Abstract

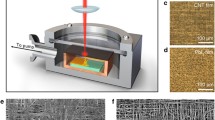

High-resolution 3D printing technologies can print thin films; however, they are not commonly available because of their high initial cost, and the majority of them employ a pneumatic-driven printing technique that hinders retraction, which is crucial for printing complex geometries. The main objective of this paper is to modify an extrusion-based 3D printing technology and investigate its potential for thin-film printing for electronic device applications like perovskite solar cells (PSCs). The modification is done by replacing the filament extrusion system with a liquid extrusion system using a syringe pump. CAD software, CATIA V5R20, is used to model the parts of the syringe pump, which are then 3D printed from polylactic acid (PLA) filaments. To validate the functionality of the modified 3D printer for thin-film printing, a physical experiment is conducted to print a poly 3,4-ethylenedioxythiophene:polystyrene sulfonate (PEDOT:PSS) solution, a widely used conductive polymer, by varying the 3D printing parameters, namely; print speed, bed temperature, nozzle diameter, and x-distance offset. Based on the experiment, a thin PEDOT:PSS film was successfully printed with a thickness of 142 nm and a notable level of surface uniformity when compared to the spin coating. Further, the modified 3D printer is utilized to print a PEDOT:PSS and a perovskite methylammonium leadtriiodide-chloride (CH3NH3PbI3 − xClx) solution in a layer-by-layer fashion sequentially and tested for validity for perovskite solar cell (PSC) application by printing other layers of PSC on top of the perovskite layer using the spin coating method. Based on the test conducted, a competitive open-circuit voltage of 740 mV was successfully generated from the printed PSC. Finally, it has been observed that extrusion-based 3D printing technology can be modified and optimized to print thin films for PSC applications. This has tremendous advantages for rapidly printing and testing electronic devices in general, and PSCs in particular.

Similar content being viewed by others

Data availability

The paper covers all of the data except the G-code, which will be provided upon request.

References

Su A, Al’Aref SJ (2018) History of 3D printing. In: In 3D printing applications in cardiovascular medicine. Academic Press, pp 1–10

Horvath J, Horvath J (2014) A brief history of 3D printing. Mastering 3D Printing:3–10

Deng C, Kang J, Shangguan H, Hu Y, Huang T, Liu Z (2018) Effects of hollow structures in sand mold manufactured using 3D printing technology. J Mater Process Technol 255:516–523

McCullough EJ, Yadavalli VK (2013) Surface modification of fused deposition modeling ABS to enable rapid prototyping of biomedical microdevices. J Mater Process Technol 213(6):947–954

Aimar A, Palermo A, Innocenti B (2019) The role of 3D printing in medical applications: a state of the art. J Healthc Eng 2019

Bose S, Robertson SF, Bandyopadhyay A (2018) Surface modification of biomaterials and biomedical devices using additive manufacturing. Acta Biomater 66:6–22

Ford S, Minshall T (2019) Invited review article: where and how 3D printing is used in teaching and education. Addit Manuf 25:131–150

Wang G, Zhu K, Zhou L, Guo M, Chen H, Yan Z, Pan D, Jeong J, Park H, Lee Y, Kang J, Chun J (2021) Developing parametric design fashion products using 3D printing technology. Fash Text 8:1–25

Liang C, Li P, Gu H, Zhang Y, Li F, Song Y et al (2018) One-step inkjet printed perovskite in air for efficient light harvesting. Sol RRL 2(2):1700217

Bag S, Deneault JR, Durstock MF (2017) Aerosol-jet-assisted thin-film growth of CH3NH3PbI3 perovskites—a means to achieve high quality, defect-free films for efficient solar cells. Adv Energy Mater 7(20):1701151

Knott A, Makarovskiy O, O’Shea J, Wu Y, Tuck C. Scanning photocurrent microscopy of 3D printed light trapping structures in dye-sensitized solar cells

Zhu M, Duan Y, Liu N, Li H, Li J, Du P et al (2019) Electrohydrodynamically printed high-resolution full-color hybrid perovskites. Adv Funct Mater 29(35):1903294

Muldoon K, Song Y, Ahmad Z, Chen X, Chang MW (2022) High precision 3D printing for micro to nano scale biomedical and electronic devices. Micromachines 13(4):642

Mao M, He J, Li X, Zhang B, Lei Q, Liu Y, Li D (2017) The emerging frontiers and applications of high-resolution 3D printing. Micromachines 8(4):113

Wilkinson NJ, Smith MAA, Kay RW, Harris RA (2019) A review of aerosol jet printing—a non-traditional hybrid process for micro-manufacturing. Int J Adv Manuf Technol 105:4599–4619

Hunde BR, Woldeyohannes AD (2023) 3D printing and solar cell fabrication methods: a review of challenges, opportunities, and future prospects. Results Opt 11, 100385

