Abstract

The irritable bowel syndrome (IBS) is a functional disorder of the gastrointestinal tract that may afflict even 12% of the European population. One of the ways to counteract IBS-related ailments is to implement a diet with reduced contents of fermentable oligosaccharides, disaccharides, monosaccharides, and polyols (FODMAPs). The prevailing components from the FODMAPs group that may be found in rye bread include fructans. The study was conducted with endosperm and wholemeal rye flours. Dough was prepared from both flours with the use of two methods: I-stage method—with the addition of dry leavening—and II-stage method with the use of a sourdough produced with Lactobacillus plantarum, and all with fermentation times of 90, 120, 150, and 180 min. After baking, bread loaves were subjected to quality and consumer analysis and fructan content determination. The endosperm rye flour used for bread-making revealed better baking properties. Bread made of this flour had a higher loaf volume and received higher scores in the consumer assessment than bread made with wholemeal. Study results conclude that the content of fructans in bread was significantly affected by the dough-making method, and that it was decreased by the use of the sourdough. In contrast, the extended fermentation time of dough failed to reduce the fructan content of the bread.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Cereals and cereal products are the major sources of carbohydrates in a well-balanced diet. They not only affect the physiological processes in the body that are essential to maintain a good health condition and to prevent diseases but are also rich in FODMAPs [1]. The FODMAPs represent a group of short-chain carbohydrates that escape absorption in the small intestine and are rapidly fermented in the upper section of the colon. They include fructans (inulin, oligofructose), galactooligosaccharides (GOS), lactose and polyols (sorbitol and mannitol), which may be found mainly in cereal products [2].

Fructans represent the prevailing group of FODMAP components in commonly consumed cereal products, such as groats, bread, breakfast cereals, pastas or biscuits. Considering the entire bread assortment, rye bread is the richest source of fructans [3]. According to Dodevska et al. [4], of the entire bread assortment, it is the rye bread that is the richest source of fructans. For instance, Besiekierski et al. [1] studied contents of short-chain carbohydrates in bread and confirmed that fructans are the major compounds in wholemeal rye bread (1.42 g/100 g) and in leavened rye bread (1.07 g/100 g). These authors detected also other FODMAP components, like mannitol and raffinose, but in trace amounts (0.20 g/100 g).

Fructans are carbohydrates produced from fructose units with or without glucose units, differing in their molecular structure. They may be divided into three main groups: inulin group, levan group, and branched group [4]. The inulin-type and levan-type fructans are linear fructans which contain β-(1,2) and β-(6,2) fructosyl-fructose bonds, respectively. Both types of these bonds occur in fructans with branched chains and may be split by such enzymes such as endoinulinase, exo-β-fructosidase, endolevanase, β-fructofuranosidase, and levansucrase. Endoinulinase and endolevanase influence internal bonds that generate oligosaccharides with a lower degree of polymerization, whereas exo-β-fructosidase and β-fructofuranosidase release terminal fructose [5].

In normal subjects, fructans—which serve as prebiotics—are beneficial substrates for the desired bacterial flora, in particular for bifidobacteria. These bacteria metabolize fructans to acetic and lactic acids, thus maintaining proper colonic pH and inhibiting the development of putrefying and pathogenic bacteria. In a human body, bifidobacteria from the Lactobacillus and Bifidobacterium genera and their metabolites excite the immune system, synthesize B-group vitamins and short-chain fatty acids that mitigate enteritis, as well as contribute to immunity improvement [6]. In turn, a diet with a low content of short-chain carbohydrates has been demonstrated to alleviate disease symptoms in patients suffering from IBS (irritable bowel syndrome) [6, 7].

