Abstract

The aim of the present study was to investigate the impact of two lager brewing yeasts (KVL001 and KVL018), known to produce different levels of sulfite and thioredoxin, on the flavor stability of beer during storage for 24 weeks at 25 °C and 35 °C. Fermentations with the two yeast strains were carried out in two identical pilot scale brews and provided fresh beers with very similar sensory profiles, only differing significantly in content of sulfite, iron, thioredoxin, and free amino acids. No difference in protein thiols was observed indicating that thioredoxin was not active in the final beer. The yeast strain KVL018 consumed less free amino acids than KVL001 resulting in fresh beers with a higher content of free amino acids. During storage, the beers developed very similarly, but the beers fermented with KVL018 developed more 'fruity aged/vinous' flavor, especially at 35 °C. This suggested that a higher degree of the Maillard reaction took place in these beers due to the higher content of free amino acids. Beers fermented with KVL018 also contained more sulfite and less iron, but scored lower in the general evaluation of the sensory analysis. In conclusion, our results indicate that the yeast strain (KVL001) taking up more free amino acids resulted in more flavor-stable beer due to a lower degree of the Maillard reaction, while no clear effects were observed on oxidation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The majority of beers are not intended for exposure to long storage times, because of a decrease in quality over time. Beer is naturally unstable and its properties change with time, which often include decreased foam stability, formation of haze, and flavor deterioration [1]. Consumers do not always regard aged flavors as off-flavors, but the flavor of a particular beer brand has to be constant to avoid consumer rejection. Prolonging the fresh flavor and thereby the shelf life of beer is, therefore, a major focus for breweries, and is dependent on a complex balance of several components in the beer, such as the concentration of pro- and antioxidants, flavor compounds and their precursors. Beer flavor stability is a particularly critical quality parameter in pale beer types, where the flavor profile is more delicate [2]. In addition, export beers often suffer from high temperatures during transportation, which accelerates the reactions that cause flavor changes.

Oxidation and the Maillard reaction are the main reaction pathways responsible for beer staling [2]. The Maillard reaction is initiated by the reaction between reducing carbohydrates and proteins, peptides, or amino acids, and includes a complex cascade of reactions leading to flavor compounds and brown-colored polymers, called melanoidins [3]. The Maillard reaction is responsible for development of bready, sweet and wine-like flavor notes during beer staling. Some of the most important Maillard reaction-derived flavor compounds in aged beer are furfural, 5-hydroxymethyl furfural and Strecker aldehydes [2]. Oxidation plays a dominant role in beer stability affecting flavor changes. A well-known lipid-derived oxidation product is the aldehyde (E)-2-nonenal, causing cardboard flavor in stored beer, but the loss of initial fresh flavor notes such as fruity/estery and floral aroma, is also a contributing factor to staling [1, 2]. Beer oxidation is initiated by trace levels of metal ions, such as iron and copper, converting molecular oxygen into reactive oxygen species, such as hydrogen peroxide, superoxide and hydroxyl radicals (Supporting information, Scheme S1) [4, 5]. Yeast produces sulfite during fermentation [6], which functions as the primary antioxidant in beer by quenching hydrogen peroxide [7, 8]. When the amount of free sulfite falls below a certain threshold, hydrogen peroxide will react with iron and copper, generating highly reactive hydroxyl radicals via the Fenton reaction. Hydroxyl radicals will predominantly react with ethanol, because of its high abundance in beer, and form 1-hydroxyethyl radicals [9]. The 1-hydroxyethyl radicals can either react with beer components, such as bitter acids from hops [10,11,12], or with oxygen to form acetaldehyde and peroxyl radicals leading to a chain reaction that creates more oxidative damage [12, 13]. Fresh beer contains peptide- and protein-derived thiol groups (R-SH), that have been suggested to act as secondary antioxidants [14, 15] as they react fast with 1-hydroxyethyl radicals, while being inactive as disulfides [16, 17]. Approximately 2/3 of the total content of thiols are present in a reversible oxidized form in wort and fresh beer [16, 18]; i.e. as disulfides or sulfenic acid, which can be reduced back to the original thiol form by sulfite [19] or thioredoxin (Trx), a redox protein capable of reducing disulfides [20]. Reversibly oxidized thiols present in wort and beer thus represent a potential pool of natural antioxidants. If the reversibly oxidized thiols are reduced back to free thiols, they may be able to compete with oxygen and hop bitter acids in the reaction with 1-hydroxyethyl radicals, and potentially work as a secondary antioxidant in the later stages of beer storage [17]. However, to obtain a significant reduction of the pool of oxidized thiols by sulfite, a very high concentration is required (higher than what is allowed by EU legislation) [19], and reduction by Trx requires the presence of thioredoxin reductase (TrxR) and the co-factor NADPH (Supporting information, Scheme S1) [20]. It is well-known that yeast strains secrete sulfite at different concentrations, and recently it was shown that some yeast strains also secrete Trx during laboratory fermentation [21], but it is not known whether the Trx secreted by yeast is active in wort nor if yeast strains also secrete TrxR and NADPH. In the present study, we hypothesized that yeast strains that secrete Trx during laboratory fermentation, would also secrete Trx during pilot scale fermentation, and that the secreted Trx would be able to reduce the pool of oxidized thiols in beer with a positive effect on flavor stability during storage.

