Abstract

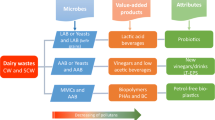

The resulting whey from cheese manufacture consists mainly of water and lactose, a sugar with little sweetening and fermentable power and low commercial value. Aiming at valorizing the whey and faced with the challenge to reduce and treat an industrial wastewater present at high volumes and composed of high organic load, several ways to enhance the commercial value lactose have been sought. Thanks to the functional and technological traits of lactose and to the biotechnological advances, several applications have been proposed either for direct use or for the production and application of chemical and enzymatic derivatives or by-products from microbiological processes. Nowadays, lactose has numerous potential applications in food, feed, nutraceutical, pharmaceutical and cosmetic industry, an overview of which is given in this review. On the other hand, many compounds of high added value are produced from lactose, such as oligosaccharides with prebiotic properties, lactobionic acid with antioxidant properties, lactitol as sweetener with dietetic and prebiotic functions, and lactulose as prebiotic ingredient. Nevertheless, the implementation of industrial processes for whey collection and lactose recovery and valorization faces practical difficulties, particularly of logistical and financial investment nature. This communication aims at giving an overview with respect to the problems associated with the high volumes of whey produced in the dairy industry and some of the foremost technological routes for its commercial exploitation through the use of lactose and its derivatives. It also presents a set of considerations regarding the main bottlenecks to overcome towards the creation and implementation of integrated systems tailored for collecting and processing cheese whey in an efficient, sustainable and cost-effective approach.

(Source: [24])

Similar content being viewed by others

Availability of supporting data

Not applied.

References

Affertsholt T, Nielsen MD (2014) 3A: Whey and lactose to grow to a more than US$14 billion market in 2017. AgriHQ Grain & Feed Insight, https://agrihq.co.nz/#. Accessed 29 June 2017

Affertsholt T (2010) Dairy and whey ingredients – market and industry trends. Presented at American Dairy Products Institute/American Butter Institute (ADPI/ABI) annual conference, Chicago, 27 April 2010. 3A Business Consulting, Aarhus, Denmark. http://www.adpi.org/Portals/0/PDF/10Conference/Affertsholt.pdf. Accessed 29 June 2017

Aider M, de Halleux D (2007) Isomerization of lactose and lactulose production: review. Trends Food Sci Technol 18:356–364

ANIL-Associação Nacional dos Industriais de Lacticínios [National Association of Dairy Industry] (2016): http://www.anilact.pt/. Accessed 10 Mar 2016

Audic J-L, Chaufer B, Daufin G (2003) Non-food applications of milk components and dairy co-products: a review. Dairy Sci Technol 83:417–438

Banaszewska A, Cruijssen F, Claassen GDH, van der Vorst JGAJ (2014) Effect and key factors of byproducts valorization: the case of dairy industry. J Dairy Sci 97:1893–1908

Bartkiene E, Lele V, Ruzauskas M, Mayrhofer S, Domig K, Starkute V, Zavistanaviciute P, Bartkevics V-, Pugajeva I, Klupsaite D, Juodeikiene G, Mickiene R, Rocha JM (2020) Lactic acid bacteria isolation from spontaneous sourdough and their characterization including antimicrobial and antifungal properties evaluation. Microorganisms 8(1):64

Bobe G, Beitz DC, Freeman AE, Lindberg GL (1998) Separation and quantification of bovine milk proteins by reversed-phase high-performance liquid chromatography. J Agric Food Chem 46:458–463

Bosco F, Carletto RA, Marmo L (2018) An Integrated Cheese Whey Valorization Process. Chem Eng Trans 64:379–384

Brew K, Castellino FJ, Vanaman TC, Hill RL (1970) The complete amino acid sequence of bovine α-lactalbumin. J Biol Chem 10:4570–4582

Chen XY, Gänzle MG (2017) Lactose and lactose-derived oligosaccharides: more than prebiotics? Int Dairy J 67:61–72

Das M, Raychaudhuri A, Ghosh SK (2016) Supply chain of bioethanol production from whey: a review. Proc Environ Sci 35:833–846

Demaimay M, Baron C (1978) Isomerization on ion exchange resins of lactose in aqueous solutions and whey. Lait 58:234–245

Douglas FW Jr, Greenberg R, Farrell HM Jr, Edmondson LP (1981) Effects of ultra- high-temperature pasteurization on milk proteins. J Agric Food Chem 29:11–15

Drug development and delivery (2016) http://www.drug-dev.com/Main/Home.aspx. Accessed 14 Jan 2016

