Abstract

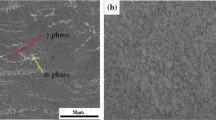

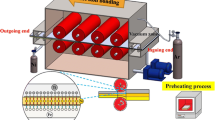

Electrically assisted superplastic forming and diffusion bonding (EASPF/DB) is based on the electrically assisted technique in which the electric current is directly and simply introduced into metallic sheets during hot processing. Through the rapidly increasing heat by the Joule effect after several minutes, the advantages of the EASPF/DB process are further strengthened, and the limitations of commercial exploitation (e.g., long processing period) are partly overcome. In this study, an experimental setup of EASPF/DB was assembled for the experimental validation of this concept. The Ti2AlNb alloy sheet, which is regarded as a superior substitute for the nickel-based alloy, was diffusion-bonded and formed, and a double-layer structure was fabricated by means of the EASPF/DB process. The temperature distribution measured by an infrared imaging camera was apparently influenced by detour effects of the electric current. To examine the forming and bonding effects, the height and thickness were measured in different positions. The microstructures of the bonding interface were observed, and no microcavity and crack were found, which indicated the feasibility of the variant of the SPF/DB process. Meanwhile, the large-size grains of B2 phase compose the microstructure of forming zone with some fine needle–like precipitates. Finally, the hardness test showed higher values of Vickers hardness than that of the as-received sheet and the compression test showed three stages of the double-layer structure during continuous loading. The important values and significance for use of this variant are presented by markedly reducing the heating and cooling time and the targeted heating manner for metallic sheets.

Similar content being viewed by others

References

Banerjee D, Gogia AK, Nandi TK, Joshi VA (1988) A new ordered orthorhombic phase in a Ti3AlNb alloy. Acta Metall 36:871–882

Banerjee D (1997) The intermetallic Ti2AlNb. Prog Mater Sci 42:135–158

Lin P, He Z, Yuan S, Shen J (2012) Tensile deformation behavior of Ti–22Al–25Nb alloy at elevated temperatures. Mater Sci Eng A 556:617–624

Xue C, Zeng W, Wang W, Liang X, Zhang J (2013) The enhanced tensile property by introducing bimodal size distribution of lamellar O for O+B2 Ti2AlNb based alloy. Mater Sci Eng A 587:54–60

Zheng Y, Zeng W, Li D, Liang X, Zhang J, Ma X (2017) Effect of orthorhombic case on the creep rupture of Ti-22Al-25Nb (at%) orthorhombic alloy. Mater Sci Eng A 696:529–535

Wang W, Zeng W, Xue C, Liang X, Zhang J (2014) Microstructural evolution, creep, and tensile behavior of a Ti–22Al–25Nb (at%) orthorhombic alloy. Mater Sci Eng A 603:176–184

Jiao X, Liu G, Wang D, Wu Y (2017) Creep behavior and effects of heat treatment on creep resistance of Ti-22Al-24Nb-0.5Mo alloy. Mater Sci Eng A 680:182–189

Wu Y, Liu G, Liu Z, Wang B (2016) Formability and microstructure of Ti22Al24.5Nb0.5Mo rolled sheet within hot gas bulging tests at constant equivalent strain rate. Mater Design 108:298–307

Du Z, Jiang S, Zhang K, Lu Z, Li B, Zhang D (2016) The structural design and superplastic forming/diffusion bonding of Ti2AlNb based alloy for four-layer structure. Mater Design 104:242–250

Wu Y, Liu G, Jin S, Liu Z (2017) Microstructure and mechanical properties of Ti2AlNb cup-shaped part prepared by hot gas forming: determining forming temperature, strain rate, and heat treatment. Int J Adv Manuf Technol 92:4583–4594

Huda Z, Edi P (2013) Materials selection in design of structures and engines of supersonic aircrafts: a review. Mater Design 46:552–560

Wang C, Zhao T, Wang G, Gao J, Fang H (2015) Superplastic forming and diffusion bonding of Ti–22Al–24Nb alloy. J Mater Process Technol 222:122–127

Kumpfert J, Leyens C, Peters M (2005) Titanium and titanium alloys: fundamentals and applications. DE: John Wiley & Sons, Ltd Chapter 3

Hefti LD (2010) Fine-grain titanium 6AI-4V for superplastic forming and diffusion bonding of aerospace products. JOM 62:42–45

Mori K, Maki S, Tanaka Y (2005) Warm and hot stamping of ultra high tensile strength steel sheets using resistance heating. CIRP-Annual 54:209–212

Maeno T, Mori K, Ogihara T, Fujita T (2018) Blanking immediately after heating and ultrasonic cleaning for compact hot-stamping systems using rapid resistance heating. Int J Adv Manuf Technol 97:3827–3837

Yanagimoto J, Izumi R (2009) Continuous electric resistance heating—hot forming system for high-alloy metals with poor workability. J Mater Process Technol 209:3060–3068

