Abstract

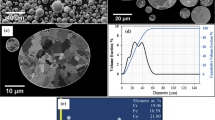

CoCrFeNiTi high entropy alloy (HEA) has been extensively studied to serve as coating materials on complexly shaped parts of equipment used in industries such as oil, gas, and mining due to its high hardness, excellent wear resistance, and good high-temperature stability. Laser-directed energy deposition has potential to fabricated HEA caotings due to its advantages of excellent metallurgical bonding, high coating density, suppressed element segregation, and the capability of thick coating deposition. However, limited investigations have been conducted on the effects of input parameters (such as powder geometry and laser power) on the mechanical properties of laser DED fabricated CoCrFeNiTi high-entropy alloy coatings. In this study, CoCrFeNiTi HEA coatings have been fabricated on Ti substrates from spherical-shaped and irregular-shaped powders under different levels of laser power. The effects of powder geometry and laser power on molten pool thermal characteristics (including temperature, cooling rate, and solidification time), phase constitution, microstructure, and mechanical properties of hardness and wear resistance have been investigated. Under the same laser power, the utilization of irregular-shaped powders resulted in uniform microstructures and higher hardness. For the coatings fabricated from spherical-shaped powders, the increase of laser power could improve the microhardness and wear resistance. For the coatings fabricated from spherical-shaped powders, the increase of laser power could increase the microhardness. However, the wear resistance is increased and then decreased due to the increase in friction of coefficient.

Similar content being viewed by others

Data availability

The data supporting the conclusions are included in the article.

References

Harea E, Stoček R, and Machovský M (2017) Study of friction and wear of thermoplastic vulcanizates: the correlation with abraded surfaces topology. J Phys Conf Ser. 843:012070. IOP Publishing

Tsai M-H, Yeh J-W (2014) High-entropy alloys: a critical review. Mater Res Lett 2(3):107–123

Guo S, Ng C, Lu J, Liu C (2011) Effect of valence electron concentration on stability of fcc or bcc phase in high entropy alloys. J Appl Phys 109(10):103505

Yeh JW, Chen YL, Lin SJ, Chen SK (2007) High-entropy alloys–a new era of exploitation. Mater Sci Forum 560:1–9 (Trans Tech Publ)

Zhang, Y (2019) High-Entropy Materials. Springer Nat Singap Pte Ltd 2:215–232

Gwalani B, Ayyagari AV, Choudhuri D, Scharf T, Mukherjee S, Gibson M, Banerjee R (2018) Microstructure and wear resistance of an intermetallic-based Al0.25Ti0.75CoCrFeNi high entropy alloy. Mater Chem Phys 210:197–206

Haftlang F, Zargaran A, Son S, Lee S, Hong S-J, Kim HS (2022) The subsurface deformed region and superficial protective tribo-oxide layer during wear in a non-equiatomic CoCrFeNiV high entropy alloy. Mater Des 218:110685

Fang S, Chen W, Fu Z (2014) Microstructure and mechanical properties of twinned Al0.5CrFeNiCo0.3C0.2 high entropy alloy processed by mechanical alloying and spark plasma sintering. Mater Des 54:973–979

Fu Z, Chen W, Fang S, Zhang D, Xiao H, Zhu D (2013) Alloying behavior and deformation twinning in a CoNiFeCrAl0.6Ti0.4 high entropy alloy processed by spark plasma sintering. J Alloy Compd 553:316–323

Zhang P, Li Y, Chen Z, Zhang J, Shen B (2019) Oxidation response of a vacuum arc melted NbZrTiCrAl refractory high entropy alloy at 800–1200 C. Vacuum 162:20–27

Liu Y, Wang G, Zhao Y, Wang M, He R, Tan C, ... Zhou X (2021) Joining of SiC using CoFeCrNiCuTi high entropy alloy filler by electric current field assisted sintering. J Eur Ceramic Soc 42(5):1995–2003

Wang R, Zhang K, Davies C, Wu X (2017) Evolution of microstructure, mechanical and corrosion properties of AlCoCrFeNi high-entropy alloy prepared by direct laser fabrication. J Alloy Compd 694:971–981

Yin S, Li W, Song B, Yan X, Kuang M, Xu Y, ... Lupoi R (2019) Deposition of FeCoNiCrMn high entropy alloy (HEA) coating via cold spraying. J Mater Sci Technol 35(6):1003–1007

Kgoete F, Popoola A, Fayomi O (2018) Influence of spark plasma sintering on microstructure and corrosion behaviour of Ti-6Al-4V alloy reinforced with micron-sized Si3N4 powder. Defence Technol 14(5):403–407

Sriharitha R, Murty B, Kottada RS (2014) Alloying, thermal stability and strengthening in spark plasma sintered AlxCoCrCuFeNi high entropy alloys. J Alloy Compd 583:419–426

Karthikeyan J (2007) The advantages and disadvantages of the cold spray coating process. In The cold spray materials deposition process, Woodhead Publishing. p 62–71

Agarwala M, Bourell D, Beaman J, Marcus H, Barlow J (1995) Direct selective laser sintering of metals. Rapid Prototyp J 1:26

Hu Y, Wang H, and Cong W (2019) Laser deposition-additive manufacturing of graphene oxide reinforced IN718 alloys: effects on surface quality, microstructure, and mechanical properties. Int Manuf Sci Eng Conf Am Soc Mech Eng 58752:V002T003A050

Jiang L, Lu Y, Dong Y, Wang T, Cao Z, Li T (2014) Annealing effects on the microstructure and properties of bulk high-entropy CoCrFeNiTi0.5 alloy casting ingot. Intermetallics 44:37–43

