Abstract

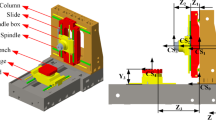

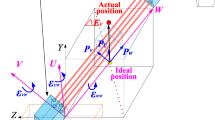

For the identification of the geometric error in the CNC machine tools, this paper proposes a geometric error identification method for machine tools based on the spatial body diagonal error model. A body diagonal error measurement method is proposed to obtain the spatial error, which avoids repeated installation errors. In order to address the pathological problem in geometric error identification, a two-step regularization method based on the spatial body diagonal error model is proposed. Firstly, the mapping relationship between the geometric error of the machine tools and the spatial body diagonal error, which is measured by a multibeam laser interferometer, is established. Secondly, a two-step regularization method is adopted to improve the identification accuracy and the stability. Finally, the body diagonal error measurement method is applied to a horizontal three-axis machining center, and the measurement results show that the method is feasible. Simulations and experiments are performed to compare the two-step regularized identification method with the least square identification method, and the results prove the good reliability and validity of the proposed method. Comparing the identification results with the measurement results, the absolute error is less than 4.8584 μm, and the relative error is less than 25.6062%. It shows that the spatial body diagonal error model proposed in this paper is comprehensive, and the geometric error identification method is systematic and universal.

Similar content being viewed by others

Availability of data and material

Not applicable.

Code availability

Not applicable.

Abbreviations

- x, y, z :

-

The displacement in x, y and z axes

- \(\begin{aligned}&{^{W}\boldsymbol{T}_{Z}},\;{^{Z}\boldsymbol{T}_{{Z}_{0}}},\;{^{{Z}_{0}}\boldsymbol{T}_{O}},\;{^{O}\boldsymbol{T}_{{X}_{0}}},\\&{^{{X}_{0}}\boldsymbol{T}_{X}},\;{^{X}\boldsymbol{T}_{{Y}_{0}}},\;{^{{Y}_{0}}\boldsymbol{T}_{Y}},\;{^{Y}\boldsymbol{T}_{T}}\end{aligned}\) :

-

The macroscopic displacement matrix between the components of the machine tool

- \(\begin{aligned}&{^{W}y_{Z}},\;{^{{Z_{0}}}x_{O}},\;{^{O}y_{{X_{0}}}},\\&{^{O}z_{{X_{0}}}},\;{^{X}y_{{Y_{0}}}},\;{^{X}z_{{Y_{0}}}},\;{^{Y}z_{T}}\end{aligned}\) :

-

The distance between the origin of the coordinate system for each component

- \(\begin{aligned}&{^{W}\Delta_{Z}},\;{^{Z}\Delta_{{Z_{0}}}},\;{^{{Z_{0}}}\Delta_{O}},{^{O}\Delta_{{X_{0}}}},\\&{^{{X_{0}}}\Delta_{X}},\;{^{X}\Delta_{{Y_{0}}}},\;{^{{Y_{0}}}\Delta_{Y}},\;{^{Y}\Delta_{T}}\end{aligned}\) :

-

The microscopic displacement matrix between the components of the machine tool

- \(\delta_{i} (j),\;\varepsilon_{i} (j)\) :

-

The position-dependent geometric error of the machine tool, i, j = x, y, z

- \(\alpha, \;\beta,\; \gamma\) :

-

The squareness error of the machine tool

- \(\theta_{Y0},\;\theta_{X1},\;\theta_{Z2}\) :

-

The rotation angle during the transformation of the body diagonal coordinate system and the bed coordinate system

- \(l_{x},\;l_{y},\;l_{z}\) :

-

The working stroke of x, y, and z axes

- \(x_{m},\;y_{m},\;z_{m}\) :

-

The coordinate value of the space point under the measurement coordinate system

- \(x_{o},\;y_{o},\;\;z_{o}\) :

-

The coordinate value of the space point under the bed coordinate system

- P w :

-

The workpiece machining point coordinate vector in the worktable coordinate system

- P t :

-

The tool tip point coordinate vector in the tool coordinate system

- \(x_{w},\;y_{w},\;z_{w}\) :

-

The workpiece machining point coordinate value in the worktable coordinate system

- \(x_{t},\;y_{t},\;z_{t}\) :

-

The tool tip point coordinate value in the tool coordinate system

- \({\boldsymbol{T}}_{1}\) :

-

The coordinate transformation matrix between different body diagonal coordinate systems and the bed coordinate system

- \(^{M}{\boldsymbol{P}}_{w},\;^{M}{\boldsymbol{P}}_{t}\) :

-

The coordinate vector of the workpiece machining point and the tool tip point under the measurement coordinate system

