Abstract

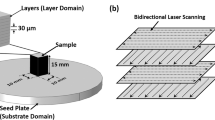

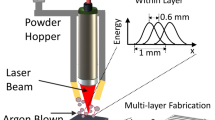

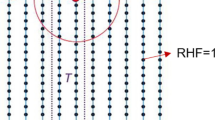

Using an efficient hybrid Cellular Automata/Phase Field (CA-PF) dendrite growth model in combination with a solid-state phase transformation model, microstructure evolution and solid-state phase transformation were predicted during laser direct deposition (LDD) of H13 tool steel powder within a large domain across multiple deposition tracks and layers. Temperature and surface geometry data were provided by a comprehensive physics-based laser deposition model. The computational efficiency of the CA-PF model allows for simulating domains large enough to capture dendrite growth across an entire molten pool and into multiple neighboring LDD tracks and layers. The microstructure of the target track is strongly affected by heat from neighboring tracks including re-melting, re-solidification and solid-state phase transformation including austenitization, martensite formation and martensite tempering. Dendrite size and growth direction across the entire fusion zone, as well as predicted hardness values, are found to be in good agreement with experimental results.

Similar content being viewed by others

References

Wen S, Shin YC (2010) Modeling of transport phenomena during the coaxial laser direct deposition process. J Appl Phys 108(4)

Wen S, Shin YC (2011) Modeling of the off-axis high power diode laser cladding process. J Heat Transfer 133(3):31007

Cormier D, Harrysson O, West H (2004) Characterization of H13 steel produced via electron beam melting. Rapid Prototyp J 10(1):35–41

Mazur M, Leary M, McMillan M, Elambasseril J, Brandt M (2016) SLM additive manufacture of H13 tool steel with conformal cooling and structural lattices. Rapid Prototyp J 22(3):504–518

Mazur M, Brincat P, Leary M, Brandt M (2017) Numerical and experimental evaluation of a conformally cooled H13 steel injection mould manufactured with selective laser melting. Int J Adv Manuf Technol 93(1–4):881–900

Tan W, Bailey NS, Shin YC (2013) Investigation of keyhole plume and molten pool based on a three-dimensional dynamic model with sharp interface formulation. J Phys D Appl Phys 46(5):55501

Tan W, Wen S, Bailey N, Shin YC (2011) Multiscale modeling of transport phenomena and dendritic growth in laser cladding processes. Metall Mater Trans B 42(6):1306–1318

Wen S, Shin YC (2013) Comprehensive predictive modeling and parametric analysis of multitrack direct laser deposition processes Comprehensive predictive modeling and parametric analysis of multitrack direct laser deposition processes. ASM Int 022003(2011):1–7

Bailey NS, Katinas C, Shin YC (2017) Laser direct deposition of AISI H13 tool steel powder with numerical modeling of solid phase transformation, hardness, and residual stresses. J Mater Process Technol 247:223–233

Flemings MC (1974) Solidification processing. Metall Trans 5(10):2121–2134

Kurz W, Fisher D (1998) Fundamentals of solidification, 4th edn. Enfield Publishing & Distribution Company, Enfield, NH

Stefanescu DM (2010) Science and engineering of casting solidification, second ed. Springer

Zhu MF, Hong CP (2002) A three dimensional modified cellular automaton model for the prediction of solidification microstructures. ISIJ Int 42(5):520–526

Kurz W, Giovanola B, Trivedi R (1986) Theory of microstructural development during rapid solidification. Acta Metall 34(5):823–830

Beltran-Sanchez L, Stefanescu DM (2003) Growth of solutal dendrites: a cellular automaton model and its quantitative capabilities. Metall Mater Trans A 34(2):367–382

Pavlyk V, Dilthey U (2003) Simulation of weld solidification microstructure and its coupling to the macroscopic heat and fluid flow modelling. Model Simul Mater Sci Eng 12(1):S33

Wang W, Lee PD, Mclean M (2003) A model of solidification microstructures in nickel-based superalloys: predicting primary dendrite spacing selection. Acta Mater 51(10):2971–2987

Krane MJM, Johnson DR, Raghavan S (2009) The development of a cellular automaton-finite volume model for dendritic growth. Appl Math Model 33(5):2234–2247

Zhu M, Pan S, Sun D, Zhao H (2010) Numerical simulation of microstructure evolution during alloy solidification by using cellular automaton method. ISIJ Int 50(12):1851–1858

Dong HB, Lee PD (2005) Simulation of the columnar-to-equiaxed transition in directionally solidified Al–Cu alloys. Acta Mater 53(3):659–668

