Abstract

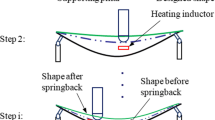

Small-batched metal plates with free-form surfaces are widely used in different manufacturing industries; however, it is unrealistic to produce such metal plates based on traditional die stamping and rolling processes. Over the last few decades, numerous efforts have been adopted to produce the metal plates with free-form surfaces with acceptable quality, efficiency, and cost through flexible forming processes. In the present paper, a heat-assisted incremental bending process was proposed to manufacture metal plates with large unsymmetrical curvatures. The test metal plates were supported by some hydraulic cylinders, and the punch moved up and down to press the metal plates according to the loading path determined by the minimum energy method. In addition, an induction heating system was applied to heat the metal plates at the punching position. One objective metal plate with large unsymmetrical curvature is deformed based on the heat-assisted incremental bending experiments. The obtained results indicate that the proposed thermo-mechanical flexible forming process could produce complex metal plates with good accuracy and high efficiency.

Similar content being viewed by others

Availability of data and materials

All data generated or analyzed during this study are included in this published article.

References

Shim DS, Yang DY (2014) Multi-stage forming using optimized preform in the line array roll set process and its industrial application. Int J Precis Eng Manuf 15(10):2085–2092

Yoon SJ, Yang DY (2003) Development of a highly flexible incremental roll forming process for the manufacture of a doubly curved sheet metal. Cirp Ann-Manuf Techn 52(1):201–204

Matsuno K (1997) Recent research and development in metal forming in Japan. J Mater Process Technol 66(1-3):1–3

Li YL, Chen XX, Liu ZB, Sun J, Li FY, Li JF, Zhao GQ (2017) A review on the recent development of incremental sheet-forming process. Int J Adv Manuf Technol 92:2439–2462

Liu QQ, Lu C, Fu WZ, Tieu K, Li MZ, Gong XP (2012) Optimization of cushion conditions in micro multi-point sheet forming. J Mater Process Technol 212(3):672–677

Heo SC, Seo YH, Ku TW, Kang BS (2010) A study on thick plate forming using flexible forming process and its application to a simply curved plate. Int J Adv Manuf Technol 51:103–115

Zhang Q, Wang ZR, Dean TA (2008) The mechanics of multi-point sandwich forming. Int J Mach Tools Manuf 48(12-13):1495–1503

Dang XB, He K, Zhang FF, Zuo QY, Du RX (2019) Multi-stage incremental bending to form doubly curved metal plates based on bending limit diagram. Int J Mech Sci 155:19–30

Zhang FF, He K, Dang XB, Du RX (2018) Experimental and numerical study on one flexible incremental bending process. Int J Adv Manuf Technol 96(1):2643–2655

Zhang FF, Zhang J, Zuo QY, Dang XB, He K (2019) Experimental and numerical study on deformation behavior of doubly curved metal plates during incremental bending process. Int J Adv Manuf Technol 104(1-3):1–12

Lim HK, Lee JS (2017) On the material properties of shell plate formed by line heating. Int J Nav Arch Ocean 9(1):66–76

Shen H, Zhou WT, Wang H (2018) Laser forming of doubly curved plates using minimum energy principle and comprehensive strain control. Int J Mech Sci 145:42–52

Chu GN, Lin YL, Chen G (2016) A green line heating forming technology for ultra-thick plate. Int J Adv Manuf Technol 87:1977–1984

Wang JC, Yi B, Zhang CH, Zhou H, Shu YQ (2019) Experiments of double curvature plate bending with induction heating and processing parameters investigation by computational analysis. Ocean Eng 192:106596

Kant R, Joshi SN (2013) Finite element simulation of laser assisted bending with moving mechanical load. Int J Mech Manu Syst 6(4):351–366

Gisario A, Barletta M, Venettacci S (2016) Improvements in springback control by external force laser-assisted sheet bending of titanium and aluminum alloys. Opt Laser Technol 86:46–53

Liu ZB (2018) Heat-assisted incremental sheet forming: a state-of-the-art review. Int J Adv Manuf Technol 98:2987–3003

Li PY, He J, Liu Q, Yang MS, Wang QD, Yuan QL, Li Y (2017) Evaluation of forming forces in ultrasonic incremental sheet metal forming. Aerosp Sci Technol 63:132–139

Wang ZH, Cai S, Chen J (2020) Experimental investigations on friction stir assisted single point incremental forming of low-ductility aluminum alloy sheet for higher formability with reasonable surface quality. J Mater Process Technol 277:116488

Duflou JR, Callebaut B, Verbert J, Baerdemaeker HD (2007) Laser assisted incremental forming: formability and accuracy improvement. Cirp Ann-Manuf Techn 56(1):273–276

Fan GQ, Gao L, Hussain G, Wu ZL (2008) Electric hot incremental forming: A novel technique. Int J Mach Tool Manu 48(15):1688–1692

Adams DW (2013) Improvements on single point incremental forming through electrically assisted forming contact area prediction and tool development. Dissertation, Queen’s University Kingston, Ontario, Canada, November

Dang XB, He K, Li W, Zuo QY, Du RX (2017) Incremental bending of three-dimensional free form metal plates using minimum energy principle and model-less control. J Manuf Sci E T ASEM 139(7):071009

Safari M, Mostaan H (2016) Experimental and numerical investigation of laser forming of cylindrical surfaces with arbitrary radius of curvature. Alex Eng J 55:1941–1949

Wei B, Wei YN, Zhang FF, He K, Dang XB, Du RX (2021) Springback control and plastic deformation of metal plates with large curvature in heat-assisted incremental bending process. Int J Adv Manuf Technol 112:1483–1500

Funding

The research is supported by SIAT-CUHK Joint Laboratory of Precision Engineering, SIAT Innovation Program for Excellent Young Researchers (2019Y9G031), and Guangdong Basic and Applied Basic Research Foundation (2019A1515012035).

Author information

Authors and Affiliations

Contributions

Bo Wei wrote the paper and carried out the experiments; Feifei Zhang helped with the framework of the paper and provided data analysis; Kai He provided the experimental condition; Chenghui Zhou helped with the experiments; Ruxu Du contributed to the main idea of combining heat and incremental bending.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

All authors have read and agreed to the published version of the paper.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wei, B., Zhang, F., He, K. et al. Heat-assisted incremental bending of metal plates with unsymmetrical curvatures. Int J Adv Manuf Technol 114, 3437–3448 (2021). https://doi.org/10.1007/s00170-021-07067-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07067-6