- \(^{W}{\boldsymbol{T}}_{T},\;^{W}{\boldsymbol{T}}_{T}^{\prime }\) :

-

The coordinate transformation matrix from the worktable coordinate system to the tool coordinate system under the ideal and actual conditions

- \(^{W}{\boldsymbol{E}}_{T}\) :

-

The error motion matrix between the worktable coordinate system and the tool coordinate system

- \(\Delta {P}_{X},\;\Delta {P}_{Y},\;\Delta {P}_{Z}\) :

-

The position error in X, Y and Z directions, respectively, under the measurement coordinate system

- \(\Delta {V}_{X},\;\Delta {V}_{Y},\;\Delta {V}_{Z}\) :

-

The angular error in X, Y and Z directions, respectively, under the measurement coordinate system

- \(\Delta {P}_{x},\;\Delta {P}_{y},\;\Delta {P}_{z}\) :

-

The position error in x, y and z directions, respectively, under the bed coordinate system

- \(\Delta {V}_{x},\;\Delta {V}_{y},\;\Delta {V}_{x}\) :

-

The angular error in x, y and z directions, respectively, under the bed coordinate system

- T :

-

The spatial coordinate transformation matrix

- \(\Delta {\boldsymbol{r}}\) :

-

The spatial error matrix of the machine tool

- A :

-

The mapping matrix between the spatial error and the twenty-one geometric errors of the machine tool

- ε :

-

The twenty-one geometric errors matrix of the machine tool

- \(\delta_{ij,k},\;\boldsymbol\varepsilon_{ij,k}\) :

-

The k-th polynomial coefficient in the position error and the angular error \(i,j = x,y,z\); \(k = 1,2, \cdots ,n\)

- \({\boldsymbol{p}}_{{\delta_{i} (j)}},\;{\boldsymbol{p}}_{{\varepsilon_{i} (j)}}\) :

-

The polynomial coefficient vector of the position error and the angular error, \(i,j = x,y,z\)

- \({\boldsymbol{h}}_{{\delta_{i} (j)}}, \;{\boldsymbol{h}}_{{\varepsilon_{i} (j)}}\) :

-

The position matrix corresponding to the position error and angular error, \(i,j = x,y,z\)

- H :

-

The mapping matrix consisting of the machine tool position coordinates

- p :

-

The geometric error polynomial coefficient vector

- M :

-

The mapping matrix between the spatial error and the geometric error polynomial coefficient

- m :

-

The number of measurement points involved in identification

- n :

-

The polynomial order

- \(\hat{\boldsymbol{p}}\) :

-

The identification result of p

- R :

-

The regularization matrix

- \(\alpha\) :

-

The regularized parameter

- TIKHONOV:

-

The regularization theory

- \(MESM(\hat{\boldsymbol{p}})\) :

-

The mean square error matrix of \(\hat{\boldsymbol{p}}\)

- \(\hat{\sigma }_{0}^{2}\) :

-

The unit weight variance of \(\hat{\boldsymbol{p}}\)

- \(\xi\) :

-

The deviation between \(\hat{\boldsymbol{p}}\) and \(\boldsymbol p\)

References

Lei WT, Hsu YY (2017) Accuracy enhancement of five-axis CNC machines through real-time error compensation. Int J Mach Tool Manufact 43(9):871–877. https://doi.org/10.1016/S0890-6955(03)00089-0

Chu CH, Huang WN, Hsu YY (2008) Machining accuracy improvement in five-axis flank milling of ruled surfaces. Int J Mach Tool Manufact 48(7–8):914–921. https://doi.org/10.1016/j.ijmachtools.2007.10.023

Andolfatto L, Lavernhe S, Mayer JRR (2011) Evaluation of servo, geometric and dynamic error sources on five axis high-speed machine tool. Int J Mach Tool Manufact 51(10–11):787–796. https://doi.org/10.1016/j.ijmachtools.2011.07.002

Abdulshahed AM, Longstaff AP, Fletcher S, Potdar A (2016) Thermal error modelling of a gantry-type 5-axis machine tool using a Grey Neural Network Model. J Manuf Syst 41:130–142. https://doi.org/10.1016/j.jmsy.2016.08.006

Ma C, Liu JL, Wang SL (2020) Thermal error compensation of linear axis with fixed-fixed installation-ScienceDirect. Int J Mech Sci. https://doi.org/10.1016/j.ijmecsci.2020.105531

Chen JX, Lin SW, He BW (2014) Geometric error measurement and identification for rotary table of multi-axis machine tool using double ball-bar. Int J Mach Tool Manufact 77:47–55. https://doi.org/10.1016/j.ijmachtools.2013.10.004