Zhu MF, Stefanescu DM (2007) Virtual front tracking model for the quantitative modeling of dendritic growth in solidification of alloys. Acta Mater 55(5):1741–1755

Pan S, Zhu M (2010) A three-dimensional sharp interface model for the quantitative simulation of solutal dendritic growth. Acta Mater 58(1):340–352

Michelic SC, Thuswaldner JM, Bernhard C (2010) Polydimensional modelling of dendritic growth and microsegregation in multicomponent alloys. Acta Mater 58(7):2738–2751

Li Q, Wang Y, Zhang HW, Xie SS, Huang GJ (2013) Numerical simulation of microstructure and solutal microsegregation formation of ternary alloys during solidification process. Ironmak Steelmak

Chen R, Xu Q, Liu B (2015) Cellular automaton simulation of three-dimensional dendrite growth in Al-7Si-Mg ternary aluminum alloys. Comput Mater Sci 105:90–100

Tan W, Shin YC (2015) Multi-scale modeling of solidification and microstructure development in laser keyhole welding process for austenitic stainless steel. Comput Mater Sci 98:446–458

Gu C, Ridgeway CD, Luo AA (2019) Examination of dendritic growth during solidification of ternary alloys via a novel quantitative 3D cellular automaton model. Metall Mater Trans B 50(1):123–135

Ao X, Xia H, Liu J, He Q (2020) Simulations of microstructure coupling with moving molten pool by selective laser melting using a cellular automaton. Mater Des 185:108230

Ode M, Kim SG, Suzuki T (2001) Recent advances in the phase-field model for solidification. ISIJ Int 41(10):1076–1082

Boettinger WJ, Warren JA, Beckermann C, Karma A (2002) Phase-field simulation of solidification. Mater Res 32(1):163

Chen L-Q (2002) Phase-field models for microstructure evolution. Annu Rev Mater Res 32(1):113–140

Gránásy L, Pusztai T, Warren JA (2004) Modelling polycrystalline solidification using phase field theory. J Phys Condens Matter 16(41):R1205

Takaki T, Ohno M, Shimokawabe T, Aoki T (2014) Two-dimensional phase-field simulations of dendrite competitive growth during the directional solidification of a binary alloy bicrystal. Acta Mater 81:272–283

Grafe U, Böttger B, Tiaden J, Fries SG (2000) Coupling of multicomponent thermodynamic databases to a phase field model: application to solidification and solid state transformations of superalloys. Scr Mater 42(12):1179–1186

Ode M, Lee JS, Kim SG, Kim WT, Suzuki T (2000) Phase-field model for solidification of ternary alloys. ISIJ Int 40(9):870–876

Cha P-R, Yeon D-H, Yoon J-K (2001) A phase field model for isothermal solidification of multicomponent alloys. Acta Mater 49(16):3295–3307

Kobayashi H, Ode M, Kim SG, Kim WT, Suzuki T (2003) Phase-field model for solidification of ternary alloys coupled with thermodynamic database. Scr Mater 48(6):689–694

Qin RS, Wallach ER, Thomson RC (2005) A phase-field model for the solidification of multicomponent and multiphase alloys. J Cryst Growth 279(1):163–169

Zhang L, Danilova EV, Steinbach I, Medvedev D, Galenko PK (2013) Diffuse-interface modeling of solute trapping in rapid solidification: Predictions of the hyperbolic phase-field model and parabolic model with finite interface dissipation. Acta Mater 61(11):4155–4168

Bailey NS, Hong K-M, Shin YC (2020) Comparative assessment of dendrite growth and microstructure predictions during laser welding of Al 6061 via 2D and 3D phase field models. Comput Mater Sci 172:109291

Suzuki T, Ode M, Kim SG, Kim WT (2002) Phase-field model of dendritic growth. J Cryst Growth 237:125–131

Kim SG, Kim WT, Suzuki T (1999) Phase-field model for binary alloys. Phys Rev e 60(6):7186

Cha P-R, Yeon D-H, Yoon J-K (2005) Phase-field model for multicomponent alloy solidification. J Cryst Growth 274(1):281–293

Berghoff M, Nestler B (2015) Phase field crystal modeling of ternary solidification microstructures. Comput Condens Matter 4:46–58

Böttger B, Eiken J, Steinbach I (2006) Phase field simulation of equiaxed solidification in technical alloys. Acta Mater 54(10):2697–2704

Eiken J (2010) Phase-field simulation of microstructure formation in technical magnesium alloys. Int J Mater Res 101(4):503–509

