Abstract

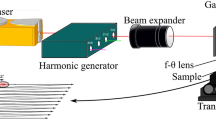

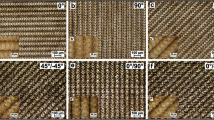

While pure titanium is a material of choice for medical applications for its excellent mechanical and chemical properties, further improving its surface-related functionalities by surface texturing is also promising. In the present work, we experimentally investigate the fabrication, as well as the resulting functionalities of surface wettability and biocompatibility, of precise mesh-type surface textures on pure titanium by picosecond pulsed laser ablation operating at 1064 nm wavelength. Specifically, the dependence of microgroove morphology on average power and scanning speed is evaluated to yield optimized laser processing parameters, which are utilized to fabricate high precision mesh-type surface textures with uniform feature size and limited thermal effects on pure titanium. Subsequent performance evaluation tests demonstrate that the mesh-type surface textures induce a beneficial effect on the biocompatibility with respect to BMSC cells due to the enhanced hydrophilicity.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

Reference

Geetha M, Singh AK, Asokamani R, Gogia AK (2009) Ti based biomaterials, the ultimate choice for orthopaedic implants-A review. Prog Mater Sci 54:397–425

Panjan P, Drnovšek A, Gselman P, Čekada M, Panjan M (2020) Review of growth defects in thin films prepared by PVD techniques. Coatings 10:447

Shokrani A, Dhokia V, Newman ST (2012) Environmentally conscious machining of difficult-to-machine materials with regard to cutting fluids. Int J Mach Tool Manuf 57:83–101

Durairaj S, Guo J, Aramcharoen A, Castagne S (2018) An experimental study into the effect of micro-textures on the performance of cutting tool. Int J Adv Manuf Technol 98:1011–1030

Guo B, Sun J, Hua Y, Zhan N, Jia J, Chu K (2020) Femtosecond Laser Micro/Nano-manufacturing: Theories, Measurements, Methods, and Applications. Nanomanufacturing and Metrology 3:26–67

Kurella A, Dahotre NB (2005) Surface modification for bioimplants: the role of laser surface engineering. J Biomater Appl 20:5–50

Earl C, Castrejón-Pita JR, Hilton PA, O’Neill W (2016) The dynamics of laser surface modification. J Manuf Process 21:214–223

Wang MZ, Wang CB, Kang JJ, Zhu LN, Yue W, Fu ZQ (2017) Effect of laser surface texture shape parameters on the tribological properties of titanium alloys. China Surface Engineering 30:71–77

Kümmel D, Hamann-Schroer M, Hetzner H, Schneider J (2019) Tribological behavior of nanosecond-laser surface textured Ti6Al4V. Wear 422:261–268

Xu JL, Tan WS, Hu ZR, Wang ST, Zhou JZ (2022) Study on High Temperature Friction and Wear Properties of Laser Surface Microtexture of TC4 Titanium Alloy. Laser Optoelectron Prog 59:1114002

Cunha A, Serro AP, Oliveira V, Almeida A, Vilar R, Durrieu MC (2013) Wetting behaviour of femtosecond laser textured Ti-6Al-4V surfaces. Appl Surf Sci 265:688–696

Li HY, Li LQ, Huang RR, Tan CW, Yang J, Xia HB, Chen B, Song XG (2021) The effect of surface texturing on the laser-induced wetting behavior of AlSi5 alloy on Ti6Al4V alloy. Appl Surf Sci 566:150630

MacDonald DE, Markovic B, Allen M, Somasundaran P, Boskey AL (1998) Surface analysis of human plasma fibronectin adsorbed to commercially pure titanium materials. J Biomed Mater Res 41:120–130

Conradi M, Kocijan A, Klobčar D, Godec M (2020) Influence of Laser Texturing on Microstructure, Surface and Corrosion Properties of Ti-6Al-4V. Metals 10:1504

Xu Y, Li ZP, Zhang GQ, Wang G, Zeng ZX, Wang CT, Wang CC, Zhao SC, Zhang YD, Ren TH (2019) Electrochemical corrosion and anisotropic tribological properties of bioinspired hierarchical morphologies on Ti-6Al-4V fabricated by laser texturing. Tribol Int 134:352–364

Zhou Y, Yang GZ, Zhang WJ, Hu J (2018) Investigating the effect of picosecond laser texturing on microstructure and biofunctionalization of titanium alloy. J Mater Process Technol 255:129–136

Kumari R, Scharnweber T, Pfleging W, Besser H, Majumdar JD (2015) Laser surface textured titanium alloy (Ti-6Al-4V)-Part II-Studies on bio-compatibility. Appl Surf Sci 357:750–758