Ding S, Song ZQ, Wu WW, Guo EK, Huang XD, Song AP (2020) Geometric error modeling and compensation of horizontal CNC turning center for TI worm turning-ScienceDirect. Int J Mech Sci. https://doi.org/10.1016/j.ijmecsci.2019.105266

Zhu SW, Ding GF, Qin SF, Lei J, Zhuang L, Yan KY (2012) Integrated geometric error modeling, identification and compensation of CNC machine tools. Int J Mach Tool Manufact 52(1):24–29. https://doi.org/10.1016/j.ijmachtools.2011.08.011

Hsu YY, Wang SS (2007) A new compensation method for geometric errors of five-axis machine tools. Int J Mach Tool Manufact 47(2):352–360. https://doi.org/10.1016/j.ijmachtools.2006.03.008

Qiu H, Li Y, Li YB (2001) A new method and device for motion accuracy measurement of NC machine tools. Part 1: principle and equipment. Int J Mach Tool Manufact 41(4):521–534. https://doi.org/10.1016/S0890-6955(00)00092-4

Knapp W (1983) Circular test for three-coordinate measuring machines and machine tools. Precis Eng 5(3):115–124. https://doi.org/10.1016/0141-6359(83)90007-7

Bryan JB (1982) A simple method for testing measuring machines and machine tools Part 1: principles and applications. Precis Eng 4(2):61–69. https://doi.org/10.1016/0141-6359(82)90018-6

Bryan JB (1982) A simple method for testing measuring machines and machine tools. Part 2: construction details. Precis Eng 4(3):125–138. https://doi.org/10.1016/0141-6359(82)90075-7

Wang JD, Guo JJ (2016) Research on the base station calibration of multi-station and time-sharing measurement based on hybrid genetic algorithm. Measurement 94:139–148. https://doi.org/10.1016/j.measurement.2016.07.076

Schwenke H, Franke M, Hannaford J, Kunzmann H (2005) Error mapping of CMMs and machine tools by a single tracking interferometer. CIRP Ann-Manuf Technol 54(1):475–478. https://doi.org/10.1016/S0007-8506(07)60148-6

Lee JH, Liu Y, Yang SH (2006) Accuracy improvement of miniaturized machine tool: geometric error modeling and compensation. Int J Mach Tool Manufact 46(12–13):1508–1516. https://doi.org/10.1016/j.ijmachtools.2005.09.004

Ezedine F, Linares JM, Sprauel JM, Chaves-Jacob J (2016) Smart sequential multilateration measurement strategy for volumetric error compensation of an extra-small machine tool. Precis Eng 43:178–186. https://doi.org/10.1016/j.precisioneng.2015.07.007

Sun GM, He GY, Zhang DW, Sang YC, Zhang XL, Ding BH (2018) Effects of geometrical errors of guideways on the repeatability of positioning of linear axes of machine tools. Int J Adv Manuf Technol 98(9–12):2319–2333. https://doi.org/10.1007/s00170-018-2291-4

Su SP, Li SY, Wang GL (2002) Geometric error identification method of machining center based on spatial error model. China J Mech Eng 38(7):121–125. https://doi.org/10.3321/j.issn:0577-6686.2002.07.026

Sun K, Shen XQ (2009) Technology of NC error parameter identification based on 22 displacement measurement line. Mech Eng. https://doi.org/10.3969/j.issn.1002-2333.2009.03.060

Chen GQ, Yuan JX, Ni J (2001) A displacement measurement approach for machine geometric error assessment. Int J Mach Tool Manufact 41(1):149–161. https://doi.org/10.1016/S0890-6955(00)00049-3

Liu YW, Liu LB, Zhao XS, Zhang Q, Wang SX (1998) Investigation of error compensation technology for NC machine tool. China Mech Eng (12):4852–4852. CNKI:SUN:ZGJX.0.1998-12-014

Xia CJ, Wang SL, Ma C, Wang SB, Xiao YL (2020) Crucial Geometric Error Compensation Towards Gear Grinding Accuracy Enhancement Based on Simplified Actual Inverse Kinematic Model. Int J Mech Sci. https://doi.org/10.1016/j.ijmecsci.2019.105319

Shen JH (2008) Key technique and application in error compensation for CNC machine tools. Dissertation, Graduate Shanghai Jiao Tong University

Xu K, Li GL, He K, Tao XH (2020) Identification of Position-Dependent Geometric Errors with Non-Integer Exponents for linear axis Using Double Ball Bar. Int J Mech Sci. https://doi.org/10.1016/j.ijmecsci.2019.105326