Eigel WN, Butler JE, Ernstrom CA, Farrell HM, Harwalkar VR, Jenness R (1984) Nomenclature of proteins of cow’s milk: fifth revision. J Dairy Sci 67:1599–1631

El-Agamy E (2009) Bioactive components in camel milk. In: Park YW (ed) Bioactive components in milk and dairy products. Wiley-Blackwell, Iowa

Filippini A (1985) Lactulose purification process. European Patent App EP 0 158 148 Al

Foster-Powell K, Holt SH, Brand-Miller JC (2002) International table of glycemic index and glycemic load values. Am J Chem Nutr 76:5–56

Gänzle MG (2012) Enzymatic synthesis of galacto-oligosaccharides and other lactose derivatives (hetero-oligosaccharides) from lactose. Int Dairy J 22:116–122

Gänzle MG, Haase G, Jelen P (2008) Lactose: crystallization, hydrolysis and value-added derivatives. Int Dairy J 18:685–694

Gosling A, Stevens GW, Barber AR, Kentish SE, Gras SL (2010) Recent advances refining galactooligosaccharide production from lactose. Food Chem 121:307–318

Green BA, Edison BL, Sigler ML (2008) Antiaging effects of topical lactobionic acid: results of a controlled usage study. J Cosmetic Dermatol 21:76–82

Guerra MA (2002) Controlling of fouling and concentration polarization during cross-flow flow micro filtration of skim milk. PhD thesis Nº 97-0158-035, Department of Chemical Engineering, Technical University of Denmark

Guimarães PMR, Teixeira JA, Domingues L (2010) Fermentation of lactose to bio-ethanol by yeasts as part of integrated solutions for the valorisation of cheese whey. Biotechnol Adv 28:375–384

Gutiérrez L-F, Hamoudi S, Belkacemi K (2012) Lactobionic acid: a high value-added lactose derivative for food and pharmaceutical applications. Int Dairy J 26:103–111

Harper WJ (1992) Lactose and Lactose Derivatives. In: Zadow JG (ed) Whey and Lactose Processing. Springer, Netherlands

Hebbink GA, Dickhoff BHJ (2019) Application of lactose in the pharmaceutical industry. In: Paques M, Lindner C (eds) Lactose: evolutionary role, health effects, and applications. Elsevier Academic Press, London, pp 175–233

Hernández-Ledesma B, Ramos M, Gómez-Ruiz JÁ (2011) Bioactive components of ovine and caprine cheese whey. Small Ruminant Res 101:196–204

Hicks KB, Parrish FW (1980) A new method for preparing lactulose from lactose. Carbohyd Res 82:393–397

Hiele M, Ghoos Y, Rutgeerts P, Vantrappen G (1993) Metabolism of erythritol in humans—comparison with glucose and lactitol. Br J Nutr 69(1):169–176

Hogarth CJ, Fitzpatrick JL, Nolan AM, Young FJ, Pitt A, Eckersall PD (2004) Differential protein composition of bovine whey: a comparison of whey from healthy animals and from those with clinical mastitis. Proteomics 4:2094–2100

Jenness R, Patton S (1959) Lactose. In: Principles of dairy chemistry, Chapter 3, John Wiley & Sons, New York

Joesten MD, Hogg JL, Castellion ME (2007) The World of Chemistry: Essentials, 4th edn. Thomson Brooks/Cole, Belmont

Kappeler SR (1998) Compositional and structural analysis of camel milk proteins with emphasis on protective proteins, PhD thesis, Swiss Federal Institute of Technology, Zurich

Khramtsov AG, Kravchenko EF, Matvievskii VYa (1978) Lactulose production from lactose solutions. 20th International Dairy Congress 966–968

Kosseva MR (2013) Use of immobilized biocatalyst for valorization of whey lactose. Chapter 8. In: Kosseva MR, Webb C (eds) Food industry wastes: assessment and recuperation of commodities, 1st edn. Academic Press, Elsevier, Amsterdam, pp 137–156

Küley E, Özyurt G, Özogul I, Boga M, Akyol I, Rocha JM, Özogul F (2020) The role of selected lactic acid bacteria on organic acid accumulation during wet and spray-dried fish-based silages. Contributions to the winning combination of microbial food safety and environmental sustainability. Microorganisms 8(2):172

Linko P (1982) Lactose and lactitol. In: Birch GO, Parks KJ (eds) Nutritive sweeteners. Applied Science Publishers, London