The FODMAP components that were not digested and absorbed in the small intestine are easily fermentable by enteric microflora, which triggers symptoms of the irritable bowel syndrome. The IBS is a common disease, it is estimated to affect 7–21% of people in the world including gastrointestinal disorders such as chronic recurring flatulence, pain perceptible in the abdomen, and changes in defecation rhythm [8]. The mechanisms of FODMAP’s effects on the emergence of undesirable manifestations rely on the accumulation of gases (carbon dioxide, hydrogen, and methane) in the intestines as a result of the fermentation of FODMAPs and undigested molecules of simple and short-chain fatty acids produced by enteric bacteria. A high intake of oligosaccharides, which are rapidly fermented by the intestinal microflora, may cause flatulence and other unpleasant ailments which are benign for normal subjects but acute for IBS patients. Hence, reduced consumption of FODMAP-rich products is recommended in the case of the latter [3, 9, 10]. Previous research of Biesiekierski et al. [1] has demonstrated that the patients suffering from intolerance to gluten did not report a recurrence of the ailments after gluten implementation into their diet on condition that they stuck to the low-FODMAP diet.

Consumption of gluten-free cereal products is recommended among IBS patients. This recommendation, however, reduces the consumption of dietary fibre, which has a negative impact on the intestinal microflora. Therefore, the negative impact of the low-FODMAP diet, which usually consists of the complete elimination of dietary fibre-rich bread which causes unpleasant ailments of the gastrointestinal system, should be mitigated by the introduction of cereal products rich in dietary fibre but with low fructan content.

The use of sourdough in the production of wholemeal bread with specified FODMAP-oriented metabolic properties may help in a significant reduction of the content of undesirable fructans to the levels tolerable by patients (15 g/day) without compromising on the well-tolerable dietary fiber level and also in preserving the beneficial intestinal microbiome [6, 11].

In the bread-making process, part of the fructan is degraded by active invertase of yeast. The remaining fructans have a lower degree of depolymerization and are more rapidly fermentable than the fructans with higher molecular weights [6]. According to Katina et al. [12], by affecting cell wall degradation, the process of fermentation may lead to the release or synthesis of various active compounds. During fermentation, the native enzymes of the grain and enzymes synthesized during this process (e.g. amylases, xylanases, proteases) take part in the modification of the chemical composition of the raw materials, simultaneously affecting the content of fructans. Microflora of the leavening usually includes lactic acid bacteria which convert fructose into mannitol; hence mannitol degradation during the baking process of low-FODMAP products requires the presence of bacterial bacilli capable of mannitol fermentation. The mannitol-converting enzymes are present in lactic acid bacteria from the following groups: L. delbrueckii, L. casei, Lactobacillus plantarum, and L. salivarius. A predominating enzyme is the extracellular exofructase which exhibits over 80% of its maximal activity in a pH range of 4–6 and a temperature range of 30–60 °C. Fructan hydrolysis in the leavening releases fructose, part of which is conversed into mannitol by L. reuteri group microorganisms. The use of sourdough in the baking process causes the reduction and conversion of FODMAPs in rye flour; however, the extent of fructans reduction is affected by fermenting organisms, fermentation process, and cereal raw material. The production of bread with a low content of FODMAPs requires the presence of extracellular fructanase and lactic acid bacteria or yeast which expresses fructanase [6].

Some works have already been published regarding methods used to reduce fructan content in rye bread owing to their prevailing share as FODMAPs. Marco et al. [11] investigated changes in the content of fructans during the manufacture of rye bread and observed their greatest loss (from 5 to 1.9%) as a result of fermentation with the use of yeast coupled with lactic acid bacteria, whereas changes in fructan content observed by the mentioned authors upon the use of yeast only were significantly smaller (from 5 to 3.4%). However, Biesiekierski et al. [1] noticed differences in the content of fructans depending on the bread production method and flour type, i.e. bread made of wholemeal flour without the sourdough had the highest content of this oligosaccharide. In turn, studies conducted by Menezes et al. [5] have demonstrated that lactic acid bacteria used together with bakery yeast showed the best results in terms of saccharide consumption during wheat dough fermentation. Ziegler et al. [13] proved that prolonged proofing times by yeast only led to effective FODMAP reduction.

