Abstract

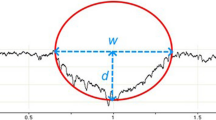

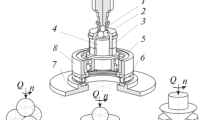

Friction and wear phenomena alter the behavior of the material surface, where certain relevant parameters which characterize the surface are influenced. Therefore, the objective of this work is to identify the parameters most influencing the friction coefficient (f), the wear rate (Ws), and the volume parameters (Vmc and Vvv) during the friction test. The friction tests were carried out by adopting the methodology of 23 complete planes with three factors (D, V, and Py), at two levels each. The results show a decrease in the wear rate when all three factors are at their highest level and a decrease in the friction coefficient when using minimum load on speed long distances. In addition, the mathematical models developed allow to reveal a correlation between the test parameters (D, V, and Py), and the responses studied (f, Ws) in their study field. Moreover, the volume parameters Vmc and Vvv were evaluated during the tests, and the morphology of the worn surface shows that the friction under a load of 1 N leads to the predominance of an abrasive wear mechanism, while a load of 10 N promotes an adhesive wear mechanism.

Similar content being viewed by others

Abbreviations

- D:

-

Traveled distance

- V:

-

Linear speed

- Py:

-

Normal load

- Vmc:

-

Volume of core material

- Vvv:

-

Volume of the valleys void

- X1:

-

Coded factors for D

- X2:

-

Coded factors for V

- X3:

-

Coded factors for Py

- Y:

-

Output response (for f, and Ws

- RSM:

-

Responses surface methodology

References

M Bourebia 2019 Study of the effect burnishing on superficial hardness and hardening of S355JR steel using experimental planning Energy Procedia 157 568 577

B.V. Padmini et al, Influence of substrate roughness on the wear behaviour of kinetic spray coating, Materials Today: Proceedings, https://doi.org/10.1016/j.matpr.2019.09.225.

M Bourebia 2021 Effect of ball burnishing process on mechanical properties and impact behavior of S355JR steel Int J Adv Manuf Technol 116 3 1373 1384 https://doi.org/10.1007/s00170-021-07454-z

S Atlati 2017 Interaction between the local tribological conditions at the tool–chip interface and the thermomechanical process in the primary shear zone when dry machining the aluminum alloy AA2024–T351 Tribol Int 105 326 333

C Lorenzo 2015 Surface hardening and enhanced tribological performance of 4140 steel by friction stir processing Wear 333 962 970

H. Sassoulas, Thermal treatments of stainless steels, Engineering techniques, treated Metallic materials, M 1 155.

H Liu 2011 Study on the variation of 3D topography of specific spot on sliding wear surface Mater Lett 65 3512 3515

G Straffelini G Bizzotto V Zanon 2010 Improving the wear resistance of tools for stamping Wear 269 693 697

ZK Zhang YY Zhang YS Zhu 2010 A new approach to analysis of surface topography PrecisEng (Precision Engineering) 34 4 807 810

PL Menezes SV Kailas 2016 Role of surface texture and roughness parameters on friction and transfer film formation when UHMWPE sliding against steel Biosurface and Biotribology 2 1 1 10 https://doi.org/10.1016/j.bsbt.2016.02.001

CQ Yuan 2008 Surface roughness evolutions in sliding wear process Wear 265 341 348

R Deltombe KJ Kubiak 2011 Bigerelle M, How to select the most relevant 3D roughness parameters of a surface Scanning 36 1 150 160

P. MENEZES et al, Influence of roughness parameters on coefficient of friction under lubricated conditions, S¯adhan¯a Vol. 33, Part 3, pp. 181–190, June 2008.

T Kagnaya 2009 Wear mechanisms of WC–co cutting tools from high-speed tribological tests Wear 267 5–8 890 897

J Rech 2009 Identification of a friction model—application to the context of dry cutting of an AISI 1045 annealed steel with a TiN-coated carbide tool Tribol Int 42 5 738 744

C Bonnet 2008 Identification of a friction model—application to the context of dry cutting of an AISI 316L austenitic stainless steel with a TiN coated carbide tool Int J Mach Tools Manuf 48 11 1211 1223

AI Fernández-Abia 2012 Behavior of austenitic stainless steels at high speed turning using specific force coefficients Int J Adv Manuf Technol 62 505 515 https://doi.org/10.1007/s00170-011-3846-9

A.I. Fernández-Abia et al, Behaviour of PVD coatings in the turning of austenitic stainless steels, Procedia Engineering 63, p. 133 – 141, 2013. The Manufacturing Engineering Society International Conference, MESIC 2013.

R Polvorosa 2017 Tool wear on nickel alloys with different coolant pressures : comparison of Alloy 718 and Waspaloy J Manuf Process 26 44 56

J Pereira 2015 Tribology and high temperature friction wear behavior of MCrAlY laser cladding coatings on stainless Wear 330–331 280 287

K Lin 2019 Effect of tool nose radius and tool wear on residual stresses distribution while turning in situ TiB2/7050 Al metal matrix composites The International Journal of Advanced Manufacturing Technology 100 143 151

J Rech 2018 Toward a new tribological approach to predict cutting tool wear CIRP Ann 67 1 65 68

JF Archard 1961 Single contacts and multiple encounters J Appl Phys 32 1420 1425

M. Fellah et al, Tribological behavior of Ti-6Al-4V and Ti-6Al-7Nb alloys for total hip prosthesis, Advances in Tribology, Volume 2014, Article ID 451387, 13 pages, https://doi.org/10.1155/2014/451387

M.Bourebia et al, Effect of heat treatment on surface hardness and tribological behavior of XC38 steel - approach by the experiments plans, Materials Research Express, Volume 6 Numéro 7, 2019.

M. Bourebia, Effet de la rugosité sur les performances d’un système mécanique-Approche par fractale, Thèse de doctorat, université Badji-Mokhtar-Annaba, 2017.

François Blateyron, Digital Surf mesures 787 - septembre 2006 - www.mesures.com. Accessed 10/02/20

R Gras 2008 Tribology principles and industrial solution the new factory Duno Paris

N. P. Suh, Update on the delamination theory of wear,” in Fundamentals of Friction and Wear of Materials, D. A. Rigney,Ed., p. 43, ASM, Materials Park, Ohio, USA, 1980.

Lahmar.Sihem, friction and wear behavior of steel treated differently, IC-WNDT-MI’14csc-Annaba, Novembre 2014.

Acknowledgements

I would like to thank the entire of laboratory engineers of National Higher School of Mines and Metallurgy-Ammar Laskri, P.O. Box.32, 23000, Annaba, Algeria.

Author information

Authors and Affiliations

Contributions

Investigation: Meddah Soumaya, Kahloul Latifa; methodology: Bourebia Mounira, Laouar Lakhdar; superviser: Achouri Sihem, Oulabbas Amel; redaction English: Gherfi Kaddour.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Meddah, S., Bourebia, M., Gherfi, K. et al. Influence of dry friction on the wear behavior of X52 steel—experimental study and simulation using response surfaces method. Int J Adv Manuf Technol 119, 4031–4041 (2022). https://doi.org/10.1007/s00170-021-08264-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08264-z