Abstract

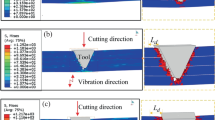

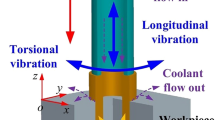

Machining of CFRP composites is usually described as a challenging process from tool life and surface quality perspectives. To achieve a flawless machined surface at reasonable cutting tool life/cost, an optimum combination of cutting tool material and geometry is the key. The cutting tool angles are of importance as these dictate the cutting mechanism as well as the cutting edge robustness and the introduction of vibration to the machining process opens up new horizons of improvement and stirs further research questions. This article investigates the effect of tools with different geometry possessing different rake angles when used in ultrasonic-assisted edge trimming operation dealing with multidirectional CFRP laminates. A full-factorial experimental design was adopted to analyze the effect of process parameters typically cutting speed, feed rate, rake angle, amplitude, and their interactions. Machining performance indicators were captured which were the cutting forces, tool wear, chip temperature, and surface roughness. The results showed that UAM mode contributed to an increase in the cutting forces, tool wear, and chip temperature compared to the conventional mode. On the other hand, UAM mode improved the quality of the machined surface. Additionally, the ultrasonic mode enhanced the material removal mechanism using a tool with a negative rake angle.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

Davim JP, Reis P (2005) Damage and dimensional precision on milling carbon fiber-reinforced plastics using design experiments. J Mater Process Technol 160:160–167

El-Hofy M, Soo S, Aspinwall D, Sim W, Pearson D, Harden P (2011) Factors affecting workpiece surface integrity in slotting of CFRP. Procedia Eng 19:94–99

Wang J (1999) Abrasive waterjet machining of polymer matrix composites–cutting performance, erosive process and predictive models. Int J Adv Manuf Technol 15:757–768

El-Hofy M, Helmy M, Escobar-Palafox G, Kerrigan K, Scaife R, El-Hofy H (2018) Abrasive water jet machining of multidirectional CFRP laminates. Procedia Cirp 68:535–540

Wang H, Sun J, Li J, Lu L, Li N (2016) Evaluation of cutting force and cutting temperature in milling carbon fiber-reinforced polymer composites. Int J Adv Manuf Technol 82:1517–1525

Sheikh-Ahmad JY (2009) Machining of polymer composites. Springer, p 387355391

Ucar M, Wang Y (2005) End-milling machinability of a carbon fiber reinforced laminated composite

Wang YG, Yan XP, Chen X, Sun CY, Liu G (2011) Cutting performance of carbon fiber reinforced plastics using PCD tool. Adv Mater Res:14–18

Cao P, Zhu Z, Buck D, Guo X, Ekevad M, Wang XA (2019) Effect of rake angle on cutting performance during machining of stone-plastic composite material with polycrystalline diamond cutters. J Mech Sci Technol 33:351–356

Henerichs M, Voss R, Kuster F, Wegener K (2015) Machining of carbon fiber reinforced plastics: influence of tool geometry and fiber orientation on the machining forces. CIRP J Manuf Sci Technol 9:136–145

Faraz A, Biermann D, Weinert K (2009) Cutting edge rounding: an innovative tool wear criterion in drilling CFRP composite laminates. Int J Mach Tools Manuf 49:1185–1196

Ghidossi P, El Mansori M, Pierron F (2004) Edge machining effects on the failure of polymer matrix composite coupons. Compos A: Appl Sci Manuf 35:989–999

Wang D, Ramulu M, Arola D (1995) Orthogonal cutting mechanisms of graphite/epoxy composite. Part II: multi-directional laminate. Int J Mach Tools Manuf 35:1639–1648

Wang XM, Zhang L (2003) An experimental investigation into the orthogonal cutting of unidirectional fibre reinforced plastics. Int J Mach Tools Manuf 43:1015–1022

Gara S, Tsoumarev O (2016) Effect of tool geometry on surface roughness in slotting of CFRP. Int J Adv Manuf Technol 86:451–461

Jahromi AS, Bahr B (2010) An analytical method for predicting cutting forces in orthogonal machining of unidirectional composites. Compos Sci Technol 70:2290–2297

Calzada KA, Kapoor SG, DeVor RE, Samuel J, Srivastava AK (2012) Modeling and interpretation of fiber orientation-based failure mechanisms in machining of carbon fiber-reinforced polymer composites. J Manuf Process 14:141–149

Wang D, Ramulu M, Arola D (1995) Orthogonal cutting mechanisms of graphite/epoxy composite. Part I: unidirectional laminate. Int J Mach Tools Manuf 35:1623–1638

Jahromi AS, Bahr B, Krishnan KK (2014) An analytical method for predicting damage zone in orthogonal machining of unidirectional composites. J Compos Mater 48:3355–3365