The first randomized trials performed by Laatikainen et al. [2] with rye bread have demonstrated that the low-FODMAPs bread offers multiple benefits to IBS patients. First, it represents an excellent source of dietary fiber which is a scarce component in their diet. Second, it induces a lower number of unpleasant symptoms from the gastrointestinal system, like flatulence or abdominal pains.

The aim of this study was to produce rye bread made from endosperm and wholemeal flours with a reduced content of fructans by means of the use of sourdough as a source of lactic acid bacteria L. plantarum in combination with extended fermentation time with Saccharomyces cerevisiae yeast.

Materials and methods

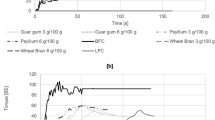

The experimental material included rye grain that was ground in a Quadrumat Senior laboratory grinder (Brabender, Germany) into wholemeal flour and endosperm flour. Ash content for both flours was determined by AOAC method [14], described in detail by Dubat [15]. The quality of flours was established based on the determination of flour particle size, falling number [16], protein content assayed with the Kjeldahl method using a nitrogen-to-protein conversion factor of 6.25 [17], and rheological parameters of dough evaluated with the Mixolab apparatus using the chopin + protocol lasting 45 min [18]. The weight of the dough was 80 g and the torque resulting from the water absorption of the flour was 1.1 N m. The temperature profile included dough mixing at 30 °C for 8 min followed by heating the dough to 90 °C at a rate of 4 °C/min. The temperature of 90 °C was maintained for 7 min and then the cooling started at a rate of 4 °C/min to reach 50 °C, which was kept for 5 min. At characteristic points, the temperature, time and torque were determined and selected results are presented in Table 2.

Dough was prepared with the I-stage and II-stage method. In the I-stage method, dough formula included flour 100%, water in the amount needed to obtain dough with a consistency of 250 FU, fresh Saccharomyces cerevisiae yeast 3.5%, and salt 1%. Because of the need for rye dough souring, in I-stage method where sourdough was not used, 5% rye dry leavening (Plenus Natura, Rzeszów, Poland) was added. In the II-stage method, dough was made with the use of a sourdough prepared with the addition of a pure culture of L. plantarum, which was left to ferment at a temperature of 30 °C and humidity of 85% for 24 h. In this method, the dough that consisted of leavening accounted for 50% of the flour in the dough and other components included in I-stage method (remaining part of flour and water as well the yeast and salt). The dough was mixed in a laboratory mixer (Stephan, Germany), then divided into four pieces of 500 g, placed in pans, transferred to a fermentation chamber (IBIS, Poland), and fermented for 60, 90, 120, and 150 min. After 1 h of each fermentation process (except for the first process, after which the dough was directly intended for baking), the dough was kneaded every 30 min, while the final fermentation lasted till the dough reached oven maturity. Afterwards, dough was baked into bread in an IBIS GT 600 oven (IBIS, Poland) at a temp. of 220 °C for 30 min.

After 24 h, the volume of bread was measured with a “Sa-Wy” apparatus (ZBPP Bydgoszcz, Poland) and expressed per 100 g of bread. The bread crust and crumb colour in CIELAB colour space were measured in five replicates with a Minolta Chroma Meter CR 410 (Konica Minolta, Japan). The consumer evaluation of bread was performed by ten persons aged 23–25, both males and females recruited among master's students, who used a 9-point hedonic scale. The evaluation involved the assessment of their appearance, crust colour, crumb colour, consistency, aroma, and taste. Lyophilized and disintegrated samples of flour and bread were analysed for the content of fructans with a fructan determination kit based on the AACC Method [19].

Parameters of flour were compared with the one-way analysis of variance at α = 0.05. In turn, the multi-way analysis of variance was used to compare the effects of dough development method, fermentation time, and flour type on the quality parameters and fructan content of rye bread. Homogenous groups were determined with Duncan’s test. All statistical analyses were performed using Statistica 13.3 software (StatSoft Polska Sp. z o.o., Poland).

