Abstract

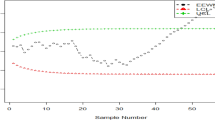

Statistical process control (SPC) has its own importance in the field of quality control. In SPC, control charts are significant tools to monitor process parameters, and exponentially weighted moving average (EWMA) control chart is one such tool. It is a memory-type chart, which is used to target mainly the smaller shifts in the process parameters. Adaptive EWMA (AEWMA) scheme is used to identify small as well as large shifts. EWMA and AEWMA are based on the assumption of normality, which is quite hard to find in practice, and there are many situations where outliers are occasionally present. In the current study, we have proposed four robust adaptive EWMA schemes for monitoring process location parameter. We have investigated their performance under uncontaminated normal and contaminated normal environments. We have carried out comparisons amongst different competing charts based on average run length (ARL), standard deviation of run length (SDRL) and different percentiles of run length distribution. Two examples related to manufacturing processes are also provided for practical implementation of the proposed schemes.

Similar content being viewed by others

References

Roberts S (1959) Control chart tests based on geometric moving averages. Technometrics 1(3):239–250

Page E (1954) Continuous inspection schemes. Biometrika 41:100–115

Lucas JM, Saccucci MS (1990) Exponentially weighted moving average control schemes: properties and enhancements. Technometrics 32(1):1–12

Capizzi G, Masarotto G (2003) An adaptive exponentially weighted moving average control chart. Technometrics 45(3):199–207

Yashchin E (1987) Some aspects of the theory of statistical control schemes. IBM J Res Dev 31(2):199–205

Lucas JM, Crosier RB (1982) Fast initial response for CUSUM quality-control schemes: give your CUSUM a head start. Technometrics 24(3):199–205

Tatum LG (1997) Robust estimation of the process standard deviation for control charts. Technometrics 39(2):127–141

Moustafa A, Mokhtar BA (1999) New robust statistical process control chart for location. Qual Eng 12(2):149–159

Borror CM, Montgomery DC, Runger GC (2000) Robustness of the EWMA control chart to non-normality. Qual Control Appl Stat 45(2):125–128

Testik MC, Runger GC, Borror CM (2003) Robustness properties of multivariate EWMA control charts. Qual Reliab Eng Int 19(1):31–38

Abbas N, Riaz M, Does RJ (2013) Mixed exponentially weighted moving average cumulative sum charts for process monitoring. Qual Reliab Eng Int 29(3):345–356

De Mast J, Roes KC (2004) Robust individuals control chart for exploratory analysis. Qual Eng 16(3):407–421

Maravelakis PE, Panaretos J, Psarakis S (2005) An examination of the robustness to non-normality of the EWMA control charts for the dispersion. Commun Stat Simul Comput 34(4):1069–1079

Abu-Shawiesh MO (2008) A simple robust control chart based on MAD. J Math Stat 4(2):102–107

Shahriari H, Maddahi A, Shokoui AH (2009) A robust dispersion control chart based on M-estimate. Journal of Industrial and Systems Engineering, Vol. 2. No. 4(2009):297–307

Nazir HZ, Riaz M, Does RJ, Abbas N (2013) Robust CUSUM control charting. Qual Eng 25(3):211–224

Alkahtani SS (2013) Robustness of DEWMA versus EWMA control charts to non-normal processes. J Mod Appl Stat Methods 12(1):148–163

Zaman B, Lee MH, Riaz M, Abujiya MAR (2017) An adaptive EWMA scheme-based CUSUM accumulation error for efficient monitoring of process location. Qual Reliab Eng Int 33(8):2463–2482

Abbas N (2018) Homogeneously weighted moving average control chart with an application in substrate manufacturing process. Comput Ind Eng 120:460–470

Haq A, Gulzar R, Khoo MB (2018) An efficient adaptive EWMA control chart for monitoring the process mean. Qual Reliab Eng Int 34(4):563–571

