Abstract

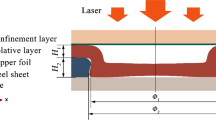

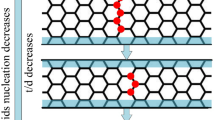

Micro-scale plastic deformation (microforming) is a promising manufacturing technology in modern industries. To put microformed parts in a more competitive position compared with micro-products made by other micro-manufacturing methods (such as micromachining and 3D printing), micro-progressive forming must be fully studied for the mass production of micro-parts to obtain good grain texture and decrease product costs. Simultaneously, the undiscovered dislocation strengthening effect of micro-scale progressive forming should be investigated. Using micro-universal joint progressive forming as a case study, the influence of the dead metal zone–induced strengthening effect on ductile fracture in micro-progressive forming is discussed. Based on the results of upsetting experiment and finite element simulation, it was found that the specimen produced via metal foil forward-extrusion-blanking process eliminated the ductile fracture when applying the same experiment condition to the specimen produced by micromachining. Based on the micro-indentation and X-ray diffraction results, a dead metal zone–induced dislocation strengthening model was established, and the mechanism for the strengthening effect during micro-progressive forming was revealed. This research thus provides an in-depth understanding of the micro-scale progressive forming process and takes an important step in the field of ductile fracture in multi-stage plastic deformation.

Similar content being viewed by others

References

Xu J, Guo B, Shan DB, Wang CJ, Li J, Liu YW, Qu DS (2012) Development of a micro-forming system for micro-punching process of micro-hole arrays in brass foil. J Mater Process Technol 212:1501–1512

Fu MW, Chan WL (2013) Micro-scaled progressive forming of bulk micropart via directly using sheet metals. Mater Des 49:774–783

Chan WL, Fu MW (2013) Meso-scaled progressive forming of bulk cylindrical and flanged parts using sheet metal. Mater Des 43:249–257

Ghassemali E, Tan MJ, Jarfors AEW, Lim SCV (2013) Optimization of axisymmetric open-die micro-forging/extrusion processes: an upper bound approach. J Mater Process Technol 71:58–67

Ghassemali E, Tan MJ, Wah CB, Lim SCV, Jarfors AEW (2015) Effect of cold-work on the Hall–Petch breakdown in copper based micro-components. Mech Mater 80:124–135

Meng B, Fu MW, Fu CM, Wang JL (2015) Multivariable analysis of micro shearing process customized for progressive forming of micro-parts. Int J Mech Sci 93:191–203

Lemaitre J (1985) A continuous damage mechanics model for ductile fracture. J Eng Mater Technol 107:83–89

Gurson AL (1977) Continuum theory of ductile rupture by void nucleation and growth, I. Yield criteria and flow rules for porous ductile media. J Eng Mater Technol 99:2–15

Xue L, Wierzbicki T (2008) Ductile fracture initiation and propagation modeling using damage plasticity theory. Eng Fract Mech 75:3276–3293

Li H, Fu MW, Lu J, Yang H (2011) Ductile fracture: experiments and computations. Int J Plast 27:147–180

Freudenthal FA (1950) The inelastic behavior of solids. Wiley, New York

Tirosh J (1971) On the dead-zone formation in plastic axially-symmetric converging flow. J Mech Phys Solids 19:39–47

Eivani AR, Taheri AK (2008) The effect of dead metal zone formation on strain and extrusion force during equal channel angular extrusion. Comput Mater Sci 42(1):0–20

Qamar SZ (2010) Shape complexity, metal flow, and dead metal zone in cold extrusion. Mater Manuf Process 25:1454–1461

Lee DJ, Yoon EY, Park LJ, Kim HS (2012) The dead metal zone in high-pressure torsion. Scr Mater 67:384–387

Wan L, Wang D (2015) Numerical analysis of the formation of the dead metal zone with different tools in orthogonal cutting. Simul Model Pract Theory 56:1–15

Wan L, Haddag B, Wang DZ, Sheng Y, Yang DM (2018) Effects of friction conditions on the formation of dead metal zone in orthogonal cutting – a finite element study. Mach Sci Technol 22:934–952

Ran JQ, Fu MW (2014) A hybrid model for analysis of ductile fracture in micro-scaled plastic deformation of multiphase alloys. Int J Plast 61:1–16

Ran JQ, Fu MW, Chan WL (2013) The influence of size effect on the ductile fracture in micro-scaled plastic deformation. Int J Plast 41:65–81

Liu JG, Fu MW, Chan WL (2012) A constitutive model for modeling of the deformation behavior in microforming with a consideration of grain boundary strengthening. Comput Mater Sci 55:85–94

Xu ZT, Peng LF, Lai XM, Fu MW (2014) Geometry and grain size effects on the forming limit of sheet metals in micro-scaled plastic deformation. Mater Sci Eng A 611:345–353

Xu ZT, Peng LF, Fu MW, Lai XM (2015) Size effect affected formability of sheet metals in micro/meso scale plastic deformation: experiment and modeling. Int J Plast 68:34–54

Chen FK, Tsai JW (2006) A study of size effect in micro-forming with micro-hardness tests. J Mater Process Technol 177(1–3):146–149

Williamson GK, Smallman RE (1955) Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray debye-Scherrer spectrum. Philos Mag 1:34–46

Ashby MF (1970) The deformation of plastically non-homogeneous materials. Philos Mag 21:399–424

Petch NJ (1953) J Iron Steel Inst 174:25–28

Armstrong RW (1962) The plastic deformation of polycrystalline aggregates. Philos Mag 7:45–48

Armstrong RW (1982) The yield and flow stress dependence on polycrystal grain size. In: Baker TN, Petch NJ (eds) Yield, Flow and FracturePolycrystals, pp 1–31

Bouquerel J, Verbeken K, De Cooman BC (2006) Microstructure-based model for the static mechanical behavior of multiphase steels. Acta Mater 54:1443–1456

Argon AS (2008) Strengthening mechanisms in crystal plasticity. Oxford University Press, Oxford

Rodriguez R, Gutierrez I (2003) Correlation between nanoindentation and tensile properties. Influence of the indentation size effect. Mater Sci Eng A 361:377–384

Funding

The work described in this paper was supported by grants from the National Natural Science Foundation of China (Grant No. 51705333), the key laboratory of Guangdong Province and the Natural Science Foundation of Guangdong Province (Grant No. 2017A030310352), the Natural Science Foundation of ShenZhen University (Grant No. 2016039), the open project of the key laboratory of Guangdong Province (PEM201605), and the Shenzhen Science and Technology Program (Grant Nos. JCYJ20160520175255386 and JCYJ20170818104529523).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ran, J.Q., Xu, L., Wang, J.L. et al. Influence of dead metal zone on dislocation strengthening effect during micro-progressive forming. Int J Adv Manuf Technol 105, 1129–1141 (2019). https://doi.org/10.1007/s00170-019-04147-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04147-6