Wang F-j, Yin J-w, Ma J-w, Jia Z-y, Yang F, Niu B (2017) Effects of cutting edge radius and fiber cutting angle on the cutting-induced surface damage in machining of unidirectional CFRP composite laminates. Int J Adv Manuf Technol 91:3107–3120

Mkaddem A, Demirci I, El Mansori M (2008) A micro–macro combined approach using FEM for modelling of machining of FRP composites: Cutting forces analysis. Compos Sci Technol 68:3123–3127

Sheikh-Ahmad J, El-Hofy M, Almaskari F, Kerrigan K, Takikawa Y (2019) The evolution of cutting forces during slot milling of unidirectional carbon fiber reinforced polymer (UD-CFRP) composites. Procedia CIRP 85:127–132

Sheikh-Ahmad J, Almaskari F, El-Hofy M (2021) Characterization of the cutting forces and friction behavior in machining UD-CFRP using slot milling test. Int J Adv Manuf Technol:1–13

Helmy MO, El-Hofy M, El-Hofy H (2018) Effect of cutting fluid delivery method on ultrasonic assisted edge trimming of multidirectional CFRP composites at different machining conditions. Procedia CIRP 68:450–455

Helmy MO, El-Hofy M, El-Hofy H (2020) Influence of process parameters on the ultrasonic assisted edge trimming of aerospace CFRP laminates using MQL. Int J Mach Mach Mater 22:349–373

Tao C, Rui L, Jiupeng X, Weijie G, Yongsheng W (2020) Study on the design and cutting performance of stepped bi-directional milling cutters for hole making of CFRP. Int J Adv Manuf Technol 108:3021–3030

Chen T, Wang C, Xiang J, Wang Y (2020) Study on tool wear mechanism and cutting performance in helical milling of CFRP with stepped bi-directional milling cutters. Int J Adv Manuf Technol 111:2441–2448

Tao C, Yongsheng W, Yujiang L, Gang L, Guangjun L (2021) Comparative study on cutting performance of conventional and ultrasonic-assisted bi-directional helical milling of CFRP. PREPRINT (Version 1) available at Research Square ed.

Nik MG, Movahhedy MR, Akbari J (2012) Ultrasonic-assisted grinding of Ti6Al4V alloy. Procedia Cirp 1:353–358

Jian-Hua Z, Yan Z, Fu-Qiang T, Shuo Z, Lan-Shen G (2015) Kinematics and experimental study on ultrasonic vibration-assisted micro end grinding of silica glass. Int J Adv Manuf Technol 78:1893–1904

Yang Z, Zhu L, Zhang G, Ni C, Lin B (2020) Review of ultrasonic vibration-assisted machining in advanced materials. Int J Mach Tools Manuf 156:103594

Wang J, Feng P, Zhang J, Guo P (2018) Reducing cutting force in rotary ultrasonic drilling of ceramic matrix composites with longitudinal-torsional coupled vibration. Manuf Lett 18

Phadnis VA, Roy A, Silberschmidt VV (2013) A finite element model of ultrasonically assisted drilling in carbon/epoxy composites. Procedia CIRP 8:141–146

Sun G, Shi F, Ma Z (2020) Effects of axial ultrasonic vibration on grinding quality in peripheral grinding and end grinding of ULE. Int J Adv Manuf Technol 109:2285–2298

Abd Halim NFH, Ascroft H, Barnes S (2017) Analysis of tool wear, cutting force, surface roughness and machining temperature during finishing operation of ultrasonic assisted milling (UAM) of carbon fibre reinforced plastic (CFRP). Procedia Eng 184:185–191

Colligan K, Ramulu M (1999) Edge trimming of graphite/epoxy with diamond abrasive cutters.

Soo SL, Shyha IS, Barnett T, Aspinwall DK, Sim W-M (2012) Grinding performance and workpiece integrity when superabrasive edge routing carbon fibre reinforced plastic (CFRP) composites. CIRP Ann 61:295–298

Yang D, Wan Z, Xu P, Lu L (2018) Rake angle effect on a machined surface in orthogonal cutting of graphite/polymer composites. Adv Mater Sci Eng

Acknowledgements

The authors would like to thank the Mission Department of the Ministry of Higher Education in Egypt (MoHE) and Tokyo University of Agriculture and Technology for facilitating the access to Sasahara Lab, and the OSG Corporation for supplying the tools and to thank Airbus for the material used in this research.

Code availability

N/A

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

N/A

Consent to participate

N/A

Consent for publication

N/A

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Helmy, M.O., El-Hofy, H., Sasahara, H. et al. Rake angle effects on ultrasonic-assisted edge trimming of multidirectional CFRP laminates. Int J Adv Manuf Technol 115, 3467–3484 (2021). https://doi.org/10.1007/s00170-021-07383-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07383-x