Abstract

In this paper, we present a constant temperature mashing procedure where grist made of Pilsner malt is mashed-in directly in the temperature regime of alpha-amylase activity, thus omitting all conventional steps, followed by constant temperature mashing at 72 °C. The aim was to investigate an alternative mashing procedure for the production of alcohol-reduced beers. The mashing proceeds with a rapid buildup of sugars and is completed after 120 min at the latest, giving an iodine normal and clear wort. However, the distribution of the different sugars in the worts is strongly altered, in comparison to a more classical mashing procedure. The free amino nitrogen (FAN) concentration is sufficient for vivid fermentation with the bottom fermenting yeast Saccharomyces pastorianus TUM 34/70. The lag phase and initial fermentation performance of this yeast strain are comparable for conventionally and isothermally (72 °C) mashed wort. Under the given conditions the fermentation of the isothermally (72 °C) made wort is finished after 6 days whereas a conventional wort needs 4–5 days more to be completed. The alcohol concentration is remarkably reduced by isothermal mashing leading to roughly 3.4 vol.-% with an original gravity of 11°P whereas with a conventional mashing procedure 4.4 vol.-% are obtained for the same original gravity. In both cases the concentrations of the fermentation by-products are comparable. A preliminary comparison of taste and foam stability did not show striking differences. Constant temperature mashing at 72 °C is a simple way to reduce the alcohol content of beer enriching it at the same time with non-fermentable sugars.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In a conventional brewing procedure (infusion mashing), malt grist is mashed-in into about 50–55 °C warm water, usually followed by a proteolysis rest at 50–55 °C, a maltose rest at 60–65 °C, and a saccharification rest at 70–75 °C [1,2,3]. In the first step proteins are cleaved to amino acids measurable e.g. as the FAN value, the beta-amylase cleaves starch to mainly maltose and some glucose at 60–65 °C, and at 70–75 °C the alpha-amylase is active, cleaving starch into maltose, maltotriose, and higher sugars, the latter ones are only fermentable to some extent by some bottom fermented yeast strains. Additionally, limit dextrinase cleaves α-1,6-linkages of starch to produce linear dextrins as new attack points for the beta-amylase [4, 5]. Many breweries nowadays omit proteolysis and cytolysis rests [6] as today’s malts—done with current barley varieties—have been that well prepared during the malting process that there is no negative impact on beer quality if malt grist is directly mashed-in at 60–65 °C or even at 67–68 °C, which is in the range of the optimal temperature to produce fermentable sugars [7].

In the latter case, at least for a short period of time, both beta- and alpha-amylase are equally active together, which can lead to an optimum cleavage of starch to fermentable sugars. The beta-amylase is quite sensitive to temperature and, according to literature, above 70 °C a rapid denaturation starts. In contrast, the alpha-amylase is believed to be much more heat-resistant allowing an efficient starch cleaving above 70 °C [8]. Henson et al. recently investigated in detail the activity of beta- and alpha-amylase from two different malts in the presence of maltose and mannitol at 63 °C, 68 °C, 73 °C, and 78 °C and found that the stability of the enzymes is dependent on wort composition [9]. The activity of beta-amylase is highest at 63 °C rapidly losing activity, and after 120 min only 15% of the original activity remains in the absence of maltose. In the presence of maltose, however, the enzymatic activity is remarkably stable over 2 h at 63 °C. At 73 °C the activity of the beta-amylase decreases within 30 min to about 10% of its original activity, and the maltose concentration only plays a minor role on enzyme stability at that temperature. The alpha-amylase, on the other hand, showed a reasonably high activity over at least 90 min at 73 °C in the presence of maltose [10]. From these data, it can be concluded that the activity of these two starch cleaving enzymes, beta- and alpha-amylase, is dependent on malt, temperature, and wort composition.

In a recent study by Evans et al. [11], the diastatic power and thermostability of amylolytic enzymes was investigated. The study shows the thermostability of the beta-amylase, alpha-amylase, and limit dextrinase at a rest temperature of 65 °C. Whereas the alpha-amylase shows no reduction of activity over 70 min at 65 °C, it drops rapidly to around 20–40% of its original activity after increasing the temperature to 74 °C. Beta-amylase on the other hand declines progressively during the 60 min rest at 65 °C and its activity is about 40–60% of its initial value at the end of the rest. The enzyme stops working entirely after raising the temperature to 74 °C. Limit dextrinase shows a rapid increase of activity in the first 20 min of the 65 °C rest and quickly declines due to thermal deactivation. The activity increases around 50–70% in the beginning and subsequently drops to 45–70% of its initial activity, which is maintained for the remaining resting time at 65 °C. At 74 °C limit dextrinase activity drops to range between 15 and 30% of its first value [12].

