Abstract

The creation of 3D printed food with programmed texture has the ambition of getting personalized properties through novel texture perceptions with many different ingredients and is helping the swallowing or mastication problems of vulnerable people. This study is done to determine the correlation between the instrumental and sensory evaluation of 3D-printed protein-fortified puree potatoes. At the moment there are not many studies about this correlation, and this information can be very helpful for food texture development. For people with swallowing difficulties, it is critical to have access to safe food with the desired texture. Therefore, understanding the correlation between texture-modified food will aid in the formulation of safe foods with desired sensory properties. Instrumental measurements of fortified puree were performed by a texture analyzer and the attributes obtained were firmness, consistency, cohesiveness, and index of viscosity. Quantitative descriptive analysis with eight trained panelists was employed to characterize the texture of the the3D-printed protein-fortified puree based on six sensory attributes: firmness, thickness, smoothness, rate of breakdown, adhesive, and difficulty swallowing. Three proteins (soy, cricket, and egg albumin with two different concentrations of 3 and 5%) were evaluated against puree potato without any protein as a control. The correlation results obtained from texture analysis and sensory evaluation were statistically significant (P < 0.05) which can be used to understand the impact of ingredients on textured modified puree to predict the sensory attributes which need a lot of time for training panelists.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Three-dimensional (3D) printing is a technology that is based on a layer-by-layer deposition technique to build computer-aided designed objects [1]. The application of 3D printing technology has been gaining interest in many industrial sectors, including the field of food and gastronomy [2]. In food manufacture, hydrocolloids or proteins are commonly used to improve quality attributes and sensory properties [3]. 3D printing could also enable nutritional optimization of one’s tailored diet. For instance, the prospect of personalized nutrition will benefit hospitalized patients with compromised eating ability or reduced appetite by providing appealing small portions adapted to their needs. Among this population, the provision of protein-enriched products will allow the fulfillment of nutrient requirements and facilitate recovery [4]. Several studies have successfully conducted research on 3D printed food with efforts made to elucidate the effect of printer parameters and textural properties of food inks on printability. However, investigation of the sensory and consumer aspect of 3D printed food is limited [5].

Food is maintaining the energy supply necessary for survival in humans but has a very important role as a source of pleasure [6]. Characterization of food products instrumental and sensory evaluation can be done to achieve quantifiable textural attributes for pureed foods. In addition, the textural properties of novel food products are also of critical importance in the attempts of new product development for many food products [7].

The back extrusion method, based on compression and extrusion tests, has been used to measure the textural properties (cohesiveness and index of viscosity) of semisolid foods [8]. Whereas the new method of textural analysis such as the force of extrusion which is for 3D printing is developed for puree food textural measurements (cohesiveness and index of viscosity) [9].

Sensory properties have been used to characterize the perception in-mouth and associate the reasoning of acceptance or rejection of food [10]. Quantitative descriptive analysis (QDA) is a comprehensive sensory technique that yields quantitative product description and can be used to correlate sensory characteristics to instrumental data. The main principle of QDA is to train panelists to measure specific quality attributes of a food product [11].

Both instrumental and sensory characterization of texture-modified food could be used to understand the qualitative and quantitative textural attributes of pureed foods, which ultimately seeks to improve the quality of life of people for instance people with dysphagia. However, there are few research papers have explored the correlation between instrumental and sensory measurements for puree foods. The aim of this study was to investigate the sensory properties of high protein puree potato products and to study the possible correlations with the textural attributes and 3D food printing extrusion. This correlation can be used as a quick and effective tool to measure relevant textural and sensorial attributes.

