Abstract

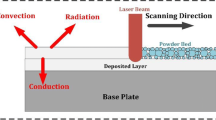

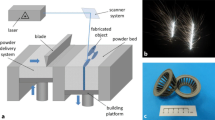

Selective laser melting (SLM) has emerged as one of the leading additive manufacturing (AM) processes for the fabrication of complex metallic components, due to its capability to achieve high quality at acceptable times. However, due to the complexity of physical phenomena occurring during SLM, such as heat transfer and phase transformations, laser absorption, molten metal flow, and moving interfaces, it is still necessary to conduct research in order to achieve a deeper understanding of the process and improve it. In the present work, a comprehensive simulation model for the study of conduction mode single-track SLM process of 316L stainless steel is presented. This model incorporates temperature and phase-dependent material properties for both powder bed and substrate, detailed calculation of the absorption coefficient, and temperature-dependent boundary conditions. The simulation results are in excellent agreement with experimental findings, regarding the morphology and dimensions of melt pool under various process conditions. Moreover, with the proposed model, analysis of power losses as well as cooling and heating rates is conducted, identifying the characteristics of SLM process and providing valuable insights for its optimization.

Similar content being viewed by others

References

Srivatsan TS, Sudarshan TS (2016) Additive manufacturing, innovations, advances, and applications

Gebhardt A (2012) Understanding additive manufacturing

Ian Gibson,David Rosen BS (2013) Additive manufacturing technologies

Furumoto T, Egashira K, Munekage K, Abe S (2018) Experimental investigation of melt pool behaviour during selective laser melting by high speed imaging. CIRP Ann 67:253–256. https://doi.org/10.1016/j.cirp.2018.04.097

Gong H, Rafi K, Gu H, Starr T, Stucker B (2014) Analysis of defect generation in Ti-6Al-4V parts made using powder bed fusion additive manufacturing processes. Addit Manuf 1:87–98. https://doi.org/10.1016/j.addma.2014.08.002

Niu X, Singh S, Garg A, Singh H, Panda B, Peng X, Zhang Q (2019) Review of materials used in laser-aided additive manufacturing processes to produce metallic products. Front Mech Eng 14:282–298. https://doi.org/10.1007/s11465-019-0526-1

Yadroitsev I, Yadroitsau I, Yadroitsev I (2009) Selective laser melting: direct manufacturing of 3D-objects by selective laser melting of metal powders. Appl Catal B Environ 75:229–238

Kamath C, El-Dasher B, Gallegos GF et al (2014) Density of additively-manufactured, 316L SS parts using laser powder-bed fusion at powers up to 400 W. Int J Adv Manuf Technol 74:65–78. https://doi.org/10.1007/s00170-014-5954-9

Yadroitsev I, Smurov I (2011) Surface morphology in selective laser melting of metal powders. Phys Procedia 12:264–270. https://doi.org/10.1016/j.phpro.2011.03.034

Shrestha S, Chou K (2018) Single track scanning experiment in laser powder bed fusion process. Procedia Manuf 26:857–864. https://doi.org/10.1016/j.promfg.2018.07.110

Guo Y, Jia L, Kong B, Wang N, Zhang H (2018) Single track and single layer formation in selective laser melting of niobium solid solution alloy. Chin J Aeronaut 31:860–866. https://doi.org/10.1016/j.cja.2017.08.019

Gunenthiram V, Peyre P, Schneider M, et al (2017) Analysis of laser – melt pool – powder bed interaction during the selective laser melting of a stainless steel to cite this version : HAL Id : hal-01664637

Gunenthiram V, Peyre P, Schneider M, Dal M, Coste F, Koutiri I, Fabbro R (2018) Experimental analysis of spatter generation and melt-pool behavior during the powder bed laser beam melting process. J Mater Process Technol 251:376–386. https://doi.org/10.1016/j.jmatprotec.2017.08.012