Tümer EH, Erbil HY (2021) Extrusion-based 3D printing applications of PLA composites: a review. Coatings 11(4):390

James S, Contractor R (2018) Study on nature-inspired fractal design-based flexible counter electrodes for dye-sensitized solar cells fabricated using additive manufacturing. Sci Rep 8:17032

Vak D, Hwang K, Faulks A, Jung YS, Clark N, Kim DY et al (2015) 3D printer based slot-die coater as a lab-to-fab translation tool for solution-processed solar cells. Adv Energy Mater 5:1401539

Ahn BY, Duoss EB, Motala MJ, Guo X, Park S-I, Xiong Y et al (2009) Omnidirectional printing of flexible, stretchable, and spanning silver microelectrodes. Science 323:1590–1593

Chen M, Yang J, Wang Z, Xu Z, Lee H, Lee H et al (2019) 3D nanoprinting of perovskites. Adv Mater 31:1904073

Jiang Y, Chen Y, Zhang M, Qiu Y, Lin Y, Pan F (2016) 3D-printing Ag-line of front-electrodes with optimized size and interface to enhance performance of Si solar cells. RSC Adv 6:51871–51876

Shi H, Liu C, Jiang Q, Xu J (2015) Effective approaches to improve the electrical conductivity of PEDOT:PSS: a review. Adv Electron Mater 1(4):1500017

Sun K, Zhang S, Li P, Xia Y, Zhang X, Du D et al (2015) Review on application of PEDOTs and PEDOT:PSS in energy conversion and storage devices. J Mater Sci Mater Electron 26:4438–4462

Lang U, Naujoks N, Dual J (2009) Mechanical characterization of PEDOT:PSS thin films. Synth Met 159(5-6):473–479

Nair S, Patel SB, Gohel JV (2020) Recent trends in efficiency-stability improvement in perovskite solar cells. Mater Today Energy 17:100449

Fu H (2019) Review of lead-free halide perovskites as light-absorbers for photovoltaic applications: from materials to solar cells. Sol Energy Mater Sol Cells 193:107–132

Green MA, Ho-Baillie A, Snaith HJ (2014) The emergence of perovskite solar cells. Nat Photonics 8(7):506–514

Tashman JW, Shiwarski DJ, Feinberg AW (2021) A high performance open-source syringe extruder optimized for extrusion and retraction during FRESH 3D bioprinting. HardwareX 9:e00170

Pusch K, Hinton TJ, Feinberg AW (2018) Large volume syringe pump extruder for desktop 3D printers. HardwareX 3:49–61

Koch F, Thaden O, Tröndle K, Zengerle R, Zimmermann S, Koltay P (2021) Open-source hybrid 3D-bioprinter for simultaneous printing of thermoplastics and hydrogels. HardwareX 10:e00230

Ahmadian-Yazdi MR, Rahimzadeh A, Chouqi Z, Miao Y, Eslamian M (2018) Viscosity, surface tension, density and contact angle of selected PbI2, PbCl2 and methylammonium lead halide perovskite solutions used in perovskite solar cells. AIP Adv 8(2)

Rahman I, Shahriar MA, Rahman S (2021) Numerical analysis of flow and heat transfer characteristics between two parallel plates with constriction (s). Comput Eng Phys Model 4:55–69

Hu L, Song J, Yin X, Su Z, Li Z (2020) Research progress on polymer solar cells based on PEDOT:PSS electrodes. Polymers 12(1):145

Qiu L, He S, Ono LK, Liu S, Qi Y (2019) Scalable fabrication of metal halide perovskite solar cells and modules. ACS Energy Lett 4(9):2147–2167

Kim DH, Whitaker JB, Li Z, van Hest MF, Zhu K (2018) Outlook and challenges of perovskite solar cells toward terawatt-scale photovoltaic module technology. Joule 2(8):1437–1451

Chan JM, Wang M (2022) Visualizing the orientation of single polymers induced by spin-coating. Nano Lett 22:5891–5897

Gao L, Huang K, Long C, Zeng F, Liu B, Yang J (2020) Fully slot-die-coated perovskite solar cells in ambient condition. Appl Phys A 126:1–7

Acknowledgements

We would like to express our deepest appreciation to the African-UniNet project for the financial support, to the Sustainable Energy Center of Excellence, Addis Ababa Science and Technology University, Addis Ababa, Ethiopia, and to the Linz Institute of Organic Solar Cells (LIOS), Institute of Physical Chemistry, JKU, Linz, Austria, for the lab facility provided.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hunde, B.R., Woldeyohannes, A.D. Modification of an extrusion-based 3D printing technology for thin-film printing for electronic device applications. Int J Adv Manuf Technol 132, 5537–5556 (2024). https://doi.org/10.1007/s00170-024-13588-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-024-13588-7