Materials and methods

Materials and sample preparation

Dehydrated potato puree (Maggi, purchased in a local supermarket) has the following nutritional values: energy 348 kcal, fat 0.8 g, carbohydrates 75 g, fiber 6.8 g, and proteins 7.4 g. Soy Protein acid hydrolysate (SPAH) food-grade was procured from Sigma-Aldrich (Nitrogen analysis ≥ 12% total = 75% protein (S), calculated applying a factor of 6.25 g prot/g N. Cricket protein powder70% protein (Acheta domesticus) (C) from Origen farms Albacete, Spain. Egg albumin 75% protein (A) was obtained from Avantor®. According to the regulation (EC) N.1924/2006 [12] all the formulations were high in protein 3S (2.9 g protein/100 g product), 5S (4.6 g protein/100 g product), 3C (2.7 g protein/100 g product), 5C (4.4 g protein/100 g product), 3A (2.9 g protein/100 g product), and 5A (4.6 g protein/100 g product).

Different proteins (soy (SPAH), cricket, and egg albumin) were dissolved in 100 mL of distilled water at 2 different levels (3 and 5%) and later 17 g potato powder was added. The formulations were prepared by mixing 100 mL of distilled water and protein (albumin or cricket) and keeping the mixture in an oven at 40 °C for 30 min (with a lid to avoid evaporation) to denature the protein. The control sample shares the same formulation but with no protein added, and the preparation condition was in an oven at 40 °C for 30 min. For soy protein (SPAH), the conditions to denature the protein were 90 °C (with a lid to avoid evaporation) for 30 min [13]. All Formulations were coded with a number expressing the amount of protein added (3 or 5%) and a letter indicating the protein source (S, C, or A for soy, cricket, or egg albumin, respectively).

Samples were kept overnight (22–24 h) in a fridge set at 2 °C and before starting the textural measurements all samples were placed in an incubator at 20 °C for two hours. The whole experiment was repeated 3 times.

3D food printing conditions

For printing of all formulations Foodini®, an extrusion-based 3D printer, was used. Before printing the samples were passed through the sieve as a means to eliminate or reduce the presence of lumps that may avoid printing through the nozzle. The samples were produced using a nozzle size of 1.5 mm, and an 8 layers hexagon prism was created for printing. The print speed was set at 3500 mm/min, the first ingredient holds at 4.2 mm, and the first layer nozzle height at 1.4 mm.

Instrumental texture analysis

This part is according to the textural tests done by Mirazimi et al. [9]. The back extrusion and force of extrusion measurements were analyzed by the TA. XT Plus, Stable Micro Systems, UK.

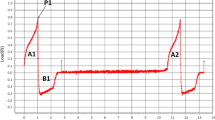

Backward-extrusion test

The different formulations of fortified puree were placed in a cylindrical container 5 cm in diameter and 6.5 cm high and filled to 75% of the volume of the container. A 3.5 cm diameter plate probe was plugged through the sample at a speed of 2 mm/s and for a distance of 30 mm. The method was adjusted to mimic the speed of the printing conditions of the Foodini® and the index of viscosity (N·s) and cohesivness (N) were obtain from this method.

Force of extrusion

To determine the firmness (N) and consistency (N·s) the 304 stainless steel capsules of the printer (© 2021 Natural Machines), with a capacity of 100 mL and 4 mm mouthpiece have been filled with each of the formulae to be tested. The probe plunger of the capsule (38 mm in diameter) was forced into the capsule at a speed of 2 mm/s and for a distance of 30 mm, pushing the fortified puree out through the 4 mm mouth placed at the bottom of the capsule. The maximum force needed to extrude the product was obtained by the analysis of the results of a test performed.

Sensory evaluation

The textural attributes of the fortified puree potato samples were evaluated by trained panelists at BDF company using QDA (Quantitative Descriptive Analysis) and hedonic evaluation. Each 3D printed protein-fortified sample served at room temperature (25 °C) for sensory evaluation. Room temperature water was provided for the panelists to cleanse their palates after testing each sample. The control sample was considered as a central point and served to evaluate the other samples taking this one as a reference. Eight panelists (two males and six females, aged between 25 and 45 years) were recruited and trained for sensory evaluation. According to the definition (Table 1) following parameters were measured: firmness, Thickness, Smoothness, Rate of breakdown, Stickiness, and Difficulty to swallow [14].

