Abstract

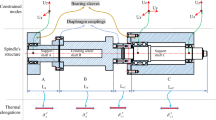

The coolant absorbing cutting heat has strong influence on thermal behaviors for high precision machine tool using flood cooling technique. However, the majority of applied thermal error compensation models are without considering cutting fluid thermal effect, which results in poor simulation accuracy of thermal deformation. This paper experimentally investigated the effect of coolant temperature on the thermal characteristics of a worm gear precision grinding machine. Experiments were carried out under three conditions: no-load with coolant, no-load with heated coolant, and load test. Moreover, a real-time thermal error compensation model was theoretically developed and validated based on the experimental data involving the cutting fluid thermal effect. The results show that the temperature distribution of the machine tool was more uniform and the temperature gradient was decreased when the grinding heat was partially considered using heated coolant, which indicates that coolant can positively affect the thermal behavior if it is controlled to flow correctly. The thermal error compensation model was built based on the optimal four temperature variables and with a high accurate prediction and robustness. For the no-load operating conditions, the maximum absolute errors and mean absolute errors are 2.7 μm and 1.5 μm respectively. For the load operating conditions, the prediction accuracy of the model built by no-load measuring data is also greatly improved because the grinding heat is partially considered by heated coolant in the no-load test. And the maximum prediction error is 13.0% when the influence of the feed drive system adjustment is considered.

Similar content being viewed by others

References

Yang JG, Ren YQ, Liu GL, Zhao HT, Dou XL, Chen WZ, He SW (2005) Testing, variable selecting and modeling of thermal errors on an index-g200 turning center. Int J Adv Manuf Technol 26(7-8):814–818. https://doi.org/10.1007/s00170-003-1908-3

Bryan JB (1990) International status of thermal error research. Annals Cirp CIRP Annals—Manufacturing Technology 39(2):645–656. https://doi.org/10.1016/S0007-8506(07)63001-7

Li Y, Zhao W, Lan S, Ni J, Wu W, Lu B (2015) A review on spindle thermal error compensation in machine tools. Int J Mach Tool Manu 95:20–38. https://doi.org/10.1016/j.ijmachtools.2015.04.008

Aguirre G, Pérez de Nanclares A & Urreta H (2014). Thermal error compensation for large heavy duty milling-boring machines. Proceedings of the 29th annual meeting of the American Society for Precision Engineering, 57–62. http://www.aspe.net/publications/Short%20Abstracts%2014A/4085.pdf

Brecher C, Wissmann A (2011) Compensation of thermo-dependent machine tool deformations due to spindle load: investigation of the optimal transfer function in consideration of rough machining. Prod Eng 5(5):565–574. https://doi.org/10.1007/s11740-011-0311-4

Liang R, Zhang HH, Yang Q (2012) The thermal error optimization models for CNC machine tools. Int J Adv Manuf Technol 63(9-12):1167–1176. https://doi.org/10.1007/s00170-012-3978-6

Chen JS (1996) A study of thermally induced machine tool errors in real cutting conditions. Int J Mach Tool Manu 36(12):1401–1411. https://doi.org/10.1016/0890-6955(95)00096-8

Horejš O, Mareš M, Hornych J (2014) A general approach to thermal error modelling of machine tools. In: Machines et Usinage à Grande Vitesse (MUGV). Clermont Ferrand, France

Martin M, Otakar H (2017) Modelling of cutting process impact on machine tool thermal behaviour based on experimental data. Procedia CIRP 58:152–157. https://doi.org/10.1016/j.procir.2017.03.208

Brecher C, Hirsch P, Weck M (2004) Compensation of thermo-elastic machine tool deformation based on control internal data. CIRP Ann Manuf Technol 53(1):299–304. https://doi.org/10.1016/S0007-8506(07)60702-1

Vyroubal J (2012) Compensation of machine tool thermal deformation in spindle axis direction based on decomposition method. Precis Eng 36(1):121–127. https://doi.org/10.1016/j.precisioneng.2011.07.013

Lee JH, Yang SH (2002) Statistical optimization and assessment of a thermal error model for CNC machine tools. Int J Mach Tool Manu 42(1):147–155. https://doi.org/10.1016/s0890-6955(01)00110-9

Du ZC, Yang JG, Yao ZQ, Xue BY (2002) Modeling approach of regression orthogonal experiment design for the thermal error compensation of a CNC turning center. J Mater Process Technol 129(1-3):619–623. https://doi.org/10.1016/s0924-0136(02)00668-4

Ramesh R, Mannan MA, Poo AN (2002) Support vector machines model for classification of thermal error in machine tools. Int J Adv Manuf Technol 20(2):114–120. https://doi.org/10.1007/s001700200132

Lin WLW & Fu JFJ (2010). Support vector machine and neural network united system for NC machine tool thermal error modeling. Sixth International Conference on Natural Computation. IEEE, 4305–4309 https://doi.org/10.1109/ICNC.2010.5583620.

