et al (2014) Models for predicting wood density variation in Scots pine. Forestry 87:449–458. https://doi.org/10.1093/forestry/cpu005

Bacher M (2014) Data recording, Viscan Portable, Microtec, Bressanone, Italy

Barrett JD, Kellogg RM (1984) Strength and stiffness of second-growth Douglas-fir dimension lumber. Forintek Canada Corp. Western Laboratory, contract 50–69–559. 73 pp

Brazier JD, Mobbs ID (1993) The influence of planting distance on structural wood yields of unthinned Sitka spruce. Forestry 66:333–352. https://doi.org/10.1093/forestry/66.4.333

Brunetti M, Aminti G, Nocetti M, Russo G (2021) Validation of visual and machine strength grading for Italian beech with additional sampling. iForest - Biogeosciences For 14:260–267. doi: https://doi.org/10.3832/ifor3649-014

Brunetti M, Nocetti M, Burato P (2013) Strength Properties of Chestnut Structural Timber with Wane. Adv Mater Res 778:377–384. https://doi.org/10.4028/www.scientific.net/AMR.778.377

Brunetti M, Nocetti M, Pizzo B et al (2020) Structural products made of beech wood: quality assessment of the raw material. Eur J Wood Prod 78:961–970. https://doi.org/10.1007/s00107-020-01542-9

Brus DJ, Hengeveld GM, Walvoort DJJ et al (2012) Statistical mapping of tree species over Europe. Eur J for Res 131:145–157. https://doi.org/10.1007/s10342-011-0513-5

Cameron AD, Dunham RA, Petty JA (1995) The effects of heavy thinning on stem quality and timber properties of silver birch (Betula pendula Roth). Forestry 68:275–286. https://doi.org/10.1093/forestry/68.3.275

DIN 4074–5:2008–12, Strength grading of wood – Part 5: Sawn hard wood; DIN Deutsches Institut für Normung e.V. 19

Downes GM, Gwinyai Nyakuengama J, Evans R et al (2002) Relationship between wood density, microfibril angle and stiffness in thinned and fertilized Pinus radiata. IAWA J 23:253–265. https://doi.org/10.1163/22941932-90000302

Ehrhart T (2019) European beech glued laminated timber. Doctoral thesis, DISS.ETH NO. 26173, ETH Zurich, 200 pp

Ehrhart T, Fink G, Steiger R, Frangi A (2016) Experimental investigation of tensile strength and stiffness indicators regarding European beech timber. In: WCTE 2016 - World Conference on Timber Engineering, Vienna, Austria, August 22–25, 2016. p 8

Ehrhart T, Steiger R, Frangi A (2018) A non-contact method for the determination of fibre direction of European beech wood (Fagus sylvatica L.). Eur J Wood Prod 76:925–935. https://doi.org/10.1007/s00107-017-1279-3

EN 384:2016+A1:2018, Structural timber – Determination of characteristic values of mechanical properties and density; DIN Deutsches Institut für Normung e. V. 21

EN 13183–1:2002, Moisture content of a piece of sawn timber - Part 1: Determination by oven dry method

EN 14358:2016; Timber structures - Calculation and verification of characteristic values. 17

Erasmus J, Drew DM, Wessels CB (2020) The flexural lumber properties of Pinus patula Schiede ex Schltdl. & Cham. improve with decreasing initial tree spacing. Ann For Sci 77:73. https://doi.org/10.1007/s13595-020-00975-9

Erasmus J, Wessels CB (2020) The effect of stand density management on Pinus patula lumber properties. Eur J for Res 139:247–257. https://doi.org/10.1007/s10342-019-01253-8

Fischer C, Vestøl GI, Høibø O (2016) Modelling the variability of density and bending properties of Norway spruce structural timber. Can J for Res 46:978–985. https://doi.org/10.1139/cjfr-2016-0022

Fischer C, Vestøl GI, Øvrum A, Høibø OA (2015) Pre-sorting of Norway spruce structural timber using acoustic measurements combined with site-, tree- and log characteristics. Eur J Wood Prod 73:819–828. https://doi.org/10.1007/s00107-015-0946-5

