Abstract

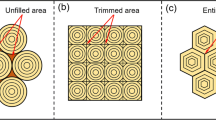

In roll-to-roll (R2R) manufacturing of optical films, machining the microstructure on the roller mold is a crucial step. However, a trimmed radial Fresnel lens structure is discontinuous, and direct diamond cutting the trimmed radial Fresnel lens structure array on the surface of a roller mold was considered infeasible. Hence, a new machining method, diamond micro-scraping (DMS), combined with the polygonal Fresnel lens structure array characteristics, provides a possible solution for machining the Fresnel lens structure array on the roller molds. Tool path planning and simulation analysis were based on the layout of the polygonal Fresnel structure array. In this paper, a polygonal Fresnel lens structure array is processed directly on the periphery roller surface with a diamond tool. The machining performance of DMS was evaluated by studying the influence of different materials and machining parameters on the machined surface quality. The proposed method guides the design and precision manufacturing of the Fresnel lens structure array on precision rollers.

Similar content being viewed by others

Availability of data and materials

All data used in the article are available from the author on reasonable request.

References

Zhang XQ, Huang R, Liu K, Kumar AS, Shan XC (2018) Rotating-tool diamond turning of Fresnel lenses on a roller mold for manufacturing of functional optical film. Precis Eng 51:445–457. https://doi.org/10.1016/j.precisioneng.2017.09.016

Jaaz AH, Hasan HA, Sopian K, Haji Ruslan MHB, Zaidi SH (2017) Design and development of compound parabolic concentrating for photovoltaic solar collector: Review. Renew Sust Energ Rev 76:1108–1121. https://doi.org/10.1016/j.rser.2017.03.127

Alda J, González FJ (2009) Polygonal Fresnel zone plates. J Opt A-Pure Appl Op 11(8):085707. https://doi.org/10.1088/1464-4258/11/8/085707

Meng S, Yin Z, Guo Y, Yao J, Chai N (2020) Ultra-precision machining of polygonal Fresnel lens on roller mold. Int J Adv Manuf Technol 108(7-8):2445–2452. https://doi.org/10.1007/s00170-020-05545-x

Neo DWK, Kumar AS, Rahman M (2015) An automated Guilloche machining technique for the fabrication of polygonal Fresnel lens array. Precis Eng 41(Complete):55–62. https://doi.org/10.1016/j.precisioneng.2015.01.006

Niu LG, Wang D, Jiang T, Wu SZ, Li AW, Song JF (2011) High fill-factor multilevel Fresnel zone plate arrays by femtosecond laser direct writing. Opt Commun 284(3):777–781. https://doi.org/10.1016/j.optcom.2010.09.066

Liu M, Cheung CF, Feng X, Wang C (2019) Diamond machining of freeform-patterned surfaces on precision rollers. Int J Adv Manuf Technol 103(9-12):4423–4431. https://doi.org/10.1007/s00170-019-03628-y

Hatefi S, Abou-El-Hossein K (2019) Review of single-point diamond turning process in terms of ultra-precision optical surface roughness. Int J Adv Manuf Tech 106(5-6):2167–2187. https://doi.org/10.1007/s00170-019-04700-3

Zhong ZW, Shan XC (2012) Microstructure formation via roll-to-roll UV embossing using a flexible mould made from a laminated polymer–copper film. J Micromech Microeng 22(8):085010. https://doi.org/10.1088/0960-1317/22/8/085010

Shan XC, Liu T, Mohaime M, Salam B, Liu YC (2015) Large format cylindrical lens films formed by roll–to–roll ultraviolet embossing and applications as diffusion films. J Micromech Microeng 25(3):035029. https://doi.org/10.1088/0960-1317/25/3/035029

Shan X, Zhang X, Huang R, Liu K (2017) Micromachining of a roller mould and roll-to-roll imprinting to form large area optical films with radial Fresnel lens arrays. Jpn J Appl Phys 56(5S2):05EA02. https://doi.org/10.7567/jjap.56.05ea02