Yeast cells may also reduce oxidation in beer by taking up prooxidative metal ions through metal transporters in their membranes as they are essential for cell growth [22, 23], or by binding them to their outer surface dependent on the pH of their environment [24, 25]. It has previously been shown that the ability of yeast strains to take up iron was more important for improvement of oxidative stability of beer rather than their ability to secrete Trx [21], but the secretion of TrxR and NADPH was not investigated in the study.

Yeast is also responsible for secretion of desirable flavors in beer, e.g. esters that may contribute with fruity flavors [26]. These esters are formed from higher alcohols that are produced by the yeast during fermentation via the Ehrlich pathway (catabolic) or the amino acid metabolism (anabolic) [27, 28]. The formation of these higher alcohols depends on the concentration of amino acids available [29]. Amino acids are the major source of nitrogen for brewing yeast, where the degree of uptake depends on the specific amino acid [30]. On the other hand, a high level of free amino acids in beer is expected to result in Maillard-reaction derived flavor components during storage [18], such as Strecker aldehydes that are formed from the Strecker degradation of amino acids [3]. Esters can also result in unpleasant flavors if present in excess, as they have a very low odor threshold [31]. Thus, the flavor profile of beer is dependent on a delicate balance of aroma compounds and their individual concentration. When different yeast strains are evaluated, it is therefore important to consider not only the secretion of antioxidants, but also the uptake of prooxidants and how the yeast strains affect the pool of aroma compounds and their precursors, such as free amino acids.

In the present study, the influence of two different yeast strains on flavor stability of beer brewed in pilot scale during storage for up to 24 weeks at 25 °C and 35 °C was investigated. The chosen yeast strains are known to produce different levels of sulfite and Trx and take up different levels of iron during laboratory fermentations of a synthetic beer media [21]. The fresh beers were characterized by chemical analyses of sulfite, free and total thiols, iron and copper, free amino acids, and NADPH and by Western Blotting of Trx, while sulfite and free thiol concentration were analyzed during storage in combination with sensory analyses and gas chromatography–mass spectrometry (GC–MS) analysis of volatile compounds.

Materials and methods

Chemicals and reagents

ThioGlo1 fluorescent thiol reagent was obtained from Berry and Associates, Inc. (Dexter, MI, USA). Acetonitrile, glutathione, N-acetyl-l-cysteine, tris(2-carboxyethyl)phosphine (TCEP), norvaline, hydrogen chloride, sodium sulfite, nitric acid (65%), hydrogen peroxide (30%) and acetic acid (≥ 99.7%) were purchased from Sigma-Aldrich (St. Louis, MO, USA). Tris(hydroxymethyl) amino methane (Tris), trifluoroacetic acid (≥ 99.8%), disodium hydrogen phosphate dehydrate, sodium dihydrogen phosphate dehydrate, and sodium chloride were obtained from Merck (Darmstadt, Germany). NuPAGE Novex 12% Bis–Tris gels, lithium dodecyl sulfate (LDS) sample buffer, 3-(N-Morpholino) propanesulfonic acid running buffer (MOPS) and SeeBlue™ pre-stained standard were obtained from Invitrogen (Carlsbad, CA, USA). Dithiothreitol and acetic acid were obtained from AppliChem (Darmstadt, Germany). The primary antibody anti-yeast thioredoxin was a kind gift from Professor Chris M. Grant, University of Manchester, UK. Secondary antibody anti-rabbit immunoglobulin-alkaline phosphatase conjugate was obtained from Santa Cruz Biotechnology (Dallas, TX, USA). Bradford Bio-Rad protein assay dye reagent concentrate was obtained from Bio-Rad Laboratories (Hercules, CA, USA). Bovine serum albumin (BSA) standard of 2.0 mg/mL, 1-step NBT/BCIP substrate, PVDF membrane and yeast thioredoxin recombinant protein were obtained from Thermo Fisher Scientific (Rockford, IL, USA). Ethanol (96%) was obtained from Kemetyl (Køge, Denmark). All chemicals were of analytical grade or the highest purity available. Water was purified through a Milli-Q water purification system from Millipore (Billerica, MA, USA).

Brewing and storage of beers

Two identical brews (20 hL) with 100% pilsner malt were performed at Bitburger Brewery pilot plant (Bitburg, Germany), applying a standard double decoction mashing regime. Wort separation was performed in a lauter tun, followed by wort boiling in a low-pressure kettle. Hop addition was done in the beginning of wort boiling with a total hopping of 5 g α-acids/hL (20 IBU). After trub separation, wort was cooled within one hour to 9.5 °C and each of the two brews was divided into two fermentation vessels, resulting in a total of four fermentation vessels of 9 hL each. The two yeast strains used in this study, KVL001 and KVL018, were both lager brewing strains belonging to the species Saccharomyces pastorianus, obtained from the yeast strain collection at Food Microbiology and Fermentation, Department of Food Science, University of Copenhagen. Fermentations with KVL001 and KVL018 were carried out separately in brew 1 (KVL001.A and KVL018.C) and brew 2 (KVL001.B and KVL018.D) at 11 °C until apparent extract reached 3% resulting in 4 different fresh beers. Samples of boiled wort and fresh beer from the end of fermentation were collected and frozen (at − 20 °C at the Bitburger brewery and at − 80 °C at University of Copenhagen) until analysis. To prevent further impact from the yeast, fermented samples were centrifuged and the pellet discarded before freezing. After fermentation, the beers were kept for 14 days at − 1.5 °C, followed by filtration, bottling into brown 0.3 L bottles using a crown cork closure, and finally the beers were chamber pasteurized with 52 pasteurization units (PU) (20 min at 62 °C including heating and cooling time).