Gusarov AV, Yadroitsev I, Bertrand P, Smurov I (2009) Model of radiation and heat transfer in laser-powder interaction zone at selective laser melting. J Heat Transf 131:1–10. https://doi.org/10.1115/1.3109245

Antony K, Arivazhagan N, Senthilkumaran K (2014) Numerical and experimental investigations on laser melting of stainless steel 316L metal powders. J Manuf Process 16:345–355. https://doi.org/10.1016/j.jmapro.2014.04.001

Lee YS, Zhang W (2016) Modeling of heat transfer, fluid flow and solidification microstructure of nickel-base superalloy fabricated by laser powder bed fusion. Addit Manuf 12:178–188. https://doi.org/10.1016/j.addma.2016.05.003

Heeling T, Cloots M, Wegener K (2017) Melt pool simulation for the evaluation of process parameters in selective laser melting. Addit Manuf 14:116–125. https://doi.org/10.1016/j.addma.2017.02.003

Gusarov AV, Kruth JP (2005) Modelling of radiation transfer in metallic powders at laser treatment. Int J Heat Mass Transf 48:3423–3434. https://doi.org/10.1016/j.ijheatmasstransfer.2005.01.044

Ye Q, Chen S (2017) Numerical modeling of metal-based additive manufacturing using level set methods. J Manuf Sci Eng 139:071019. https://doi.org/10.1115/1.4036290

Bian Q, Tang X, Dai R, Zeng M (2018) Evolution phenomena and surface shrink of the melt pool in an additive manufacturing process under magnetic field. Int J Heat Mass Transf 123:760–775. https://doi.org/10.1016/j.ijheatmasstransfer.2018.03.024

Zhang D, Zhang P, Liu Z, Feng Z, Wang C, Guo Y (2018) Thermofluid field of molten pool and its effects during selective laser melting (SLM) of Inconel 718 alloy. Addit Manuf 21:567–578. https://doi.org/10.1016/j.addma.2018.03.031

Tran HC, Lo YL (2018) Heat transfer simulations of selective laser melting process based on volumetric heat source with powder size consideration. J Mater Process Technol 255:411–425. https://doi.org/10.1016/j.jmatprotec.2017.12.024

Bruna-Rosso C, Demir AG, Previtali B (2018) Selective laser melting finite element modeling: validation with high-speed imaging and lack of fusion defects prediction. Mater Des 156:143–153. https://doi.org/10.1016/j.matdes.2018.06.037

Goldak J, Chakravarti A, Bibby M (1984) A new finite element model for welding heat sources. Metall Trans B 15:299–305. https://doi.org/10.1007/BF02667333

Yang J, Han J, Yu H, Yin J, Gao M, Wang Z, Zeng X (2016) Role of molten pool mode on formability, microstructure and mechanical properties of selective laser melted Ti-6Al-4V alloy. Mater Des 110:558–570. https://doi.org/10.1016/j.matdes.2016.08.036

Yang H, Yang J, Huang W, Wang Z, Zeng X (2018) The printability, microstructure, crystallographic features and microhardness of selective laser melted Inconel 718 thin wall. Mater Des 156:407–418. https://doi.org/10.1016/j.matdes.2018.07.007

Qi T, Zhu H, Zhang H, Yin J, Ke L, Zeng X (2017) Selective laser melting of Al7050 powder: melting mode transition and comparison of the characteristics between the keyhole and conduction mode. Mater Des Des 135:257–266. https://doi.org/10.1016/j.matdes.2017.09.014

King WE, Barth HD, Castillo VM, Gallegos GF, Gibbs JW, Hahn DE, Kamath C, Rubenchik AM (2014) Journal of materials processing technology observation of keyhole-mode laser melting in laser powder-bed fusion additive manufacturing. J Mater Process Technol 214:2915–2925. https://doi.org/10.1016/j.jmatprotec.2014.06.005

Tenbrock C, Gabriel F, Wissenbach K et al (2020) Influence of keyhole and conduction mode melting for top-hat shaped beam profiles in laser powder bed fusion. J Mater Process Technol 278:116514. https://doi.org/10.1016/j.jmatprotec.2019.116514