Peng L, Deng Y, Yi P, Lai X (2014) Micro hot embossing of thermoplastic polymers: a review. J Micromech Microeng 24(1):013001. https://doi.org/10.1088/0960-1317/24/1/013001

Wang MW, Tseng CC (2009) Analysis and fabrication of a prism film with roll-to-roll fabrication process. Opt Express 17(6):4718–4725. https://doi.org/10.1364/oe.17.004718

Ting C-J, Chang F-Y, Chen C-F, Chou CP (2008) Fabrication of an antireflective polymer optical film with subwavelength structures using a roll-to-roll micro-replication process. J Micromech Microeng 18(7):075001. https://doi.org/10.1088/0960-1317/18/7/075001

Lee Y-C, Chen H-W, Hsiao F-B (2012) Fabrication of seamless roller mold for continuous roller imprinting of microlens array films. J Microelectromech S 21(2):316–323. https://doi.org/10.1109/jmems.2011.2178115

Huang R, Zhang X, Rahman M, Kumar AS, Liu K (2015) Ultra-precision machining of radial Fresnel lens on roller moulds. Cirp Ann-Manuf Techn 64(1):121–124. https://doi.org/10.1016/j.cirp.2015.04.062

Zhang X, Liu K, Shan X, Liu Y (2014) Roll-to-roll embossing of optical linear Fresnel lens polymer film for solar concentration. Opt Express 22(Suppl 7):A1835–A1842. https://doi.org/10.1364/OE.22.0A1835

Liu C-W, Yan J, Lin S-C (2016) Diamond turning of high-precision roll-to-roll imprinting molds for fabricating subwavelength gratings. Opt Eng 55(6):064105. https://doi.org/10.1117/1.Oe.55.6.064105

Kong LB, Cheung CF, Lee WB (2016) A theoretical and experimental investigation of orthogonal slow tool servo machining of wavy microstructured patterns on precision rollers. Precis Eng 43:315–327. https://doi.org/10.1016/j.precisioneng.2015.08.012

Zhang X, Liu K, Sunappan V, Shan X (2015) Diamond micro engraving of gravure roller mould for roll-to-roll printing of fine line electronics. J Mater Process Technol 225:337–346. https://doi.org/10.1016/j.jmatprotec.2015.05.032

Zhang SJ, Zhou YP, Zhang HJ, Xiong ZW, To S (2019) Advances in ultra-precision machining of micro-structured functional surfaces and their typical applications. Int J Mach Tool Manu 142:16–41. https://doi.org/10.1016/j.ijmachtools.2019.04.009

Zhang XQ, Huan R, Kumar AS, Liu K (2018) High-efficiency swinging-rotating diamond shaping of Fresnel lenses on roller molds. Cirp Ann-Manuf Techn 67(1):121–124. https://doi.org/10.1016/j.cirp.2018.03.020

Brinksmeier E, Karpuschewski B, Yan J, Schönemann L (2020) Manufacturing of multiscale structured surfaces. Cirp Ann-Manuf Techn 69(2):717–739. https://doi.org/10.1016/j.cirp.2020.06.001

Funding

This work was supported by the National Natural Science Foundation of China (No.51575520) and the Science and Technology Program of Guangzhou, China (No.201804020040).

Author information

Authors and Affiliations

Contributions

Songtao Meng and Ziqiang Yin conceived the idea of the study, analyzed most of the data, and wrote the initial draft of the paper. The remaining authors discussed the results and revised the manuscript.

Corresponding author

Ethics declarations

Ethical approval

Not applicable

Consent to participate

Consent to participate

Consent to publish

Not applicable

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Meng, S., Yin, Z., Xia, S. et al. Diamond micro-scraping for the fabrication of polygonal Fresnel lens structure array on roller molds. Int J Adv Manuf Technol 116, 1951–1959 (2021). https://doi.org/10.1007/s00170-021-07581-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07581-7