Abstract

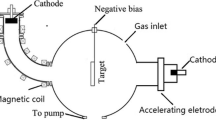

Diamond-like carbon films with Ti dopant (Ti-DLC) are synthesized by reactive magnetron sputtering using a pure Ti metal target. This study determines the effect of methane flow ratios (Rm=CH4/(Ar + CH4), ranging from 4 to 12%) on the surface morphology, microstructure, mechanical properties, and cermet cutting tool insert features of Ti-DLC films. The GIXRD diffraction spectrum for Ti-DLC film depicts an amorphous structure. There are peaks for nano-crystalline TiC at 2θ values of 35.88°, 41.52°, and 60.14°, which respectively correspond to the (111), (200), and (220) planes of the face-centered cubic structure. The characteristic binding energy of C 1s, Ti 2p, and O 1s for Ti-DLC film is determined using a high-resolution XPS spectrum. Increasing Rm flow ratio (reducing Ti metal doping) increases the intensity of the Raman spectrum because there is an increased sp2-C (sp2/sp3 ratio) site fraction for DLC components. The experimental results show that the hardness of the DLC film increases from 11.07 to 14.76 GPa as the Rm flow ratio is increased from 4 to 12%. The adhesive strength of the Ti-DLC film coating is measured using a scratch test and shows that the film adheres well to the substrate. The Ti-DLC films are coated onto cutter inserts for the dry milling of an Inconel 718 workpiece, and the results show that all coated tools have a significantly longer tool life than uncoated tools.

Similar content being viewed by others

Data availability

All necessary data is shown in the figures and tables within the document. The raw data can be made available upon request.

Code availability

Not applicable.

References

Kim JI, Lee WY, Tokoroyama T, Umehara N (2023) Long-term low-friction of Ti-overcoated and-doped DLCs: robustly developed carbonous transfer layer with titanium. Carbon 204:263–283. https://doi.org/10.1016/j.carbon.2022.12.012

Li X, Tang W, Chen C, Xu C (2021) Effect of the methane flow ratio on the structural and mechanical properties of high-entropy alloy co-doped DLC films. Diam Relat Mat 117:108486–108496. https://doi.org/10.1016/j.diamond.2021.108486

Zhang M, Xie T, Qian X, Zhu Y, Liu X (2020) Mechanical properties and biocompatibility of Ti-doped diamond-like carbon films. ACS omega 5:22772–22777. https://doi.org/10.1021/acsomega.0c01715

Wongpanya P, Wongpinij T, Photongkam P, Siritapetawee J (2022) Improvement in corrosion resistance of 316L stainless steel in simulated body fluid mixed with antiplatelet drugs by coating with Ti-doped DLC films for application in biomaterials. Corrosion Sci 208:110611. https://doi.org/10.1016/j.corsci.2022.110611

Jordi OP, Raül B, Elisa R, Miquel P, M’onica OH, Jordi GM, Arturo L, David C, Cristina D, Gonzalo GF, Jaume C (2021) Bactericidal silver-doped DLC coatings obtained by pulsed filtered cathodic arc co-deposition. Surf Coat Tech 411:126977. https://doi.org/10.1016/j.surfcoat.2021.126977

Wang CJ, Cheng LD, Liu Y, Zhang H, Wang Y, Shan DB, Guo B (2019) Research on micro-deep drawing process of concial part with ultra-thin copper foil using multi-layered DLC film-coated die. Int J Adv Manuf Technol 100:569–575. https://doi.org/10.1007/s00170-018-2757-4

Li X, Chen CS, Tsao CC, Hu CC, Chen C, Hsu CY (2022) Characteristics of DLC films doped with multi-element alloy. Int J Adv Manuf Technol 121:2631–2646. https://doi.org/10.21203/rs.3.rs-1425602/v1

Hao T, Du J, Su G, Zhang P, Sun Y, Zhang J (2020) Mechanical and cutting performance of cemented carbide tools with Cr/x/DLC composite coatings. Int J Adv Manuf Technol 106:5241–5254. https://doi.org/10.1007/s00170-020-05014-5

Wu YM, Ma LQ, Zhou SG, Zhao WJ, Ouyang L (2018) Effect of methane flow rate on microstructure and tribological properties of (Cu, Ce)/Ti co-doped DLC films fabricated via reactive magnetron sputtering technology. Mater Res Express 5:076405–076414. https://doi.org/10.1088/2053-1591/aad07c

Dai W, Gao X, Liu J, Wang Q (2016) Microstructure, mechanical property and thermal stability of diamond-like carbon coatings with Al, Cr and Si multi-doping. Diam Relat Mat 70:98–104. https://doi.org/10.1016/j.diamond.2016.10.017

Chen C, Tang W, Li X, Wang W, Xu C (2020) Structure and cutting performance of Ti-DLC films prepared by reactive magnetron sputtering. Diam Relat Mat 104:107735–107741. https://doi.org/10.1016/j.diamond.2020.107735

