Abstract

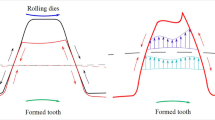

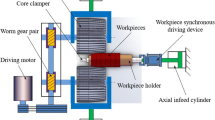

The cylindrical die forced throughfeed rolling process for gears was proposed to overcome an end-effect behavior of the standard radial-feed gear rolling process which can result in pitch variation and excessive axial end-flow. In the rolling process, the workpieces are pushed through the gap of the rolling tools to form the gear teeth. Understanding of material flow is important for grasping the cause of defect formation and improving the quality of formed gears. In this paper, the material flow behavior of the gear forced throughfeed rolling process was studied on the flow velocity and displacement of key locations by using finite element analysis (FEA). The experiment was also conducted and its blank was sliced to thin pieces, and the grid pattern (GP) was utilized to track the trajectory of flowing materials. The results show that the end-flow is located at the root rather than the tooth crest of the formed workpiece, because the compressive forces from rolling tool mainly take effect at the root of the formed workpiece. The asymmetry of circumferential flow displacements with respect to the gear teeth results in the asymmetrical flanks defect, and this is due to the meshing between teeth of rolling tool and workpiece. The local displacement in the radial direction is larger than that in the circumferential direction.

Similar content being viewed by others

References

Kamouneh AA, Ni J, Stephenson D, Vriesen R, DeGrace G (2007) Diagnosis of involutometric issues in flat rolling of external helical gears through the use of finite-element models. Int J Mach Tools Manuf 47:1257–1262. https://doi.org/10.1016/j.ijmachtools.2006.08.015

Kamouneh AA, Ni J, Stephenson D, Vriesen R (2007) Investigation of work hardening of flat-rolled helical-involute gears through grain-flow analysis, FE-modeling, and strain signature. Int J Mach Tools Manuf 47:1285–1291. https://doi.org/10.1016/j.ijmachtools.2006.08.015

Neugebauer R, Putz M, Hellfritzsch U (2007) Improved process design and quality for gear manufacturing with flat and round rolling. Ann CIRP 56(1):307–312. https://doi.org/10.1016/j.cirp.2007.05.071

Neugebauer R, Klug D, Hellfritzsch U (2007) Description of the interaction during gear rolling as a basis for a method for the prognosis of the attainable quality parameters. Prod Eng 1(3):253–257. https://doi.org/10.1007/s11740-007-0041-9

Neugebauer R, Hellfritzsch U, Lahl M (2008) Advanced process limits by rolling of helical gears. Int J Mater Form 1(1):1183–1186. https://doi.org/10.1007/s12289-008-0152-7

Khodaee A, Melander A (2014) A study of the effects of reversal cycle in the gear rolling process by using finite element simulations. Key Eng Mater 611-612(3):134–141. https://doi.org/10.4028/www.scientific.net/kem.611-612.134

Kretzschmar J, Stockmann M, Lhlemann J, Schiller S, Hellfritzsch U (2015) Experimental–numerical investigation of the rolling process of high gears. Exp Tech 39:28–36. https://doi.org/10.1111/ext.12016

Li J, Wang GC, Wu T (2016) Numerical simulation and experimental study of slippage in gear rolling. J Mater Process Technol 234:280–289. https://doi.org/10.1016/j.jmatprotec.2016.03.030

Li J, Wang GC, Wu T (2017) Numerical-experimental investigation on the rabbit ear formation mechanism in gear rolling. Int J Adv Manuf Technol 91(9–12):3551–3559. https://doi.org/10.1007/s00170-017-0009-7

Ma ZY, Luo YX, Wang YQ (2018) On the pitch error in the initial stage of gear roll-forming with axial-infeed. J Mater Process Technol 252:659–672. https://doi.org/10.1016/j.jmatprotec.2017.10.023

Ma ZY, Luo YX, Wang YQ (2017) Study on the pitch error in the initial stage of gear rolling process. ASME Int Power Trans Gear Conf 10

Zhu XX, Zhu Y, Wang SS, Wang BY (2015) Numerical simulation and experiment of hot roll forming large module spur gear. Mach Des Manuf-Chin 7:67–69. https://doi.org/10.3969/j.issn.1001-3997.2015.07.020

Domblesky JP, Feng F (2002) A parametric study of process parameters in external thread rolling. J Mater Process Technol 121:341–349. https://doi.org/10.1016/S0924-0136(01)01223-7

Sieczkarek P, Wernicke S, Gies S, Martins PAF, Tekkaya AE (2016) Incipient and repeatable plastic flow in incremental sheet-bulk forming of gears. Int J Adv Manuf Technol 86:3091–3100. https://doi.org/10.1007/s00170-016-8442-6

Yan HJ, Wang LJ, Liu YZ, Li GC, Liu JP, Hu ZH (2014) Effect of thread helix angle on the axial metal flow of cross wedge rolling thread shaft. Appl Mech Mater 440:177–181. https://doi.org/10.4028/www.scientific.net/AMM.440.177

