Abstract

A grinding wheel with orderly-micro-grooves is a new type of structured grinding wheel for grinding narrow-deep slots. It can improve the carrying capacity of the coolant in the grinding zone effectively. The wear and evolution of grains directly determine the sharpness of the grinding wheel, and this affects the grinding performance in terms of efficiency, surface integrity, and tool life. In order to design the grinding wheel for minimized wear in its use, this study elucidates the wear behaviors of the grinding wheel with orderly-micro-grooves in grinding narrow-deep slots. Through the comparative experiments of the grinding narrow-deep slot, the impacts of micro-grooves on the wear behaviors of the grinding wheel are evaluated, and the wear behavior of the grains on the cut-in edge, cut-out edge, cylindrical surface, and side surface is observed, respectively. The analysis of the grinding ratio, grinding force, and force ratio further verifies the analysis of the wear mechanism and the grinding performance. It is found that (1) the macro-fracture of grain on the cut-in edge occurred due to the large cutting thickness increasing the load of the grain; (2) the debonding phenomenon reduces the anchoring force of the grain, and this tends to pull out the grain on the cut-out edge; (3) due to the adhesion action of the micro-welds, the main failure behavior of the grain on the cylindrical surface is chip adhesion, and the bridge adhesion appears at the small inter-grain space; (4) grains on the side surface are less engaged in removing workpiece materials, the cutting depths of the grains in the middle and inner zones are ignorable, and attrition wears and micro-fractures occur on the grains on the side surface. The grinding force and force ratio variation further verifies that the grinding wheel with orderly-micro-grooves can achieve self-sharpening to maintain excellent grinding performance.

Similar content being viewed by others

References

Bai YY, Lv M, Li WB, Liang GX (2017) An experimental study on the creep feed grinding of narrow deep grooves of stainless steel. Int J Adv Manuf Technol 90:1835–1844

Wang JW, Yu TY, Ding WF, Fu YC, Bastawros AF (2018) Wear evolution and stress distribution of single CBN superabrasive grain in high-speed grinding. Precis Eng 54:70–80

Li HN, Axinte D (2016) Textured grinding wheels: a review. Int J Mach Tool Manuf 109:8–35

Guo B, Zhao QL, Fang XY (2014) Precision grinding of optical glass with laser micro-structured coarse-grained diamond wheels. J Mater Process Technol 214(5):1045–1051

Denkena B, Grove T, Göttsching T, Silva EJ, Coelho RT, Filleti R (2015) Enhanced grinding performance by means of patterned grinding wheels. Int J Adv Manuf Technol 77:1935–1941

Shi CF, Li X, Chen ZT (2014) Design and experimental study of a micro-groove grinding wheel with spray cooling effect. Chin J Aeronaut 27(2):407–412

Tawakoli T, Heisel U, Daneshi A (2012) An experimental investigation on the characteristics of cylindrical plunge dry grinding with structured cBN wheels. Procedia CIRP 1:399–403

Aurich JC, Kirsch B, Herzenstiel P, Kugel P (2011) Hydraulic design of a grinding wheel with an internal cooling lubricant supply. Prod Eng 5:119–126

Walter C, Komischke T, Kuster F (2014) Laser-structured grinding tools-generation of prototype patterns and performance evaluation. J Mater Process Technol 214(5):951–961

Mohamed A-MO, Bauer R, Warkentin A (2013) Application of shallow circumferential grooved wheels to creep-feed grinding. J Mater Process Technol 213(5):700–706

Oliveira JFG, Bottene AC, França TV (2010) A novel dressing technique for texturing of ground surfaces. CIRP Ann Manuf Technol 59(1):361–364

Ding WF, Zhao B, Zhang QL, Fu YC (2021) Fabrication and wear characteristics of open-porous CBN abrasive wheels in grinding of Ti–6Al–4V alloys. Wear 477:203786

Xiao GD, Zhao B, Ding WF, Huan HX (2021) On the grinding performance of metal-bonded aggregated CBN grinding wheels based on open-pore structures. Ceram Int 47(14):19709–19715

Cao Y, Ding WF, Zhao B, Wen XB, Li SP, Wang JZ (2022) Effect of intermittent cutting behavior on the ultrasonic vibration-assisted grinding performance of Inconel718 nickel-based superalloy. Precis Eng 78:248–260

Yuan HP, Gao H, Bao YJ, Wu Y (2009) Grinding of carbon/epoxy composites using electroplated CBN wheel with controlled abrasive clusters. Key Eng Mater 389:24–29

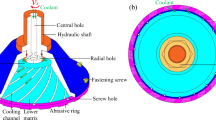

Mao C, Long P, Tang WD, Xiao LF, Luo YQ, Shu ZR, Hu YL, Bi ZM, Lin ZH, Guan FR (2022) Simulation and experiment of electroplated grinding wheel with orderly-micro-grooves. J Manuf Process 79:284–295

