Abstract

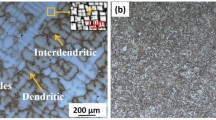

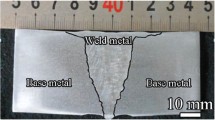

In the present study, the effect of microstructure and precipitation phenomena on the micro hardness, tensile strength, impact toughness, and electrochemical behavior of tungsten inert gas (TIG)-welded AA6061-T6 aluminum alloy are investigated. The microstructure features showed mainly the grains of aluminum solid solution with the presence of some precipitates at the grain boundaries. Scanning electron microscope micrographs exhibited the presence of Fe-based intermetallic and β-equilibrium precipitates throughout α-Al grains. In the heat-affected zone (HAZ), the dissolution, over-aged, and coalescence of precipitates are observed; their hardening effects disappear and a decrease in strength and hardness are noticed. The fracture toughness values of each zone at different temperatures using Charpy V-notch test remained constant where the HAZ presents the highest absorbed energy. However, the temperature did not have a significant effect on the absorbed energy for each zone. In addition, the fractured surface of base metal (BM) and HAZ are characterized by dimple-like structure and they are larger in the HAZ. The electrochemical behavior of each zone of the weld evaluated in NaCl + H2O2 solution revealed that the corrosion current density of BM and HAZ is lower than that of molten zone (MZ), which displays high corrosion current density in this electrolyte and would be fastest to corrode.

Similar content being viewed by others

References

Mrowka-Nowotnic G, Sieniawski J (2005) Influence of heat treatment on the microstructure and mechanical properties of 6005 and 6082 aluminium alloys. J Mater Process Technol 162–163:367–372. https://doi.org/10.1016/j.jmatprotec.2005.02.115

Ozturk F, Sisman A, Toros S, Kilic S, Picu RC (2010) Influence of aging treatment on mechanical properties of 6061 aluminum alloy. Mater Des 31:972–975. https://doi.org/10.1016/j.matdes.2009.08.017

Wang L, Jin L, Huang W, Xu M, Xue J (2015) Effect of thermal frequency on AA6061 aluminum alloy double pulsed gas metal arc welding. Mater Manuf Process 31:2152–2157. https://doi.org/10.1080/10426914.2015.1103863

Martukanitz RP (1993) Selection and weldability of heat-treatable aluminum alloys. In: ASM handbook. Welding Brazing and Soldering, vol 6

Kumar TS, Balasubramanian V, Sanavullah MY (2007) Influences of pulsed current tungsten inert gas welding parameters on the tensile properties of AA 6061 aluminium alloy. Mater Des 28:2080–2092. https://doi.org/10.1016/j.matdes.2006.05.027

M K WHK (1987) Investigation of heat-affected zone cracking of GTA welds of Al-Mg-Si alloys using the Varestraint test. Weld J 66:360–368

Dwivedi D (2002) Influence of modifier and grain refiner on solidification behavior and mechanical properties of cast Al-Si base alloy. Inst Eng India 83:46–50

Lee WB, Yeon YM, Jung SB (2003) Evaluation of the microstructure and mechanical properties of friction stir welded 6005 aluminum alloy. Mater Sci Technol 19:1513–1518. https://doi.org/10.1179/026708303225008068

Simar A, Br Y, De MB et al (2008) Microstructure, local and global mechanical properties of friction stir welds in aluminium alloy 6005A-T6. Mater Sci Eng A 486:85–95. https://doi.org/10.1016/j.msea.2007.08.041

Heinz B, Skrotzki B (2002) Characterization of a friction-stir-welded aluminum alloy 6013. Metall Mater Trans B Process Metall Mater Process Sci 33B:489–498

Mathivanan A, Devakumaran K, Kumar AS (2014) Comparative study on mechanical and metallurgical properties of AA6061 aluminum alloy sheet weld by pulsed current and dual pulse gas metal arc welding arc welding processes. Mater Manuf Process 29:941–947. https://doi.org/10.1080/10426914.2014.912314

Narsimhachary D, Bathe RN, Padmanabham G, Basu A (2014) Influence of temperature profile during laser welding of aluminum alloy 6061 T6 on microstructure and mechanical properties. Mater Manuf Process 29:948–953. https://doi.org/10.1080/10426914.2013.872258

