Abstract

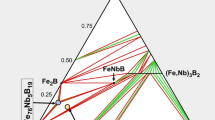

In this paper, Fe3Al-based alloy with a designed 30 at% Al content is fabricated using an innovative wire-arc additive manufacturing process. In order to investigate the influences of postproduction heat treatments on the additively manufactured alloy, three postproduction heat treatment methods were applied to the as-fabricated material. The morphologies, phase constituents, and mechanical properties of samples produced by the different heat treatments were characterized and analyzed in detail. According to the results, the applied heat treatments can considerably change the microstructure and mechanical properties of the as-fabricated Fe3Al-based alloy. Also, the hardness and tensile properties of Fe3Al-based alloy are found relevant to the Al-rich precipitates observed in the morphologies, which are generated by the additional thermal processes on the homogenized Fe3Al-based alloy.

Similar content being viewed by others

References

McKamey CG, DeVan JH, Tortorelli PF, Sikka VK (1991) A review of recent developments in Fe3Al-based alloys. J Mater Res 6:1779–1805

Zhang ZR, Liu WX (2006) Mechanical properties of Fe3Al-based alloys with addition of carbon, niobium and titanium. Mater Sci Eng A 423:343–349

Liu CT, George EP, Maziasz PJ, Schneibel JH (1998) Recent advances in B2 iron aluminide alloys: deformation, fracture and alloy design. Mater Sci Eng A 258:84–98

Morris DG, Nazmy M, Noseda C (1994) Creep resistance in a new alloy based on Fe3Al. Scripta Metal et Mater 31:173–178

McKamey CG, Horton JA, Liu CT (1989) Effect of chromium on properties of Fe3Al. J Mater Res 4:1156–1163

Hadef F, Otmani A, Djekoun A, Grenche JM (2011) Nanocrystalline FeAl intermetallics obtained in mechanically alloyed Fe50Al40Ni10 powder. Superlattice Microstruct 49:654–665

Zamanzade M, Barnoush A (2014) Effect of chromium on the electrochemical properties of iron aluminide intermetallics. Corros Sci 78:223–232

Baligidad RG, Prakash U, Rao VR, Rao PK, Ballal NB (1994) Electroslag remelting of Fe-28 at.-% Al intermetallic alloy. Ironmak Steelmak 21:324–331

Skoglund H, Wedel MK, Karlsson B (2004) Processing of fine-grained mechanically alloyed FeAl. Intermetallics 12:977–983

Ma Y, Cuiuri D, Hoye N, Li H, Pan Z (2015) The effect of location on the microstructure and mechanical properties of titanium aluminides produced by additive layer manufacturing using in-situ alloying and gas tungsten arc welding. Mater Sci Eng A 631:230–240

Ma Y, Cuiuri D, Hoye N, Li H, Pan Z (2014) Characterization of in-situ alloyed and additively manufactured titanium aluminides. Metall Mater Trans B Process Metall Mater Process Sci 45:2299–2303

Shen C, Pan Z, Ma Y, Cuiuri D, Li H (2015) Fabrication of iron-rich Fe–Al intermetallics using the wire-arc additive manufacturing process. Additive Manuf 7:20–26

Ma Y, Cuiuri D, Hoye N, Li H, Pan Z (2014) Effects of wire feed conditions on in situ alloying and additive layer manufacturing of titanium aluminides using gas tungsten arc welding. J Mater Res 29:2066–2071

Ma Y, Cuiuri D, Shen C, Li H, Pan Z (2015) Effect of interpass temperature on in-situ alloying and additive manufacturing of titanium aluminides using gas tungsten arc welding. Additive Manuf 8:71–77

Shen C, Pan Z, Cuiuri D, Ding D, Li H (2016) Influences of deposition current and interpass temperature to the Fe3Al-based iron aluminide fabricated using wire-arc additive manufacturing process. Int J Adv Manuf Tech 88:2009–2018

Ding D, Pan Z, Cuiuri D, Li H (2015) A practical path planning methodology for wire and arc additive manufacturing of thin-walled structures. Robot Cim-int Manuf 34:8–19

Ding D, Pan Z, Cuiuri D, Li H (2015) Wire-feed additive manufacturing of metal components: technologies, developments and future interests. Int J Adv Manuf Tech 1:1–17

Ding D, Pan Z, Cuiuri D, Li H (2015) A multi-bead overlapping model for robotic wire and arc additive manufacturing (WAAM). Robot Cim-int Manuf 31:101–110

Wang F, Williams S, Rush M (2011) Morphology investigation on direct current pulsed gas tungsten arc welded additive layer manufactured Ti6Al4V alloy. Int J Adv Manuf Tech 57:597–603

Shen C, Pan Z, Cuiuri D, Dong B, Li H (2016) In-depth study of the mechanical properties for Fe3Al based iron aluminide fabricated using the wire-arc additive manufacturing process. Mater Sci Eng A 669:118–126

Ma Y, Cuiuri D, Li H, Pan Z, Shen C (2016) The effect of postproduction heat treatment on γ-TiAl alloys produced by the GTAW-based additive manufacturing process. Mater Sci Eng A 657:86–95

Łyszkowski R (2015) High-temperature oxidation of Fe3Al intermetallic alloy prepared by additive manufacturing LENS. Materials 8:1499–1512

Michalcová A, Senčekova L, Rolink G, Weisheit A, Pešička J, Stobik M, Palm M (2017) Laser additive manufacturing of iron aluminides strengthened by ordering, borides or coherent Heusler phase. Mater Design 116:481–494

Ozaki H, Kutsuna M, Nakagawa S, Miyamoto K (2010) Laser roll welding of dissimilar metal joint of zinc coated steel to aluminum alloy. J Laser Appli 22:1–6

Shen C, Liss KD, Pan Z, Wang Z, Li X, Li H (2018) Thermal cycling of Fe3Al based iron aluminide during the wire-arc additive manufacturing process: an in-situ neutron diffraction study. Intermetallics 92:101–107

Hasemann G, Schinebel JH, Krüger M, George EP (2014) Vacancy strengthening in Fe3Al iron aluminides. Intermetallics 54:95–103

Morris DG, Gunther S (1997) Room and high temperature mechanical behaviour of a Fe3Al-based alloy with α-α″ microstructure. Acta Mater 45:811–822

Acknowledgements

The authors acknowledge use of the facilities within the UOW Electron Microscopy Centre.

Funding

The authors gratefully acknowledge financial support from China Scholarship Council (CSC), University of Wollongong (UOW), and Welding Technology Institute of Australia (WTIA).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shen, C., Pan, Z., Cuiuri, D. et al. Influences of postproduction heat treatment on Fe3Al-based iron aluminide fabricated using the wire-arc additive manufacturing process. Int J Adv Manuf Technol 97, 335–344 (2018). https://doi.org/10.1007/s00170-018-1954-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1954-5