The beers were stored in a dark room at 25 °C and in a heating cabinet at 35 °C for up to 24 weeks. Stored bottles were chilled to 4 °C and used for sensory analysis within 3 days, while chemical analyses were performed on frozen samples, kept at − 80 °C until analysis. Throughout sampling, transportation and analysis, exposure to oxygen was kept at a minimum to maintain stable levels of thiols and sulfite and allow comparison of brews with different yeast strains; sampling was performed in an anaerobic chamber (Coy Laboratories, Grass Lake, USA) and samples were quick-frozen in liquid nitrogen.

Wort and beer quality analyses

Wort and beer analyses performed in the laboratory of the Bitburger brewery were conducted according to MEBAK [32]. The following methods were applied (method number is stated in brackets): extract (2.10), pH (2.14), color (2.13), alcohol (2.10.7) bitterness units (2.18.1), and foam stability by NIBEM (2.19.2).

Protein determination

Protein concentrations in boiled wort and fresh beer was determined with the Bio-Rad Protein Assay Dye Reagent Concentrate based on the Bradford method according to the manufacturer’s procedure with a few modifications as described previously [33].

Free amino acid analysis

Free amino acid concentrations were determined in boiled wort and fresh beer by derivatization and analysis using the EZ:faast™ GC-FID free amino acid analysis kit. Derivatization and analysis were carried out according to Barba et al. [34]. A gas chromatograph (GC) Agilent Technologies 6890 equipped with a flame ionization detector (FID) was used for the analysis of derivatized amino acids. A Zebron EZ-AAA column (10 m × 0.25 mm I.D., 0.25 μm film) was used. Concentrations of each amino acid in wort and beer were calculated by replication of two samples, each with duplicate injection.

Metal ion determination

Metal ion analysis was performed on fresh beer samples by microwave digesting the samples with HNO3 and H2O2 according to Wyrzykowska et al. [35] and applying yttrium (0.5 mg/L) as internal standard. The metal ion concentration was analyzed in duplicate using inductively coupled plasma (ICP-OES; Agilent 5100, Agilent Technologies, Manchester, UK) according to Skou et al. [36].

Western blot for determination of thioredoxin

Fresh beer samples were first loaded in the wells of NuPAGE Novex 12% Bis–Tris gels, as previously described [33] with a few modifications. A SeaBlue pre-stained protein standard were loaded to each gel, followed by electrophoresis run at 200 V for 50 min in cassettes containing ice-cold MOPS running buffer. Separated proteins were blotted on polyvinylidene difluoride membranes using an iBlot™ 2 Dry Blotting System (Thermofisher Scientific, Waltham, MA). Blots were incubated in primary antibody anti-yeast Trx (1:1000 dilution). Bound anti-yeast Trx was visualized by 1-Step NBT/BCIP after incubation with secondary antibody anti-rabbit immunoglobulin-alkaline phosphatase conjugate (1:5000 dilution). ImageJ (Wayne Rasband, National Institute of Mental Health, Maryland, USA) was used to quantify band intensity on the final blot. To estimate the concentration of Trx, a dilution series of purified yeast Trx was added to the blot.

NADPH determination

A liquid chromatography–mass spectrometry (LC–MS) method was used for the analysis of NADPH in fresh beer samples on a Thermo Scientific Ultimate 3000 UHPLC coupled to a Thermo Scientific Q Exactive orbitrap mass spectrometer. Chromatographic separation was achieved using a Phenomenex Synergi–RP Hydro column (4.6 × 150 mm), with 50 mM ammonium acetate as solvent A and methanol as solvent B. The samples (10 uL) were injected onto the column at 100% solvent A using a flow rate of 600 uL/min. The gradient was as follows: 0 min, 0% B; 1 min, 0% B; 5 min, 90% B; 6 min, 90% B; 7 min, 0% B; 10 min, 0% B. A heated electrospray ionization (HESI) source was used to introduce the column eluent into the mass spectrometer operating in either positive (2.5 kV spray voltage) or negative ion mode (2 kV spray voltage), scanning m/z 744.85–747.35 (positive mode) or m/z 743.3–744.8 (negative mode) with a resolution of 70,000 at m/z 200. Other parameters were as follows: probe heater temperature 450 °C and capillary temperature 390 °C, and maximum injection time was 256 ms. According to Lu et al. [37], samples and NADPH standards were added ammonium bicarbonate (10 mM) to increase the stability of NADPH.

Thiol and sulfite determination

Concentration of thiol (free and total) and sulfite were determined in boiled wort, fresh beer and beer stored at 25 °C and 35 °C for up to 24 weeks by derivatization with the fluorescent probe ThioGlo1 and separation of sulfite and thiol adducts by HPLC followed by fluorescence detection as described previously [38, 39]. Separation was performed on a Jupiter C18 column (150, 2.0 mm, 5 μm particle size, 300 Å pore size) (Phenomenex, Torrance, CA). Milli-Q water (mobile phase A) and methanol (mobile phase B) were acidified with trifluoroacetic acid (pH 2.0, 10 mM). The gradient was held at 25% B for 8 min (isocratic), instantly increased to 95% B and kept at 95% B for 6 min, and finally it was returned to starting conditions for 7 min. Total thiols were determined in wort or beer samples after reduction with varying TCEP concentrations for 5 min as described previously [16].