Elangovan K, Balasubramanian V (2008) Influences of tool pin profile and tool shoulder diameter on the formation of friction stir processing zone in AA6061 aluminium alloy. Mater Des 29:362–373. https://doi.org/10.1016/j.matdes.2007.01.030

Lakshminarayanan AK, Balasubramanian V, Elangovan K (2009) Effect of welding processes on tensile properties of AA6061 aluminium alloy joints. Inter J Adv Manuf Technol 40:286–296. https://doi.org/10.1007/s00170-007-1325-0

Dawood HI, Mohammed KS, Rahmat A, Uday MB (2015) Effect of small tool pin profiles on microstructures and mechanical properties of 6061 aluminum alloy by friction stir welding. Trans Nonferrous Met Soc China 25:2856–2865. https://doi.org/10.1016/S1003-6326(15)63911-5

Wahid MA, Khan ZA, Siddiquee AN (2018) Review on underwater friction stir welding: a variant of friction stir welding with great potential of improving joint properties. Trans Nonferrous Met Soc China 28:193–219. https://doi.org/10.1016/S1003-6326(18)64653-9

Munoz AC, Ruckert G, Huneau B et al (2008) Comparison of TIG welded and friction stir welded Al-4.5Mg-0.26Sc alloy. J Mater Process Technol 197:337–343. https://doi.org/10.1016/j.jmatprotec.2007.06.035

Maisonnette D, Suery M, Nelias D, Chaudet P, Epicier T (2011) Effects of heat treatments on the microstructure and mechanical properties of a 6061 aluminium alloy. Mater Sci Eng A 528:2718–2724. https://doi.org/10.1016/j.msea.2010.12.011

Cicolin D, Trueba M, Trasatti SP (2014) Electrochim Acta Effect of chloride concentration, pH and dissolved oxygen, on the repassivation of 6082-T6 Al alloy. Electrochimi Acta 124:27–35. https://doi.org/10.1016/j.electacta.2013.09.003

Gharavi F, Matori KA, Yunus R, Othman NK, Fadaeifard F (2015) Corrosion behavior of Al6061 alloy weldment produced by friction stir welding process. J Mater Res Technol 4:314–322. https://doi.org/10.1016/j.jmrt.2015.01.007

ASME (2007) IX: Qualification Standard for Welding and Brazing Procedures, Welders, Brazers, and Welding and Brazing Operators, ASME International, The American Society of Mechanical Engineers (ASME), New York, United States

ASTM (2003) Standard Test Methods for Notched Bar Impact Testing of Metallic Materials (Designation: E23), ASTM International, West Conshohocken, United States

Andersen SJ, Zandbergen HW, Jansen J, TrÆholt C, Tundal U, Reiso O (1998) The crystal structure of the b phase in Al-mg-Si alloys. Acta Mater 46:3283–3298

Massardier V, Epicier T (2002) Study of the influence of a low copper addition and of an excess of silicon on the precipitation kinetics and on the precipitation sequence of Al-Mg2Si alloys. Mater Sci Forum 402:851–856. https://doi.org/10.4028/www.scientific.net/MSF.396-402.851.

Murayama M, Hono K (1999) Pre-precipitate clusters and precipitation processes in Al-Mg-Si alloys. Acta Mater 47:1537–1548. https://doi.org/10.1016/S1359-6454(99)00033-6

Fang X, Song M, Li K, Du Y (2010) Precipitation sequence of an aged Al-Mg-Si alloy. J Min Metall Sect B: Metall 46:171–180. https://doi.org/10.2298/JMMB1002171F

Menzemer C, Lam PC, Srivatsan TS, Wittel CF (1999) Investigation of fusion zone microstructures of welded aluminum alloy joints. Mater Lett 41:192–197. https://doi.org/10.1016/S0167-577X(99)00129-9.

JIA Z, DING L, WENG Y et al (2016) Effect of high temperature pre-straining on the natural aging and bake hardening response of Al-Mg-Si alloys. Trans Nonferrous Met Soc China 26:924–929. https://doi.org/10.1016/j.jallcom.2016.07.066.

