Abstract

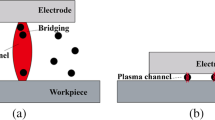

The long-existing contradiction between cutting speed and surface quality in wire electrical discharge machining (WEDM) detrimentally hinders its further development and application. To address this problem, this work proposed a multi-channel discharge method that performs WEDM on several workpieces, each electrically insulated and connected to a pulse power supply with a resistor. As a result, the machining energy normally exerted on one plasma channel can be dispersed into multiple discharge channels when each pulse voltage is applied. Firstly, the mechanism of multi-channel discharge was theoretically illustrated. Secondly, machining waveforms and high-speed imaging of gap phenomena were captured to prove the feasibility of multi-channel discharge in high-speed WEDM (HSWEDM). Although the multi-channel discharge is stochastic, a certain probability exists due to the vibration of wire electrodes. Lastly, verification experiments were conducted to investigate the performance of multi-channel discharge. The results indicate that the multi-channel discharge can significantly improve surface quality without reducing cutting speed, thus achieving a better balance between productivity and surface quality.

Similar content being viewed by others

Availability of data and materials

The data and materials set supporting the results are included within the article.

References

Ho K, Newman S, Rahimifard S, Allen R (2004) State of the art in wire electrical discharge machining (WEDM). Int J Mach Tools Manuf 44(12–13):1247–1259. https://doi.org/10.1016/j.ijmachtools.2004.04.017

Mandal A, Dixit AR (2014) State of art in wire electrical discharge machining process and performance. Int J Mach Mach Mater 16(1):1–21. https://doi.org/10.1504/IJMMM.2014.063918

Radhakrishnan P, Vijayaraghavan L, Ramesh Babu N (2017) Assessment of material removal capability with vibration-assisted wire electrical discharge machining. J Manuf Processes 26:323–329. https://doi.org/10.1016/j.jmapro.2017.03.002

Yan MT, Cheng YC, Luo SY (2019) Improvement of wire electrical discharge machining characteristics in machining boron-doped polycrystalline diamond using a novel iso-pulse generator. Int J Precis Eng Manuf 20:159–166. https://doi.org/10.1007/s12541-019-00052-w

Almeida S, Mo J, Bil C, Ding S, Wang X (2021) Comprehensive servo control strategies for flexible and high-efficient wire electric discharge machining. A systematic review. Precis Eng 71:7–28. https://doi.org/10.1016/j.precisioneng.2021.02.007

Kapoor J, Singh S, Khamba JS (2012) High-performance wire electrodes for wire electrical-discharge machining-a review. Proc Inst Mech Eng, Part B: J Eng Manuf 226(11):1757–1773. https://doi.org/10.1177/0954405412460354

Chakraborty S, Dey V, Ghosh S (2015) A review on the use of dielectric fluids and their effects in electrical discharge machining characteristics. Precis Eng 40:1–6. https://doi.org/10.1016/j.precisioneng.2014.11.003

Tonday HR, Tigga AM (2019) An empirical evaluation and optimization of performance parameters of wire electrical discharge machining in cutting of Inconel 718. Measurement 140:185–196. https://doi.org/10.1016/j.measurement.2019.04.003

Slătineanu L, Dodun O, Coteaţă M, Nagîţ G, Băncescu IB, Hriţuc A (2020) Wire electrical discharge machining-a review. Machines 8(4):69. https://doi.org/10.3390/machines8040069

Maher I, Sarhan AA, Barzani MM, Hamdi M (2015) Increasing the productivity of the wire-cut electrical discharge machine associated with sustainable production. J Cleaner Prod 108:247–255. https://doi.org/10.1016/j.jclepro.2015.06.047

Yan H, Kabongo DB, Yan Z, Han F, Chen Z (2020) Sustainable production of high-uniformity workpiece surface quality in wire electrical discharge machining by fabricating surface microstructure on wire electrode. J Cleaner Prod 259:120881. https://doi.org/10.1016/j.jclepro.2020.120881

Mohri N, Saito N, Takawashi T, Kobayashi K (1985) Mirror-like finishing by EDM (multi divided electrode method). In: Proceedings of the twenty-fifth international machine tool design and research conference. p 329–336, https://doi.org/10.1007/978-1-349-07529-4_38

Kunieda M, Muto H (2000) Development of multi-spark EDM. CIRP Ann 49(1):119–122. https://doi.org/10.1016/S0007-8506(07)62909-6

Yang X, Yang K, Liu Y, Wang L (2016) Study on characteristic of multi-spark EDM method by using capacity coupling. Procedia CIRP 42:40–45

Han F, Kunieda M (2004) Development of parallel spark electrical discharge machining. Precis Eng 28(1):65–72. https://doi.org/10.1016/S0141-6359(03)00076-X

Prakash V, Kumar P, Singh P, Hussain M, Das AK, Chattopadhyaya S (2019) Micro-electrical discharge machining of difficult-to-machine materials: a review. Proc Inst Mech Eng, Part B: J Eng Manuf 233(2):339–370. https://doi.org/10.1177/0954405417718591

Joshi AY, Joshi AY (2019) A systematic review on powder mixed electrical discharge machining. Heliyon 5(12):e02963. https://doi.org/10.1016/j.heliyon.2019.e02963

Pan H, Liu Z, Qiu M, Zhang M, Deng C (2021) Extreme wire electrical discharge machining based on semiconductor characteristics. Int J Adv Manuf Technol 115(7–8):2477–2489. https://doi.org/10.1007/s00170-021-07019-0

Wang X, Qiu M, Guo H, Ding S (2022) Powder-mixed multi-channel discharge wire electrical discharge machining. Int J Adv Manuf Technol 119(9–10):6275–6286. https://doi.org/10.1007/s00170-021-08221-w

Shi W, Liu Z, Qiu M, Tian Z, Yan H (2016) Simulation and experimental study of wire tension in high-speed wire electrical discharge machining. J Mater Process Technol 229:722–728. https://doi.org/10.1016/j.jmatprotec.2015.11.001

Gostimirovic M, Kovac P, Sekulic M, Skoric B (2012) Influence of discharge energy on machining characteristics in EDM. J Mech Sci Technol 26:173–179. https://doi.org/10.1007/s12206-011-0922-x

Yan BH, Tsai HC, Huang FY, Lee LC (2005) Examination of wire electrical discharge machining of Al\(_2\)O\(_3\)p 6061Al composites. Int J Mach Tools Manuf 45(3):251–259. https://doi.org/10.1016/j.ijmachtools.2004.08.015

Acknowledgements

The authors extend their sincere thanks to those who contributed in the preparation of the instructions.

Funding

This work was supported by the National Natural Science Foundation of China (grant number 51975290).

Author information

Authors and Affiliations

Contributions

All authors have been personally and actively involved in substantive work leading to the report.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pan, H., Liu, Z. & Deng, C. Research on the characteristics of multi-channel discharge in wire electrical discharge machining. Int J Adv Manuf Technol 129, 3063–3071 (2023). https://doi.org/10.1007/s00170-023-12461-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12461-3