Provatas N, Goldenfeld N, Dantzig J (1998) Efficient computation of dendritic microstructures using adaptive mesh refinement. Phys Rev Lett 80(15):3308

Provatas N, Greenwood M, Athreya B, Goldenfeld N, Dantzig J (2005) Multiscale modeling of solidification: phase-field methods to adaptive mesh refinement. Int J Mod Phys B 19(31):4525–4565

Feng WM, Yu P, Hu SY, Liu Z-K, Du Q, Chen L-Q (2006) Spectral implementation of an adaptive moving mesh method for phase-field equations. J Comput Phys 220(1):498–510

Tan W, Bailey NS, Shin YC (2011) A novel integrated model combining Cellular Automata and Phase Field methods for microstructure evolution during solidification of multi-component and multi-phase alloys. Comput Mater Sci 50(9):2573–2585

Bailey NS, Tan W, Shin YC (2009) Predictive modeling and experimental results for residual stresses in laser hardening of AISI 4140 steel by a high power diode laser. Surf Coatings Technol 203(14):2003–2012

Katinas C, Shang W, Shin YC, Chen J (2018) Modeling Particle Spray and Capture Efficiency for Direct Laser Deposition Using a Four Nozzle Powder Injection System. J Manuf Sci Eng 140(4):41014

Osher S, Sethian JA (1988) Fronts propagating with curvature-dependent speed: algorithms based on Hamilton-Jacobi formulations. J Comput Phys 79(1):12–49

Wang W, Lee PD, McLean M (2003) A Model of Solidification Microstructures in Nickel-Based Superalloys: Predicting Primary Dendrite Spacing Selection. Acta Mater 51:2971–2987

Raghavan S (2005) A numerical model for dendritic growth in binary alloys. Purdue University

Martorano MA, Fortes MA, Padilha AF (2006) A numerical method for curvature driven boundary migration. Model Simul Mater Sci Eng 14(1):83

Zhang R, Jing T, Jie W, Liu B (2006) Phase-field simulation of solidification in multicomponent alloys coupled with thermodynamic and diffusion mobility databases. Acta Mater 54(8):2235–2239

Kim SG (2007) A phase-field model with antitrapping current for multicomponent alloys with arbitrary thermodynamic properties. Acta Mater 55(13):4391–4399

Skvarenina S, Shin YC (2006) Predictive modeling and experimental results for laser hardening of AISI 1536 steel with complex geometric features by a high power diode laser. Surf Coatings Technol 201(6):2256–2269

Ashby MF, Easterling KE (1984) The transformation hardening of steel surfaces by laser beams: I. Hypo-eutectoid steels. Acta Metall 32(11):1935–1948

Lakhkar RS, Shin YC, Krane MJM (2008) Predictive modeling of multi-track laser hardening of AISI 4140 steel. Mater Sci Eng A 480(1):209–217

Callister WD, Rethwisch DG (2007) Materials science and engineering: an introduction, vol 7. Wiley, New York

Kang S-H, Im Y-T (2005) Three-dimensional finite-element analysis of the quenching process of plain-carbon steel with phase transformation. Metall Mater Trans A 36(9):2315–2325

Woodard PR, Chandrasekar S, Yang HTY (1999) Analysis of temperature and microstructure in the quenching of steel cylinders. Metall Mater Trans B 30(4):815–822

Patwa R, Shin YC (2007) Predictive modeling of laser hardening of AISI5150H steels. Int J Mach Tools Manuf 47(2):307–320

Andersson J-O, Lange N (1988) An experimental study and a thermodynamic evaluation of the Fe-Cr-Mo system. Metall Trans A 19(6):1385–1394

Benedyk JC (2008) High performance alloys database, H13. CINDAS LLC, West Lafayette IN

Bailey NS, Katinas C, Shin YC (2017) Laser direct deposition of AISI H13 tool steel powder with numerical modeling of solid phase transformation, hardness, and residual stresses. J Mater Process Technol 247

Funding

The authors declare that no funds, grants or other support was received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Neil Bailey and Yung Shin. The first draft of the manuscript was written by Neil Bailey, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bailey, N.S., Shin, Y.C. Multi-track, multi-layer dendrite growth and solid phase transformation analysis during additive manufacturing of H13 tool steel using a combined hybrid cellular automata/phase field, solid-state phase prediction models. Int J Adv Manuf Technol 120, 2089–2108 (2022). https://doi.org/10.1007/s00170-022-08901-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-08901-1