Devaraj A, Perea DE, Liu J, Gordon LM, Prosa TJ, Parikh P, Diercks DR, Meher S, Kolli RP, Meng YS, Thevuthasan S (2017) Three-dimensional nanoscale characterisation of materials by atom probe tomography. Int Mater Rev 63:68–101. https://doi.org/10.1080/09506608.2016.1270728

Yang X, Liu J, Chen J, Wan C, Fang L, Liu P, Wu C (2014) Relationship between the strengthening effect and the. Acta Metall Sin (Engl Lett) 27:1070–1077. https://doi.org/10.1007/s40195-014-0122-7

Starke EA Jr (1977) Aluminium alloys of the 70’s: scientific solutions to engineering problems. An invited review. Mater Sci Eng 29:99–115. https://doi.org/10.1016/0025-5416(77)90114-8

Wang HQ, Sun WL, Xing YQ (2013) Microstructure analysis on 6061 aluminum alloy after casting and diffuses annealing process. Phys Procedia 50:68–75. https://doi.org/10.1016/j.phpro.2013.11.013

Zhang Z, Xu H, Wu S, Liu Y (2013) Effects of combined pre-straining and pre-aging on natural aging and bakehardening response of an Al-Mg-Si alloy. Acta Metall Sin (Engl Lett) 26:340–344. https://doi.org/10.1007/s40195-012-0239-5

Losana L (1931) The ternary system Al-Mg-Si (in Italian) (Equi. Diagram, experimental, 14). Met Ital 23:367–382

Milkereit B, Wanderka N, Schick C, Kessler O (2012) Continuous cooling precipitation diagrams of Al-Mg-Si alloys. Mater Sci Eng A 550:87–96. https://doi.org/10.1016/j.msea.2012.04.033

Lin DC, Wang GX, Srivatsan TS (2003) A mechanism for the formation of equiaxed grains in welds of aluminum Á lithium alloy 2090. Technical note Mater Sci Eng A 351:304–309. https://doi.org/10.1016/S0921-5093(02)00858-4

Ahmad R, Asmael MBA (2016) Influence of cerium on microstructure and solidification of eutectic Al-Si piston alloy. Mater Manuf Process 31:1948–1957. https://doi.org/10.1080/10426914.2015.1127942

Madhusudhan Reddy G, Gokhale AA, Prasad Rao K (1997) Weld microstructure refinement in a 1441 grade aluminium-lithium alloy. J Mater Sci 32:4117–4126

Abúndez A, Pereyra I, Campillo B, Serna S, Alcudia E, Molina A, Blanco A, Mayén J (2016) Improvement of ultimate tensile strength by artificial ageing and retrogression treatment of aluminium alloy 6061. Mater Sci Eng A 668:201–207. https://doi.org/10.1016/j.msea.2016.05.062

Feufel H, Gödecke T, Lukas HL, Sommer F (1997) Investigation of the Al-Mg-Si system by experiments and thermodynamic calculations. J Alloys Compd 247:31–42. https://doi.org/10.1016/S0925-8388(96)02655-2

Reiso O, Ryum N, Strid J (1993) Melting of secondary phase particles in Al-Mg-Si alloys. Met Mater Trans A 24:2629–2641

Manti R, Dwivedi DK, Agarwal A (2008) Microstructure and hardness of Al-Mg-Si weldments produced by pulse GTA welding. Int J Adv Manuf Technol 36:263–269. https://doi.org/10.1007/s00170-006-0849-z

Kumar V, Singh IV, Mishra BK, Jayaganthan R (2014) Improved fracture toughness of cryorolled and room temperature rolled 6082 al alloys. Acta Met Sin (Engl Lett) 27:359–367. https://doi.org/10.1007/s40195-014-0057-z

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hakem, M., Lebaili, S., Mathieu, S. et al. Effect of microstructure and precipitation phenomena on the mechanical behavior of AA6061-T6 aluminum alloy weld. Int J Adv Manuf Technol 102, 2907–2918 (2019). https://doi.org/10.1007/s00170-019-03401-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03401-1