Abstract

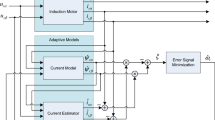

This paper presents MRAS speed sensorless control of induction motor using type-2 fuzzy logic controller (T2FLC). These controllers replace the PI ones, in the new MRAS strategy proposed in Benlaloui et al. (IEEE Trans Energy Convers 30(2):588–595, 2015), in order to improve the induction motor performances and robustness at low speed region. Indeed, the choice of these controllers is made because of their adaptation-based schemes which permit to handle nonlinear uncertain systems without the need of precise mathematical model required when using PI controllers. Comparative study had shown a better rejection of disturbance and high insensitivity to stator resistance compared to the PI and the T1FLC controllers. The effectiveness of the proposed speed-based T2FLC estimation method and its good robustness are validated by simulation and by experimental results.

Similar content being viewed by others

Abbreviations

- MRAS:

-

Model Reference Adaptive System

- T2FLC:

-

Type-2 Fuzzy Logic Controller

- IM:

-

Induction machines

- FOC:

-

Field-oriented control

- PI:

-

Proportional–integral

- IFOC:

-

Indirect field-oriented control

- s, r :

-

Rotor and stator indices

- d, q :

-

Direct and quadrate indices for orthogonal components

- P :

-

Number of pairs poles

- Ω :

-

Rotor speed (rd/s)

- ω r :

-

Induced rotor current frequency (rd/s)

- J in :

-

Inertia

- Γ :

-

Unknown torque

- *:

-

Symbol indicating the command value

- \(\overline{x}^{*}\) :

-

Complex conjugate

- \(R_{{\text{s}}} ,R_{{\text{r}}}\) :

-

Stator and rotor resistances

- \(L_{s} ,L_{r}\) :

-

Stator and rotor inductances

- \(T_{{\text{s}}} ,T_{{\text{r}}}\) :

-

Stator and rotor time constants (Ts,r = Ls,r/Rs, r)

- σ :

-

Leakage flux total coefficient (σ = 1 − M2/LrLs)

- M :

-

Mutual inductance

- ω :

-

Mechanical rotor frequency (rd/s)

- ω s :

-

Stator current frequency (rd/s)

- f :

-

Coefficient of viscous

- Γ e :

-

Electromagnetic torque

References

Ha J-I, Sul S-K (1999) Sensorless field-orientation control of an induction machine by high-frequency signal injection. IEEE Trans Ind Appl 35(1):45–51. https://doi.org/10.1109/28.740844

Maiti S, Chakraborty C, Hori Y, Ta MC (2008) Model reference adaptive controller-based rotor resistance and speed estimation techniques for vector controlled induction motor drive utilizing reactive power. IEEE Trans Ind Electron 55(2):594–601. https://doi.org/10.1109/TIE.2007.911952

Comanescu M, Xu L (2006) Sliding-mode MRAS speed estimators for sensorless vector control of induction machine. IEEE Trans Ind Electron 53(1):146–153. https://doi.org/10.1109/TIE.2005.862303

Ravi Teja AV, Verma V, Chakraborty C (2015) A new formulation of reactive-power-based model reference adaptive system for sensorless induction motor drive. IEEE Trans Ind Electron 62(11):6797–6808. https://doi.org/10.1109/TIE.2015.2432105

Zorgani YA, Koubaa Y, Boussak M (2016) MRAS state estimator for speed sensorless ISFOC induction motor drives with Luenberger load torque estimation. ISA Trans 61:308–317. https://doi.org/10.1016/j.isatra.2015.12.015

Das S, Kumar R, Pal A (2019) MRAS-based speed estimation of induction motor drive utilizing machines’ d- and q-circuit impedances. IEEE Trans Ind Electron 66(6):4286–4295. https://doi.org/10.1109/TIE.2018.2860530

Kumar R, Das S, Bhaumik A (2019) Speed sensorless model predictive current control of doubly-fed induction machine drive using model reference adaptive system. ISA Trans 86:215–226. https://doi.org/10.1016/j.isatra.2018.10.025

Dehghan-Azad E, Gadoue S, Atkinson D, Slater H, Barrass P, Blaabjerg F (2018) Sensorless control of IM based on stator-voltage MRAS for limp-home EV applications. IEEE Trans Power Electron 33(3):1911–1921. https://doi.org/10.1109/TPEL.2017.2695259

Korzonek M, Tarchala G, Orlowska-Kowalska T (2019) A review on MRAS-type speed estimators for reliable and efficient induction motor drives. ISA Trans 93:1–13. https://doi.org/10.1016/j.isatra.2019.03.022

Sun X, Chen L, Yang Z, Zhu H (2013) Speed-sensorless vector control of a bearingless induction motor with artificial neural network inverse speed observer. IEEE/ASME Trans Mechatron 18(4):1357–1366. https://doi.org/10.1109/tmech.2012.2202123

Sun X, Hu C, Lei G, Yang Z, Guo Y, Zhu J (2020) Speed sensorless control of SPMSM drives for EVs with a binary search algorithm-based phase-locked loop. IEEE Trans Veh Technol 69:4968–4978. https://doi.org/10.1109/tvt.2020.2981422