Data analysis

Data obtained from both instrumental measurements and sensory evaluations were analyzed using Minitab 18. The ANOVA and general linear model at a 95% confidence level were used to determine significant differences. A Tukey’s honest significant difference test was used to identify the differences among the samples. In addition, Pearson’s correlation was used to determine the correlation between instrumental and sensory parameters.

Results and discussion

Instrumental texture analysis

The average results of the different parameters derived from force of extrusion and back extrusion parameters for each formulation are listed in Table 2. The firmness and consistency values were obtained from the force of extrusion test while cohesiveness and index of viscosity values were obtained from the back extrusion test.

The highest firmness and consistency belonged to the formulation 5S. The formulations 5C and 3S showed high firmness respectively with significant differences (P < 0.05). The formulations 3S for firmness had the same behavior of formulation 5C. Regarding to consistency the formulation 5C showed high measurement and after formulations 3S and 3C showed the same behavior without significant differences (P > 0.05).

Additionally, the parameters achieved from back extrusion test showed the highest cohesiveness for formulation 5C and highest index of viscosity for formulation 5S. Following these results formulations 3S and 3C showed the same behavior for cohesiveness and index of viscosity. Formulations with egg albumin protein had the lowest values referring to all parameters, even below those of the control sample.

Generally, with the addition of SPAH and cricket proteins from 3 to 5%, textural attributes measurements increased which can be explained by increasing the interactions that could be created between starch and protein that increase along with protein concentration. The formation of starch-protein mixed systems was weak in the case of egg albumin because of the activity of ovalbumin depends more on protein concentration, temperature, and heating process [15]. The condition of this study involved in the thermally induced the native proteins have become disrupted and thus, convert to denatured forms, cannot build a strong network between protein and starch [16].

Sensory analysis

Hedonic evaluation

For a better interpretation of the results of sensory evaluation, they are represented in a spiderweb diagram (Fig. 1) depicting the ratings for color, flavor, mouthfeel, aroma, and overall acceptability of all formulations. Regarding the aroma, flavor, and overall scores of formulations, the level of added protein (3% and 5%) had no significant differences. However, there was a noticeable and significant effect on the rating for the cited parameters between the different proteins following descending order: cricket > egg albumin > SPAH. The color rate score of all formulations was in the range 3.10–4.25 (3 = acceptable color and 4 = attractive color) for all the panelists for all the high protein puree potato products. However, the hedonic mouthfeel characteristics scores had significant differences and the highest liking score belonged to the cricket protein samples followed by the control sample, egg albumin, and SPAH in this order.

The SPAH protein likeability kept on declining in all the sensory attributes which shows that the addition of this protein was not acceptable for flavor and aroma attributes. Hence, it can be concluded that the cricket protein 3% and 5% are the best formulation in terms of hedonic characteristics.

Sensory evaluation

In this study, a trained QDA panel evaluated a similar set of fortified puree formulations that were also characterized by the texture analyzer as described earlier. The overall mean scores for each sample are shown in Fig. 2.

Summary of sensory attributes evaluated by a trained panel(n = 8) for fortified formulated with three proteins with the control sample as a central point. 3S (3% Soy), 5S (5% Soy), 3C (3% Cricket), 5C (5% Cricket), 3A (3% Albumin), and 5A (5% Albumin). Different superscript letters indicate a significant difference (P < 0.05)

Based on the plot, all samples with the sensory attributes: firmness, thickness, smoothness, stickiness, and difficulty to swallow, with the exception of the rate of breakdown, followed a descending order of 5C and 5S > 3C and 3S > control > 3A and 5A.

The 5C and 5S formulations had the highest intensity scores for firmness and thickness respectively with significant (P < 0.05) differences from the rest of the formulations. The formulations 3C and 3S showed a high score on these parameters as well. It has also been suggested [17] that viscosity and firmness are interrelated as the more thick a product is, the more force will be needed to compress the pureed food. The force needed to compress the puree can be estimated from the measurement of firmness from the force of extrusion, as done in the present study.

