Abstract

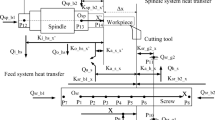

CNC lathes often use hydraulic systems or motors to lock the turret, which causes the turret to have a high temperature rise and a large thermal deformation. The traditional measuring method couples the thermal distortions of the spindle and the turret together, which is not conducive to establishing the thermal error model. To solve this problem, a new measuring method was used in this research to decouple the thermal linear and angular distortions of the spindle and the turret. In addition, constraints on the model coefficients were proposed by studying the effects of long-term and short-term variations in ambient temperature on the thermal deformation of machine tools, thus transforming the thermal deformation modeling of the spindle and turret into nonlinear programming problems. After building the thermal deformation models of the spindle and the turret, the thermal distortion model of the whole machine tool was obtained by combining them. Finally, three experiments were designed to verify the validity of the established models, and the models were compared with those established using conventional methods. The experimental results showed that the models built based on thermal distortion decoupling and nonlinear programming had higher accuracy and robustness.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Bryan J (1990) International status of thermal error research. CIRP Ann Manuf Technol 39(2):645–656. https://doi.org/10.1016/s0007-8506(07)63001-7

Mayr J, Jedrzejewski J, Uhlmann E, Alkan Donmez M, Knapp W, Härtig F, Wendt K, Moriwaki T, Shore P, Schmitt R, Brecher C, Würz T, Wegener K (2012) Thermal issues in machine tools. CIRP Ann Manuf Technol 61(2):771–791. https://doi.org/10.1016/j.cirp.2012.05.008

Li Y, Zhao W, Lan S, Ni J, Wu W, Lu B (2015) A review on spindle thermal error compensation in machine tools. Int J Mach Tools Manuf 95:20–38. https://doi.org/10.1016/j.ijmachtools.2015.04.008

Ge Z, Ding X (2018) Design of thermal error control system for high-speed motorized spindle based on thermal contraction of CFRP. Int J Mach Tools Manuf 125:99–111. https://doi.org/10.1016/j.ijmachtools.2017.11.002

Grama SN, Mathur A, Badhe AN (2018) A model-based cooling strategy for motorized spindle to reduce thermal errors. Int J Mach Tools Manuf 132:3–16. https://doi.org/10.1016/j.ijmachtools.2018.04.004

Weng L, Gao W, Zhang D, Huang T, Liu T, Li W, Zheng Y, Shi K, Chang W (2021) Analytical modelling method for thermal balancing design of machine tool structural components. Int J Mach Tools Manuf 164:1–20. https://doi.org/10.1016/j.ijmachtools.2021.103715

Yue H, Guo C, Li Q, Zhao L, Hao G (2020) Thermal error modeling of CNC milling machine tool spindle system in load machining: based on optimal specific cutting energy. J Braz Soc Mech Sci Eng 42(9):456. https://doi.org/10.1007/s40430-020-02538-5

Zimmermann N, Lang S, Blaser P, Mayr J (2020) Adaptive input selection for thermal error compensation models. CIRP Ann Manuf Technol 69(1):485–488. https://doi.org/10.1016/j.cirp.2020.03.017

Liu H, Miao E, Wei X, Zhuang X (2017) Robust modeling method for thermal error of CNC machine tools based on ridge regression algorithm. Int J Mach Tools Manuf 113:35–48. https://doi.org/10.1016/j.ijmachtools.2016.11.001

Miao E, Liu Y, Liu H, Gao Z, Li W (2015) Study on the effects of changes in temperature-sensitive points on thermal error compensation model for CNC machine tool. Int J Mach Tools Manuf 97:50–59. https://doi.org/10.1016/j.ijmachtools.2015.07.004

Yan Z, Tao T, Du H, Shi H, Mei X (2022) An experiment-based multi-objective modeling method for thermal errors of slant bed CNC lathes. Int J Adv Manuf Technol 120(9-10):6565–6583. https://doi.org/10.1007/s00170-022-09158-4

Liu J, Ma C, Wang S (2020) Data-driven thermally-induced error compensation method of high-speed and precision five-axis machine tools. Mech Syst Signal Process 138. https://doi.org/10.1016/j.ymssp.2019.106538

Hu J, Zhou Z, Liu Q, Lou P, Yan J, Li R (2019) Key point selection in large-scale FBG temperature sensors for thermal error modeling of heavy-duty CNC machine tools. Front Mech Eng 14(4):442–451. https://doi.org/10.1007/s11465-019-0543-0