Matsumoto K, Kamiyama S, Watanabe T, Kuroda K, Mutai K (1987) Method for making growth accelerating factos for bifidobacteria. Japanese Unexam. Patent JP 62:208–293

Matvievskii VYa., Kravchenko EF, Kramtsov AG, Surkov BA, Krayushkin VA (1978) Study of carbohydrate composition of lactolactulose syrups. Tr. Vses. Nauchno-Issled. Inst. Maslodel. Syrodel’n Promsti Nauchno-proizvodst. Obedin. ‘Uglich’

McCooey A (2017) Sugar and sweetener guide. http://www.sugar-and-sweetener-guide.com/index.html. Accessed 30 June 2017

Mendez A, Olano A (1979) Lactulose. A review of some chemical properties and applications in infant nutrition and medicine. Dairy Sci Abstract 41:531–535

Mercier A, Gauthier SF, Fliss I (2004) Immunomodulating effects of whey proteins and their enzymatic digests. Int Dairy J 14:75–183

Mollea C, Marmo L, Bosco F (2013) Valorisation of Cheese Whey, a By-Product from the Dairy Industry. In: Muzzalupo I (ed) Food industry. Intechopen, New York, pp 549–588

Mozaffar Z, Nakanishi K, Matsuno R (1985) Formation of oligosaccharides during hydrolysis of lactose in milk using β-galactosidase from Bacillus circulans. J Food Sci 50:1602–1606

Nickerson TA (1974) Lactose: occurence. In: Fundamentals of dairy chemistry. Webb BH, Johnson AH, Alford JA. (ed.). Fundamentals of dairy chemistry, 2nd edn, AVI publishing Co Inc, Westport, Conn

Nojiri K, Takasaki K, Deie H, Igarashi K (1987) Novel oligosaccharide, and method for making it. Japanese Unexam. Patent JP 62:205–793

Ogasa K, Tomita M, Mizota T (1979) Method for preparing a non-hygroscopic lactulose-containing powder. US Patent 4:142–916

Okado K, Ogas K, Tomita M (1977) Process for preparing a lactulosecontaining powder for feed. US Patent 4:142–916

Olano A, Martinez-Castro I (1981) Formation of lactulose and epilactose from lactose in basic medium: a quantitative study. Milchwissenschaft 36:533–536

Păcularu-Burada B, Georgescu LA, Vasile MA, Rocha JM, Bahrim G-E (2020) Selection of wild lactic acid bacteria strains as promoters of postbiotics in gluten-free sourdoughs. Microorganisms 8:643

Pangborn RM (1963) Relative taste intensities of selected sugars and organic acids. J Food Sci 28:726–733

Panghal A, Patidar R, Jaglan S, Chhikara N, Khatkar SK, Gat Y, Sindhu N (2018) Whey valorization: current options and future scenario – a critical review. Nutr Food Sci Nutr Food Sci 48(3):520–535

Papademas P, Kotsaki P (2019) Technological utilization of whey towards sustainable exploitation. Adv Dairy Res 7:1–10

Paterson AHJ, Kellam SJ (2009) Transformation of lactose for value-added ingredients. In: Corredig M (ed) Dairy-derived ingredients – Food and nutraceutical uses, Chapter 24, 1st edn. Woodhead Publishing Series, Cambridge, pp 625–643

Paterson AHJ (2017) Lactose processing: from fundamental understanding to industrial application. Int Dairy J 67:80–90

Porter ME (1980) Competitive Strategy. Free Press, New York

Porter ME (1985) Competitive advantage. Free Press, New York

Prazeres AR, Carvalho F, Rivas J (2012) Cheese whey management: a review. J Environ Manage 110:48–68

Pritzwald-Stegmann BF (1986) Lactose and some of its derivates. J Soc Dairy Technol 39:91–96

Roberts HR, McFarren EF (1953) The chromatographic observation of oligosaccharides formed during the lactase hydrolysis of lactose. J Dairy Sci 36:620–632

Rocha JM (2011) Microbiological and lipid profiles of broa: contributions for the characterization of a traditional Portuguese bread, PhD thesis, Instituto Superior de Agronomia, Universidade de Lisboa, Lisboa, Portugal, 705, 91–106. http://hdl.handle.net/10400.5/3876

Rocha JM (2016) Microencapsulation of probiotic bacteria. ECronicon. Microbiology 3:480–481

Rocha JM, Malcata FX (2012) Microbiological profile of maize and rye flours, and sourdough used for the manufacture of traditional Portuguese bread. Food Microbiol 31:72–88