Volatile profile determined by dynamic headspace GC–MS

Volatile compounds were analyzed in fresh beer and beer stored at 25 °C and 35 °C for 16 weeks. In total, 20 mL of beer and 1 mL of 4-methyl-1-pentanol (5 mg/L) as internal standard was heated to 37 °C in a gas washing flask. The beer was then purged with nitrogen (100 mL/min) on adsorbent traps (Tenax TA, 200 mg of Tenax with 60/80 mesh, Markes International Limited, Llantrisant, UK) for 20 min, followed by a dry purge for 10 min to remove water. The trapped volatiles were, according to Steen et al. [40], desorbed (Turbo Matrix 350; Perkin Elmer, Shelton, CT, USA) and transferred to a GC–MS (7890A GC system interfaced with a 5975C VL MSD, Agilent Technologies, Palo Alto, CA, USA). Separation of the volatiles was carried out on a DB-Wax capillary column (30 m × 0.25 mm, with 0.50 μm film thickness). Volatile compounds were identified by an MS database (G1033A NIST PBM Library) and identification was confirmed by comparison with retention indices of authentic reference compounds or retention indices reported in the literature. Peak area and mass spectra were extracted from the chromatograms using PARAFAC2-based software PARADISe (University of Copenhagen, Copenhagen, Denmark) as described in Johnsen et al. 2017 [41].

Sensory analysis

Sensory analysis was carried out at Niras A/S, Virum, Denmark, according to DS/EN ISO 9001. Six trained panelists evaluated fresh beers and beers stored at 25 °C and 35 °C for 16 weeks, determining the sensory descriptors listed in Supporting Information, Table S1. A structural scale from 0 to 5 was used, where 0 = absent, 1 = very slight, 2 = easily noticeable, 3 = moderate, 4 = strong and 5 = very strong.

Statistical data analysis

Statistical analysis was performed by a paired sample t test using IBM SPSS Statistics V22.0. Means were used to compare differences, and least significant difference was applied to compare the mean values. The significance level was p < 0.05. Multivariate data analysis was performed for volatile compounds and sensory descriptors using MatLab R2023a (The MathWorks, Inc., Natick, MA, USA) with both in-house written routines and the use of PLS_Toolbox (Eigenvector Research, Inc., Manson, WA, USA).

Results and discussion

Effect of yeast strain on redox active compounds in wort and fresh beer

Wort analyses showed minor differences between the two brews (Table 1), with only a small, but non-significant, difference in free thiol concentration between two brews (p = 0.09). Accordingly, the two wort batches were considered to be comparable. Analyses of the fresh beers provided comparable values of ethanol, bitter units, color, foam stability, pH and real degree of fermentation (Table 1). The small differences observed in protein content between the beers were dependent on the brews and not the applied yeast strain. Thus, beers brewed from brew 1 resulted in a slightly higher protein concentration than beers brewed from brew 2.

The yeast strains differed substantially in how much sulfite they produced during fermentation; fresh beer brewed with yeast strain KVL018 contained significantly more sulfite (262 µM compared to KVL001 with 178 µM on average). This result was opposite to what was observed by Berner and Arneborg [21], who found a higher sulfite concentration in model beer fermented with KVL001 compared to KVL018, but may be due to differences in fermentation conditions between the two studies (pilot scale with beer versus lab scale with model beer). The concentration of free thiols was almost the same for the four samples, where only one of the samples fermented with KVL018 (KVL018.C) had a significantly higher content than the others. For total thiols (obtained after reduction with TCEP), only one of the samples (KVL001.B) had a significantly lower content of total thiols compared to the other samples. For prooxidative metal ions, the concentration of copper was the same in all four samples while the iron concentration was significantly lower in samples fermented with KVL018 compared to KVL001, concurring with the results reported by Berner and Arneborg [21]. The two yeast strains clearly secreted different levels of Trx as evaluated by Western Blotting (Fig. 1a and Table 1); KVL001 had more than twofold higher content of Trx than KVL018, which was in agreement with the study by Berner and Arneborg [21]. Overall, the yeast strains resulted in clear differences in concentration of iron, sulfite and Trx, while no differences were observed in copper, and free and total thiol concentration.

A Western blot detection of extracellular thioredoxin in fresh beer produced by yeast strain KVL001 (01.a, 01.b) and KVL018 (18.c, 18.d). Mw = the molecular weight standards. B Concentrations of free amino acid in boiled wort (black bars) and fresh beers brewed with yeast strains KVL001 (dark grey bars) and KVL018 (light grey bars) (n = 3)

It is unknown whether TrxR and NADPH can be released from yeast cells together with Trx during beer fermentation. An extensive proteomics study has previously been carried out on beer, where TrxR was not detected [42]. In the present study, the presence of TrxR was not investigated as it was not possible to acquire a specific antibody towards TrxR. The presence of NADPH was investigated by LC–MS/MS in the fresh beer samples to examine its potential to function as a co-factor for the Trx system in beer. Our analysis showed that the beers contained no detectable (below LOD; 1.7 pmol) NADPH and NADP+ (data not shown), which suggests that Trx was not active in the beers. In addition, Trx has been shown to be inactivated in the presence of sulfite [20, 43], which further supports this suggestion. Finally, the concentration of free thiols was not significantly higher in beer brewed with KVL001, containing significantly more Trx, further supporting the conclusion that Trx is not active in the beer. These data may, in fact, explain the findings by Berner and Arneborg [21] showing that the oxidative stability of model beer is not related to the ability of yeast strains to secrete Trx.