In general, sugars stabilize proteins, like enzymes, against heat denaturation [13]. This is due to the effect of sugars and polyols on the structure of water and the increase of its surface tension. Hydrophobic interactions stabilize the three-dimensional structure of proteins. The hydrophobic interactions between pairs of hydrophobic groups are stronger in sucrose solutions than in pure water, therefore, the thermostability of enzymes is enhanced in sugary solutions [14, 15].

For a constant temperature single-step mashing procedure at 72 °C it can be expected that the beta-amylase is active for only quite a short time followed by denaturation, whereas the alpha-amylase can cleave starch for at least 90 min.

In this context, the question came up if and how the concentration of the different sugars resulting from starch cleaving is influenced if malt grist is mashed isothermally at 72 °C.

For a vivid fermentation, especially if starting with a low amount of pure yeast, the wort needs to contain a sufficient amount of nitrogen sources, such as amino acids. Literature states values from 200 to 250 mg/l of free amino nitrogen (FAN) [16], which summarizes the amino acids and other nitrogen containing compounds. Kok et al. reviewed 2019 the brewing process with malted barley and raw barley [17] and concluded based on literature [18] that a lower FAN in 100% raw barley wort did not translate to yeast fermentability issue. Various experiments done at the authors institutes with different types of malts have resulted in values between 100 and 300 mg/l FAN (at 12°P), and also experiences from observations of industrial worts by the authors with a similar FAN range had in single-batch-fermentations no negative impact on the fermentation performance of bottom fermented yeast. Thus, it can be concluded, that modern barley malts contain a sufficiently high amount of amino acids, as well as di- and tri-peptides and in general nitrogen sources to ensure the first and second doubling cycles in the initial phase, for cell mass propagation, protein related cell functions and a vivid fermentation.

The aim of this paper was to examine an alternative mashing method to produce alcohol-reduced beer, while maintaining or improving full-bodied properties of these beers. Constant temperature mashing at 72 °C to Pilsner malt was applied, in comparison to rather a conventional mashing procedure with rests. In the isothermal case the malt was mashed-in such that after mashing-in a temperature of 72 °C was obtained immediately. This temperature was kept constant for at least 120 min and samples for analysis were taken during mashing, in the case of conventional mashing at the beginning and at the end of each rest, respectively. The concentrations of glucose, fructose, sucrose and maltose + maltotriose as well as the FAN values were determined. The worts were subsequently fermented and the obtained beers analyzed, with a focus on alcohol concentration and fermentation by-products.

Materials and methods

Malt, malt grist, hop and yeast

For the present study 2-row Pilsner malt was used, made by the Weyermann Company (Bamberg, Germany) and was rated as organic Pilsner malt [19]. The gelatinization temperature of this organic Pilsner malt was determined at BLQ according to [20] to be at 64.8 °C.

The Weyermann Pilsner malt was ground in a 2 roller mill MaltMan® 75 from Sommer Maschinenbau (Osnabrück, Germany). The roller distance scale was calibrated using a 3 mm thick tin wire that was manually pulled through the mill. The malt was subsequently ground with a roller distance of 1.9 mm. The grist distribution was determined at BLQ with a Pfungstädter Plansichter sieving device according to DIN ISO 3310-1.

A simple bitter hopping was applied to the worts using Hallertauer Magnum (pellets 90) with an alpha value of 13%.

The water used here was tap water from the Upper Harz Mountains Area and is rated with 1–2 German degrees of hardness.

The bottom fermenting yeast for each experiment was 500 ml of pure Saccharomyces pastorianus Frisinga—TUM 34/70® (TUM 34/70) with a cell concentration of 200 million cells per ml, provided by BLQ.

Brewing devices and brewing procedure

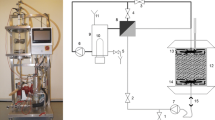

For these experiments mainly a device with the malt pipe technique was used, a Brew Monk Magnus (Brouwland bv, Beverlo, Belgium) with a volume of 50 l. In this device, the wort is circulated such that it is pumped from the heated bottom through an external tube to the top of the device from where it flows passively through the malt grist to the bottom. The device was heat insulated with an insulation jacket. For upscaling, a 300 L device with classical agitator and lauter tun was used.

Brew Monk Magnus

In one set of experiments, 37 l of water were heated to 75 °C. After mashing-in of 10 kg of malt grist the temperature decreased rapidly to 72 °C and was kept constant for 120 min. A 20 min rest at 78 °C was subsequently applied before the malt pipe was lifted for lautering. The grist was washed with 78 °C hot water until 50 l of wort resulted. The wort with 50 g of added hop pellets was boiled for 60 min with the help of a Brüden hood and the evaporated water was replaced by boiling water at the end to have identical volumes in the respective experiments. After hot trub removal with a whirlpool the wort was chilled through a plate heat exchanger and poured into a 60 l fermentation container made of polyethylene (from Speidel Tank-und Behälterbau GmbH, Ofterdingen, Germany) with a controlled temperature of 12 °C, followed by addition of the above mentioned 500 ml yeast suspension. For comparison, the same amounts of water and malt were used for a conventional mashing procedure. In this case the malt grist was mashed for 10 min at 50 °C, 15 min at 56 °C, 40 min at 63 °C, and 30 min at 72 °C, followed by heating to 78 °C and lautering. The subsequent procedure was identical. The malt pipe system of the Brew Monk Magnus can be seen in Scheme .