The formulations with cricket and soy protein had not any significant differences in smoothness and stickiness to each other. However, they were different (P < 0.05) from the control sample and the samples with egg albumin. From our data, the degree of smoothness was observed in the order of 5S, 3C, 5C, 3S > control > 3A, and 5A with significant differences (P < 0.05). This could be contributed by cricket and SPAH interactions with starch granules, which provided a coating layer between the tongue and palate giving a smooth perception.

The formulations with cricket and SPAH with different concentrations had high stickiness and all formulations including these kinds of proteins (5C, 5S, 3C, and 3S) (P > 0.05). Control formulation, because not having any protein added, and the egg albumins formulations because of protein incompatibility that is discussed earlier, had the lowest rating for stickiness.

Formulations with egg albumin protein were rated the highest in the rate of breakdown (P value < 0.05). The rate of breakdown shows an opposing trend to the attribute difficult to swallow. This trend is conceivably logical for panelists with normal swallowing. This is because food that has a too low or too high rate of breakdown may not always be perceived to have the same degree on the difficult to swallow or easy to swallow parameter. The rate of breakdown from the highest to lowest are 5A and 3A > control > 3S, 5C, 5S, and 3C. The sample with egg albumin had the highest score for the rate of breakdown, which means that it could be deformed and disintegrated easily when subjected to an applied force between the tongue and the upper palate in the mouth. As the control did not have any protein added, it is expected that the puree sample was easily broken down in the mouth and can be explained by poor instrumental texture analysis (low measurements for different parameters) which can show these formulations can break very fast.

In the case of 3A and 5A samples containing egg albumin, the high rate of breakdown could be attributed to incompatibility between protein and starch due to limited protein denaturation of egg albumin and starch gelatinisation, which rapidly reduces the binding ability and consistency of the samples.

The difficulty to swallow parameter had no significant difference among all samples.

Overall, the sensory evaluation results showed that the textural attributes of fortified potato puree formulations perceived during oral manipulation varied significantly with the different proteins and are in agreement with the data obtained using back extrusion and force of extrusion by instrumental texture analysis.

3D printing and correlation between textural analysis

All the formulations were extruded out from the nozzle at 25 °C. A hexagon shape was applied to see the printability and stability of the formulations. The hexagon shape for all formulations as well as the control sample was able to keep the structure for more than 15 min. Figure 3 shows the result of 3D printing. The formulations with SPAH and cricket protein were extruded very well on printing process and the materials showed the ability to form self-supporting structures. Also, the control sample showed very good, extruded meantime printing and establish 3D printed shape. Egg albumin showed very poor resolution due to the low textural properties. In addition, during printing the fortified formulations with albumin was not able to tolerate the load of layers.

In the present day, there are many studies found that printed shape stability was closely related to textural properties [18, 19]. Protein incompatibility is a reason that egg albumin during formation and functional properties of starch-protein mixed systems worked very weak which is on account that incompatibility is strongly dependent upon the conformational state of the proteins and it is enhanced by protein denaturation [20].

Correlation between sensory and textural analysis

For a better understanding of the behavior of different proteins in fortified puree potato, the Pearson correlation method was used. This method is used to examine the direction and strength of the linear relationship between two variables. In this study correlations of the attributes obtained by texture analysis and attributes from the sensory evaluation were calculated. The Pearson correlation method was a correlation coefficient with an absolute value of 1 points to a perfect linear relationship. Strong correlations (0.806–0.994) were obtained for certain attributes obtained by instrumental and sensory measurements as shown in Table 2. A P value lower than 0.05 indicates that the attributes were significantly correlated to each other. From the analysis, the consistency (instrumental) was positively correlated to thickness (sensory) and smoothness (sensory) with coefficients of 0.994 and 0.893, respectively (Table 3).