Effect of yeast strain on free amino acids and higher alcohols in wort and fresh beer

Free amino acids were found to be taken up at different degrees by the two yeast strains (Fig. 1). Amino acids known to be utilized by brewer’s yeast first (asparagine, glutamine, serine, lysine, arginine, valine, methionine, leucine, and isoleucine) were present in a lower amount in the fresh beers compared to the boiled wort. This indicates that the nitrogen source for the yeast growth was sufficient, as the yeast consumed mainly the easily utilized amino acids. When comparing amino acids present in the fresh beer brewed with KVL001 to beer brewed with KVL018, a significantly lower concentration was observed for seven out of the fourteen quantified amino acids (alanine, valine, leucine, isoleucine, asparagine, phenylalanine, and methionine) in KVL001 (Fig. 1b). Yeast strain KVL001 generally took up more amino acids, as the total amino acid concentration was significantly lower in these beers. Cysteine and cystine (two cysteine residues bound together by a disulfide bond) were not detected in boiled wort or fresh beer (LOD 0.001 mM). Matsui et al. [44] found the amount of free cysteine in lager beer to be on average 5.8 mg/L (corresponding to 0.048 mM) and mostly derived from wort. Additionally, it has been reported that detectable levels of cysteine in wort brewed from pilsner malt was only achieved by increasing the duration of the mashing procedure and addition of protease [45]. The lack of cysteine in wort and fresh beer could, therefore, possibly be explained by a low level of protease activity during mashing. Threonine was detected in the analyzed beer, but chromatograms from free amino acid analysis showed that the response from threonine was not linear, and therefore, threonine was not quantified in the beer.

When amino acids are taken up by yeast cells, they are converted during the Ehrlich pathway to higher alcohols with α-keto acids and aldehydes as intermediates [28], and some of these were detected by GC–MS in the present study as listed in Table 2. The increased uptake of leucine, isoleucine, valine and phenylalanine observed for KVL001 compared to KVL018 was found to result in increased levels of 3-methylbutanol, 2-methylbutanol, 2-methylpropanol, and 2-phenylethanol, respectively, while the levels of intermediate aldehydes (3-methylbutanal, 2-methylbutanal, 2-methylpropanal, and 2-phenylacetaldehyde, respectively) were not found to differ between the two yeast strains. 1-Butanol and 1-propanol, which can be formed from threonine during the Ehrlich pathway, were also detected, but opposite to the other alcohols the levels were significantly higher in beer brewed with yeast strain KVL018 compared to KVL001. Unfortunately, the content of threonine could not be quantified in the amino acid analysis so it is not possible to conclude on the relationship between these compounds.

Loss of sulfite and thiols during storage of beers brewed with different yeast strains

The concentration of sulfite decreased in all beers during storage and was highly affected by storage temperature (Fig. 2a), which is consistent with previous studies [8, 18]. As expected, the rate of sulfite consumption was higher at 35 °C than at 25 °C for both beers, and the rate of consumption was very similar for the two beers. Throughout the storage trial, the sulfite concentration was found to be significantly higher in beer brewed with KVL018 stored at both 25 °C and 35 °C. The concentration of free thiols was found to be stable during the first 8 weeks of storage at both 25 °C and 35 °C (Fig. 2b), while sulfite was rapidly consumed, which was also observed in our previous study [17]. Once sulfite was consumed to a certain level, the concentration of free thiols started to decrease until a plateau was reached, after which the concentration of free thiols seemed to stabilize. Free thiol concentration decreased during storage at both storage temperatures and for both yeast strains, indicating that the free thiols were reacting with reactive oxygen species in beer during storage, in agreement with previous studies [17, 18]. The free thiol concentration was comparable in fresh beer brewed with yeast strain KVL001 and KVL018 (Table 1). When comparing the free thiol concentration during storage in beer brewed with KVL001 to beer brewed with KVL018, a significantly higher free thiol concentration throughout storage was found in beer brewed with KVL018, which also contained most sulfite. These results are consistent with our previous study, where we showed that a sulfite concentration of 250 μM significantly increased the free thiol concentration in wort by approximately 30% [19].

Flavor stability of the beers during storage

Brewing beer with different yeast strains may result in very different flavor profiles of fresh beer, which would make it difficult to compare their flavor stability at later stages of storage, but sensory analysis showed that the flavor profiles of the fresh beers were very comparable, and all the beers were scored as “good” in the general evaluation (Table 3). Only sensory descriptors being significantly different between samples are included in Table 3.

Overall staling increased during storage in both beer types, even though batch variations could be observed. Increased staling was more pronounced at high storage temperature (Table 3), which is in agreement with Cejka et al. [46] who found an increased stale flavor in beer stored at 30 °C compared to 0, 8 and 20 °C. The highest score in overall staling was found for beer fermented with KVL018 and stored at 35 °C, and it was clear that the overall staling was mainly derived from the development of fruity aged/vinous character rather than papery. The descriptor papery, which is often associated with oxidation, had a low score in both beer types, but was slightly higher in beer brewed with KVL018 than KVL001 and stored at 35 °C. This was unexpected since beer brewed with KVL018 contained more sulfite and less iron than beer brewed with KVL001, which would contribute to a lower level of oxidation. This indicates that the fruity aged/vinous descriptor, which scored higher in KVL018 compared to KVL001, was potentially masking the papery character. Bushnell et al. suggested that chemical measurements of sulfite overstate the antioxidative benefits that may accrue from higher sulfite content, because of the complexity of aging [47]. Small quantities of volatile compounds related to aging can be highly important for the flavor, and not necessarily the ones that are most efficiently removed or inhibited by agents such as sulfite [47].