In another set of experiments 40 l of water were heated to 74 °C and 8 kg of malt grist were mashed-in, resulting in a temperature of 72 °C that was kept constant for 149 min. A 20 min rest at 78 °C was subsequently applied before the malt pipe was lifted for lautering. The grist was washed with 78 °C hot water until 40 l of wort resulted. The wort was boiled as described above for 60 min with 40 g of hop pellets and the evaporated water was replaced by boiling water at the end. The subsequent procedure was identical to the one described above. For comparison, the same amounts of water and malt were used for a conventional mashing procedure. In this case the malt grist was mashed for 25 min at 52 °C, 40 min at 62 °C, and 40 min at 72 °C, followed by heating to 78 °C and lautering. The subsequent procedure was identical (Scheme 1).

300 l brewing device

The experiments were up-scaled with a 300 l brewing device by Sudhausbau GmbH (Schwarzenbek, Germany) having a classical agitator and lauter tun at Brauakademie Zellerfeld. 63 kg of barley malt were mashed, either into 230 l of 74 °C hot water, resulting in a temperature of 72 °C that was kept constant for 120 min, or into 230 l of 65 °C hot water, followed by rests at 63 °C for 45 min and 72 °C for 30 min (20 min heating time between the rests). The worts were fermented with TUM 34/70 with a pitching temperature of 15 °C and fermentation temperature of 10 °C.

Analysis methods

In the case of constant temperature mashing 20 ml of wort were each taken after 5, 20, 40, 60, 80, 100, and 120 min and filled into Pyrex laboratory bottles. For the experiments with rests the samples were taken at the beginning and at the end of the respective rest. To stop enzymatic activity the well closed bottles were heated to 95 °C within 2–3 min in a water bath and kept at that temperature for 30 min. Subsequently the bottles were cooled down to 2 °C in a cooling chamber before they were refrigerated to − 20 °C before analysis. The original gravity of the worts during mashing, given in °P, was determined at 20 °C both with an Anton Paar Easydens and a HANNA digital refractometer. Both instruments delivered the same values.

The free amino nitrogen (FAN) was determined with the standard ninhydrin method [16]. For selected trials the distribution of the different amino acids was determined by BLQ with high-performance liquid chromatography, HPLC [21].

The viscosities of the filtered worts were determined at 20 °C with a “RheoSense microVisc” viscometer.

The concentrations of sucrose, glucose, and fructose as well as of maltose + maltotriose were determined with enzymatic kits from r-biopharm, Maltose/Sucrose/D-Glucose UV-Test (order number Roche or r-biopharm 11113950035) and D-Glucose/D-Fructose UV-Test (order number Roche or r-biopharm 10139106035).

According to the test instructions the determination of the different sugars was performed by different enzymes in separate reactions (polystyrene UV cuvettes) with the corresponding blank samples (separate UV cuvettes). Before the test, the beer samples were centrifuged for 10 min with 3800 × g to clear the sample and diluted with water to be in the determination range of the sugars, according to the test instructions. NADPH, as the UV–visible reaction product, was measured at 365 nm (against air) in a UV/Vis spectrometer. From the absorption values the concentration of the different sugars within the beer samples can be calculated with the Beer–Lambert law. This enzymatic test measures maltose and maltotriose at the same time without distinction. Therefore, the concentrations of glucose, maltose and maltotriose were also determined with HPLC [22,23,24,25].

To get a first insight into the distribution of higher sugars and to determine maltose and maltotriose as individual values, the worts were treated with 3-methyl-1-phenyl-5-pyrazolone. This reaction introduces a chromophore to reducing sugars and makes them detectable with a UV/Vis detector. Figure 1 shows the chemical reaction using glucose as example for reducing sugars. In this way, the reducing sugars are modified with two molecules of a chromophore, which shows strong absorbance at 245 nm and is thus detectable with a UV/Vis detector. Fructose is modified with only one molecule, sucrose as a non-reducing sugar does not react with the chromophore.