Results and discussion

Rye flour quality

The analysed quality parameters of rye flour including falling number, particle size, protein content, and fructan content results are presented in Table 1. The whole meal flour was characterized by greater particle size, a higher falling number, and higher protein and fructan contents, compared to the endosperm flour.

The whole meal flour was composed of more coarse particles (122 µm) compared to the flour with a lower ash content (97 µm). The technological value of rye flour, determined based on the activities of its amylolytic enzymes, is expressed as the falling number. The falling number of the wholemeal flour was high (210 s), whereas the endosperm flour reached a falling number of 182 s, which was indicative of the medium level of α-amylases. In turn, rye flour bread types made with high falling number values, i.e. with low α-amylase activity, are characterized by a coarse and more compact crumb structure and are less susceptible to souring [20]. The wholemeal flour differs from the endosperm flour also in protein content, i.e. the endosperm flour contains ca. 6 g/100 g d.m., whereas wholemeal flour—ca. 9 g/100 g d.m. of protein.

The analysis of fructan content in both types of flour demonstrated their significantly higher content in the wholemeal flour (4.57 g/100 g d.m.) than in the flour with a lower yield (4.35 g/100 g d.m.). A similar observation was made for rye flour by Jasińska-Kuligowska et al. [21], who concluded that the fructan content depends on the share of kernel anatomical part. The highest content of fructans—from 6.6 g/100 g d.m. to 7.7 g/100 g d.m.—is found in the bran, whereas the lowest one reaching ca. 3.1 g/100 g d.m. in light flours [21].

The baking value of the flour was assessed using the Mixolab apparatus and evaluated by the following parameters: water absorption of flour, dough development time, dough stability and softening, peak viscosity, activity of amylolytic enzymes, and starch retrogradation. The results are shown in Table 2. Flour type had a significant effect on the values of water absorption and dough stability. The dough made of the wholemeal flour had higher values of water absorption and dough stability than endosperm flour dough due to higher concentration of dietary fibre.

Rye bread quality

The assessed rye bread quality parameters included loaf volume as well as L*, a*, and b* colour parameters of crust and crumb shown in Table 3. Most of these parameters were significantly affected by three factors: flour type, dough development method, and dough fermentation time. The bread made of the endosperm flour had a higher loaf volume as well as brighter and more yellow crust and crumb compared to the wholemeal bread. In turn, the colour of wholemeal bread was characterized by darker crust and crumb with warmer hues than the bread made of the endosperm flour. Fragments of fruit-seed coat rich in mineral compounds and dietary fibre are responsible for the colour of wholemeal flour bread [22, 23].

The method of dough development had a significant effect on loaf volume, crust colour, and crumb colour (Table 3). The bread produced with the I-stage method was characterized by a higher loaf volume and by a lighter colour of crust and crumb, compared to the bread made with the II-stage method. In contrast, the colour of bread made with II-stage method was characterized by more reddish (a higher value of parameter a*) and more yellow (a higher value of parameter b*) crust and crumb colour compared to the bread produced with the I-stage method.

Duration of dough fermentation had a significant effect on loaf volume as well as L*, a*, and b* colour parameters of crust and crumb (Table 3). Bread loaf reached the highest volume at dough fermentation time of 150 min, and the lowest one at 90 min. The brightest crust colour (higher values of parameter L*) was obtained for bread made of dough allowed to ferment for 90 and 180 min, and the darkest one for bread made of dough allowed to ferment for 150 min. In the case of the 120-min fermentation, the crust was characterized by the warmest hue (parameter a*), whereas in the case of the longest fermentation time the crust had the most golden colour (parameter b*).

Bread volume reflects the quality of raw materials and technological process used in the bread making. The higher the loaf volume at the same weight, the better its quality, because bread dough has a greater capability of carbon dioxide production and retention during baking. In our study, bread made of the endosperm flour had higher volume than bread made of wholemeal flour and bread made with the I-stage method had a higher volume than those made with the II-stage method. The negative correlation of the falling number with the volume of bread is reported by Szafrańska and Słowik [24].