Soylemez E (2018) Modelling the melt pool of the laser sintered Ti6Al4V layers with Goldak’s double-ellipsoidal heat source

Dilip JJS, Zhang S, Pal D, Stucker B (2017) Influence of processing parameters on the evolution of melt pool , porosity , and microstructures in Ti-6Al-4V alloy parts fabricated by selective laser melting. Prog Addit Manuf https://doi.org/10.1007/s40964-017-0030-2

Le T, Lo Y (2019) Effects of sulfur concentration and Marangoni convection on melt-pool formation in transition mode of selective laser melting process. Mater Des 179:107866. https://doi.org/10.1016/j.matdes.2019.107866

Chen ZW, Guraya T, Darvish K, Phan MAL (2019) Solidification during selective laser melting of Co-29Cr-6Mo alloy. JOM 71:691–696. https://doi.org/10.1007/s11837-018-3264-7

Aboulkhair NT, Maskery I, Tuck C, et al Nano-hardness and microstructure of selective laser melted AlSi10Mg scan tracks. 9657:1–7. https://doi.org/10.1117/12.2190015

Le KQ, Tang C, Wong CH (2019) On the study of keyhole-mode melting in selective laser melting process. Int J Therm Sci 145:105992. https://doi.org/10.1016/j.ijthermalsci.2019.105992

Scipioni Bertoli U, Wolfer AJ, Matthews MJ, Delplanque JPR, Schoenung JM (2017) On the limitations of volumetric energy density as a design parameter for selective laser melting. Mater Des 113:331–340. https://doi.org/10.1016/j.matdes.2016.10.037

Philo AM, Mehraban S, Holmes M, Sillars S, Sutcliffe CJ, Sienz J, Brown SGR, Lavery NP (2019) A pragmatic continuum level model for the prediction of the onset of keyholing in laser powder bed fusion. Int J Adv Manuf Technol 101:697–714. https://doi.org/10.1007/s00170-018-2770-7

Metelkova J, Kinds Y, Kempen K, de Formanoir C, Witvrouw A, van Hooreweder B (2018) On the influence of laser defocusing in selective laser melting of 316L. Addit Manuf 23:161–169. https://doi.org/10.1016/j.addma.2018.08.006

Tang M, Pistorius PC, Beuth JL (2017) Prediction of lack-of-fusion porosity for powder bed fusion. Addit Manuf 14:39–48. https://doi.org/10.1016/j.addma.2016.12.001

Hodge NE, Ferencz RM, Solberg JM (2014) Implementation of a thermomechanical model for the simulation of selective laser melting. Comput Mech 54:33–51. https://doi.org/10.1007/s00466-014-1024-2

Guo M, Gu D, Xi L, du L, Zhang H, Zhang J (2018) Formation of scanning tracks during selective laser melting (SLM) of pure tungsten powder: morphology, geometric features and forming mechanisms. Int J Refract Met Hard Mater 79:37–46. https://doi.org/10.1016/j.ijrmhm.2018.11.003

Krakhmalev P, Yadroitsava I, Fredriksson G, Yadroitsev I (2015) In situ heat treatment in selective laser melted martensitic AISI 420 stainless steels. JMADE 87:380–385. https://doi.org/10.1016/j.matdes.2015.08.045

Kundakc E, Lazoglu I, Poyraz Ö et al (2018) Thermal and molten pool model in selective laser melting process of Inconel 625. Int J Adv Manuf Technol 95:3977–3984

Zhang D, Wang W, Guo Y, Hu S, Dong D, Poprawe R, Schleifenbaum JH, Ziegler S (2019) Numerical simulation in the absorption behavior of Ti6Al4V powder materials to laser energy during SLM. J Mater Process Technol 268:25–36. https://doi.org/10.1016/j.jmatprotec.2019.01.002