Fortuna B, Plos M, Turk G (2018) Tehnologija razvrščanja lesa listavcev (The technology of hardwood strength grading). Milestone report of the Slovenian national project TIGR4smart - RRP 1.1. Hybrid composites. University of Ljubljana, Faculty of Civil and Geodetic Engineering. Ljubljana

Frese M, Riedler T (2010) Untersuchung von Buchenschnittholz (Fagus sylvatica L.) hinsichtlich der Eignung für Brettschichtholz. (Investigation of beech lumber (Fagus sylvatica L.) in regard to suitability for glulam) (In German). Eur J Wood Prod 68:445–453. https://doi.org/10.1007/s00107-009-0385-2

Frühwald K, Schickhofer G (2005) Strength grading of hardwoods. In: Proceedings of the 14th International Symposium on Nondestructive Testing of Wood, May 2–4, Hannover, Germany. pp 198–210

Fujimoto T, Koga S (2009) An application of mixed-effects model to evaluate the effects of initial spacing on radial variation in wood density in Japanese larch (Larix kaempferi). J Wood Sci 56:7–14. https://doi.org/10.1007/s10086-009-1045-1

Gil-Moreno D, Ridley-Ellis D, Harte AM (2019) Timber grading potential of Douglas fir in the Republic of Ireland and the UK. Int Wood Prod J 10:64–69. https://doi.org/10.1080/20426445.2019.1617984

Giroud G, Bégin J, Defo M, Ung C-H (2017) Regional variation in wood density and modulus of elasticity of Quebec’s main boreal tree species. For Ecol Manage 400:289–299. https://doi.org/10.1016/j.foreco.2017.06.019

Glos P, Lederer B (2000) Sortierung von Buchen- und Eichenschnittholz nach der Tragfähigkeit und Bestimmung der zugehörigen Festigkeits- und Steifigkeitskennwerte [Strength grading of beech and oak timber and derivation of strength and stiffness property values]. Report Nr. 98508. TU München, München, p 125

Høibø O, Vestøl GI (2010) Modelling the variation in modulus of elasticity and modulus of rupture of Scots pine round timber. Can J for Res 40:668–678. https://doi.org/10.1139/X10-021

Høibø O, Vestøl GI, Fischer C et al (2014) Bending properties and strength grading of Norway spruce: variation within and between stands. Can J for Res 44:128–135. https://doi.org/10.1139/cjfr-2013-0187

Kovryga A, Schlotzhauer P, Stapel P et al (2019) Visual and machine strength grading of European ash and maple for glulam application. Holzforschung 73:773–787. https://doi.org/10.1515/hf-2018-0142

Kovryga A, Stapel P, Van de Kuilen JWG (2016) Tensile strength classes for hardwoods. In: International Network on Timber Engineering Research Proceedings: Meeting 49 Graz, Austria. KIT Scientific Publishing, p 16

Kovryga A, Stapel P, Van de Kuilen JWG (2017) Quality control for machine strength graded timber. Eur J Wood Prod 75:233–247. https://doi.org/10.1007/s00107-016-1105-3

Kovryga A, Stapel P, Van de Kuilen JWG (2020) Mechanical properties and their interrelationships for medium-density European hardwoods, focusing on ash and beech. Wood Mater Sci Eng 15:5, 289–302 1–14. doi: https://doi.org/10.1080/17480272.2019.1596158

Krajnc L, Farrelly N, Harte AM (2019) The effect of thinning on mechanical properties of Douglas fir, Norway spruce, and Sitka spruce. Ann for Sci 76:3. https://doi.org/10.1007/s13595-018-0787-6

Lasserre J-P, Mason EG, Watt MS, Moore JR (2009) Influence of initial planting spacing and genotype on microfibril angle, wood density, fibre properties and modulus of elasticity in Pinus radiata D. Don Corewood for Ecol Manag 258:1924–1931. https://doi.org/10.1016/j.foreco.2009.07.028