Loaf volume increased along with fermentation time till the 150th min when it reached the highest value of 242 cm3/100 g. Afterwards, loaf volume decreased insignificantly to 225 cm3/100 g. Fuckerer et al. [25] noted a decrease in the volume of bread with an increase in pH in the range from 13.0 to 28.3%. Segichi et al. [26] reported that the volume of wheat bread resulted primarily from the baking properties of flour and the amount of acetic acid whose excess contributed to the reduction of bread volume. Extending the fermentation time causes the accumulation of lactic acid, which contributes to the worsening of rheological properties of the dough and decreases the volume of bread. The colour of bread crust and crumb was evaluated based on L*, a*, and b* parameters. The crust and crumb of the bread made of the endosperm flour had a brighter colour compared to bread made of whole meal flour which is characterized by a darker colour due to the higher percentage of the seed coat. The bread made of dough developed with the I-stage method had brighter crumb and crust than the bread produced with the II-stage method. In turn, the latter had more yellowish crust and crumb. In addition, it was noticed that with prolonged fermentation time, the colour of crumb turned darker and that of the crust turned more golden.

Consumer evaluation

The consumer evaluation made by a group of persons included the evaluation of appearance, crust colour, crumb colour, consistency, aroma, and taste of rye bread (Table 4). Statistical computations demonstrate that results of the consumer assessment were significantly influenced by the flour type and dough development method. Flour type had a significant effect on appearance, crust colour, crumb colour, consistency, aroma, and taste. The bread made of the endosperm flour received higher scores for all quality attributes assessed, compared to the wholemeal bread. The dough development method had a significant effect on bread crust colour and taste. Higher scores for crust colour and taste were obtained for bread produced with the I-stage method than those produced with the II-stage method. Other evaluated parameters were not influenced by the bread production method. In turn, Brandt [27] showed that the bread with the addition of dry leavening had worse aroma and taste. Bread made with traditional sourdough has higher contents of volatile compounds and, therefore, iis better scored in the consumer assessment. Lactic acid and acetic acid produced during sourdough fermentation with lactic acid bacteria contribute to the characteristic aroma and taste of bread. Dry leavenings are usually produced by dehydration of natural leavenings, whereas the drying process results in loss of volatile compounds and valuable acetic acid, which consequently deteriorates the flavour values of the finished product [20].

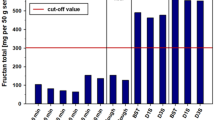

Fructan content

The reduction of fructans in the bread was the primary objective of this study. Their content in the analysed samples was the same (2.25 g/100 g d.m.) upon the use of both types of flour, i.e. endosperm flour and wholemeal (Fig. 1). A similar content of fructans (2.2 g/100 g d.m.) in rye bread was also determined by Dodevska et al. [4]. The fructan content in rye bread was significantly influenced only by the dough development method. The use of the II-stage method, due to the preliminary fermentation by L. plantarum bacteria, contributed to fructan content decrease compared to the I-stage method. The bread made of dough developed with the I-stage method contained 2.6 g/100 g d.m. of fructans in dry matter, whereas in the bread produced with the II-stage method, their content reached 1.9 g/100 g d.m. Similar conclusions were drawn by Jasińska-Kuligowska et al. [21] who demonstrated that fermentation with the sourdough using pure cultures of L. plantarum had a significant impact on fructan level reduction in rye bread. In the study of Anderson et al. [28] the content of fructans in bread fermented with the use of yeast and bacteria was also significantly lower than in bread fermented with yeast alone. Fraberger et al. [29] analysed 13 strains of microorganisms for their fructan-reducing capability. In each case, microbiota metabolism led to a significant decrease in the fructan content in the bread, even by 83% compared to the control bread. In turn, time of dough relatively short fermentation by yeast (90–180 min) had no effect on fructan content in bread. Menezes et al. [5] claimed that the biotechnology of leavening required longer fermentation time. Short fermentation spanning for 30–180 min inhibits the hydrolysis of FODMAP components. All fermentable carbohydrates (saccharose, maltose, glucose, and fructose) rapidly deplete in the first hours of the fermentation process, whereas these with a higher degree of polymerization (like fructans) undergo hydrolysis in a longer time.

