Abstract

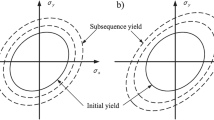

This paper focuses on numerical simulation of single point incremental forming (SPIF) process. Via a user-defined material (VUMAT) subroutine is employed to implement a non-associated mixed isotropic–kinematic hardening material model. The accuracy of the proposed non-associated flow rule model to predict the material behavior and the anisotropy in sheet metal forming simulations is examined by comparing numerical results with experimental measurements. The suggested model shows good agreement with experimental results compared to the associated Hill_R and Hill_S models. The proposed non-associated flow rule demonstrates a good efficiency to simulate the springback after sheet metal forming and to predict the thickness variation during incremental sheet metal forming process. The present non-associated model can improve the prediction of both anisotropic and hardening behaviors of material used in numerically controlled sheet metal forming technology.

Similar content being viewed by others

References

Lu B, Fang Y, Xu DK, Chen J, Ai S, Long H, Cao J (2015) Investigation of material deformation mechanism in double side incremental sheet forming. Int J Mach Tools Manuf 93:37–48

Ambrogio G, De Napoli L, Filice L, Gagliardi F, Muzzupappa M (2005) Application of incremental forming process for high customized medical product manufacturing. J Mater Process Technol 162:156–162

Duflou JR, Lauwers B, Verbert J, Gelaude F, Tunckol Y (2005) Medical application of single point incremental forming: cranial plate manufacturing. In: Proceedings of the 2nd international conference on advanced research in virtual and rapid prototyping. 161–166

Oleksik V, Pascu A, Deac C, Fleaca R, Roman M, Bologa O (2010) The influence of geometrical parameters on the incremental forming process for knee implants analyzed by numerical simulation. In Conference Proceedings. AIP Publishing, 1208–1215

Behera AK, Lauwers B, Duflou JR (2015) Tool path generation for single point incremental forming using intelligent sequencing and multi-step mesh morphing techniques. Int J Mater Form 8:517–532

Lievers WB, Pilkey AK, Lloyd DJ (2004) Using incremental forming to calibrate a void nucleation model for automotive aluminum sheet alloys. Acta Mater 52:3001–3007

Amino M, Mizoguchi M, Terauchi Y, Maki T (2014) Current status of Dieless Amino’s incremental forming. Procedia Eng 81:54–62

Behera AK, de Sousa RA, Ingarao G, Oleksik V (2017) Single point incremental forming: an assessment of the progress and technology trends from 2005 to 2015. J Manuf Process 27:37–62

Salem E, Shin J, Nath M, Banu M, Taub A (2016) Investigation of thickness variation in single point incremental forming. Procedia Manufacturing 5:828–837

Li Y, Daniel William JT, Liu Z, Lu H, Meehan PA (2015) Deformation mechanics and efficient force prediction in single point incremental forming. J Mater Process Technol 221:100–111

Wang J, Nair M, Zhang Y (2016) An efficient force prediction strategy in single point incremental sheet forming. Procedia Manufacturing 5:761–771

Jin K, Guo X, Tao J, Wang H, Kim N, Gu YA (2016) Model of one-surface cyclic plasticity with Lemaitre damage criterion for plastic instability prediction in the incremental forming process. Int J Mech Sci 114:88–97

Pereira Bastos RN, Alves de Sousa RJ, Fernandes Ferreira JA (2016) Enhancing time efficiency on single point incremental forming processes. Int J Mater Form 9:653–662

Ankush B, Rakesh L, Sateesh KY, Venkata Reddy N (2017) Prediction of forming forces in single point incremental forming. J Manuf Process 28:486–493

Uheida EH, Oosthuizen GA, Dimitrov D (2017) Investigating the impact of tool velocity on the process conditions in incremental forming of titanium sheets. Procedia Manufacturing 7:345–350

Shim MS, Park JJ (2001) The formability of aluminum sheet in incremental forming. J Mater Process Technol 113:654–658

Hill R (1990) Constitutive modelling of orthotropic plasticity in sheet metals. J Mech Phys Solids 38:405–417

Hill R (1993) A user-friendly theory of orthotropic plasticity in sheet metals. Int J Mech Sci 35:19–25

Barlat F, Maeda Y, Chung K, Yanagawa M, Brem JC, Hayashida Y, Lege DJ, Matsui K, Murtha SJ, Hattori S, Becker RC, Makosey S (1997) Yield function development for aluminum alloy sheets. J Mech Phys Solids 45:1727–1763

Karafillis AP, Boyce MC (1993) A general anisotropic yield criterion using bounds and a transformation weighting tensor. J Mech Phys Solids 41:1859–1886

Tourki Z, Zeghloul A, Ferron G (1996) Sheet metal forming simulations using a new model for orthotropic plasticity. Comput Mater Sci 5:255–262

Banabic D, Aretz H, Comsa DS, Paraianu L (2005) An improved analytical description of orthotropy in metallic sheets. Int J Plast 21:493–512

Montáns FJ, Benítez JM, Caminero MÁ (2012) A large strain anisotropic elastoplastic continuum theory for nonlinear kinematic hardening and texture evolution. Mech Res Commun 43:50–56

Robert C, Delamézière A, Dal Santo P, Batoz JL (2012) Comparison between incremental deformation theory and flow rule to simulate sheet-metal forming processes. J Mater Process Technol 212:1123–1131