Xu Z, Tang G, Tian S, Ding F, Tian H (2007) Research of electroplastic rolling of AZ31 Mg alloy strip. J Mater Process Technol 182:128–133

Zhu R, Tang G (2017) The improved plasticity of NiTi alloy via electropulsing in rolling. Mater Sci Tech-Lond 33:546–551

Kuang J, Li X, Zhang R, Ye Y, Luo AA, Tang G (2016) Enhanced rollability of Mg3Al1Zn alloy by pulsed electric current: a comparative study. Mater Design 100:204–216

Terhorst M, Ozhoga-Maslovskaja O, Trauth D, Shirobokov A, Mattfeld P (2017) Electro-thermo-mechanical contact model for bulk metal forming under application of electrical resistance heating. Int J Adv Manuf Technol 89:3601–3618

Li C, Jiang S, Zhang K (2012) Pulse current-assisted hot-forming of light metal alloy. Int J Adv Manuf Technol 63:931–938

Li C, Zhang K, Jiang S, Zhang Z (2012) Pulse current auxiliary bulging and deformation mechanism of AZ31 magnesium alloy. Mater Design 34:170–178

Liu J, Zhang K (2015) Resistance heating superplastic forming and influence of current on deformation mechanism of TA15 titanium alloy. Int J Adv Manuf Technol 76:1673–1680

Bao W, Chu X, Lin S, Gao J (2015) Experimental investigation on formability and microstructure of AZ31B alloy in electropulse-assisted incremental forming. Mater Design 87:632–639

Xu D, Lu B, Cao T, Zhang H, Chen J, Long H, Cao J (2016) Enhancement of process capabilities in electrically-assisted double sided incremental forming. Mater Design 92:268–280

Santos TG, Miranda RM, Vilaça P (2014) Friction stir welding assisted by electrical Joule effect. J Mater Process Technol 214:2127–2133

Liu X, Lan S, Ni J (2015) Electrically assisted friction stir welding for joining Al 6061 to TRIP 780 steel. J Mater Process Technol 219:112–123

Moradi M, Ng M, Lee T, Cao J, Pivard YN (2017) Interface characterization of Al-Cu laminates fabricated by electrically assisted rolling bonding. J Micro Nano-Manuf 5:0310013

Ruszkiewicz BJ, Grimm T, Ragai I, Mears L, Roth JT (2017) A review of electrically-assisted manufacturing with emphasis on modeling and understanding of the electroplastic effect. J Manuf Sci E-T ASME 139:110801

Wang X, Xu J, Shan D, Guo B, Cao J (2016) Modeling of thermal and mechanical behavior of a magnesium alloy AZ31 during electrically-assisted micro-tension. Int J Plast 85:230–257

Li X, Wang G, Gu Y, Yang J (2019) Electrically assisted diffusion bonding of Ti2AlNb alloy sheet using CP-Ti foil interlayer: microstructural characterization and mechanical tests. Mater Sci Eng A 744:733–745

Wang G, Li X, Liu S, Gu Y (2018) Improved superplasticity and microstructural evolution of Ti2AlNb alloy sheet during electrically assisted superplastic gas bulging. Int J Adv Manuf Technol 99:773–787

Jovane F (1968) An approximate analysis of the superplastic forming of a thin circular diaphragm: theory and experiments. Int J Mech Sci 10:403–427

Zheng Y, Zeng W, Zhao Q, Li D, Ma X, Liang X, Zhang J (2018) Deformation and microstructure evolution above the B2 transus of Ti-22Al-25Nb (at%) orthorhombic alloy. Mater Sci Eng A 710:164–171

Liu TJ (2014) Joule heating behaviors around through crack emanating from circular hole under electric load. Eng Fract Mech 123:2–20

Xu Q, Tang G, Jiang Y (2011) Thermal and electromigration effects of electropulsing on dynamic recrystallization in Mg–3Al–1Zn alloy. Mater Sci Eng A 528:4431–4436

Jiang Y, Tang G, Shek C, Liu W (2011) Microstructure and texture evolution of the cold-rolled AZ91 magnesium alloy strip under electropulsing treatment. J Alloys Compd 509:4308–4313

Shao B, Shan D, Guo B, Zong Y (2019) Plastic deformation mechanism and interaction of B2, α2, and O phases in Ti-22Al-25Nb alloy at room temperature. Int J Plast 113:18–34

Acknowledgments

The authors gratefully acknowledge the Associate Professor Baoyou Zhang of Harbin Institute of Technology for the support of EPMA operation.

Funding

This study is financially supported by the National Natural Science Foundation of China under the Grant No. 51875122.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, X., Wang, G., Zhang, J. et al. Electrically assisted superplastic forming/diffusion bonding of the Ti2AlNb alloy sheet. Int J Adv Manuf Technol 106, 77–89 (2020). https://doi.org/10.1007/s00170-019-04458-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04458-8