Conclusions

Fructans are the prevailing FODMAP carbohydrates in rye bread. To produce low-fructan bread, analyses were conducted to determine the effects of the following factors on their content: flour type, dough development method, and time of dough fermentation. The use of the II-stage method of bread making, in which L. plantarum sourdough was used, caused a significant decrease in fructan content in the final rye bread to 1.90% comparing to bread made with I-stage method (2.61%). The effects of flour type and prolonged dough fermentation by yeast on fructan content decrease in the bread were not so significant. The method of dough preparation affects also rye bread quality. The bread made of dough prepared with the I-stage method, in which dry leavening addition was used instead of sourdough, reached a higher loaf volume, was characterized by brighter crust and crumb colour, and received higher scores in consumer assessment for crust colour and taste values. In turn, the bread made of dough prepared with the II-stage method was characterized by finer crumb porosity and more golden hue of crust and crumb colour compared to the bread produced with the I-stage method. This study demonstrated that it was feasible to produce rye bread with a reduced content of fructans using an appropriate method for dough development and lactic acid bacteria from the L. plantarum genus. Future investigations into the feasibility of producing low-FODMAP rye bread would aim at further optimization of dough development methods, choice of bacterial strains for leavening production, and extension of dough fermentation time.

References

Biesiekierski RJ, Rosella O, Rose R, Liels K, Barrett JS, Shepherd SJ, Gibson PR, Muir JG (2011) Quantification of fructans, galacto-oligosaccharides and other short-chain carbohydrates in processed grains and cereals. J Acad Nutr Diet 24:154–176

Laatikainen R, Koskenpato J, Hongisto S-M, Loponen J, Poussa T, Hillilä M, Korpela R (2016) Randomised clinical trial: low—FODMAP rye bread vs. regular rye bread to relieve the symptoms of irritable bowel syndrome. Aliment Pharmacol Ther 44(5):460–470

Whelan K, Abrahmsohn O, David GJP, Staudacher H, Irving P, Lomer MCE, Ellis PR (2011) Fructan content of commonly consumed wheat, rye and gluten-free breads. Int J Food Sci Nutr 62(5):498–503

Dodevska MS, Djordjevic BI, Sobajic SS, Miletic ID, Djordjevic PB, Dimitrijevic-Sreckovic VS (2013) Characterisation of dietary fibre components in cereals and legumes used in Serbian diet. Food Chem 141:1624–1629

Menezes LAA, Minervini F, Filannino P, Sardaro MLS, Gatti M, De Dea LJ (2018) Effects of sourdough on FODMAPs in bread and potential outcomes on irritable bowel syndrome patients and healthy subjects. Front Microbiol 9:1–7

Loponen J, Gänzle M (2018) Use of sourdough in low FODMAP baking. Foods 7(96):1–12

Rao SSC, Yu S, Fedewa A (2015) Systematic review: dietary fibre and FODMAP-restricted diet in the management of constipation and irritable bowel syndrome. Aliment Pharmacol Ther 41:1256–1270

Lovell RM, Ford AC (2012) Global prevalence of and risk factors for irritable bowel syndrome: a meta-analysis. Clin Gastroenterol Hepatol 10(7):712–721

El-Salhy M, Gundersen D (2015) Diet in irritable bowel syndrome. Nutr J 14:36

Mansueto P, Seidita A, D’Alcamo A, Carroccio A (2015) Role of FODMAPs in patients with irritable bowel syndrome. Nutr Clin Pract 30(5):665–682