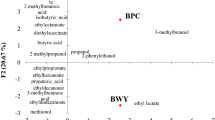

Volatile compounds were analyzed by GC–MS in fresh and stored beers to examine if specific groups of volatile compounds could describe the sensory profile of the beers, and the sensory and GC–MS results were analyzed by principal component analysis (PCA) (Figs. 3, 4). Figure 3 shows the score plot with principal components PC1 and PC2 explaining 29% and 19% of the variation, respectively. The fresh beers fermented with KVL001 and KVL018 are placed close together in the score plot, which indicates that they are found to be similar. Storage separates the samples along PC1, with the largest separation from the fresh samples observed for samples stored at 35 °C, indicating that PC1 explains variation caused by storage/temperature. In addition, samples fermented with different yeast strains further separates to some degree along PC2, indicating that PC2 explains some variation caused by the yeast strain. The score plot demonstrates that storage temperature has a higher impact on flavor changes in beer than our choice of yeast strain, but also that storage induces a difference in the flavor profiles, which was not evident in the fresh samples.

Principal component analysis loadings plot (B) of data from volatile profile and sensory analysis of beer brewed with yeast strain KVL001 and KVL018. Fresh beers and beer stored for 16 weeks at 25 °C or 35 °C. S: sensory data (black), A: aldehydes (green), AC: alcohols (blue), AH: aromatic hydrocarbon (yellow), CA: carboxylic acids (purple), E: esters (blue), ET: ethers (red), HC: heterocyclic compounds (pink), K: ketones (orange), SA: Strecker aldehydes (dark green)

The loading plot (Fig. 4) describes the connection between volatile compounds and significant sensory descriptors, addressed as the variables. Due to the large number of volatile compounds and sensory descriptors, most names are replaced by labels (explanation to the labels can be found in Supporting Information, Tables S1 and S2). The most interesting and relevant volatile compounds and sensory descriptors are written with full names. Comparison of the score plot and loading plot illustrates that variables placed in the same position as a sample are high in intensity in that sample. For example, at 35 °C the beers developed quite differently, starting with sulfur and ester/fruity in the fresh samples to papery, stale and fruity aged/vinous in the stored samples, and especially KVL018 scored high in these descriptors as mentioned above. From the loadings plot (Fig. 4), it can be observed that papery, fruity aged/vinous and overall staling correlated positively with the Maillard reaction product furfural, consistent with Lund et al. [18], as well as the majority of ketones, Strecker aldehydes, lipid-derived aldehydes, carboxylic acids, heterocyclic compounds, and higher alcohols. However, comparison of individual volatile compounds between stored beers fermented with the two different yeast strains, did not reveal any significant differences (example shown in Supporting Information, Fig. S1). This is likely caused by the complex mixture of volatile compounds leading to development of the fruity aged/vinous sensory descriptor, of which only some are detected by the GC–MS method used in the present study.

The increased intensity of fruity aged/vinous sensory character observed in KVL018 when stored at 35 °C for 16 weeks is suggested to be caused by an increase in Maillard reaction compounds induced by an increased content of free amino acids (Fig. 1). Fresh beer brewed with yeast strain KVL018 contained significantly higher levels of the amino acids valine, isoleucine, leucine and phenylalanine (Fig. 1), which are precursors for the Strecker degradation products 2-methylpropanal, 2-methylbutanal and 3-methylbutanal, and the oxidation product benzaldehyde. The mentioned Strecker aldehydes as well as furfural were detected in higher levels in beer stored at 35 °C as can be seen in Fig. 4, where these variables are placed on the right of the loading plot, but no significant difference was observed between the yeast strains (Supporting information, Fig. S1). It was expected that the relative intensity for 2-methylbutanal and 3-methylbutanal would have been more pronounced for stored beer brewed with yeast strain KVL018, as the fresh beer contained higher levels of the amino acids isoleucine and leucine, respectively. However, formation of Strecker aldehydes are known to increase by oxidation [48], and therefore, the higher level of sulfite in beer brewed with KVL018 are suggested to reduce the formation of Strecker aldehydes compared to beer brewed with yeast strain KVL001.

Conclusion

Our hypothesis stating that a higher secretion of Trx would reduce the pool of oxidized thiols in beer with a positive effect on flavor stability during storage was rejected in the current study, as no increase in free thiol concentration was observed in fresh beer fermented with KVL001, which secreted a higher level of Trx.