Guo Q, Fan S, Xu R, Cheng X, Zhao G, Yang J (2017) Spindle thermal error optimization modeling of a five-axis machine tool. Chin J Mech Eng 30(3):746–753. https://doi.org/10.1007/s10033-017-0098-0

Liu J, Ma C, Gui H, Wang S (2021) Thermally-induced error compensation of spindle system based on long short term memory neural networks. Appl Soft Comput 102:1–19. https://doi.org/10.1016/j.asoc.2021.107094

Liu P, Du Z, Li H, Deng M, Feng X, Yang J (2021) Thermal error modeling based on BiLSTM deep learning for CNC machine tool. Adv Manuf 9(2):235–249. https://doi.org/10.1007/s40436-020-00342-x

Miao E, Gong Y, Xu Z, Zhou X (2015) Comparative analysis of thermal error compensation model robustness of CNC machine tools. Journal of. Mech Eng 51(7). https://doi.org/10.3901/jme.2015.07.130

Abdulshahed AM, Longstaff AP, Fletcher S (2017) A cuckoo search optimisation-based grey prediction model for thermal error compensation on CNC machine tools. Grey Syst: Theory Appl 7(2):146–155. https://doi.org/10.1108/gs-08-2016-0021

Abdulshahed AM, Longstaff AP, Fletcher S, Potdar A (2016) Thermal error modelling of a gantry-type 5-axis machine tool using a Grey Neural Network Model. J Manuf Syst 41:130–142. https://doi.org/10.1016/j.jmsy.2016.08.006

Liu J, Ma C, Gui H, Wang S (2022) Transfer learning-based thermal error prediction and control with deep residual LSTM network. Knowl-Based Syst 237:107704. https://doi.org/10.1016/j.knosys.2021.107704

Liu K, Liu H, Li T, Liu Y, Wang Y (2019) Intelligentization of machine tools: comprehensive thermal error compensation of machine-workpiece system. Int J Adv Manuf Technol 102(9-12):3865–3877. https://doi.org/10.1007/s00170-019-03495-7

Liu K, Song L, Han W, Cui Y, Wang Y (2022) Time-varying error prediction and compensation for movement axis of CNC machine tool based on digital twin. IEEE Trans Ind Inform 18(1):109–118. https://doi.org/10.1109/tii.2021.3073649

Mareš M, Horejš O, Havlík L (2020) Thermal error compensation of a 5-axis machine tool using indigenous temperature sensors and CNC integrated Python code validated with a machined test piece. Precision Eng 66:21–30. https://doi.org/10.1016/j.precisioneng.2020.06.010

Yang Y, Du Z, Feng X, Yang J (2021) Real-time thermal modelling approach of a machine tool spindle based on bond graph method. Int J Adv Manuf Technol 113(1-2):99–115. https://doi.org/10.1007/s00170-021-06611-8

Dai Y, Zhan S, Wang J, Xuan L, Wang G (2021) Thermal error modeling of motorized spindle under variable pressure preload based on the bonding graph method. Chin J Sci Instrum 42(5):42–48. https://doi.org/10.19650/j.cnki.cjsi.J2107533

Yang J, Yuan J, Ni J (1999) Thermal error mode analysis and robust modeling for error compensation on a CNC turning center. Int J Mach Tools Manuf 39(9):1367–1381

Hou R, Du H, Yan Z, Yu W, Tao T, Mei X (2019) The modeling method on thermal expansion of CNC lathe headstock in vertical direction based on MOGA. Int J Adv Manuf Technol 103(2):3629–3641. https://doi.org/10.1007/s00170-019-03728-9

Funding

This research is financially supported by the National Key Research and Development Program of China (Grant No. 2018YFB1701205).

Author information

Authors and Affiliations

Contributions

Hongyang Du: methodology, writing; Gedong Jiang: data analysis; Tao Tao: funding acquisition, supervision; Ruisheng Hou: software; Zongzhuo Yan: validation; Xuesong Mei: conceptualization, supervision.

Corresponding author

Ethics declarations

Ethics approval

The article follows the guidelines of the Committee on Publication Ethics (COPE) and involves no studies on human or animal subjects.

Consent to participate

All authors voluntarily consent to participate in this research.

Consent for publication

All authors consent to publish this article.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Du, H., Jiang, G., Tao, T. et al. A thermal error modeling method for CNC lathes based on thermal distortion decoupling and nonlinear programming. Int J Adv Manuf Technol 128, 2599–2612 (2023). https://doi.org/10.1007/s00170-023-12038-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12038-0