Marco ML, Heeney D, Binda S, Cifelli CJ, Cotter PD, Foligné B, Gänzle M, Kort R, Pasin G, Pihlanto A, Smid EJ, Hutkins R (2017) Health benefits of fermented foods: microbiota and beyond. Curr Opin Biotechnol 44:94–102

Katina K, Liukkonen KH, Kaukovirta-Norja A, Adlercreutz H, Heinonen S-M, Lampi AM, Pihlava J-M, Poutanen K (2007) Fermentation-induced changes in the nutritional value of native or germinated rye. J Cereal Sci 46:348–355

Ziegler JU, Steiner D, Longin CFH, Würschum T, Schweiggert RM, Carle R (2016) Wheat and the irritable bowel syndrome- FODMAP levels of modern and ancient species and their retention during bread making. J Funct Foods 25:257–266

AOAC (2005) Official methods of analysis of the association of official analytical chemists international. Method 930.05. Ash of Plants. USA: Maryland

Dubat A (2010) A new AACC international approved method to measure rheological properties of a dough sample. Cereal Foods World 55(3):150–153

AACC Method 56-81.03 (2010) Determination of falling number. AACC international. Approved methods of analysis

AACC Intl. 46-12.01 (2010) Crude protein—Kjeldahl method, boric acid modification. AACC international. Approved methods of analysis

AACC Method 54-60.01 (2010) Determination of rheological behavior as a function of mixing and temperature increase in wheat flour and whole wheat meal by mixolab. AACC international. Approved methods of analysis.

AACCI Method 32-32.01 (2010) Measurement of total fructan in foods by an enzymatic/spectrophotometric method. AACC International, St. Paul. AACC International. Approved methods of analysis

Gänzle M (2014) Enzymatic and bacterial conversions during sourdough fermentation. Food Microbiol 27:2–10

Jasińska-Kuligowska I, Kuligowski M, Kołodziejczyk P, Michniewicz J (2013) Wpływ procesów fermentacji, ekstruzji i wypieku na zawartość fruktanów w produktach żytnich. ZYWN Nauk Technol Ja 5(90):129–141

Bushuk W (2001) Rye: production, chemistry, and technology. AACC Incorporated, 2nd edn. St. Paul, Minnesota, pp 63–110

Koistinen VM, Mattila O, Katina K (2018) Metabolic profiling of sourdough fermented wheat and rye bread. Sci Rep 8:5684

Szafrańska A, Słowik E (2014) Zmiany właściwości wypiekowch mąki żytniej pod wpływem dodatku alfa-amylazy. Acta Agrophysica 21(2):233–245

Fuckerer K, Treude J, Hensel O, Schmitt JJ (2016) Influence of calcium acetate on rye bread volume. Food Sci Technol 36(3):401–405

Seguchi M, Hayashi M, Matsumoto H (1997) Effect of gaseous acetic acid on dough rheological and breadmaking properties. Cereal Chem 74(2):129–134

Brandt M (2007) Sourdough products for convenient use in baking. Food Microbiol 24:161–164

Andersson R, Fransson G, Tietjen M, Åman P (2009) Content and molecular-weight distribution of dietary fiber components in whole-grain rye flour and bread. J Agric Food Chem 57:2004–2008

Fraberger V, Call L-M, Domig KJ, D’Amico S (2018) Applicability of yeast fermentation to reduce fructans and other FODMAPs. Nutrients 10(9):1247

Acknowledgements

Publication supported by the Wroclaw Centre of Biotechnology under the Leading National Research Centre Program (KNOW) 2014–2018 and purpose subsidy 2019 (MNiSW) for the Faculty of Biotechnology and Food Science, Wrocław University of Environmental and Life Sciences. The authors thank Emilia Jamik for contributing to the research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Compliance with ethics requirements

This article does not contain any studies with human or animal subjects performed by the any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Pejcz, E., Spychaj, R. & Gil, Z. Technological methods for reducing the content of fructan in rye bread. Eur Food Res Technol 246, 1839–1846 (2020). https://doi.org/10.1007/s00217-020-03537-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-020-03537-5