Cunha A, Zouani OF, Plawinski L, Rego AMB, Almeida1 A, Vilar R, Durrieu MC (2015) Human mesenchymal stem cell behavior on femtosecond laser-textured Ti-6Al-4V surfaces. Nanomedicine 10:725–739

Ataee A, Li Y, Brandt M, Wen C (2018) Ultrahigh-strength titanium gyroid scaffolds manufactured by selective laser melting (SLM) for bone implant applications. Acta Mater 158:354–368

Yan M, Xu W, Dargusch MS, Tang HP, Brandt M, Qian M (2014) Review of effect of oxygen on room temperature ductility of titanium and titanium alloys. Powder Metall 57:251–257

Duan WQ, Mei XS, Fan ZJ, Li JC, Wang KD, Zhang YF (2020) Electrochemical corrosion assisted laser drilling of micro-hole without recast layer. Optik 202:163577

Yang Z, Sista S, Elmer JW, Debroy T (2000) Three dimensional Monte Carlo simulation of grain growth during GTA welding of titanium. Acta Mater 48:4813–4825

Mishra S, Debroy T (2004) Measurements and Monte Carlo simulation of grain growth in the heat-affected zone of Ti-6Al-4V welds. Acta Mater 52:1183–1192

Li JB, Liu S, Yu AB, Xiang ST (2018) Effect of laser surface texture on CuSn6 bronze sliding against PTFE material under dry friction. Tribol Int 118:37–45

Zhan XH, Yi P, Liu YC, Xiao PF, Zhu XY, Ma J (2020) Effects of single-and multi-shape laser-textured surfaces on tribological properties under dry friction. Proc IME C J Mech Eng Sci 234:1382–1392

Wang W, He YY, Zhao J, Mao JY, Hu YT, Luo JB (2020) Optimization of groove texture profile to improve hydrodynamic lubrication performance: Theory and experiments. Friction 8:83–94

Pratap T, Patra K (2020) Tribological performances of symmetrically micro-textured Ti-6Al-4V alloy for hip joint. Int J Mech Sci 182:105736

Li D, Neumann AW (1992) Contact angles on hydrophobic solid surfaces and their interpretation. J Colloid Interface Sci 148:190–200

Khosroshahi ME, Mahmoodi M, Saeedinasab H, Tahrir M (2008) Evaluation of mechanical and electrochemical properties of laser surface modified Ti-6Al-4V for biomedical applications: in vitro study. Surf Eng 24:209–218

Xu SZ, Chen Y, Liu H, Miao MM, Yuan XD, Jiang XD (2020) Femtosecond laser ablation of Ti alloy and Al alloy. Optik 212:164628

Wenzel RN (1936) Resistance of solid surfaces to wetting by water. Ind Eng Chem 28:988–994

Marmur A (1983) Equilibrium and spreading of liquids on solid surfaces. Adv Colloid Interface Sci 19:75–102

Wang XD, Zhang Y, Lee DJ, Peng XF (2007) Spreading of completely wetting or partially wetting power-law fluid on solid surface. Langmuir 23:9258–9262

Liang ZP, Wang XD, Lee DJ, Peng XF, Su A (2009) Spreading dynamics of power-law fluid droplets. J Phys Condens Matter 21:464117

Tiainen L, Abreu P, Buciumeanu M, Silva F, Gasik M, Guerrero RS, Carvalho O (2019) Novel laser surface texturing for improved primary stability of titanium implants. J Mech Behav Biomed Mater 98:26–39

Cai L, Zhang L, Dong J, Wang S (2012) Photocured biodegradable polymer substrates of varying stiffness and microgroove dimensions for promoting nerve cell guidance and differentiation. Langmuir 28:12557–12568

Zheng Q, Mao L, Shi Y, Fu W, Hu Y (2020) Biocompatibility of Ti-6Al-4V titanium alloy implants with laser microgrooved surfaces. Mater Technol 1–10

Acknowledgements

The authors gratefully acknowledge the National Natural Science Foundation of China (NSFC)-German Research Foundation (DFG) international joint research programme (51761135106), the Science Challenge Project (TZ2018006-0201-02).

Author information

Authors and Affiliations

Contributions

Junjie Zhang and Yu Liu conceived the project. Haoyu Li, Xin Wang and Binyu Wang established the device and performed the experiments; Marina Breisch, Alexander Hartmaier, Igor Rostotskyi and Vyacheslav Voznyy discussed the results. Haoyu Liu, Junjie Zhang, Alexander Hartmaier and Yu Liu wrote the paper. All authors read and approved the final manuscript for the submission.

Corresponding authors

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent to publish

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, H., Wang, X., Zhang, J. et al. Experimental investigation of laser surface texturing and related biocompatibility of pure titanium. Int J Adv Manuf Technol 119, 5993–6005 (2022). https://doi.org/10.1007/s00170-022-08710-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-08710-6