Abid M, Nazir HZ, Riaz M, Lin Z (2018) In-control robustness comparison of different control charts. Trans Inst Meas Control 40(13):3860–3871

Huber PJ (1981) Robust statistics. Wiley, New York

Beaton AE, Tukey JW (1974) The fitting of power series, meaning polynomials, illustrated on based spectroscopic data. Technometrics 19:161–164

Rousseeuw, PJ (1991) Tutorial to Robust Statistics. Journal of Chemometrics 5(1):1–20

Dixon WJ, Massey FJ (1969) Introduction to statistical analysis, 3rd edn. McGraw-Hill, New York

Weisberg HF (1992). Central tendency and variability. Sage University Paper Series on Quantitative Application in Social Sciences, Series no. 07-038. A. Virding, Ed. Newbury Park: Sage.

Tukey JW (1977). Exploratory data analysis. Reading: Addison Wesley

Wang T, Li Y, Cui H (2007) On weighted randomly trimmed means. J Syst Sci Complex 20(1):47–65

Hossain MP, Sanusi RA, Omar MH, Riaz M (2018) On designing Maxwell CUSUM control chart: an efficient way to monitor failure rates in boring processes. Int J Adv Manuf Technol 100(5–8):1923–1930 1–8

Mahmood T, Riaz M, Omar MH, Xie M (2018) Alternative methods for the simultaneous monitoring of simple linear profile parameters. Int J Adv Manuf Technol 97(5–8):2851–2871

Riaz M, Ahmad S (2016) On designing a new Tukey-EWMA control chart for process monitoring. Int J Adv Manuf Technol 82(1–4):1–23

Zaman B, Riaz M, Ahmad S, Abbasi SA (2015) On artificial neural networking-based process monitoring under bootstrapping using runs rules schemes. Int J Adv Manuf Technol 76(1–4):311–327

Ahmad S, Riaz M, Hussain S, Abbasi SA (2018) On auxiliary information-based control charts for autocorrelated processes with application in manufacturing industry. Int J Adv Manuf Technol 100(5–8):1965–1980 1–16

Riaz M, Mahmood T, Abbasi SA, Abbas N, Ahmad S (2017) Linear profile monitoring using EWMA structure under ranked set schemes. Int J Adv Manuf Technol 91(5–8):2751–2775

Zaman B, Abbas N, Riaz M, Lee MH (2016) Mixed CUSUM-EWMA chart for monitoring process dispersion. Int J Adv Manuf Technol 86(9–12):3025–3039

Tran K, Castagliola P, Balakrishnan N (2017) On the performance of the Shewhart median chart in presence of measurement error. Qual Reliab Eng Int 33(5):1019–1029

Crowder SV (1987) Average run lengths of exponentially weighted moving average control charts. J Qual Technol 19(3):161–164

Crowder SV (1989) Design of exponentially weighted moving average schemes. J Qual Technol 21(3):155–162

Haq A (2013) A new hybrid exponentially weighted moving average control chart for monitoring process mean. Qual Reliab Eng Int 29(7):1015–1025

Moustafa A (2009) A control chart based on robust estimators for monitoring the process mean of a quality characteristic. Int J Qual Reliab Manage 26(5):480–496

Schoonhoven M, Nazir HZ, Riaz M, Does RJ (2011) Robust location estimators for the X-bar control chart. J Qual Technol 43(4):363–379

Riaz M, Abbasi SA, Ahmad S, Zaman B (2014) On efficient phase II process monitoring charts. Int J Adv Manuf Technol 70(9–12):2263–2274

Montgomery DC (2009) Introduction to Statistical Quality Control, 6th ed. Wiley, New York

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nazir, H.Z., Hussain, T., Akhtar, N. et al. Robust adaptive exponentially weighted moving average control charts with applications of manufacturing processes. Int J Adv Manuf Technol 105, 733–748 (2019). https://doi.org/10.1007/s00170-019-04206-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04206-y