Moore J, Achim A, Lyon A et al (2009a) Effects of early re-spacing on the physical and mechanical properties of Sitka spruce structural timber. For Ecol Manage 258:1174–1180. https://doi.org/10.1016/j.foreco.2009.06.009

Moore JR, Lyon AJ, Searles GJ et al (2013) Within- and between-stand variation in selected properties of Sitka spruce sawn timber in the UK: implications for segregation and grade recovery. Ann for Sci 70:403–415. https://doi.org/10.1007/s13595-013-0275-y

Moore JR, Lyon AJ, Searles GJ, Vihermaa LE (2009b) The effects of site and stand factors on the tree and wood quality of Sitka spruce growing in the United Kingdom. Silva Fenn 43:383–396

Nocetti M, Brunetti M, Bacher M (2016) Efficiency of the machine grading of chestnut structural timber: prediction of strength classes by dry and wet measurements. Mater Struct 49:4439–4450. https://doi.org/10.1617/s11527-016-0799-3

Pinheiro JC, Bates DM (2000) Mixed-Effects Models in Sand S-PLUS. Springer, New York, New York, NY

Plos M, Fortuna B, Šuligoj T, Turk G (2022) From Visual Grading and Dynamic Modulus of European Beech (Fagus sylvatica) Logs to Tensile Strength of Boards. Forests 13:77. https://doi.org/10.3390/f13010077

Pöhler E, Klingner R, Künniger T (2006) Beech (Fagus sylvatica L.) – Technological properties, adhesion behaviour and colour stability with and without coatings of the red heartwood. Ann for Sci 63:129–137. https://doi.org/10.1051/forest:2005105

Pretzsch H (2019) The effect of tree crown allometry on community dynamics in mixed-species stands versus monocultures. A review and perspectives for modeling and silvicultural regulation. Forests 10:810. doi: https://doi.org/10.3390/f10090810

Pretzsch H, Poschenrieder W, Uhl E et al (2021) Silvicultural prescriptions for mixed-species forest stands. A European review and perspective. Eur J for Res 140:1267–1294. https://doi.org/10.1007/s10342-021-01388-7

Pretzsch H, Schütze G (2021) Tree species mixing can increase stand productivity, density and growth efficiency and attenuate the trade-off between density and growth throughout the whole rotation. Ann Bot 128(6):767–786. https://doi.org/10.1093/aob/mcab077

Rais A, Bacher M, Khaloian-Sarnaghi A et al (2021) Local 3D fibre orientation for tensile strength prediction of European beech timber. Constr Build Mater 279:122527. https://doi.org/10.1016/j.conbuildmat.2021.122527

Rais A, Kovryga A, Bacher M et al (2022) Timber strength variation due to establishment density—can grading cope with it? For Int J For Res. https://doi.org/10.1093/forestry/cpac016

Rais A, Poschenrieder W, Pretzsch H, Van de Kuilen JWG (2014) Influence of initial plant density on sawn timber properties for Douglas-fir (Pseudotsuga menziesii (Mirb.) Franco). Ann for Sci 71:617–626. https://doi.org/10.1007/s13595-014-0362-8

Rais A, Pretzsch H, Van de Kuilen JWG (2020a) European beech log and lumber grading in wet and dry conditions using longitudinal vibration. Holzforschung 74:939–947. https://doi.org/10.1515/hf-2019-0227

Rais A, Van de Kuilen JWG (2017) Critical section effect during derivation of settings for grading machines based on dynamic modulus of elasticity. Wood Mater Sci Eng 12:189–196. https://doi.org/10.1080/17480272.2015.1109546

Rais A, Van de Kuilen JWG, Pretzsch H (2020b) Impact of species mixture on the stiffness of European beech (Fagus sylvatica L.) sawn timber. For Ecol Manage 461:117–935. https://doi.org/10.1016/j.foreco.2020b.117935

Ranta-Maunus A, Denzler JK, Stapel P (2011) Strength of European timber. Part 2. Properties of spruce and pine tested in Gradewood project, Vol. 179 of VTT Working Papers, VTT, Finland. VTT Technical Research Centre of Finland