The cohesiveness attribute obtained by the texture analyzer was negatively correlated to the rate of breakdown from the sensory evaluation with a correlation coefficient value of − 0.863 (P value of 0.002) (Table 3). It is to be noted that the fortified puree potato samples tested in the sensory evaluation were subjected to the conditions in the mouth, especially where the samples were mixed and diluted with saliva. The mixing of saliva with the puree and the mechanical manipulation of the puree in the mouth resulted in the formation of a food bolus. The presence of saliva has been suggested to increase cohesion and viscoelastic properties of the bolus due to the human mucin components secreted in food-stimulated saliva [21]. Nevertheless, a higher cohesiveness value obtained from instrumental measurements means that an increase in the applied force is required for the puree processing in the mouth to facilitate the mixing of the puree with the saliva to form a bolus prior to swallowing. Hence, a fortified puree sample with a higher cohesiveness value would correspondingly result in a lower perceived rate of breakdown in the mouth. Although the results obtained from this study showed a strong correlation between these two attributes, factors such as dilution of foods by saliva in the mouth, differences in the applied shear forces in the mouths of dysphagia subjects as compared to healthy subjects, and so on are important factors to be considered in future studies.

For the adhesiveness attribute obtained by the texture analyzer, positive correlations were obtained with the sensory attributes of adhesive and difficulty to swallow.

The results from this work have shown that instrumental measurements could be used as a rapid and cost-effective tool to characterize texture-modified food.

The firmness attribute measured from either force of extrusion and sensory attributes were positively correlated. Consistency was positively correlated to thickness and smoothness. Cohesiveness was negatively correlated to the rate of breakdown. However, due to the effect of saliva on the food bolus and the different shear forces in the mouth further validation is needed to establish the correlation. The index of viscosity obtained from the texture analyzer was positively correlated to sensory attributes of stickiness and difficulty to swallow.

Conclusion

3D printing of food offers many possibilities for customized nutrition, including exceptional flexibility in geometries, textures, and flavors. Increasing the number of studies using 3D printing technology and increasing the number of people with swallowing difficulties is an opportunity to investigate more about sensory and textural attributes.

According to the sensory attributes measured using QDA were strongly correlated with instrumental measurements. The knowledge from this study is helpful to understand better the correlation between textural and sensorial attributes and showed the possibility of using textural analysis to predict the sensory attributes which needs a lot of time for teaching panelists and is more cost-effective. In the report of hedonic test observed cricket and egg albumin proteins had the best overall score compared to SPAH that is because the taste and odor of hydrolyzed protein were strong and not acceptable for panelists which has a easy solution with 3D printing technology that is possible to mix the protein-fortified formulation with different flavor depends on every taste.

The cricket and SPAH protein showed a very stable shape after 3D printing and self-supporting behavior, but egg albumin had no stable shape and could not tolerate the weight of shape layers. We found that there is a direct relevancy between 3D printing and textural measurements.

This study also highlights the need for quantitative guidelines for formulators of different ingredients in selecting suitable substances and recommending appropriate concentrations for users preparing foods considering printability and texture-modified food. In general, the statistically significant correlations have demonstrated the usefulness of using an instrumental technique to characterize texture-modified food.

Data availability

The authors declare that the data supporting the findings of this study are available within the paper and its Supplementary Information files. Should any raw data files be needed in another format they are available from the corresponding author upon reasonable request.

References

Joshi S, Sahu JK, Bareen MA, Prakash S et al (2021) Assessment of 3D printability of composite dairy matrix by correlating with its rheological properties. Food Res Int 141:110111

Hod L, Melba K (2013) Fabricated: The new world of 3D printing. John Wiley & Sons, NY, USA

Saha D, Bhattacharya S (2010) Hydrocolloids as thickening and gelling agents in food: a critical review. J Food Sci Technol 47:587–597

Methven L, Rahelu K, Economou N, Kinneavy L et al (2010) The effect of consumption volume on profile and liking of oral nutritional supplements of varied sweetness: sequential profiling and boredom tests. Food Qual Prefer 21:948–955