For this purpose, the wort samples were cooled to room temperature and the original gravity was measured using an Anton Paar Easydens. The samples were then centrifuged at 2665 × g and diluted to 1:5 with demineralized water. All used chemicals were of the grade pro analysi or higher and ordered from various chemical companies. The experimental procedure was inspired by the best procedure in Bai et al. [23]. Adjustments of the used volumes and concentrations were done to adapt the diluted wort samples consisting of various sugars. In short, the following steps were performed, further details can be found in Bai et al. [23], Honda et al. [24], and Dai et al. [25] with slightly modified experimental conditions. In short, the sample (wort after centrifugation and dilution with demineralized water) was reacted with 3-methyl-1-phenyl-5-pyrazolone (dissolved in methanol) in an alkaline environment (addition of 0.6 M NaOH) for 30 min at 70 °C. After the reaction was done the sample was acidified by addition of 0.6 M HCl. To remove unreacted 3-methyl-1-phenyl-5-pyrazolone extraction with trichloromethane was performed three times. Demineralized water was added to the aqueous phase, which was subsequently filtered with a PTFE 200 nm syringe filter, before the sample was injected into the column.

According to Bai et al. [23] the separation took place on a RP-18 column (RP: Reversed Phase, ACE Equivalence 5 C18, 150 mm, 4.6 mm, 5 µm) with a Hitachi Primaide HPLC. The elution was done with a mixture of acetonitrile and ammonium acetate/acetic acid buffer (0.15 M, pH 5.0) with volume fractions of 20/80 vol.-% and a flow rate of 0.8 ml/min at 30 °C.

The allocation of the peaks in the chromatograms was done by measurements of with the chromophore modified reference substances (e.g. maltodextrins) and by comparison with literature data, such as in Baik et al. [26] and Zhong-Fu et al. [27]. To be able to compare the peaks of the various sugars, 1H-benzotriazole was added as an internal standard.

The final beers were, after de-gassing, centrifugation and ultra-filtration (100 nm pore size), analyzed with the Anton Paar alcohol and extract meter Alex-500, delivering original gravity, alcohol concentration in volume-%, apparent and real degree of fermentation. Further experiments were done at BLQ with an Anton Paar density meter DMA 5000 M, the module Alcolyzer Beer ME and the autosampler XsampleTM 520.

The vitality of the yeast cells was determined at BLQ in triplicate using the Cellometer® Vision (Nexcelom Bioscience LLC, Lawrence, MA, USA). Since macroscopic particles were perceived in the yeast samples, the yeasts were each passed through a fine sieve before dilutions were made for microscopy.

The fermentation by-products were determined according to MEBAK methods, as described in [28,29,30,31,32].

Results and discussion

In the first experiments the Brew Monk Magnus was used to make 2 × 50 l of beer in parallel, one time with constant temperature mashing at 72 °C, one time with rather a conventional Pilsner infusion mashing procedure. The malt was ground using a 2 roller malt mill with a roller distance of 1.9 mm and mashed into 37 l of water. This setting delivers a rather coarse malt grist (see Table 1), which, however, is advantageous to this device with respect to a homogenous circulation of the wort through the malt grist. Furthermore, lautering was quite fast needing only 30–45 min. Figure 2 shows the original gravity in °P for comparison, together with the temperature profile in the case of conventional mashing. The original gravity increases rapidly within 40 min for isothermal mashing with a subsequent only slight increase until the end of mashing, whereas in the case of conventional mashing an almost linear increase was seen without clear correlation with the rests. It is worth noting that after just 20 min of isothermal mashing at 72 °C saccharification is already completed by about 70%. Based on the subsequently slight increase of extract it can be concluded that the mashing time with a constant temperature mashing procedure at 72 °C can be reduced and lautering can start after 60 min of mashing time at the latest. Interestingly, at the end of mashing the original gravity of the isothermally (72 °C) made wort was 16°P, which is a little bit higher than the one of the conventionally made wort (14.4°P), in both cases for 37 l of water, as shown in Fig. 2. From these data, it can be concluded that the buildup of sugars is quite fast in the case of isothermal mashing and the extract at the end of mashing is even a little bit higher than in the case of conventional mashing.

Comparison of the buildup of original gravity in °P during mashing in the case of isothermal mashing at 72 °C (black curve) and with rests at 50 °C, 56 °C, 63 °C, and 72 °C (grey dashed curve), respectively, together with the temperature rests (grey curve), Brew Monk Magnus (50 l). Uncertainty: ± 0.2°P. Arrows indicate the respective y-axis

Figure 3 shows the buildup of the FAN concentration for isothermal and conventional mashing together with the temperature profile in the latter case. In the isothermal case, the FAN concentration increased within 40 min to > 200 mg/l and remained quite stable until the end of the mashing procedure, where a value of roughly 220 mg/l was obtained. In the case of conventional mashing, at all sampling time-points the FAN concentrations were higher than with isothermal mashing, and once the temperature is increased to the next rest there is also an increase in FAN concentration. At the end of mashing the FAN concentration in the conventionally made wort was almost 290 mg/l. From these data, it can be concluded that during isothermal mashing at 72 °C enough FAN was released from the malt into the wort thus sufficient nitrogen sources for initial yeast proliferation and a subsequent thorough fermentation performance was available. In brief, the FAN concentration of a conventionally made wort is about 30% higher than the one of an isothermally (72 °C) made wort.

