Abstract

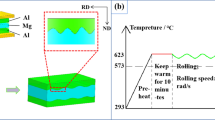

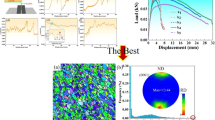

How to improve the bonding ability and quality performance of heterogeneous plates has always been one of the difficult problems in the field of high-performance heterogeneous composite sheet forming and manufacturing. In this paper, a new manufacturing method of heterogeneous clad plate, hard plate rolling clad plate, is proposed. The hot rolling process of Al/Mg/Al composite slab with or without hard plate was studied. The results show that the shear stress in the rolling direction (RD) can be transformed into the compressive stress in the normal direction (ND), and then the welding pressure between different composite layers can be increased. This method can suppress the bending and edge crack defects and significantly improve the shape quality and forming ability. At the same time, through the study of the interface structure of the composite plate, it can be known that the metallurgical bonding can be achieved with a small reduction after adding the hard plate. Two clear layers of Al3Mg2 and Al17Mg12 intermetallic compounds appear at the Al/Mg interface. The thickness of the diffusion layer is significantly larger than that of the traditional hot-rolled clad plate, and the thickness of the diffusion layer can reach 38 μm when the reduction is 60%. The yield strength is 172.3 MPa and the elongation is 21.5%. To sum up, the hot rolling of hard-plate provides a new idea for the forming and manufacturing of high performance heterogeneous composite plate.

Similar content being viewed by others

Data availability

The data obtained in the framework of this study are available to the journal upon request.

References

Huang K, Zhang K, Marthinsen K, Logé RE (2017) Controlling grain structure and texture in Al-Mn from the competition between precipitation and recrystallization. Acta Mater 141:360–373

Chen G, Chang XS, Zhang JX, Jin Y, Sun C, Chen Q, Zhao ZD (2020) Microstructures and mechanical properties of in-situ Al3Ti / 2024 aluminum matrix composites fabricated by ultrasonic treatment and subsequent squeeze casting. Met Mater Int 26:1574–1584

Wang Y, Zhang S, Wu RZ, Turakhodjaev N, Hou LG, Zhang JH, Betsofen S (2021) Coarsening kinetics and strengthening mechanisms of core-shell nanoscale precipitates in Al-Li-Yb-Er-Sc-Zr alloy. J Mater Sci Technol 61:197–203

Yan ZM, Zhang ZM, Li XB, Xu J, Wang Q, Zhang GS, Zheng J, Fan HZ, Xu KH, Zhu JX, Xue Y (2020) A novel severe plastic deformation method and its effect on microstructure, texture and mechanical properties of Mg-Gd-Y-Zn-Zr alloy. J Alloys Compd 822:153698

Wang JH, Xu L, Wu RZ, Feng J, Zhang JH, Hou LG, Zhang ML (2020) Enhanced electromagnetic interference shielding in a duplex-phase Mg-9Li-3Al-1Zn alloy processed by accumulative roll bonding. Acta Metall Sin-Eng Lett 33:490–499

Wang TL, Nie HH, Mi YJ, Hao XW, Yang F, Chi CZ, Liang W (2019) Microstructures and mechanical properties of Ti/Al/Mg/Al/Ti laminates with various rolling reductions. J Mater Res 34(2):344–353

Chen SH, Zhai ZL, Huang JH, Zhao XK, Xiong JG (2016) Interface microstructure and fracture behavior of single/dual-beam laser welded steel-Al dissimilar joint produced with copper interlayer. Int J Adv Manuf Technol 82(1-4):631–643

Zohoor M, Givi MKB, Salami P (2012) Effect of processing parameters on fabrication of Al–Mg/Cu composites via friction stir processing. Mater Des 39(1):358–365

Tang JW, Chen L, Zhao GQ, Zhang CS, Sun L (2020) Achieving three-layered Al/Mg/Al sheet via combining porthole die co-extrusion and hot forging. J Magnes Alloy 8(3):654–666