Sun X, Cao J, Lei G, Guo Y, Zhu J (2020) Speed sensorless control for permanent magnet synchronous motors based on finite position set. IEEE Trans Ind Electron 67(7):6089–6100. https://doi.org/10.1109/tie.2019.2947875

Hinkkanen M, Luomi J (2003) Modified integrator for voltage model flux estimation of induction motors. IEEE Trans Ind Electron 50(4):818–820. https://doi.org/10.1109/TIE.2003.814996

Pal A, Das S, Chattopadhyay AK (2018) An improved rotor flux space vector based MRAS for field-oriented control of induction motor drives. IEEE Trans Power Electron 33(6):5131–5141. https://doi.org/10.1109/TPEL.2017.2657648

Smith AN, Gadoue SM, Finch JW (2016) Improved rotor flux estimation at low speeds for torque MRAS-based sensorless induction motor drives. IEEE Trans Energy Convers 31(1):270–282. https://doi.org/10.1109/TEC.2015.2480961

Rashed M, Stronach AF (2004) A stable back-EMF MRAS-based sensorless low-speed induction motor drive insensitive to stator resistance variation. IEE Proc Electr Power Appl 151(6):685. https://doi.org/10.1049/ip-epa:20040609

Zaky MS, Khater MM, Shokralla SS, Yasin HA (2009) Wide-speed-range estimation with online parameter identification schemes of sensorless induction motor drives. IEEE Trans Ind Electron 56(5):1699–1707. https://doi.org/10.1109/TIE.2008.2009519

Huang S, Wang Y, Gao J, Lu J, and Qiu S (2004) The vector control based on MRAS speed sensorless induction motor drive. In: Fifth world congress on intelligent control and automation (IEEE Cat. No. 04EX788), 5: 4550–4553. https://doi.org/10.1109/wcica.2004.1342378

Karanayil B, Rahman MF, Grantham C (2004) An implementation of a programmable cascaded low-pass filter for a rotor flux synthesizer for an induction motor drive. IEEE Trans Power Electron 19(2):257–263. https://doi.org/10.1109/TPEL.2003.823181

Benlaloui I, Drid S, Khamari D, Chrifi-Alaoui L, Marhic B, and Ouriagli M (2016) Analysis and design of rotor MRAS speed sensorless with a novel approach. In: 2016 17th International conference on sciences and techniques of automatic control and computer engineering (STA) 4:73–77. https://doi.org/10.1109/STA.2016.7952016

Benlaloui I, Drid S, Chrifi-Alaoui L, Ouriagli M (2015) Implementation of a new MRAS speed sensorless vector control of induction machine. IEEE Trans Energy Convers 30(2):588–595. https://doi.org/10.1109/STA.2016.7952016

Hakju L, Jaedo L, and Sejin S (2001) Approach to fuzzy control of an indirect field-oriented induction motor drives. In: ISIE 2001. 2001 IEEE international symposium on industrial electronics proceedings (Cat. No. 01TH8570) 2(1):1119–1123. https://doi.org/10.1109/ISIE.2001.931633

Badr BM, Eltamaly AM, Alolah AI (2010) Fuzzy controller for three phases induction motor drives. IEEE Veh Power Propuls Conf 2010:1–6. https://doi.org/10.1109/VPPC.2010.5729080

Khemis A, Benlaloui I, Drid S, Chrifi-Alaoui L, Khamari D, Menacer A (2018) High-efficiency induction motor drives using type-2 fuzzy logic. Eur Phys J Plus 133(3):86. https://doi.org/10.1140/epjp/i2018-11903-6

Ramesh T, Kumar Panda A, Shiva Kumar S (2015) Type-2 fuzzy logic control based MRAS speed estimator for speed sensorless direct torque and flux control of an induction motor drive. ISA Trans 57:262–275. https://doi.org/10.1016/j.isatra.2015.03.017

Phukon LJ, Baruah N (2015) Design of fuzzy logic controller for performance optimisation of induction motor using indirect. Int J Electr Electron Data Commun 3(2):72–78

Rashed Mohan Krishna S, Febin Daya JL (2016) MRAS speed estimator with fuzzy and PI stator resistance adaptation for sensorless induction motor drives using RT-lab. Perspect Sci 8:121–126. https://doi.org/10.1016/j.pisc.2016.04.013

Hong Y-Y, Buay PMP (2020) Robust design of type-2 fuzzy logic-based maximum power point tracking for photovoltaics. Sustain Energy Technol Assess 38:100669. https://doi.org/10.1016/j.seta.2020.100669

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix

Machine parameters and rated values

Rr = 5.1498 Ω; Rs = 12.75 Ω; M = 0. 4331 H; Ls = 0. 4991 H; Lr = 0.4331 H; J = 0.0035 kg m2; f = 0.001 Nm s/rd; Pn = 0.9 kW; n = 1400 rpm; p = 2; f = 50 Hz; load torque = 10 Nm.

Rights and permissions

About this article

Cite this article

Benlaloui, I., Chrifi-Alaoui, L., Ouriagli, M. et al. Improvement of the induction motor sensorless control based on the type-2 fuzzy logic. Electr Eng 103, 1473–1482 (2021). https://doi.org/10.1007/s00202-020-01178-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00202-020-01178-1