Wu W, Zhu Z, Min J, Zhang J, Qian N, Jiang M (2017) Adhesion behavior of diamond-like carbon films with F and Si co-doping prepared by radio frequency reactive magnetron sputtering. Thin Solid Films 622:89–94. https://doi.org/10.1016/j.tsf.2016.11.043

Xu X, Zhou Y, Liu L, Guo P, Li X, Lee KR, Cui P, Wang A (2020) Corrosion behavior of diamond-like carbon film induced by Al/Ti co-doping. Appl Surf Sci 509:144877–144887. https://doi.org/10.1016/j.apsusc.2019.144877

Zahoor S, Abdul-Kader W, Shehzad A, Habib MS (2022) Milling of Inconel 718: an experimental and integrated modeling approach for surface roughness. Int J Adv Manuf Technol 120:1609–1624. https://doi.org/10.1007/s00170-021-08648-1

Yetim AF, Kovac H, Kasapoglu AE, Bozkurt YB, Celik A (2021) Influences of Ti, Al and V metal doping on the structural, mechanical and tribological properties of DLC films. Diam Relat Mat 120:108639–108649. https://doi.org/10.1016/j.diamond.2021.108639

Yin Q, Liu Z, Wang B, Song Q, Cai Y (2020) Recent progress of machinability and surface integrity for mechanical machining Inconel 718: a review. Int J Adv Manuf Technol 109:215–245. https://doi.org/10.1007/s00170-020-05665-4

Shahsavari F, Ehteshamzadeh M, Amin MH, Barlow AJ (2020) A comparative study of surface morphology, mechanical and tribological properties of DLC films deposited on Cr and Ni nanolayers. Ceram Int 46:5077–5085. https://doi.org/10.1016/j.ceramint.2019.10.251

Zhang S, Jiang G, Yang Y, Li H, Yan F, Yan M, Zhang Y (2023) Annealing effect on microstructure of novel Ti doped DLC multilayer films. Coatings 13:833. https://doi.org/10.3390/coatings13050833

Dai W, Kwon SH, Wang Q, Liu J (2018) Influence of frequency and C2H2 flow on growth properties of diamond-like carbon coatings with AlCrSi co-doping deposited using a reactive high power impulse magnetron sputtering. Thin Solid Films 647:26–32. https://doi.org/10.1016/j.tsf.2017.12.016

Wang W, Ji L, Li H, Zhou H, Chen J (2017) Self-organized formation of nano-multilayer structure in the carbon-copper thin film during reactive magnetron sputtering deposition process. J Alloy Compd 25:242–249. https://doi.org/10.1016/j.jallcom.2017.06.006

Cao L, Liu J, Wan Y, Pu J (2020) Corrosion and tribocorrosion behavior of W doped DLC coating in artificial seawater. Diam Relat Mat 109:108019–108030. https://doi.org/10.1016/j.diamond.2020.108019

Gayathri S, Kumar N, Krishnan R, Ravindran TR, Dash S, Tyagi AK, Sridharan M (2015) Influence of Cr content on the micro-structural and tribological properties of PLD grown nanocomposite DLC-Cr thin films. Mater Chem Phys 167:194–200. https://doi.org/10.1016/j.matchemphys.2015.10.031

Shen Y, Luo J, Liao B, Chen L, Zhang X, Zhao Y, Pang P, Zeng X (2022) Enhanced anti-tribocorrosion performance of Ti-DLC coatings deposited by filtered cathodic vacuum arc with the optimization of bias voltage. Coatings 12:697–711. https://doi.org/10.3390/coatings12050697

Patnaik L, Maity SR, Kumar S (2020) Comprehensive structural, nanomechanical and tribological evaluation of silver doped DLC thin film coating with chromium interlayer (Ag-DLC/Cr) for biomedical application. Ceram Int 46:22805–22818. https://doi.org/10.1016/j.ceramint.2020.06.048

Maurice V, Despert G, Zanna S, Josso P, Bacos MP, Marcus P (2007) XPS study of the initial stages of oxidation of α2-Ti3Al and γ-TiAl intermetallic alloys. Acta Mater 55:3315–3325. https://doi.org/10.1016/j.actamat.2007.01.030

Cao H, Ye X, Li H, Qi F, Wang Q, Ouyang X, Zhao N, Liao B (2021) Microstructure, mechanical and tribological properties of multilayer Ti-DLC thick films on Al alloys by filtered cathodic vacuum arc technology. Mater Des 198:109320–109335. https://doi.org/10.1016/j.matdes.2020.109320

Xu X, Guo P, Zuo X, Sun L, Li X, Lee KR, Wang A (2020) Understanding the effect of Al/Ti ratio on the tribocorrosion performance of Al/Ti co-doped diamond-like carbon films for marine applications. Surf Coat Technol 402:126347–126356. https://doi.org/10.1016/j.surfcoat.2020.126347