Cui FK, Wang XQ, Zhang FS, Xu HY, Quan JH, Li Y (2013) Metal flowing of involute spline cold roll-beating forming. Chin J Mech Eng 26(5):1056–1062. https://doi.org/10.3901/CJME.2013.05.1056

Liu ZQ, Song JL, Qi HP, Li YT, Li XD (2010) Parameters and experiments on the precision forming process of spline cold rolling. Appl Mech Mater 34-35:646–650. https://doi.org/10.4028/www.scientific.net/AMM.34-35.646

Pater Z, Gontarz A, Weroñski W (2004) New method of thread rolling. J Mater Process Technol 153-154:722–728. https://doi.org/10.1016/j.jmatprotec.2004.04.154

Szota PL, Dyja H (2006) Numerical modeling of the metal flow during the rolling process of the round screw-ribbed bar in the finishing pass. J Mater Process Technol 177:566–569. https://doi.org/10.1016/j.jmatprotec.2006.04.035

Groche P, Kramer P (2017) Numerical investigation of the influence of frictional conditions in thread rolling operations with flat dies. Int J Mater Form 3:1–17. https://doi.org/10.1007/s12289-017-1383-2

Zhang DW, Zhao SD (2014) New method for forming shaft having thread and spline by rolling with round dies. Int J Adv Manuf Technol 70:1455–1462. https://doi.org/10.1007/s00170-013-5387-x

Cui MC, Zhao SD, Zhang DW, Chen C, Li YY (2017) Finite element analysis on axial-pushed incremental warm rolling process of spline shaft with 42CrMo steel and relevant improvement. Int J Adv Manuf Technol 90:2477–2490. https://doi.org/10.1007/s00170-016-9566-4

Ma ZY, Luo YX, Wang YQ, Wang Y (2018) Integrity and modeling of gear tooth forming in the roll-forming of gear with axial infeed. J Mech Eng-Chin 54(6):133–145. https://doi.org/10.3901/JME.2018.06.133

Ma ZY, Luo YX, Wang YQ, Mao J (2018) Geometric design of the rolling tool for gear roll-forming process with axial infeed. J Mater Process Technol 258:67–79. https://doi.org/10.1016/j.jmatprotec.2018.03.006

Neugebauer R, Hellfritzsch U, Lahl M, Schiller S, Milbrandt M (2011) Innovations in rolling process of helical gears. AIP Conf Proc 1315:569–574. https://doi.org/10.1063/1.3552507

Khodaee A (2015) Gear rolling for production of high gears. Dissertation, KTH Royal Institute of Technology

Li F, Lin JF, Chu GN (2009) Metal flow in the precision forging of aluminum alloys. JOM 61(8):57–60

Valberg H (2010) Comparison of metal flow in un-lubricated direct and indirect extrusion of aluminum alloys. Int J Mater Form 3:387–390. https://doi.org/10.1007/s12289-010-0788-y

Shen XH, Chen W, Yan J, Zhang L, Zhang J (2015) Experiment and simulation of metal flow in multi-stage forming process of railway wheel. J Iron Steel Res, Int 22(1):21–29. https://doi.org/10.1016/S1006-706X(15)60004-8

Yang MS, Yuan QL, Li Y, Zheng JM (2011) Deformation force simulation of lead screw cold roll-beating. Prod Eng 15:5164–5169. https://doi.org/10.1016/j.proeng.2011.08.958

Valberg H (2012) Characterization of metal flow in metals processing by a combined approach using advanced experimental grid pattern techniques coupled with FE-analysis. ICAA13 1501–1513. https://doi.org/10.1007/978-3-319-48761-8_227

Li F, Lin JF, Yuan SJ, Liu XJ (2009) Effect of inner cone punch on metal flow in extrusion process. Int J Adv Manuf Technol 42:489–496. https://doi.org/10.1007/s00170-008-1806-9

Wang ZK, Zhang Q (2008) Numerical simulation of involutes spline shaft in cold rolling forming. J Cent South Univ Technol 15(s2):278–283. https://doi.org/10.1007/s11771-008-0471-3

Acknowledgments

The authors extend sincere gratitude to Yawen Wang, Department of Mechanical and Aerospace Engineering, University of Texas at Arlington, Arlington, Texas, USA, for his editing and technical advice.

Funding

This study was funded by the National Natural Science Foundation of China (Grant No. 51775062) and the Research Project of State Key Laboratory of Mechanical Transmission (Grant No. SKLMT-ZZKT-2015T01).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ma, Z., Luo, Y., Wang, Y. et al. Numerical and experimental investigation on material flow in gear forced throughfeed rolling process. Int J Adv Manuf Technol 104, 3361–3381 (2019). https://doi.org/10.1007/s00170-019-03895-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03895-9