Fujieda T, Chen M, Shiratori H, Kuwabara K, Yamanaka K, Koizumi Y, ... Watanabe S (2019) Mechanical and corrosion properties of CoCrFeNiTi-based high-entropy alloy additive manufactured using selective laser melting. Addit Manuf 25:412–420

Fujieda T, Shiratori H, Kuwabara K, Hirota M, Kato T, Yamanaka K, ... Watanabe S (2017) CoCrFeNiTi-based high-entropy alloy with superior tensile strength and corrosion resistance achieved by a combination of additive manufacturing using selective electron beam melting and solution treatment. Mater Lett 189:148–151

Liu H, Gao W, Liu J, Du X, Li X, Yang H (2020) Microstructure and properties of CoCrFeNiTi high-entropy alloy coating fabricated by laser cladding. J Mater Eng Perform 29(11):7170–7178

Zhang S, Han B, Li M, Zhang Q, Hu C, Niu S, ... Wang Y (2021) Investigation on solid particles erosion resistance of laser cladded CoCrFeNiTi high entropy alloy coating. Intermetallics 131:107111

Shun T-T, Chang L-Y, Shiu M-H (2012) Microstructures and mechanical properties of multiprincipal component CoCrFeNiTix alloys. Mater Sci Eng: A 556:170–174

Wang X, Liu Q, Huang Y, Xie L, Xu Q, Zhao T (2020) Effect of Ti content on the microstructure and corrosion resistance of CoCrFeNiTix high entropy alloys prepared by laser cladding. Materials 13(10):2209

Liu S, Grohol CM, Shin YC (2022) High throughput synthesis of CoCrFeNiTi high entropy alloys via directed energy deposition. J Alloys Compds 916:165469

Li Y, Hu Y, Zhang D, Cong W (2023) Laser remelting of CoCrFeNiTi high entropy alloy coatings fabricated by directed energy deposition: effects of remelting laser power. Opt Laser Technol 158:108871

Wang L, Felicelli S, Gooroochurn Y, Wang P, Horstemeyer M (2008) Optimization of the LENS® process for steady molten pool size. Mater Sci Eng: A 474(1–2):148–156

Hofmeister W, Wert M, Smugeresky J, Philliber JA, Griffith M, Ensz M (1999) Investigating solidification with the laser-engineered net shaping (LENSTM) process. Jom 51(7):1–6

Jiang Y, Cheng Y, Zhang X, Yang J, Yang X, Cheng Z (2020) Simulation and experimental investigations on the effect of Marangoni convection on thermal field during laser cladding process. Optik 203:164044

Zhang J, Gu D, Yang Y, Zhang H, Chen H, Dai D, Lin K (2019) Influence of particle size on laser absorption and scanning track formation mechanisms of pure tungsten powder during selective laser melting. Engineering 5(4):736–745

Niu H, Chang I (1999) Selective laser sintering of gas and water atomized high speed steel powders. Scr Mater 41(1):25–30

Farshidianfar MH, Khajepour A, Gerlich AP (2016) Effect of real-time cooling rate on microstructure in laser additive manufacturing. J Mater Process Technol 231:468–478

Wirth F, Freihse S, Eisenbarth D, and Wegener K (2017) Interaction of powder jet and laser beam in blown powder laser deposition processes: measurement and simulation methods. In Lasers in Manufacturing Conference, Munich, Germany, p 1–10

Chen J, Niu P, Liu Y, Lu Y, Wang X, Peng Y, Liu J (2016) Effect of Zr content on microstructure and mechanical properties of AlCoCrFeNi high entropy alloy. Mater Des 94:39–44

Radhakrishna C, Rao KP (1997) The formation and control of Laves phase in superalloy 718 welds. J Mater Sci 32(8):1977–1984

Zeng C, Tian W, Liao WH, Hua L (2016) Microstructure and porosity evaluation in laser-cladding deposited Ni-based coatings. Surf Coatings Technol 294:122–130

Geng Y, Konovalov S, Chen X (2020) Research status and application of the high-entropy and traditional alloys fabricated via the laser cladding. Usp Fiz Met 21:26–45

Takeuchi A, Inoue A (2005) Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater Trans 46(12):2817–2829

Middleburgh S, King D, Lumpkin G, Cortie M, Edwards L (2014) Segregation and migration of species in the CrCoFeNi high entropy alloy. J Alloy Compd 599:179–182

Zhou Y, Chen S, Chen X, Cui T, Liang J, Liu C (2019) The evolution of bainite and mechanical properties of direct laser deposition 12CrNi2 alloy steel at different laser power. Mater Sci Eng: A 742:150–161

Liu H, Gao Q, Dai J, Chen P, Gao W, Hao J, Yang H (2022) Microstructure and high-temperature wear behavior of CoCrFeNiWx high-entropy alloy coatings fabricated by laser cladding. Tribol Int 172:107574

Author information

Authors and Affiliations

Contributions

Yunze Li: methodology, investigation, validation, writing—original draft. Dongzhe Zhang: investigation, writing—review and editing. Yingbin Hu: writing—review and editing. Weilong Cong: writing—review and editing.

Corresponding author

Ethics declarations

Ethics approval

The authors confirm that they have abided by the publication ethics and state that this work is original and has not been used for publication anywhere before.

Consent to participate

The authors are willing to participate in journal promotions and updates.

Consent for publication

The authors give consent to the journal regarding the publication of this work.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, Y., Zhang, D., Hu, Y. et al. Laser-directed energy deposition of CoCrFeNiTi high entropy alloy coatings: effects of powder geometry and laser power. Int J Adv Manuf Technol 126, 3023–3038 (2023). https://doi.org/10.1007/s00170-023-11288-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11288-2