Severini C, Derossi A, Ricci I, Caporizzi R et al (2018) Printing a blend of fruit and vegetables. new advances on critical variables and shelf life of 3D edible objects. J Food Eng 220:89–100

Aguilera JM, Park DJ (2016) Texture-modified foods for the elderly: Status, technology and opportunities. Trends Food Sci Technol 57:156–164

McGorrin RJ (2019) Key aroma compounds in oats and oat cereals. J Agric Food Chem 67:13778–13789

Ilhamto, Nila. 2012 Producing in-house pureed food in long-term care. PhD Thesis. University of Guelph.

Mirazimi F, Saldo J, Sepulcre F, Gracia A et al (2022) Preparing a personalized meal by using soy Cricket and Egg. Foods 1–12:2244

Sharma M, Kristo E, Corredig M, Duizer L (2017) Food hydrocolloids effect of hydrocolloid type on texture of pureed carrots : rheological and sensory measures. Food Hydrocoll 63:478–487

Puri R, Khamrui K, Khetra Y, Malhotra R et al (2016) Quantitative descriptive analysis and principal component analysis for sensory characterization of Indian milk product cham-cham. J Food Sci Technol 53:1238–1246

Zicari G, Carraro E, Bonetta S (2007) The regulation (EC) N. 1924/2006 of the European parliament and of the council of 20 december 2006 on nutrition and health claims made on foods. Prog Nutr 9:264–273

Mirazimi F, Saldo J, Sepulcre F, Gracia A et al (2022) Enriched puree potato with soy protein for dysphagia patients by using 3D printing. Food Front 3(4):1–10

Peh JX, Lim W, Kim K, Goh T et al (2022) Correlation between instrumental and sensory properties of texture-modified carrot puree. J Texture Stud 53:72–80

Mine Y, Noutomi T, Haga N (1991) Emulsifying and structural properties of ovalbumin. J Agric Food Chem 39:443–446

Clark AH, Kavanagh GM, Ross-Murphy SB (2001) Globular protein gelation—theory and experiment. Food Hydrocoll 15:383–400

Stahlman LB, Garcia JM, Hakel M, Chambers E IV (2000) Comparison ratings of pureed versus molded fruits: preliminary results. Dysphagia 15:2–5

Derossi A, Caporizzi R, Paolillo M, Severini C (2021) Programmable texture properties of cereal-based snack mediated by 3D printing technology. J Food Eng 289:110160

Huang M-S, Zhang M, Bhandari B (2019) Assessing the 3D printing precision and texture properties of brown rice induced by infill levels and printing variables. Food Bioprocess Technol 12:1185–1196

Grinberg VY, Tolstoguzov VB (1997) Thermodynamic incompatibility of proteins and polysaccharides in solutions. Food Hydrocoll 11:145–158

Sukkar SG, Maggi N, Cupillo BT, Ruggiero C (2018) Optimizing texture modified foods for oro-pharyngeal dysphagia : a difficult but possible target ? Front Nutr 5:1–10

Acknowledgements

For supporting the sensorial evaluation, we want to acknowledge the help provided by BDF Ingredients company, Girona-Spain.

Funding

Open Access funding provided thanks to the CRUE-CSIC agreement with Springer Nature.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Compliance with ethics requirements

The experiment was approved by the ethics committee of the BarcelonaTech (UPC) university and was conducted according to the ethical principles with specific care on protecting personal information according to the European regulations. In addition, Participants gave informed consent via the statement “I am aware that my responses are confidential, and I agree to participate in this survey” where an affirmative reply was required to enter the survey. They were able to withdraw from the survey at any time without giving a reason. The products tested were safe for consumption.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mirazimi, F., Saldo, J., Sepulcre, F. et al. Study the correlation between the instrumental and sensory evaluation of 3D-printed protein-fortified potato puree. Eur Food Res Technol 249, 1669–1675 (2023). https://doi.org/10.1007/s00217-023-04246-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-023-04246-5