Upadhyaya RP, Fiecoat JH (2007) Factors affecting grinding performance with electroplated CBN wheels. CIRP Ann 56(1):339–342

Gift FC, Misiolek WZ (2004) Fluid performance study for groove grinding a nickel based superalloy using electroplated cubic boron nitride grinding wheels. J Manuf Sci Eng 126(3):451–458

Cao Y, Yin JF, Ding WF, Xu JH (2021) Alumina abrasive wheel wear in ultrasonic vibration-assisted creep-feed grinding of Inconel 718 nickel-based superalloy. J Mater Process Technol 297:117241

Cao Y, Zhu YJ, Li HN, Wang CX, Su HH, Yin Z, Ding WF (2020) Development and performance of a novel ultrasonic vibration plate sonotrode for grinding. J Manuf Process 57:174–186

Hartig J, Kirsch B, Aurich JC (2022) Analysis of the grinding wheel wear and machining result during cutting edge preparation with elastic bonded grinding wheels. J Manuf Process 75:181–202

Zhang ZC, Sui MH, Li CH, Zhou ZM, Liu B, Chen Y, Said Z, Debnath S, Sharma S (2022) Residual stress of grinding cemented carbide using MoS2 nano-lubricant. Int J Adv Manuf Technol 119:5671–5685

Azizi A, Rezaei SM, Rahimi A (2010) Study on the rotary cup dressing of CBN grinding wheel and the grinding performance. Int J Adv Manuf Technol 47:1053–1063

Naik DN, Mathew NT, Vijayaraghavan L (2019) Wear of electroplated super abrasive CBN wheel during grinding of Inconel 718 super alloy. J Manuf Process 43:1–8

Shi Z, Malkin S (2006) Wear of electroplated CBN grinding wheels. J Manuf Sci Eng 128(1):110–118

Miao Q, Ding WF, Kuang WJ, Xu JH (2020) Tool wear behavior of vitrified microcrystalline alumina wheels in creep feed profile grinding of turbine blade root of single crystal nickel-based superalloy. Tribol Int 145:106144

Miao Q, Ding WF, Xu JH, Cao LJ, Wang HC, Yin Z, Dai CW, Kuang WJ (2021) Creep feed grinding induced gradient microstructures in the superficial layer of turbine blade root of single crystal nickel-based superalloy. Int J Extreme Manuf 3:045102

Naskar A, Choudhary A, Paul S (2020) Wear mechanism in high-speed superabrasive grinding of titanium alloy and its effect on surface integrity. Wear 462:203475

Li BK, Yin JF, Zhu YJ, Zhang X, Ding WF (2021) Grain wear evolution of cubic boron nitride abrasives during single grain grinding of powder metallurgy superalloy FGH96. Ceram Int 47(2):2508–2516

Liu MZ, Li CH, Zhang YB, Yang M, Gao T, Cui X, Wang XM, Xu WH, Zhou ZM, Liu B, Said Z, Li RZ, Sharma S (2023) Analysis of grinding mechanics and improved grinding force model based on randomized grain geometric characteristics. Chin J Aeronaut 36(7):160–193

Li P, Jin T, Xiao H, Chen ZQ, Qu MN, Dai HF, Chen SY (2020) Topographical characterization and wear behavior of diamond wheel at different processing stages in grinding of N-BK7 optical glass. Tribol Int 151:106453

Zhu YJ, Ding WF, Rao ZW, Fu YC (2019) Effect of grinding wheel speed on self-sharpening ability of PCBN grain during grinding of nickel-based superalloys with a constant undeformed chip thickness. Wear 426:1573–1583

Li G, Liang GX, Shen XQ, Lv M, Liu DG, Hao XH, Huang YG, Tochukwu OP, Al-Nehari M (2021) Investigation of the wear behavior of abrasive grits in a dry machining Inconel 718 narrow-deep-groove with a single-layer cubic boron nitride grinding wheel. Int J Adv Manuf Technol 117:1061–1076

Funding

The present research work was sponsored by the National Natural Science Foundation of China (Grant Nos. 52275405, 52275311, 51875050), the Hunan Province Science and Technology Innovation Program (Grant No. 2023RC1078), and the Changsha City Science and Technology Innovation Program (Grant No. kh2301003).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by C.M. and X.L. The first draft of the manuscript was written by C.M. and X.L., and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mao, C., Li, X., Zhang, M. et al. Wear behaviors of electroplated CBN grinding wheel with orderly-micro-grooves in grinding narrow-deep slot. Int J Adv Manuf Technol 131, 2857–2868 (2024). https://doi.org/10.1007/s00170-023-12509-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12509-4