Comparison of the buildup of free amino nitrogen (FAN) during mashing in the case of isothermal mashing at 72 °C (black curve) and with rests at 50 °C, 56 °C, 63 °C, and 72 °C (grey dashed curve), respectively, together with the temperature rests (grey curve), Brew Monk Magnus (50 l). Uncertainty: ± 10 mg/l. Arrows indicate the respective y-axis

Figure 4 shows in comparison the viscosity of the respective worts as a function of time together with the temperature profile in the case of conventional mashing. With increasing amount of sugars in the wort the viscosities increased and at the end of mashing the viscosity of the isothermally (72 °C) made wort was less than 20% above the viscosity of the conventionally made wort. The difference in FAN content and viscosity was confirmed by isothermal mashing tests on a micro scale (data not published). A total of 2 L of wort was produced from pure pilsner malt in a standard congress mashing bath at a constant temperature of 72 °C for 90 min. This slight difference in viscosity, as seen in Fig. 4, had no relevance in our trials since the lautering time was the same at 30 min and shows that higher molecular compounds like e.g. beta-glucanes have already been cleaved during the malting process. This was confirmed by additional tests. Figure 5 shows the buildup of sugars in both cases (enzymatic/photometric method). The concentrations of the sugars sucrose, glucose, and fructose were summarized as one total value and the concentrations of maltose and maltotriose as another total value. It is shown below by HPLC how the sugar distribution varies. Throughout the observation, there is only a minor deviation in the sum of sucrose, glucose, and fructose between the two mashing procedures, whereas the sum of maltose and maltotriose shows rather a considerable difference. In the case of isothermal mashing the concentrations hardly vary after 60 min whereas in the case of conventional mashing there was an almost continuous increase from 40 to 80 min (thus in the regime of the 62 °C rest) and a further increase in the regime of the 72 °C rest. Furthermore, the total concentration of maltose + maltotriose was higher in the case of conventional mashing at the end of the procedure, as was already demonstrated by Fox et al. [33].

Comparison of the viscosity of wort samples during mashing in the case of isothermal mashing at 72 °C (black curve) and with rests at 50 °C, 56 °C, 63 °C, and 72 °C (grey dashed curve), respectively, together with the temperature rests (grey curve), Brew Monk Magnus (50 l). Uncertainty: ± 0.1 mPa s. Arrows indicate the respective y-axis

Comparison of the buildup of the sugars sucrose + glucose + fructose and of maltose + maltotriose during isothermal mashing at 72 °C (black curves) and mashing with temperature rests (grey dashed curves), respectively, together with the rest temperatures (grey curve), Brew Monk Magnus (50 l). The values have been determined with enzymatic kits. Uncertainty: ± 1 g/l for glucose + fructose + sucrose, ± 3 g/l for maltose + maltotriose. Arrows indicate the respective y-axis

Both worts were iodine normal and clear at the end of the mashing procedure without any visual hint for the blue color of the iodine–starch complex. In the following steps lautering and washing with water were done until in both cases 50 l of wort were obtained. The bitter hop was added and the worts were subject to boiling for 60 min, followed by whirlpool and chilling. Samples were taken and analyzed. The results of the final worts are presented in Table 2. Both worts were fermented with the above mentioned TUM 34/70 suspension at 12 °C. After 2 weeks they were both force carbonated inside of kegs and stored at 2 °C. The final beers were analyzed 6 weeks after brewing. Table 3 shows original gravity, alcohol concentration and degrees of fermentation of the final beers. With this rather coarse malt grist the worts before fermentation had identical values of 11.1°P. Within the uncertainty limit of ± 0.1°P of the four different worts the same values were obtained for the final beers. The FAN concentration of the conventionally mashed wort was higher than the one from isothermal mashing, but in both cases the FAN concentration was sufficient to enable vivid fermentation. The lower alcohol content of the isothermally (72 °C) made beer was a result of the higher amount of unfermentable sugars in the isothermal wort. The concentration of maltose + maltotriose was higher in the case of conventional mashing, furthermore the sum of the monosaccharides and of sucrose was a bit higher as well. Interestingly, the concentration of fructose was quite low in the case of isothermal mashing so it can be assumed that the saccharase was rapidly deactivated at 72 °C whereas it cleaved sucrose to glucose and fructose for a short time in the case of conventional mashing. The reduced activity of the enzymes could be confirmed in supporting experiments by isothermal mashing on a micro scale and an inactivation temperature of saccharase was determined to be at around 63 °C. Sugar analysis of those worts by HPLC suggests that neither saccharase nor maltase are active in the temperature regime of the isothermal mashing at 72 °C. Thus, a low fructose and glucose concentration results. The content of maltose and maltotriose is also reduced compared to a classic mashing process, suggesting a reduced activity of beta-amylase.

