Abstract

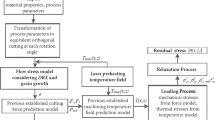

An analytical predictive model for residual stress in laser-assisted milling considering material recrystallization caused by laser preheating is proposed. The laser preheating temperature field is predicted by treating the laser beam as a heat source on top surface following Gaussian distribution. Heat convection between top surface and the environment is factored into account. Isothermal boundary conditions are assumed for the area of interest with conduction within the material. Next, the milling configuration is treated as orthogonal cutting at each instance. All process parameters including cutting depth, cutting speed, and tool geometry are therefore transferred. The recrystallization effect and thus the grain growth are considered through calibrated models describing the dependency of strain rate, strain, and temperature on dynamic recrystallization process for specific alloys using exponent functions. The residual stress is then predicted through the calculation of elastic stress distribution in loading process, actual stress with kinematic hardening, and the stress change during relaxation. The proposed model is validated through experimental measurements on the laser-assisted milling of Si3N4 and Ti-6Al-4V. The predictive model matches the trends of experimental measurements with agreement to an average error less than 30% in all cases. The proposed analytical model is valuable for providing a fast, credible, and physics-based method for the prediction of residual stress in laser-assisted milling of various materials.

Similar content being viewed by others

References

Schlauer C, Peng RL, Odén M (2002) Residual stresses in a nickel-based superalloy introduced by turning. Mater Sci Forum 404-407:173–178

Dudzinski D, Devillez A, Moufki A, Larrouquère D, Zerrouki V, Vigneau J (2004) A review of developments towards dry and high speed machining of Inconel 718 alloy. Int J Mach Tool Manu 44:439–456

Sharman ARC, Hughes JI, Ridgway K (2006) An analysis of the residual stresses generated in Inconel 718™ when turning. J Mater Process Technol 173(3):359–367

Madariaga A, Esnaola JA, Fernandez E, Arrazola PJ, Garay A, Morel F (2014) Analysis of residual stress and work-hardened profiles on Inconel 718 when face turning with large-nose radius tools. Int J Adv Manuf Technol 71(9–12):1587–1598

Outeiro JC, Pina JC, M'Saoubi R, Pusavec F, Jawahir IS (2008) Analysis of residual stresses induced by dry turning of difficult-to-machine materials. CIRP Ann Manuf Technol 57(1):77–80

Le Coz G et al (2010) Residual stresses after dry machining of Inconel 718, experimental results and numerical simulation

Ulutan D, Erdem Alaca B, Lazoglu I (2007) Analytical modelling of residual stresses in machining. J Mater Process Technol 183(1):77–87

Fergani O, Lazoglu I, Mkaddem A, el Mansori M, Liang SY (2014) Analytical modeling of residual stress and the induced deflection of a milled thin plate. Int J Adv Manuf Technol 75(1–4):455–463

Peng FY, Dong Q, Yan R, Zhou L, Zhan C (2016) Analytical modeling and experimental validation of residual stress in micro-end-milling. Int J Adv Manuf Technol 87(9–12):3411–3424

Zhou R, Yang W (2016) Analytical modeling of residual stress in helical end milling of nickel-aluminum bronze. Int J Adv Manuf Technol 89(1–4):987–996

Huang X, Zhang X, Ding H (2017) An enhanced analytical model of residual stress for peripheral milling. Procedia CIRP 58:387–392

Tian Y, Wu B, Anderson M, Shin YC (2008) Laser-assisted milling of silicon nitride ceramics and Inconel 718. J Manuf Sci Eng 130(3):031013

Bermingham MJ, Sim WM, Kent D, Gardiner S, Dargusch MS (2015) Tool life and wear mechanisms in laser assisted milling Ti–6Al–4V. Wear 322-323:151–163

Woo W-S, Lee C-M (2015) A study of the machining characteristics of AISI 1045 steel and Inconel 718 with a cylindrical shape in laser-assisted milling. Appl Therm Eng 91:33–42

Ma Q, Lin Z-q, Yu Z-q (2009) Prediction of deformation behavior and microstructure evolution in heavy forging by FEM. Int J Adv Manuf Technol 40(3–4):253–260

Huang D et al (2001) Computer simulation of microstructure evolution during hot forging of waspaloy and nickel alloy 718

Furrer D, Goetz R, Shen G (2010) Modeling and simulation of alloy 718 microstructure and mechanical properties. In 7th International Symposium on Superalloy 718 & Derivatives. The Minerals,Metals&Materials Society: Pittsburgh, Pennsylvania

Pan Z, Feng Y, Hung TP, Jiang YC, Hsu FC, Wu LT, Lin CF, Lu YC, Liang SY (2017) Heat affected zone in the laser-assisted milling of Inconel 718. J Manuf Process 30:141–147

Pan Z, Feng Y, Liang SY (2017) Material microstructure affected machining: a review. Manuf Rev 4:5

Pan Z, Feng Y, Lu YT, Lin YF, Hung TP, Hsu FC, Lin CF, Lu YC, Liang SY (2017) Microstructure-sensitive flow stress modeling for force prediction in laser assisted milling of Inconel 718. Manuf Rev 4:6

Pan Z, Feng Y, Lu YT, Lin YF, Hung TP, Hsu FC, Liang SY (2017) Force modeling of Inconel 718 laser-assisted end milling under recrystallization effects. Int J Adv Manuf Technol 92(5–8):2965–2974

Feng Y, Lu YT, Lin YF, Hung TP, Hsu FC, Lin CF, Lu YC, Liang SY (2018) Inverse analysis of the cutting force in laser-assisted milling on Inconel 718. Int J Adv Manuf Technol

Feng Y, Pan Z, Liang SY (2018) Temperature prediction in Inconel 718 milling with microstructure evolution. Int J Adv Manuf Technol 95(9–12):4607–4621

Pan Z et al (2017) Turning induced residual stress prediction of AISI 4130 considering dynamic recrystallization. Mach Sci Technol 22(3):507–521

Tian Y, Shin YC (2007) Multiscale finite element modeling of silicon nitride ceramics undergoing laser-assisted machining. J Manuf Sci Eng 129(2):287

Shen X, Lei S (2010) Experimental study on operating temperature in laser-assisted milling of silicon nitride ceramics. Int J Adv Manuf Technol 52(1–4):143–154

Hedberg GK (2013) Laser assisted milling of difficult to machine materials. Purdue University

Hedberg GK, Shin YC (2015) Laser assisted milling of Ti-6Al-4V ELI with the analysis of surface integrity and its economics. Lasers Manuf Mater Process 2(3):164–185

Pan Z et al (2017) Turning force prediction of AISI 4130 considering dynamic recrystallization. 2017(50725):V001T02A040

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Feng, Y., Hung, TP., Lu, YT. et al. Residual stress prediction in laser-assisted milling considering recrystallization effects. Int J Adv Manuf Technol 102, 393–402 (2019). https://doi.org/10.1007/s00170-018-3207-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-3207-z