Johnson PB, Christy RW (1974) Optical constants of transition metals: Ti, V, Cr, Mn, Fe, Co, Ni, and Pd. Phys Rev B 9:5056–5070. https://doi.org/10.1103/PhysRevB.6.4370

Boley CD, Khairallah SA, Rubenchik AM (2017) Calculation of laser absorption by metal powders in additive manufacturing. Addit Manuf Handb Prod Dev Def Ind:507–517. https://doi.org/10.1201/9781315119106

Yan J, Zhou Y, Gu R, Zhang X, Quach WM, Yan M (2019) A comprehensive study of steel powders (316L, H13, P20 and 18Ni300) for their selective laser melting additive manufacturing. Metals (Basel) 9:86. https://doi.org/10.3390/met9010086

Siegel E (1976) Optical reflectivity of liquid metals at their melting temperatures. Phys Chem Liq 5:9–27. https://doi.org/10.1080/00319107608084103

Trapp J, Rubenchik AM, Guss G, Matthews MJ (2017) In situ absorptivity measurements of metallic powders during laser powder-bed fusion additive manufacturing. Appl Mater Today 9:341–349. https://doi.org/10.1016/j.apmt.2017.08.006

Promoppatum P, Yao SC, Pistorius PC, Rollett AD (2017) A comprehensive comparison of the analytical and numerical prediction of the thermal history and solidification microstructure of Inconel 718 products made by laser powder-bed fusion. Engineering. 3:685–694. https://doi.org/10.1016/J.ENG.2017.05.023

Sih SS, Barlow JW (2004) The prediction of the emissivity and thermal conductivity of powder beds. Part Sci Technol 22:427–440. https://doi.org/10.1080/02726350490501682

Kim CS (1975) Thermophysical properties of stainless steels

Goett G, Kozakov R, Uhrlandt D, Schoepp H, Sperl A (2013) Emissivity and temperature determination on steel above the melting point. Weld World 57:595–602. https://doi.org/10.1007/s40194-013-0054-2

Holman JP (2010) Heat transfer, vol 41, 10th edn. McGraw-Hill Co, New York, pp 265–274. https://doi.org/10.1603/EN11245

Hirano K, Fabbro R, Muller M (2012) Study on temperature dependence of recoil pressure near the boiling temperature - towards better modeling and simulation. ICALEO 2012 - 31st Int Congr Appl Lasers Electro-Optics 678–684

Cherry JA, Davies HM, Mehmood S, Lavery NP (2015) Investigation into the effect of process parameters on microstructural and physical properties of 316L stainless steel parts by selective laser melting. 869–879. https://doi.org/10.1007/s00170-014-6297-2

Mirkoohi E, Ning J, Bocchini P, Fergani O, Chiang KN, Liang S (2018) Thermal modeling of temperature distribution in metal additive manufacturing considering effects of build layers , latent heat , and temperature-sensitivity of material properties. J Manuf Mater Process 2:63. https://doi.org/10.3390/jmmp2030063

Meier C, Penny RW, Zou Y et al (2018) Thermophysical phenomena in metal additive manufacturing by selective laser Melting: Fundamentals, Modeling, Simulation, And Experimentation. https://doi.org/10.1615/annualrevheattransfer.2018019042

Khairallah SA, Anderson AT, Rubenchik A, King WE (2016) Laser powder-bed fusion additive manufacturing: physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater 108:36–45. https://doi.org/10.1016/j.actamat.2016.02.014

Markl M, Körner C (2016) Multiscale modeling of powder bed–based additive manufacturing. Annu Rev Mater Res 46:93–123. https://doi.org/10.1146/annurev-matsci-070115-032158

LaMonica M (2013) Additive manufacturing-innovations, advances, and applications

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Papazoglou, E.L., Karkalos, N.E. & Markopoulos, A.P. A comprehensive study on thermal modeling of SLM process under conduction mode using FEM. Int J Adv Manuf Technol 111, 2939–2955 (2020). https://doi.org/10.1007/s00170-020-06294-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06294-7