Fermentation with the two yeast strains provided fresh beers with very similar sensory profiles. Fresh beers fermented with KVL018, however, contained more free amino acids than beers fermented with KVL001. Storage, especially at 35 °C, significantly increased the overall staling notes in beer fermented with KVL018 compared to KVL001, and this was mainly due to formation of a fruity aged/vinous character. Beer fermented with KVL018 also had a lower score in overall esters/fruit after storage compared to KVL001. The loss of sulfite occurred almost at the same rate at both storage temperatures for the two beers. Even though the sulfite concentration remained higher in KVL018 during the entire storage period, this beer developed more staling most probably due to the higher free amino acid content. Storage temperature was found to have a higher impact on flavor changes in beer than the choice of yeast strain, and storage induced differences in the flavor profiles, which was not obvious in the fresh samples. The improved flavor stability observed by fermentation with KVL001 (less fruity aged/vinous character) was most likely ascribed to the ability of the yeast strain to take up more free amino acids and thus a lower degree of the Maillard reaction, while no clear effects were observed on oxidation. Therefore, to obtain increased flavor stability of lager beer during storage, it seems necessary to avoid elevated concentrations of free amino acids and the Maillard reaction during storage by applying a yeast strain with a high capacity to take up amino acids. This study reveals that beer containing a high concentration of the primary antioxidant sulfite not necessarily possess a higher flavor stability, underlining the complex flavor changes of the beer matrix.

Data availability

Data will be made available upon request.

References

Bamforth CW (2011) 125th anniversary review: the non-biological instability of beer. J Inst Brew 117:488–497

Vanderhaegen B, Neven H, Verachtert H, Derdelinckx G (2006) The chemistry of beer aging—a critical review. Food Chem 95:357–381

Poojary MM, Lund MN (2022) Chemical stability of proteins in foods: oxidation and the maillard reaction. Annu Rev Food Sci Technol 13:35–58

Kaneda H, Yukinobu Kano J, Koshino S, Ohya-Nishiguchit H (1992) Behavior and role of iron ions in beer deterioration. J Am Soc Brew Chem 40:2–02

Danilewicz JC (2013) Reactions involving iron in mediating catechol oxidation in model wine. Am J Enol Vitic 64:316–324

Noble JJ, Sanchez II, Blondin BB (2015) Identification of new Saccharomyces cerevisiae variants of the MET2 and SKP2 genes controlling the sulfur assimilation pathway and the production of undesirable sulfur compounds during alcoholic fermentation. Microb Cell Fact 14:68

Andersen ML, Outtrup H, Skibsted LH (2000) Potential antioxidants in beer assessed by ESR spin trapping. J Agric Food Chem 48:3106–3111

Kaneda H, Takashio M, Osawa T et al (1996) Behavior of sulfites during fermentation and storage of beer. J Am Soc Brew Chem 54:115–120

Andersen ML, Skibsted LH (1998) Electron spin resonance spin trapping identification of radicals formed during aerobic forced aging of beer. J Agric Food Chem 46:1272–1275

De Almeida NEC, Do Nascimento ESP, Cardoso DR (2012) On the reaction of lupulones, hops β-acids, with 1-hydroxyethyl radical. J Agric Food Chem 60:10649–10656

De Almeida NEC, Homem-De-Mello P, De Keukeleire D, Cardoso DR (2011) Reactivity of beer bitter acids toward the 1-hydroxyethyl radical as probed by spin-trapping electron paramagnetic resonance (EPR) and electrospray ionization-tandem mass spectrometry (ESI-MS/MS). J Agric Food Chem 59:4183–4191

Intelmann D, Haseleu G, Dunkel A et al (2011) Comprehensive sensomics analysis of hop-derived bitter compounds during storage of beer. J Agric Food Chem 59:1939–1953

Bothe E, Schuchmann MN, Schulte-Frohlinde D, Von Sonntag C (1983) Hydroxyl radical-induced oxidation of ethanol in oxygenated aqueous solutions. A pulse radiolysis and product study. Z Naturforsch 38b:212–219

Lund MN, Krämer AC, Andersen ML (2015) Antioxidative mechanisms of sulfite and protein-derived thiols during early stages of metal induced oxidative reactions in beer. J Agric Food Chem 63:8254–8261

Lund MN, Andersen ML (2011) Detection of thiol groups in beer and their correlation with oxidative stability. J Am Soc Brew Chem 69:163–169

De Almeida NEC, Lund MN, Andersen ML, Cardoso DR (2013) Beer thiol-containing compounds and redox stability: kinetic study of 1-hydroxyethyl radical scavenging ability. J Agric Food Chem 61:9444–9452

Andersen ML, Gundermann M, Danielsen BP, Lund MN (2017) Kinetic models for the role of protein thiols during oxidation in beer. J Agric Food Chem 65:10820–10828

Lund MN, Petersen MA, Andersen ML (2015) Effect of protease treatment during mashing on protein-derived thiol content and flavor stability of beer during storage. J Am Soc Brew Chem 73:287–295

Murmann AN, Andersen P, Mauch A, Lund MN (2016) Quantification of protein-derived thiols during atmosphere-controlled brewing in laboratory scale. J Am Soc Brew Chem 74:30–35

Murmann AN, Hägglund P, Svensson B, Lund MN (2017) The reducing capacity of thioredoxin on oxidized thiols in boiled wort. J Agric Food Chem 65:10101–10106

Berner TS, Arneborg N (2011) The role of lager beer yeast in oxidative stability of model beer. Lett Appl Microbiol 54:225–232

Hudson JR (1959) Role of trace metals in brewing. J Inst Brew 65:321–330

Cyert MS, Philpott CC (2013) Regulation of cation balance in Saccharomyces cerevisiae. Genetics 193:677–713