In conclusion, from the sum of the single sugars and sucrose the concentration of glucose was slightly lower for isothermal mashing. The alcohol contents, that can be calculated from the sugar concentrations, well agree with the measured ones and the alcohol content of the beer from the isothermally (72 °C) made wort was about 1 vol.-% below the one of the conventionally made beer in this case. To get a first insight into the distribution of the different sugars the final worts were analyzed by HPLC on a RP-18 column, as described in the experimental section. Figure 6 shows the results of four different mashing tests. In all worts the concentrations of maltotriose were quite similar, whereas in the case of the conventionally made worts the concentrations of maltose and glucose were remarkably increased. On the other hand, the concentrations of higher sugars from maltotetraose to maltoheptaose were increased in the case of isothermal mashing at 72 °C. The concentrations of glucose and maltose + maltotriose, obtained from quantitative evaluation of the respective peaks in Fig. 6, agree with the ones from the enzymatic measurements. Interestingly, the concentrations of maltotriose only slightly vary in both worts and are in good agreement with earlier experiments [34].

For a more detailed analysis of both beers, the fermentation by-products were investigated. As both worts had an identical original gravity with a different distribution of sugars and a different concentration of amino acids it was worth testing if the fermentation by-products were altered. The results are summarized in Table 4. The table shows that the overall by-products had comparable concentrations, without striking differences. Only the concentrations of the esters were a little bit higher in the case of the conventional beer, whereas the concentrations of 2-phenylethanol and 2-butanol were a little bit lower. The concentrations of acetaldehyde and of 1-propanol were on the same level. It can be concluded that the fermentation delivered comparable amounts of fermentation by-products in both cases.

To shed more light on the fermentation process, again two worts were made by isothermal and conventional mashing. The only differences were that in those cases 8 kg of malt grist were mashed into 40 l of water each, and the rests in the case of conventional mashing were restricted to 25 min at 52 °C, 40 min at 62 °C, and 40 min at 72 °C, overall taking 149 min including heating times. The time for constant temperature mashing at 72 °C was prolonged to 149 min as well, to have comparable conditions. Subsequently the temperature was increased to 78 °C for 20 min followed by lautering and washing with water until in both devices 40 l of wort were obtained. The original gravity of the isothermally (72 °C) made wort was 11.8°P, thus close to the one before, the one of the conventionally made wort was 12.4°P. These considerable deviations from the results above can be due to slight variations during mashing and lautering. In other experiments original gravities of 11.5°P and 11.9°P were obtained under the same conditions. Overall it can be concluded that under the experimental conditions given similar results are obtained. An HPLC analysis of all worts showed almost the same result as the ones presented in Fig. 6. After boiling with hops and chilling, both worts were poured into fermentation containers with a constant temperature of 12 °C, subsequently 500 ml of pure TUM 34/70 suspension were added to each container.

This yeast is fresh pure culture yeast provided by the Research Center Weihenstephan for Brewing and Food Quality. During fermentation, the alcohol content and the apparent degree of fermentation were controlled the first 11 days every 24 h, with a final check after 16 days. Figure 7 shows the alcohol content and the apparent degree of fermentation as a function of time for both fermenting worts. In the first 4 days the curves of the conventional and of the isothermal wort were practically identical. After 6 days the fermentation of the isothermally (72 °C) made wort slowed down and ended after 7 days. The fermentation of the conventionally made wort proceeded for 4 more days and came to an end after 11 days. Further tests were done after 16 days, and there was no more variation in alcohol concentration or apparent degree of fermentation, meaning that the main fermentation of the isothermally (72 °C) made wort was finished after 7 days, the conventionally made wort after 11 days. The final beers had original gravities of 12.3°P (conventional) and 11.4°P (isothermal) and alcohol contents of 4.9 vol.-% and 3.2 vol.-%, respectively. These values are in good agreement with the ones reported above.

Comparison of the fermentation of an isothermally (72 °C) made wort (black curves) and of a wort made with rests at 52 °C, 62 °C, and 72 °C (grey dashed curves), Brew Monk Magnus (40 l). Uncertainties: ± 0.2°P for original gravity and ± 2% for apparent degree of fermentation. Arrows indicate the respective y-axis

The yeast viability was measured with samples taken 16 days after the beginning of fermentation. Both with a conventionally made and with an isothermally (72 °C) made wort the viability of the yeast cells was 90%, and a microscopic investigation showed no striking difference in the shape of the cells. Therefore, it can be concluded that the slightly lower amount of amino acids in the case of isothermal mashing at 72 °C has no massive negative impact on yeast growth and viability. According to Hutzler et al. [35] a specification for yeast repitching of harvest yeast is 95% viability or higher, whereas 90% can be regarded as an acceptable value after such a long fermentation phase in small-scale fermentations.

