Abstract

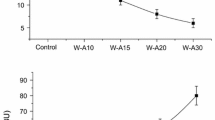

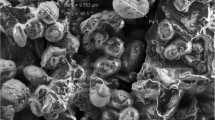

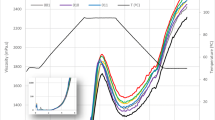

Chickpea (Cicer arietinum L.) is a legume of Fabaceae family whose grains are rich in proteins, total dietary fiber, unsaturated lipids, minerals and bioactive compounds with antioxidant activity. Therefore, chickpea flour can be an attractive high nutritional complement to wheat flour for the formulation of composite breads. In the present study, the thermal and rheological characteristics of the chickpea–wheat dough obtained by replacement of wheat flour with 100 and 200 g/Kg of chickpea flour were assessed by Differential Scanning Calorimetry (DSC), Rapid Visco Analysis (RVA), Dynamic Mechanical Thermal Analysis (DMA) and Texture Profile Analysis (TPA). Higher gelatinization temperatures in coincidence with higher pasting temperatures with lower breakdown and setback of the pastes were obtained for the chickpea–wheat mixtures. Furthermore, the viscoelasticity of the wheat dough changed with the presence of chickpea flour, leading to higher dynamic moduli (E’, E’’) and lower values of tangent of the phase angle (tan δ = E’’/E’) suggesting the formation of a more elastic matrix. At higher deformations (TPA), higher values of hardness and elasticity were observed. These changes were associated with a marked disruption of the gluten network by the presence of certain chickpea components like proteins, assessed by different microscopic techniques.

Similar content being viewed by others

References

Nwokolo E (1996) The need to increase consumption of pulses in the developing world. Food and feed from legumes and oilseeds 3–11

Global Economy of Pulses (2019) Food and Agriculture Organization of the United Nations, Rome. http://www.fao.org/3/i7108en/I7108EN.pdf Accessed10 Sept 2020

Session Periods, Resolution A/RES/68/231 (2013) Assembly General of the United Nations. http://www.un.org/es/ga/68/resolutions.shtml Accessed10 Sept 2020

Mudryj AN (2019). In: Dahl WJ (ed) Health benefits of pulses. Springer Nature, Switzerland

Carreras J, Mazzuferi V, Karlin M (2016) El Cultivo de Garbanzo (Cicer arietinum L.) en Argentina. Universidad Nacional de Córdoba, Còrdoba

Marangoni A, Alli I (1988) Composition and properties of seeds and pods of the tree legume Prosopis juliflora (DC). J Sci Food Agric 44(2):99–110

Fenn D, Lukow OM, Humphreys G, Fields PG, Boye JI (2010) Wheat-legume composite flour quality. Int J Food Prop 13:381–393

Bigne PMC, Ferrero C (2016) Fibre enrichment of wheat flour with mesquite (Prosopis spp.): effect on breadmaking performance and staling. LWT—Food Sci Technol 65:1008–1016

Fernandez ML, Berry JW (1988) Nutritional evaluation of chickpea and germinated chickpea flours. Plant Foods Hum Nutr 38(2):127–134

Ribotta PD, Arnulphi SA, León AE, Añón MC (2005) Effect of soybean addition on the rheological properties and breadmaking quality of wheat flour. J Sci Food Agric 85(11):1889–1896

Hefnawy T, El-Shourbagy GA, Ramadan MF (2012) Impact of adding chickpea (Cicer arietinum L.) flour to wheat flour on the rheological properties of toast bread. Intern Food Res J 19(2):521–525

Mohammed I, Ahmed AR, Senge B (2014) Effects of chickpea flour on wheat pasting properties and bread making quality. J Food Sci Technol 51(9):1902–1910

Ozulku G, Arıcı M (2017) Characterization of the rheological and technological properties of the frozen sourdough bread with chickpea flour addition. J Food Meas Charact 11(3):1493–1500

Yamsaengsung R, Schoenlechner R, Berghofer E (2010) The effects of chickpea on the functional properties of white and whole wheat bread. Int J Food Sci Technol 45(3):610–620

AACC International (2000) Approved methods of the American Association of Cereal Chemists, 10th edn. American Association of Cereal Chemists, Saint Paul, MN

Gómez M, Oliete B, Rosell CM, Pando V, Fernández E (2008) Studies on cake quality made of wheat-chickpea flour blends. LWT—Food Sci Technol 41(9):1701–1709

Rocha Parra AF, Ribotta PD, Ferrero C (2015) Starch-apple pomace mixtures: pasting properties and microstructure. Food Bioproc Technol 8(9):1854–1863

Collar C, Santos E, Rosell CM (2006) Significance of dietary fiber on the viscometric pattern of pasted and gelled flour-fiber blends. Cereal Chem 83(4):370–376

Bigne F, Romero A, Ferrero C, Puppo MC, Guerrero A (2017) Rheological and microstructural study of wheat doughs partially replaced with mesquite flour (Prosopis alba) and added with transglutaminase. Food Bioproc Technol 10(5):819–830

Leon A, Rosell CM, De Barber CB (2003) A differential scanning calorimetry study of wheat proteins. Eur Food Res Technol 217(1):13–16

Kaur M, Singh N (2005) Studies on functional, thermal and pasting properties of flours from different chickpea (Cicer arietinum L.) cultivars. Food Chem 91(3):403–411

Mohammed I, Ahmed AR, Senge B (2011) Dynamic rheological properties of chickpea and wheat flour dough´s. J App Sci 11(19):3405–3412

Tromp RH, van de Velde F, van Riel J, Paques M (2001) Confocal scanning light microscopy (CSLM) on mixtures of gelatine and polysaccharides. Food Res Int 34:931–938

Bigne F, Puppo MC, Ferrero C (2016) Rheological and microstructure characterization of composite dough with wheat and mesquite (Prosopis spp) flours. Int J Food Prop 19(2):243–256

Nawrocka A, Szymańska-Chargot M, Miś A, Kowalski R, Gruszecki WI (2016) Raman studies of gluten proteins aggregation induced by dietary fibres. Food Chem 194:86–94

Huang W, Kim Y, Li X, Rayas-Duarte P (2008) Rheofermentometer parameters and bread specific volume of frozen sweet dough influenced by ingredients and dough mixing temperature. J Cereal Sci 48(3):639–646

Acknowledgements

The authors acknowledge the Asociación Universitaria Iberoamericana de Postgrado (AUIP) for conceding the funds for the stay that allowed carrying out this study. The authors also kindly thank Herba Ricemills S.L.U. for providing the chickpea flour used in this study and the Microscopy services (CITIUS—Universidad de Sevilla) for providing full access and assistance to confocal and scanning electron microscopes.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Compliance with ethics requirements

The article does not contain any studies with human participants or animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bigne, F., Romero, A., Ferrero, C. et al. New thermal and rheological approaches of chickpea–wheat dough for breadmaking. Eur Food Res Technol 247, 1107–1115 (2021). https://doi.org/10.1007/s00217-021-03691-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-021-03691-4