Boulton C, Quain D (2006) Brewing yeast and fermentation. Wiley-Blackwell, Oxford

Fadel M, Hassanein NM, Elshafei MM et al (2017) Biosorption of manganese from groundwater by biomass of Saccharomyces cerevisiae. HBRC J 13:106–113

Dack RE, Black GW, Koutsidis G, Usher SJ (2017) The effect of Maillard reaction products and yeast strain on the synthesis of key higher alcohols and esters in beer fermentations. Food Chem 232:595–601

Ehrlich F (1907) Über die bedingungen der fuselölbildung und über ihren zusammenhang mit dem eiweissaufbau der hefe. Ber Dtsch Chem Ges 40:1027–1047

Hazelwood LA, Daran JM, Van Maris AJA et al (2008) The Ehrlich pathway for fusel alcohol production: a century of research on Saccharomyces cerevisiae metabolism. Appl Environ Microbiol 74:2259–2266

Willaert R, Nedovic V (2006) Primary beer fermentation by immobilised yeast—a review on flavour formation and control strategies. J Chem Technol Biotechnol 81:1353–1367

Pierce JS (1987) Horace Brown memorial lecture: the role of nitrogen in brewing. J Inst Brew 93:378–381

Guido L, Rajendram R, Barros A, Preedy V (2009) Pitching yeast and beer flavour. In: Beer in health and disease prevention. Elsevier, Amsterdam, pp 23–32

MEBAK (2002) Brautechnische Analysenmetoden, 4th ed. MEBAK, Freising-Weihenstephan

Lund MN, Lametsch R, Sørensen MB (2014) Increased protein-thiol solubilization in sweet wort by addition of proteases during mashing. J Inst Brew 120:467–473

Barba FJ, Poojary MM, Wang J et al (2017) Effect of high pressure processing and storage on the free amino acids in seedlings of Brussels sprouts. Innov Food Sci Emerg Technol 41:188–192

Wyrzykowska B, Szymczyk K, Ichichashi H et al (2001) Application of ICP sector field MS and principal component analysis for studying interdependences among 23 trace elements in Polish beers. J Agric Food Chem 49:3425–3431

Skou PB, Khakimov B, Hansen TH et al (2018) Chemical characterization by gas chromatography-mass spectrometry and inductively coupled plasma-optical emission spectroscopy of membrane permeates from an industrial dairy ingredient production used as process water. J Dairy Sci 101:135–146

Lu W, Wang L, Chen L et al (2018) Extraction and quantitation of nicotinamide adenine dinucleotide redox cofactors. Antioxid Redox Signal 28:167–179

Abrahamsson V, Hoff S, Nielsen NJ et al (2012) Determination of sulfite in beer based on fluorescent derivatives and liquid chromatographic separation. J Am Soc Brew Chem 70:296–302

Hoff S, Larsen FH, Andersen ML, Lund MN (2013) Quantification of protein thiols using ThioGlo 1 fluorescent derivatives and HPLC separation. Analyst 138:2096–2103

Steen I, Waehrens SS, Petersen MA et al (2017) Influence of serving temperature on flavour perception and release of Bourbon Caturra coffee. Food Chem 219:61–68

Johnsen LG, Skou PB, Khakimov B, Bro R (2017) Gas chromatography–mass spectrometry data processing made easy. J Chromatogr A 1503:57–64

Iimure T, Nankaku N, Hirota N et al (2010) Construction of a novel beer proteome map and its use in beer quality control. Food Chem 118:566–574

Würfel M, Hsberlein I, Follmann H (1990) Inactivation of thioredoxin by sulfite ions. FEBS Lett 268:146–148

Matsui (1984) Fluorometric determination of cysteine in beer by high performance liquid chromatography with precolumn derivatisation. J Inst Brew 90:20–23

dos Mathias TRS, Lopes MCRD, Oliveira CA et al (2017) Influence of mashing profile curve and addition of proteases on the composition of the wort and beer. MOJ Food Process Technol 5:282–286

Čejka P, Čulík J, Horák T et al (2013) Use of chemical indicators of beer aging for ex-post checking of storage conditions and prediction of the sensory stability of beer. J Agric Food Chem 61:12670–12675

Bushnell S, Guinard J-X, Bamforth C (2003) Effects of sulfur dioxide and polyvinylpolypyrrolidone on the flavor stability of beer as measured by sensory and chemical analysis. J Am Soc Brew Chem 61:133–141

Wietstock PC, Kunz T, Methner FJ (2016) Relevance of oxygen for the formation of Strecker aldehydes during beer production and storage. J Agric Food Chem 64:8035–8044

Acknowledgements

The authors acknowledge financial support from Independent Research Fund Denmark for granting the project entitled “New Defence Systems Against Beer Oxidation” (DFF-1335-00337B). The authors also thank Professor Chris Grant, University of Manchester, UK, for donating the yeast thioredoxin antibody. Finally, the authors thank Dr. Stefan Hanke, Bitburger Brewery Group GmbH, Bitburger, Germany, for assistance throughout the pilot brew.

Funding

Open access funding provided by Copenhagen University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Compliance with ethics requirements

This study does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Murmann, A.N., Bevilacqua, M., Danielsen, B.P. et al. The impact of lager brewing yeasts on flavor stability of pilot-scale beer during storage. Eur Food Res Technol 250, 715–725 (2024). https://doi.org/10.1007/s00217-023-04421-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-023-04421-8