The above presented results were confirmed with a 300 l brewing device at Brauakademie Zellerfeld. 63 kg of barley malt were mashed, either into 230 l of 74 °C hot water, resulting in a temperature of 72 °C that was kept constant for 120 min, or into 230 l of 65 °C hot water, followed by rests at 63 °C for 45 min and 72 °C for 30 min (20 min heating time between the rests). In both cases the wort was visually iodine normal after the mashing procedure. In the final beers, fermented with TUM 34/70, the isothermally (72 °C) mashed beer had an alcohol content of 3.7 vol.-% with an original gravity of 12.2°P, whereas the conventionally mashed beer had an alcohol content of 4.8 vol.-% with an original gravity of 12.3°P. These results confirm that isothermal mashing at 72 °C considerably reduces the amount of fermentable sugars. A detailed comparison of the whole isothermal mashing procedure in a device with a malt pipe and in one with a classical agitator will be presented in the future.

Conclusion

In the present study, it was shown at the example of Pilsner malt that a single-step isothermal mashing procedure at 72 °C is possible to make beers. The buildup of the extract proceeded fast and was almost completed after 60 min. In comparison, the original gravity in the case of isothermal mashing was equivalent or slightly below the one of conventional mashing with rests. The concentrations of glucose and maltose were reduced in the case of isothermal mashing whereas the ones of maltotetraose and higher sugars were increased. Consequently the amount of fermentable sugars was decreased, leading to a lower alcohol content. Isothermal mashing at 72 °C lead to a sufficient concentration of amino acids and, therefore, sufficient nitrogen sources for initial yeast proliferation and a subsequent thorough fermentation performance. In the case of the isothermal wort, fermentation was completed after 6 days whereas for the conventional wort 4–5 days more were required. In both cases about 90% of living yeast cells were obtained after 2 weeks of fermentation. The fermentation by-products of the final beers were comparable with only slight differences in their concentrations. In summary, isothermal mashing at 72 °C is rather a simple but feasible way to make beers with a reduced alcohol content. Quite recently the Lallemand company has released a “Best Practice Sheet” on low alcohol beers [36] supporting our results by mashing-in a temperature range of 82–86 °C.

References

Narziß L, Back W, Gastl M, Zarnkow M (2017) Abriss der bierbrauerei. Wiley-VCH Verlag GmbH & Co, Weinheim

Back W, Gastl M, Krottenthaler M, Narziß L, Zarnkow M (2019) Brewing techniques in practice. Fachverlag Hans-Carl, Nuremberg

Narziß L, Back W (2016) Brewing science and brewing technology. Chem Ing Tec 88:1869–1879

Evans E, Collins H, Eglinton J, Wilhelmson A (2005) Assessing the impact of the level of diastatic power enzymes and their thermostability on the hydrolysis of starch during wort production to predict malt fermmentability. J Am Soc Brew Chem 63:13

Macgregor AW, Bazin SJ, Macri LJ, Babb JC (1999) Modelling the contribution of alpha-amylase, beta-amylase and limit dextrinase to starch degradation during mashing. J Cereal Sci 29:161–169. https://doi.org/10.1006/jcrs.1998.0233

Jones BL, Marinac L (2002) The effect of mashing on malt endoproteolytic activities. J Agric Food Chem 50:7

Evans DE, Goldsmith M, Dambergs R, Nischwitz R (2011) A comprehensive reevaluation of the small-scale Congress mash protocol parameters for determination of extract and fermentability. J Am Soc Brew Chem 69:13–27. https://doi.org/10.1094/ASBCJ-2011-0111-01

Schur F, Pfenninger HB, Narziß L (1974) Einfluss verschiedener maischparameter auf die amylolyse. Schweiz Br Rdsch 85:220–227

Henson CA, Duke SH (2016) Maltose effects in barley malt diastatic power enzyme activity and thermostability at high isothermal mashing temperatures: Ibeta-amylase. J Am Soc Brew Chem 74:12

Henson CA, Duke SH (2016) Maltose effects in barley malt diastatic power enzyme activity and thermostability at high isothermal mashing temperatures: II. Alpha-amylase. J Am Soc Brew Chem 74:13

Evans DE, Fox GP (2017) Comparison of diastatic power enzyme release and persistence during modified institute of brewing 65°C and Congress programmed mashes. J Am Soc Brew Chem 75:302–311. https://doi.org/10.1094/ASBCJ-2017-4707-01

Evans E (2017) Comparison of diastatic power enzyme release and persistence during modified institue of brewing 65° C and Congress programmed mashes. J Am Soc Brew Chem 75:9

Frigon RP, Lee JC (1972) The stabilization of calf-brain microtubule protein by sucrose. Arch Biochem Biophys 153:587–589. https://doi.org/10.1016/0003-9861(72)90376-1

