Abstract

Damage evolution has a great influence on the formability and mechanical property of part. The deformation behaviour and damage evolution of aluminium alloy sheet in the electromagnetic forming processes with uniform pressure actuator were experimentally and numerically investigated. The influences of the discharge voltage and impacting distance on the impacting effects between the aluminium alloy sheet and die wall were firstly compared in electromagnetic forming process. With the elevated discharge voltage and impacting distance, the impacting velocity and contacting pressure increased, and the stress triaxiality and damage accumulation of aluminium alloy sheet decreased. Then, the influences of the pre-straining level on the damage evolution of aluminium alloy sheet were presented in hybrid electromagnetic forming process. The initial damage of aluminium alloy sheet was accumulated during the quasi-static tensile pre-straining phase. The pre-strained specimens were subsequently electromagnetically formed, and the damage increment of aluminium alloy sheet can be suppressed with the higher pre-straining level.

Similar content being viewed by others

References

Bruschi S, Altan T, Banabic D, Bariani PF, Brosius A, Cao J, Ghiotti A, Khraisheh M, Merklein M, Tekkaya AE (2014) Testing and modelling of material behaviour and formability in sheet metal forming. CIRP Ann Manuf Technol 63:727–749

Tekkaya AE, Allwood JM, Bariani PF, Bruschi S, Cao J, Gramlich S, Groche P, Hirt G, Ishikawa T, Löbbe C, Lueg-Althoff J, Merklein M, Misiolek WZ, Pietrzyk M, Shivpuri R, Yanagimoto J (2015) Metal forming beyond shaping: predicting and setting product properties. CIRP Ann Manuf Technol 64:629–653

Tekkaya AE, Ben Khalifa N, Hering O, Meya R, Myslicki S, Walther F (2017) Forming-induced damage and its effects on product properties. CIRP Ann Manuf Technol 66:281–284

Psyk V, Risch D, Kinsey BL, Tekkaya AE, Kleiner M (2011) Electromagnetic forming-a review. J Mater Process Technol 211:787–829

Li L, Li J, Wan M, Yu H, Liu L (2018) Innovation applications of electromagnetic forming and its fundamental problems. Procedia Manuf 15:14–30

Imbert JM, Winkler SL, Worswick MJ, Oliveira DA, Golovashchenko S (2005) The effect of tool-sheet interaction on damage evolution in electromagnetic forming of aluminum alloy sheet. J Eng Mater Technol 127:145–153

Imbert J, Worswick M (2012) Reduction of a pre-formed radius in aluminium sheet using electromagnetic and conventional forming. J Mater Process Technol 212:1963–1972

Kim J, Noh HG, Song WJ, Kang BS (2014) Comparative numerical analysis of sheet formed into a V-shaped die using conventional and electromagnetic forming processes. Adv Mech Eng 6:240789

Liu W, Zou XF, Huang SY, Zhu J, Lei Y (2018) Numerical simulation of collision effect on damage evolution in electromagnetic forming of aluminum alloy sheet. Key Eng Mater 765:216–221

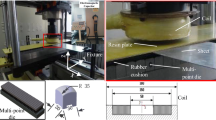

Kamal M, Daehn GS (2007) A uniform pressure electromagnetic actuator for forming flat sheets. J Manuf Sci Eng 129:369–379

Golowin S, Kamal M, Shang J, Portier J, Din A, Daehn GS, Bradley JR, Newman KE, Hatkevich S (2007) Application of a uniform pressure actuator for electromagnetic processing of sheet metal. J Mater Eng Perform 16:455–460

Thibaudeau E, Kinsey BL (2015) Analytical design and experimental validation of uniform pressure actuator for electromagnetic forming and welding. J Mater Process Technol 215:251–263

Meng Z, Huang S, Huang W, Hu J, Xia Z (2011) Effects of process parameters on warm and electromagnetic hybrid forming of magnesium alloy sheets. J Mater Process Technol 211:863–867

Feng F, Huang S, Hu J, Meng Z, Lei Y (2013) Analysis of the bulging process of an AZ31B magnesium alloy sheet with a uniform pressure coil. Int J Adv Manuf Technol 69:1537–1545

Xu J, Zhou Y, Cui J, Huang L, Zhang X, Li G (2018) Effects of temperature and driver sheet for magnesium alloy sheet in magnetic pulse forming. Int J Adv Manuf Technol 95:3319–3333

Kim JH, Kim D, Lee MG (2015) Experimental and numerical analysis of a rectangular helical coil actuator for electromagnetic bulging. Int J Adv Manuf Technol 78:825–839

Shang J, Daehn G (2011) Electromagnetically assisted sheet metal stamping. J Mater Process Technol 211:868–874

Liu W, Zou X, Huang S, Lei Y (2018) Electromagnetic-assisted calibration for surface part of aluminum alloy with a dedicated uniform pressure coil[J]. Int J Adv Manuf Technol 100:721–727

Livermore Software Technology Corp. (2018) LS-DYNA® keyword user's manual volume II material models

Noh HG, Lee K, Kang BS, Kim J (2016) Inverse parameter estimation of the Cowper-Symonds material model for electromagnetic free bulge forming. Int J Precis Eng Manuf 17(11):1483–1492

Funding

This project (2019CFB196) was supported by Natural Science Foundation of Hubei Province, China. We also would like to express our appreciation for the financial support from State Key Laboratory of Materials Processing and Die & Mould Technology (P2018-013, Huazhong University of Science and Technology, China), and Jiangsu Key Laboratory of Precision and Micro-manufacturing Technology (Nanjing University of Aeronautics and Astronautics, China).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zeng, X., Meng, Z., Liu, W. et al. Deformation behaviour and damage evolution of aluminium alloy sheet in electromagnetic forming with uniform pressure actuator. Int J Adv Manuf Technol 109, 745–754 (2020). https://doi.org/10.1007/s00170-020-05704-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05704-0