Rocha JM, Malcata FX (2015) Behavior of the complex micro-ecology in maize and rye flour and mother-dough for broa throughout storage. J Food Qual 39:218–233

Rocha JM, Malcata FX (2016) Microbial ecology dynamics during Portuguese broa sourdough. J Food Qual 39:634–648

Ross KD, Parrish FW (1978) Potential applications of lactulose in the food industry. J Dairy Sci 61(Suppl. 1):117

Saijonmaa T, Heikonen M, Kreula M, Linko P (1978) Preparation and characterization of milk sugar alcohol, lactitol. Milchwissenschaft 33:733–736

Schaafsma G (2008) Lactose and lactose derivatives as bioactive ingredients in human nutrition. Int Dairy J 18:458–465

Schuster-Wolff-Bühring R, Fischer L, Hinrichs J (2010) Production and physiological action of the disaccharide lactulose. Int Dairy J 20:731–741

Seki N, Saito H (2012) Lactose as a source for lactulose and other functional lactose derivatives. Int Dairy J 22:110–115

Silva AN, Perez R, Minim VPR, Martins DDS’A, Minim LA (2015) Integrated production of whey protein concentrate and lactose derivatives: what is the best combination? Food Res Int 73:62–74

Thelwall LAW (1985) Developments in the chemistry and chemical modification of lactose. In: Fox PF (ed) Developments in Dairy Chemistry-3: Lactose and Minor Constituents, Chapter 2. Elsevier Applied Science Publishers, London

Thelwall LAW (1986). Derivatives of lactose and their application in food products. In: Milk: The Vital Force, Proceedings of 22nd Int Dairy Congress, Reidel, Dordrecht, pp 749–759

USDEC – United States Dairy Export Council (2007) http://www.usdec.org/. Accessed 14 Jan 2016

Vaheri M, Kauppinen V (1978) The formation of lactulose (4-o-beta-galac-topyranosylfructose) by beta-galactosidase. Acta Pharmaceutica Fennica 87:75–83

Veloso ACA, Teixeira N, Ferreira IM (2002) Separation and quantification of the major casein fractions by reverse-phase high-performance liquid chromatography and urea-polyacrylamide gel electrophoresis – Detection of milk adulterations. J Chromatogr A 967:209–218

Walstra P, Jenness R (1984) Carbohydrates. In: Dairy Chemistry and Physics, Chapter 3. Wiley, New York

Webb B, Whittier EO (eds) (1970) By-products from milk. AVI publishing Co Inc, Westport

Wong NP, Jenness R, Keeney M, Marth EH (eds) (1988) Fundamentals of Dairy Chemistry. AVI, Van Nostrand Reinhold Company Inc, New York

Yang ST, Silva EM (1995) Novel products and new technologies for use a familiar carbohydrate, milk lactose. J Dairy Sci 78:2541–2562

Zadow JG (1984) Lactose: properties and uses. J Dairy Sci 67:2654–2679

Zadow JG (1986). The use of lactose in food products. In: Milk: The vital force. Proceed 22nd Int Dairy Congress, Reidel, Dordrecht, 737–748

Zimmer FC, Souza AHP, Silveira AFC, Santos MR, Matsushita M, Souza NE, Rodrigues AC (2017) Application of factorial design for optimization of the synthesis of lactulose. J Braz Chem Soc 28(12):2326–2333

Acknowledgments

This work is based upon the work from COST Action 18101 SOURDOMICS – Sourdough biotechnology network towards novel, healthier and sustainable food and bioprocesses (https://sourdomics.com/; https://www.cost.eu/actions/CA18101/), where the author J.M.R. is the Chair and Grant Holder Scientific Representative and is supported by COST (European Cooperation in Science and Technology) (https://www.cost.eu/). COST is a funding agency for research and innovation networks. The authors have no conflicts of interest whatsoever to declare.

Funding

This research received no external funding.

Author information

Authors and Affiliations

Contributions

Individual contributions from authors to this manuscript were as follows. Author J.M.R. contributed to the conceptualization, methodology, writing—original draft preparation, writing—review and editing, visualization, supervision and validation. Author M.A.G. contributed to the conceptualization, writing—original draft preparation and validation.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflict of interest.

Competing interests

No competing interests. Not applied.

Ethics approval

This manuscript is in compliance with ethical requirements.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rocha, J.M., Guerra, A. On the valorization of lactose and its derivatives from cheese whey as a dairy industry by-product: an overview. Eur Food Res Technol 246, 2161–2174 (2020). https://doi.org/10.1007/s00217-020-03580-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-020-03580-2