Miao EM, Gong YY, Niu PC, Ji CZ, Chen HD (2013) Robustness of thermal error compensation modeling models of cnc machine tools. Int J Adv Manuf Technol 69(9-12):2593–2603. https://doi.org/10.1007/s00170-013-5229-x

Ramesh R, Mannan MA, Poo AN (2003) Thermal error measurement and modelling in machine tools. Part II. Hybrid Bayesian network—support vector machine model. Int J Mach Tool Manu 43(4):405–419. https://doi.org/10.1016/s0890-6955(02)00264-x

Brinksmeier E, Meyer D, Huesmann-Cordes AG, Herrmann C (2015) Metalworking fluids—mechanisms and performance. CIRP Annals—Manufacturing Technology 64(2):605–628. https://doi.org/10.1016/j.cirp.2015.05.003

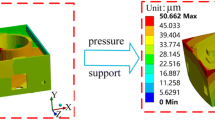

S X, Z K, W W, F L, G J (2018) A thermal characteristic analytic model considering cutting fluid thermal effect for gear grinding machine under load. Int J Adv Manuf Technol 99(5-8):1755–1976. https://doi.org/10.1007/s00170-018-2562-0

F L-j, S X-j, Z K, G J-m (2018) Experimental study on the effect of coolant on the thermal characteristics of gear grinding machine under load. Int J Mechat Manuf Syst 11(1):53–66. https://doi.org/10.1504/IJMMS.2018.091177

Mayr J, Gebhardt M, Massow BB, Weikert S, Wegener K (2014) Cutting fluid influence on thermal behavior of 5-axis machine tools. Procedia CIRP 14:395–400. https://doi.org/10.1016/j.procir.2014.03.085

Chen Z, di R (2004) The researching status analysis about the identification of the thermal key point of the machine tool. Modular Mach Tool Autom Manuf Tech 2:33–34. https://doi.org/10.3969/j.issn.1001-2265.2004.02.023

Yang J, Yuan J, Ni J (1999) Thermal error mode analysis and robust modeling for error compensation on a cnc turning center. Int J Mach Tool Manu 39(9):1367–1381. https://doi.org/10.1016/S0890-6955(99)00008-5

Weck M, McKeown P, Bonse R, Herbst U (1995) Reduction and compensation of thermal errors in machine tools. CIRP Ann—Manuf Technol 44(2):589–598. https://doi.org/10.1016/s0007-8506(07)60506-x

Lo CH, Yuan J, Ni J (1999) Optimal temperature variable selection by grouping approach for thermal error modeling and compensation. Int J Mach Tool Manu 39(9):1383–1396. https://doi.org/10.1016/S0890-6955(99)00009-7

Li YX, Yang JG, Gelvis T, Li YY (2008) Optimization of measuring points for machine tool thermal error based on grey system theory. Int J Adv Manuf Technol 35(7-8):745–750. https://doi.org/10.1007/s00170-006-0751-8

Liu H, Miao EM, Wei XY, Zhuang XD (2017) Robust modeling method for thermal error of CNC machine tools based on ridge regression algorithm. Int J Mach Tool Manu 113:35–48. https://doi.org/10.1016/j.ijmachtools.2016.11.001

Ma Shuwen (2007). Study on heat characteristics and thermal error compensation of NC machine tools. Doctoral dissertation. Southwest Jiaotong University, 55–56. http://cdmd.cnki.com.cn/Article/CDMD-10613-2007118201.htm

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shi, X., Wang, W., Mu, Y. et al. Thermal characteristics testing and thermal error modeling on a worm gear grinding machine considering cutting fluid thermal effect. Int J Adv Manuf Technol 103, 4317–4329 (2019). https://doi.org/10.1007/s00170-019-03650-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03650-0