Tsai PC, Hwang YF, Chiang JY, Chen WJ (2008) The effects of deposition parameters on the structure and properties of titanium-containing DLC films synthesized by cathodic arc plasma evaporation. Surf Coat Technol 202:5350–5355. https://doi.org/10.1016/j.surfcoat.2008.06.073

Zhang S, Yan M, Yang Y, Zhang Y, Yan F, Li H (2019) Excellent mechanical, tribological and anti-corrosive performance of novel Ti-DLC nanocomposite thin films prepared via magnetron sputtering method. Carbon 151:136–147. https://doi.org/10.1016/j.carbon.2019.05.031

Jo YJ, Zhang TF, Son MJ, Kim KH (2018) Synthesis and electrochemical properties of Ti-doped DLC films by a hybrid PVD/PECVD process. Appl Surf Sci 433:1184–1191. https://doi.org/10.1016/j.apsusc.2017.10.151

Zhou Y, Li L, Shao W, Chen Z, Wang S, Xing X, Yang Q (2020) Mechanical and tribological behaviors of Ti-DLC films deposited on 304 stainless steel: exploration with Ti doping from micro to macro. Diam Relat Mat 107:107870–107877. https://doi.org/10.1016/j.diamond.2020.107870

Dai W, Gao X, Liu J, Kwon SH, Wang Q (2017) Compositionally modulated multilayer diamond-like carbon coatings with AlTiSi multi-doping by reactive high power impulse magnetron sputtering. Appl Surf Sci 425:855–861. https://doi.org/10.1016/j.apsusc.2017.07.080

Guo T, Kong C, Li X, Guo P, Wang Z, Wang A (2017) Microstructure and mechanical properties of Ti/Al co-doped DLC films: dependence on sputtering current, source gas, and substrate bias. Appl Surf Sci 410:51–59. https://doi.org/10.1016/j.apsusc.2017.02.254

Cao H, Qi F, Ouyang X, Zhao N, Zhou Y, Li B, Luo W, Liao B, Luo J (2018) Effect of Ti transition layer thickness on the structure, mechanical and adhesion properties of Ti-DLC coatings on aluminum alloys. Materials 11:1742–1755. https://doi.org/10.3390/ma11091742

Li XY, Chen CH, Xu C (2019) Optimization of interlayer/CrWN bilayer films fabricated and monitored under Shewhart control. J Mater Eng Perform 28:6993–6905. https://doi.org/10.1007/s11665-019-04411-6

Chagnon L, Arnold G, Giljean S, Brogly M (2013) Elastic recovery and creep properties of waterborne two-component polyurethanes investigated by micro-indentation. Prog Org Coat 76:1337–1345. https://doi.org/10.1016/j.porgcoat.2013.04.003

Liu H, Zhao M, Lu C, Zhang J (2020) Characterization on the yield stress and interfacial coefficient of friction of glasses from scratch tests. Ceram Int 46:6060-6066. https://doi.org/10.1016/j.ceramint.2019.11.065

Chen KT, Kao JY, Hsu CY, Hong PD (2019) Multi-response optimization of mechanical properties for ZrWN films grown using grey Taguchi approach. Ceram Int 45:327–333. https://doi.org/10.1016/j.ceramint.2018.09.170

Akhter R, Zhou Z, Xie Z, Munroe P (2021) Enhancing the adhesion strength and wear resistance of nanostructured NiCrN coatings. Appl Surf Sci 541:148533–148547. https://doi.org/10.1016/j.apsusc.2020.148533

Li A, Zhao J, Luo H, Pei Z, Wang Z (2012) Progressive tool failure in high-speed dry milling of Ti-6Al-4V alloy with coated carbide tools. Int J Adv Manuf Technol 58:465–478. https://doi.org/10.1007/s00170-011-3408-1

Funding

The authors gratefully acknowledge the support of the Ministry of Science and Technology of the Republic of China, Taiwan, through Grant Nos. MOST 111-2637-E-262-002, MOST 111-2221-E-262-005, and NSTC 111-2622-E-262-002.

Author information

Authors and Affiliations

Contributions

Wei-Hsiang Lee and Yin-Tung Alber Sun: conceptualization. Chih-Chung Hu, Bo-Yuan Wang, and Ho Chang: experimentation. Wei-Hsiang Lee and Yin-Tung Alber Sun: characterization. Chih-Chung Hu, Bo-Yuan Wang, and Ho Chang: validation. Ho Chang and Chun-Yao Hsu: analysis. Chun-Yao Hsu: writing the draft

Corresponding authors

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lee, WH., Hu, CC., Sun, YT.A. et al. Influence of methane flow ratios on the structural and mechanical properties of Ti-doped diamond-like carbon films. Int J Adv Manuf Technol 129, 1145–1157 (2023). https://doi.org/10.1007/s00170-023-12368-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12368-z