Bohez ELJ, Ariyajunya B, Sinlapeecheewa C, Shein TMM, Lap DT, Belforte G (2007) Systematic geometric rigid body error identification of 5-axis milling machines. Comput Aided Des 39:229–244. https://doi.org/10.1016/j.cad.2006.11.006

Liu Y, Wan M, Xing WJ, Xiao QB, Zhang WH (2018) Generalized actual inverse kinematic model for compensating geometric errors in five-axis machine tools. Int J Mech Sci 145:299–317. https://doi.org/10.1016/j.ijmecsci.2018.07.022

Liu Y, Wan M, Xiao QB, Zhang WH (2019) Identification and compensation of geometric errors of rotary axes in five-axis machine tools through constructing equivalent rotary axis (ERA). Int J Mech Sci 152:211–227. https://doi.org/10.1016/j.ijmecsci.2018.12.050

Pahk HJ, Kim YS, Moon JH (1997) A new technique for volumetric error assessment of CNC machine tools incorporating ball bar measurement and 3D volumetric error model. Int J Mach Tool Manufact 37(11):1583–1596. https://doi.org/10.1016/S0890-6955(97)00029-1

Xu LX (2014) A general method for impact dynamic analysis of a planar multi-body system with a rolling ball bearing joint. Nonlinear Dyn 78(2):857–879. https://doi.org/10.1007/s11071-014-1482-2

Li BT, Hong J, Liu ZF (2014) Stiffness design of machine tool structures by a biologically inspired topology optimization method. Int J Mach Tool Manufact 84:33–44. https://doi.org/10.1016/j.ijmachtools.2014.03.005

Wang ZJ (2003) Research on the regularization solutions of ill-posed problems in geodesy. Dissertation, Graduate School of Chinese Academy of Sciences

Wang ZJ, Ou JK, Liu LT (2005) A Method for Resolving Ill-conditioned Problems-Two-Step Solution. J Wuhan Univ 09:821–824. https://doi.org/10.3321/j.issn:1671-8860.2005.09.017

Ngo SH, Kemény S, Deák A (2003) Performance of the ridge regression method as applied to complex linear and nonlinear models. Chemom Intell Lab Syst 67(1):69–78. https://doi.org/10.1016/S0169-7439(03)00062-5

Hu ZG, Hua XH (2010) Determination of Tikhonov regularization parameters by optimal regularization method. Surv Mapp Sci 35(002):51–53. CNKI:SUN:CHKD.0.2010-02-018

Wang ZJ, Ou JK (2004) Determination of ridge parameters in ridge estimation by L-curve method. J Wuhan Univ 29(003):235–238. https://doi.org/10.3321/j.issn:1671-8860.2004.03.012

Xu YB, Pei Y, Dong F (2016) An extended L-curve method for choosing a regularization parameter in electrical resistance tomography. Measurement Sci Technol. https://doi.org/10.1088/0957-0233/27/11/114002

Tao BZ (1998) On the variance of unit weight formula. Bull. Surv Mapp (09):5–6. CNKI:SUN:CHTB.0.1998-09-001

Sim HY, Ramli R, Saifizul AA, Abdullah MAK (2014) Empirical investigation of acoustic emission signals for valve failure identification by using statistical method. Measurement 58:165–174. https://doi.org/10.1016/j.measurement.2014.08.028

Funding

This research work is supported by the National Key R&D Program of China (No. 2018YFB1701201) and the National Natural Science Foundation of China (No. 51675378).

Author information

Authors and Affiliations

Contributions

Sitong Wang: Conceptualization, methodology, software, investigation, writing—original draft. Gaiyun He: Conceptualization, supervision, funding acquisition, resources. Wenjie Tian: Data curation, resources, visualization. Dawei Zhang: Validation, formal analysis, project administration. Yumeng Song: Writing, review and editing; visualization. Yichen Yan: Data curation, writing review. Ran Xie: Experiment, writing—review and editing.

Corresponding author

Ethics declarations

Ethics approval

This article does not contain any studies with human participants or animals performed by any of the authors. In this experiment, we did not collect any samples of human and animals.

Consent to participate

All the authors, namely, Sitong Wang, Gaiyun He, Wenjie Tian, Dawei Zhang, Yumeng Song, Yichen Yan, and Ran Xie have consented to participate in the paper and agreed to submit the manuscript.

Consent for publication

All the authors, namely, Sitong Wang, Gaiyun He, Wenjie Tian, Dawei Zhang, Yumeng Song, Yichen Yan, and Ran Xie have consented to publish the manuscript after peer review.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, S., He, G., Tian, W. et al. Geometric error identification method for machine tools based on the spatial body diagonal error model. Int J Adv Manuf Technol 121, 7997–8017 (2022). https://doi.org/10.1007/s00170-022-09633-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09633-y