Wei AL, Liu XH, Dong L, Liang W (2018) Binding property of Al/Mg/Al thin plates fabricated by one-pass hot rolling with different reduction ratios, temperatures and annealing treatments. Rare Metals 37(02):1–7

Zheng HP, Yang JL, Wu RZ, Wang TZ, Ma XD, Hou LG, Zhang ML, Betsofen S, Krit B (2016) Influence of annealing temperature on the microstructure and mechanical properties of Al/Mg/Al composite sheets fabricated by roll bonding. Adv Eng Mater 18(10):1792–1798

Chen L, Tang JW, Zhao GQ, Zhang CS, Chu XR (2018) Fabrication of Al/Mg/Al laminate by a porthole die co-extrusion process. J Mater Process Technol 258:165–173

Yan YB, Zhang ZW, Shen W, Wang JH, Zhang LK, Chin BA (2010) Microstructure and properties of magnesium AZ31B–aluminum 7075 explosively welded composite plate. Mater Sci Eng A 527(9):2241–2245

Zhang XP, Yang TH, Castagne S, Wang JT (2011) Microstructure; bonding strength and thickness ratio of Al/Mg/Al alloy laminated composites prepared by hot rolling. Mater Sci Eng A 528(4-5):1954–1960

Motevalli PD, Eghbali B (2015) Microstructure and mechanical properties of Tr-metal Al/Ti/Mg laminated composite processed by accumulative roll bonding. Mater Sci Eng A 628:135–142

Wang T, Li S, Ren ZK, Han JC, Huang QX (2019) A novel approach for preparing Cu/Al laminated composite based on corrugated roll. Mater Lett 234:79–82

Zhao ZL, Gao Q, Hou JF, Sun ZW, Sun ZW, Chen F (2016) Determining the microstructure and properties of magnesium aluminum composite panels by hot rolling and annealing. J Magnes Alloy 4(3):242–248

Zha M, Zhang MH, Yu ZY, Zhang XH, Meng XT, Wang HY, Jiang QC (2018) Bimodal microstructure - a feasible strategy for high-strength and ductile metallic materials. J Mater Sci Technol 34(2):257–264

Wang HY, Yu ZP, Zhang L, Liu CG, Zha M, Wang C, Jiang QC (2015) Achieving high strength and high ductility in magnesium alloy using hard-plate rolling (HPR) process. Sci Rep 5(1):17100

Pekguleryuz M, Celikin M, Hoseini M, Hoseini M, Becerra A, Mackenzie L (2012) Study on edge cracking and texture evolution during 150°C rolling of magnesium alloys: the effects of axial ratio and grain size. J Alloys Compd 510(1):15–25

Kweon S (2015) Damage in edge cracking of rolled metal slabs. Mech Res Commun 63:13–20

Tariq NU, Gyansah L, Qiu X, Jia CN, Bin AH, Zheng CW, Du H, Wang JQ, Xiong TY (2019) Achieving strength-ductility synergy in cold spray additively manufactured al/b4c composites through a hybrid post-deposition treatment. J Mater Sci Technol 35(6):1053–1063

Funding

This paper was supported by the Natural Science Foundation of Heilongjiang Province (LH2019E056) and the Fundamental Research Foundation for Universities of Heilongjiang Province (LGYC2018JQ011).

Author information

Authors and Affiliations

Contributions

Composite plate connection is currently a hot research direction in the field of plastic processing. The hot-rolled composite by hard-plate proposed in this paper provides a new idea for the connection of composite plates.

Corresponding authors

Ethics declarations

Ethical approval

Not applicable

Consent to participate

Not applicable

Consent for publication

Not applicable

Competing interests

Not applicable

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Da Huo, P., Li, F., Wang, Y. et al. Formability and interface structure of Al/Mg/Al composite sheet rolled by hard-plate rolling (HPR). Int J Adv Manuf Technol 118, 55–65 (2022). https://doi.org/10.1007/s00170-021-07178-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07178-0