Hill R (1948) A theory of the yielding and plastic flow of anisotropic metals. Proc R Soc Lond 193:281–297

Jrad H, Mars J, Wali M, Dammak F (2018) Geometrically nonlinear analysis of elastoplastic behavior of functionally graded shells. Eng Comput. https://doi.org/10.1007/s00366-018-0633-3

Wali M, Chouchene H, Ben Said L, Dammak F (2015) One-equation integration algorithm of a generalized quadratic yield function with Chaboche non-linear isotropic/kinematic hardening. Int J Mech Sci 92:223–232

Mars J, Wali M, Jarraya A, Dammak F, Dhiab A (2015) Finite element implementation of an orthotropic plasticity model for sheet metal in low velocity impact simulations. Thin-Walled Struct 89:93–100

Ben Said L, Mars J, Wali M, Dammak F (2016) Effects of the tool path strategies on incremental sheet metal forming process. Mechanics & Industry 17:411

Belhassen L, Koubaa S, Wali M, Dammak F (2016) Numerical prediction of springback and ductile damage in rubber-pad forming process of aluminum sheet metal. Int J Mech Sci 117:218–226

Koubaa S, Mars J, Wali M, Dammak F (2017) Numerical study of anisotropic behavior of aluminum alloy subjected to dynamic perforation. Int J Impact Eng 101:105–114

Koubaa S, Belhassen L, Wali M, Dammak F (2017) Numerical investigation of the forming capability of bulge process by using rubber as a forming medium. Int J Adv Manuf Technol 92:1839–1848

Autay R, Koubaa S, Wali M, Dammak F (2017) Numerical implementation of coupled anisotropic plasticity-ductile damage in sheet metal forming process. J Mech 34:417–430. https://doi.org/10.1017/jmech.2017.28

Belhassen L, Koubaa S, Wali M, Dammak F (2017) Anisotropic effects in the compression beading of aluminum thin-walled tubes with rubber. Thin-Walled Struct 119:902–910. https://doi.org/10.1016/j.tws.2017.08.010

Ben Said L, Mars J, Wali M, Dammak F (2017) Numerical prediction of the ductile damage in single point incremental forming process. Int J Mech Sci 131:546–558

Cvitanić V, Vlak F, Lozina Ž (2008) A finite element formulation based on non-associated plasticity for sheet metal forming. Int J Plast 24:646–687

Yoon JW, Yang DY, Chung K (1999) Elasto-plastic finite element method based on incremental deformation theory and continuum based shell elements for planar anisotropic sheet materials. Comput Methods Appl Mech Eng 174:23–56

Yoon JW, Yang DY, Chung K, Barlat F (1999) A general elasto-plastic finite element formulation based on incremental deformation theory for planar anisotropy and its application to sheet metal forming. Int J Plast 15:35–67

Safaei M, Zang SL, Lee MG, Waele WD (2013) Evaluation of anisotropic constitutive models: mixed anisotropic hardening and non-associated flow rule approach. Int J Mech Sci 73:53–68

Taherizadeh A, Green DE, Ghaei A, Yoon JW (2010) A non-associated constitutive model with mixed iso-kinematic hardening for finite element simulation of sheet metal forming. Int J Plast 26:288–309

Taherizadeh A, Ghaei A, Green DE, Altenhof WJ (2009) Finite element simulation of springback for a channel draw process with drawbead using different hardening models. Int J Mech Sci 51:314–325

Taherizadeh A, Green DE, Yoon JW (2015) A non-associated plasticity model with anisotropic and nonlinear kinematic hardening for simulation of sheet metal forming. Int J Solids Struct 69:370–382

Badreddine H, Saanouni K, Dogui A (2010) On non-associative anisotropic finite plasticity fully coupled with isotropic ductile damage for metal forming. Int J Plast 26:1541–1575

Wali M, Autay R, Mars J, Dammak F (2016) A simple integration algorithm for a non-associated anisotropic plasticity model for sheet metal forming. Int J Numer Methods Eng 107:183–204

Chaboche JL (1986) Time-independent constitutive theories for cyclic plasticity. Int J Plast 2:149–188

Lotfi Ben Said (2017) Formage incrémental des tôles minces Étude numérique et expérimentale. Thesis, National Engineering School of Sfax

Cho JR, Moon SJ, Moon YH, Kang SS (2003) Finite element investigation on spring-back characteristics in sheet metal U-bending process. J Mater Process Technol 141:109–116

Albut A (2008) The influence of the sheet thickness on springback effect in case of TWB’s forming. Communication and Information Technology, Circuits System and Signals, Applied Mathematics, Simulation Modeling, 13:147–150

Ayed LB, Robert C, Delameziere A, Nouari M, Batoz JL (2014) Simplified numerical approach for incremental sheet metal forming process. Eng Struct 62–63:75–86

Funding

The work is carried out thanks to the support and funding allocated to the Unit of Mechanical and Materials Production Engineering (UGPMM/UR17ES43) by the Tunisian Ministry of Higher Education and Scientific Research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bouhamed, A., Jrad, H., Said, L.B. et al. A non-associated anisotropic plasticity model with mixed isotropic–kinematic hardening for finite element simulation of incremental sheet metal forming process. Int J Adv Manuf Technol 100, 929–940 (2019). https://doi.org/10.1007/s00170-018-2782-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2782-3