Abstract

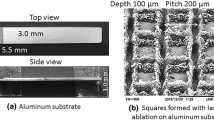

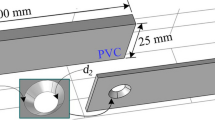

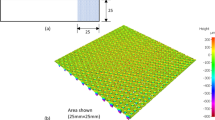

Metal–polymer direct joining helps meeting the growing demand for lightweight design in industry. Injection molded direct joining (IMDJ) is one of the promising metal–polymer direct joining methods. It needs firstly metal surface treatment and then injection insert molding. In this study, we proposed a simple, economical, and eco-friendly surface treatment, named as hot water treatment (HWT) for IMDJ. HWT produces complexed plate-like nanostructures on the aluminum surface. Polymer can flow into nanostructures and produce a mechanical interlocking effect by which metal and polymer achieve direct joining. The HWT treatment conditions, including water temperature and treatment time, were optimized. With the optimized condition, the highest joining strength of 22.5 MPa was obtained. An atomic force microscope (AFM) investigation on nanostructures and tensile shear tests to the joined specimens proved that the joining strength was strongly correlated with the combination of the arithmetical mean height (Sa) and the number of nanostructures (Nn). In addition, the joined specimens also achieved high cycle fatigue. Results showed that high-quality joint can be produced by treating aluminum with HWT. Compared with conventional chemical surface treatment methods, HWT is much easier to apply in practices. Wide applications in industries can be expected.

Similar content being viewed by others

References

Katayama S, Kawahito Y (2008) Laser direct joining of metal and plastic. Scr Mater 59(12):1247–1250. https://doi.org/10.1016/j.scriptamat.2008.08.026

Nagatsuka K, Yoshida S, Tsuchiya A, Nakata K (2015) Direct joining of carbon-fiber–reinforced plastic to an aluminum alloy using friction lap joining. Compos Part B 73:82–88. https://doi.org/10.1016/j.compositesb.2014.12.029

Balle F, Wagner G, Eifler D (2009) Ultrasonic metal welding of aluminium sheets to carbon fibre reinforced thermoplastic composites. Adv Eng Mater 11(1–2):35–39. https://doi.org/10.1002/adem.200800271

Kimura F, Kadoya S, Kajihara Y (2016) Effects of molding conditions on injection molded direct joining using a metal with nano-structured surface. Precis Eng 45:203–208. https://doi.org/10.1016/j.precisioneng.2016.02.013

Zhao S, Kimura F, Kadoya S, Kajihara Y (2020) Experimental analysis on mechanical interlocking of metal–polymer direct joining. Precis Eng 61:120–125. https://doi.org/10.1016/j.precisioneng.2019.10.009

Kadoya S, Kimura F, Kajihara Y (2019) PBT--anodized aluminum alloy direct joining: characteristic injection speed dependence of injected polymer replicated into nanostructures. Polym Test 75:127–132. https://doi.org/10.1016/j.polymertesting.2019.02.006

Kajihara Y, Tamura Y, Kimura F, Suzuki G, Nakura N, Yamaguchi E (2018) Joining strength dependence on molding conditions and surface textures in blast-assisted metal-polymer direct joining. CIRP Ann 67(1):591–594. https://doi.org/10.1016/j.cirp.2018.04.112

Kimura F, Yamaguchi E, Horie N, Suzuki G, Kajihara Y (2020) Formation of boehmite crystals on microblasted aluminum surface to enhance performance of metal–polymer direct joining. Mater Lett 260:126963. https://doi.org/10.1016/j.matlet.2019.126963

Saadi NS, Hassan LB, Karabacak T (2017) Metal oxide nanostructures by a simple hot water treatment. Sci Rep 7(1):7158–7158. https://doi.org/10.1038/s41598-017-07783-8

Godart P, Fischman J, Seto K, Hart D (2019) Hydrogen production from aluminum-water reactions subject to varied pressures and temperatures. Int J Hydrog Energy 44(23):11448–11458. https://doi.org/10.1016/j.ijhydene.2019.03.140

International Organization for Standardization (2015) Plastics-evaluation of the adhesion interface performance in plastic-metal assemblies-part 2: test specimens. Standard No ISO 19095–2

International Organization for Standardization (2012) Geometric Product Specification (GPS). Surface Texture: Areal. Part 2: Terms, Definitions and Surface Texture Parameters. Standard No. ISO 25178-2

Li X, Liu F, Gong N, Yang C, Wang B (2018) Surface topography induced high injection joining strength of polymer-metal composite and fracture mechanism. Compos Struct 184:545–553. https://doi.org/10.1016/j.compstruct.2017.10.020

Kadoya S, Kimura F, Kajihara Y (2018) Tester for tensile shear evaluation of metal–polymer single lap joints. Precis Eng 54:321–326. https://doi.org/10.1016/j.precisioneng.2018.06.009

International Organization for Standardization (2015) Plastics-evaluation of the adhesion interface performance in plastic-metal assemblies-part 4: environmental conditions for durability. Standard No. ISO 19095–4

Chen YJ, Yue TM, Guo ZN (2018) Fatigue behaviour of titanium/PET joints formed by ultrasound-aided laser welding. J Manuf Process 31:356–363. https://doi.org/10.1016/j.jmapro.2017.11.027

Hino M, Mitooka Y, Murakami K, Urakami K, Nagase H (2010) Effect of aluminum surface state on laser joining between 1050 aluminum sheet and polypropylene resin sheet using insert materials. Mater Trans 52:1104111337–1104111047. https://doi.org/10.2320/matertrans.L-M2011804

Ingram-Jones VJ, Slade RCT, Davies TW, Southern JC, Salvador S (1996) Dehydroxylation sequences of gibbsite and boehmite: study of differences between soak and flash calcination and of particle-size effects. J Mater Chem 6(1):73–79. https://doi.org/10.1039/JM9960600073

Acknowledgments

A part of this work was conducted at Advanced Characterization Nanotechnology Platform of the University of Tokyo, supported by “Nanotechnology Platform” of the Ministry of Education, Culture, Sports, Science and Technology (MEXT), Japan.

Funding

This work was supported by JSPS KAKENHI (19K14859) and Foundation for the Promotion of Industrial Science, Japan.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhao, S., Kimura, F., Yamaguchi, E. et al. Manufacturing aluminum/polybutylene terephthalate direct joints by using hot water–treated aluminum via injection molding. Int J Adv Manuf Technol 107, 4637–4644 (2020). https://doi.org/10.1007/s00170-020-05364-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05364-0