Ranta-Maunus A, Turk G (2010) Approach of dynamic production settings for machine strength grading. In: WCTE 2010 - World Conference on Timber Engineering

Ridley-Ellis D, Gil-Moreno D, Harte AM (2022) Strength grading of timber in the UK and Ireland in 2021. Int Wood Prod J 13:127–136. https://doi.org/10.1080/20426445.2022.2050549

Ridley-Ellis D, Stapel P, Baño V (2016) Strength grading of sawn timber in Europe: an explanation for engineers and researchers. Eur J Wood Prod 74:291–306. https://doi.org/10.1007/s00107-016-1034-1

Sandhaas C, Van de Kuilen JWG (2017) Strength and stiffness of timber joints with very high strength steel dowels. Eng Struct 131:394–404. https://doi.org/10.1016/j.engstruct.2016.10.046

Schützenmeister A, Piepho H-P (2012) Residual analysis of linear mixed models using a simulation approach. Comput Stat Data Anal 56:1405–1416. https://doi.org/10.1016/j.csda.2011.11.006

Simic K, Gendvilas V, O’reilly C et al (2018) The influence of planting density on modulus of elasticity of structural timber from Irish-grown Sitka spruce. Int J Des Nat Ecodynamics 12:438–447. https://doi.org/10.2495/DNE-V12-N4-438-447

Stapel P, Van de Kuilen JWG (2013) Effects of grading procedures on the scatter of characteristic values of European grown sawn timber. Mater Struct 46:1587–1598. https://doi.org/10.1617/s11527-012-9999-7

Stapel P, Van de Kuilen JWG (2014) Efficiency of visual strength grading of timber with respect to origin, species, cross section, and grading rules: a critical evaluation of the common standards. Holzforschung 68:1–14. https://doi.org/10.1515/hf-2013-0042

R Core Team (2019) R: A language and environment for statistical computing. R Foundation for Statistical Computing, Vienna, Austria

Vestøl GI, Fischer C, Høibø O, Øvrum A (2016) Between- and within-site variation of density and bending properties of Picea abies structural timber from Norway. Scand J for Res 31:758–765. https://doi.org/10.1080/02827581.2016.1174733

Westermayr M, Stapel P, Van de Kuilen JWG (2018) Tensile strength and stiffness of low quality beech (Fagus sylvatica) sawn timber. In: WCTE 2018 World Conference on Timber Engineering, Seoul Republic of Korea August https://doi.org/10.1080/02827432.2018.1174733

Westermayr M, Zeilhofer M, Rais A, Kovryga A, Van de Kuilen JWG (2022) Tensile strength grading of beech (Fagus sylvatica L.) lamellas from multiple origins, cross sections and qualities. Holzforschung 76:397–407. https://doi.org/10.1515/hf-2021-0029

Zuur AF, Ieno EN, Walker N et al (2009) Mixed effects models and extensions in ecology with R. Springer, New York, New York, NY

Acknowledgements

We thank the Bavarian State Institute of Forestry LWF for both supporting the project ‘Easy Beech – Development of economic beech components with focus on medium-sized and local companies’ and funding the project ‘Beech Connect – Optimizing hardwood structures by using modern connections’. We also thank the German Federal Ministry of Food and Agriculture for funding of the project ‘Impact of forest management on sawn timber quality of European beech (Fagus sylvatica L.) and optimizing automatic log grading’) [grant number 22025114]. Finally, we thank the European Union for funding the Horizon 2020 project “A multi-criteria decision support system for a common forest management to strengthen forest resilience, harmonize stakeholder interests and ensure sustainable wood flows” (ONEforest) [grant number 101000406]. We are grateful to Microtec (Bressanone, Italy) for assisting with data collection.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Contributions

JWGVDK, HP and AR initiated the project. AR sampled the material, analyzed and interpreted the data. AR, AK, HP and JWGVDK wrote the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rais, A., Kovryga, A., Pretzsch, H. et al. Timber tensile strength in mixed stands of European beech (Fagus sylvatica L.). Wood Sci Technol 56, 1239–1259 (2022). https://doi.org/10.1007/s00226-022-01398-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-022-01398-7