Back JF, Oakenfull D, Smith MB (1979) Increased thermal stability of proteins in the presence of sugars and polyols. Biochemistry 18:5191–5196. https://doi.org/10.1021/bi00590a025

Arakawa T, Timasheff SN (1982) Stabilization of protein structure by sugars. Biochemistry 21:6536–6544. https://doi.org/10.1021/bi00268a033

Mitteleuropäische Brautechnische Analysenkommission (MEBAK): wort, beer, beer-based beverages, chapter 2.6.4.1.1

Kok YJ, Ye L, Muller J, Siak-Wei Ow D, Bi X (2019) Brewing with malted barley or raw barley: what makes the difference in the processes? Appl Microbiol Biotechnol 103:1050–1067

Aastrup S (2010) Beer from 100% barley. Scand Brewers’ Rev 67:28–33

Mitteleuropäische Brautechnische Analysenkommission (MEBAK): wort, beer, beer-based beverages, R-200.32.283

Mitteleuropäische Brautechnische Analysenkommission (MEBAK): wort, beer, beer-based beverages, chapter 2.6.4.1.2.

Mitteleuropäische Brautechnische Analysenkommission (MEBAK): wort, beer, beer-based beverages, chapter 2.7.1.

Bai W, Fang X, Zhao W, Huang S, Zhang H, Qian M (2015) Determination of oligosaccharides and monosaccharides in Hakka rice wine by precolumn derivation high-performance liquid chromatography. J Food Drug Anal 23:645–651. https://doi.org/10.1016/j.jfda.2015.04.011

Honda S, Akao E, Suzuki S, Okuda M, Kakehi K, Nakamura J (1989) High-performance liquid chromatography of reducing carbohydrates as strongly ultraviolet-absorbing and electrochemically sensitive 1-phenyl-3-methyl-5-pyrazolone derivatives. Anal Biochem 180:351–357. https://doi.org/10.1016/0003-2697(89)90444-2

Dai J, Wu Y, Chen S-W, Zhu S, Yin H-P, Wang M, Tang J (2010) Sugar compositional determination of polysaccharides from Dunaliella salina by modified RP-HPLC method of precolumn derivatization with 1-phenyl-3-methyl-5-pyrazolone. Carbohyd Polym 82:629–635. https://doi.org/10.1016/j.carbpol.2010.05.029

Baik Y-S, Cheong W-J (2007) Determination of molecular weight distribution and average molecular weights of oligosaccharides by HPLC with a common C18 phase and a mobile phase with high water content. Bull Korean Chem Soc 28:847–850. https://doi.org/10.5012/bkcs.2007.28.5.847

Zhong-Fu W, Ying Z, Xue LIN, Lin-Juan H (2007) HPLC separation of 1-phenyl-3-methyl-5-pyrazolone derivatized oligosaccharides and its matrix-assisted laser desorption/ionization time-of-flight mass spectrometry identification. Acta Chim Sinica 65:2761–2764

Mitteleuropäische Brautechnische Analysenkommission (MEBAK): wort, beer, beer-based beverages, chapter 2.23.6, p 405–414

Mitteleuropäische Brautechnische Analysenkommission (MEBAK): wort, beer, beer-based beverages, chapter 2.21.4, p 307–310

Mitteleuropäische Brautechnische Analysenkommission (MEBAK): wort, beer, beer-based beverages, chapter 2.21.1, p 280–285

Mitteleuropäische Brautechnische Analysenkommission (MEBAK): wort, beer, beer-based beverages, chapter 2.21.5.1, p 311–314

Mitteleuropäische Brautechnische Analysenkommission (MEBAK): wort, beer, beer-based beverages, chapter 2.23.1.1, p 377–380

Fox G, Staunton M, Agnew E, D’Arcy B (2019) Effect of varying starch properties and mashing conditions on wort sugar profiles. Je Inst of Brew 125:10

Endres F, Prowald A, Oppermann S (2020) Alkoholreduzierte biere herstellen? Einfach isotherm maischen. Brauwelt 42:1098–1101

Hutzler M, Koob J, Riedl R, Schneiderbanger H, Müller-Auffermann K, Jacob F (2015) In: Hill AE (ed) Brewing microbiology: managing microbes, ensuring quality and valorising wase, Woodhead Publishing, London

5 - Yeast identification and characterization. www.lallemandbrewing.com (Best practices—low alcohol beer)

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Compliance with Ethics Requirements

The authors confirm that this manuscript has not already been published nor is it under consideration for publication elsewhere. This article does not contain any studies with human or animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Endres, F., Prowald, A., Fittschen, U.E.A. et al. Constant temperature mashing at 72 °C for the production of beers with a reduced alcohol content in micro brewing systems. Eur Food Res Technol 248, 1457–1468 (2022). https://doi.org/10.1007/s00217-022-03968-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-022-03968-2