Abstract

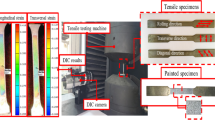

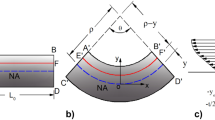

The method of cold roll forming, without using the press brake prior, is a kind of plastic forming process which produces the specified cross sections by a series of forming rollers. To measure the forming strain, the experiments adopted a non-contact strain measurement method and compared with the numerical model. A number of process parameters such as forming angle increment (F.A.I), forming velocity and station distance are studied to find the effects on the forming quality. The FEM of 45° die shear system is set up and compared with the experimental results. The effects of shear parameters such as the shear angle and the shear velocity are also discussed. The consequences demonstrate that the 45° die shear system has shear blind zones which have bad shearing quality. The shear velocity has a significant influence on the shear zone length.

Similar content being viewed by others

References

Halmos G (2006) Roll forming handbook. Taylor & Francis Group

Macdonald M, Heiyantuduwa MA, Rhodes J (2008) Recent developments in the design of cold-formed steel members and structures. Thin Wall Struct 46:1047–1053

Zeng G, Li SH, Yu ZQ, Lai XM (2009) Optimization design of roll profiles for cold roll forming based on response surface method. Mater Design 30:1930–1938

Cai ZY, Li LL, Wang M, Li MZ (2014) Process design and longitudinal deformation prediction in continuous sheet metal roll forming for three-dimensional surface. Int J Precis Eng Man 15(9):1889–1895

Liu CF, Zhou WL, Fu XS, Chen GQ (2015) A new mathematical model for determining the longitudinal strain in cold roll forming process. Int J Adv Manuf Tech 79:1055–1061

Heislitz F, Livatyali H, Ahmetoglu MA, Kinzel GL, Altan T (1996) Simulation of roll forming process with the 3-D FEM code PAM-STAMP. J Mater Process Tech 59:59–67

Hong S, Lee S, Kim N (2001) A parametric study on forming length in roll forming. J Mater Process Tech 113:774–778

Bui QV, Ponthot JP (2008) Numerical simulation of cold roll-forming processes. J Mater Process Tech 202:275–282

Jeong SH, Lee SH, Kim GH, Seo HJ, Kim TH (2008) Computer simulation of U-channel for under-rail roll forming using rigid-plastic finite element methods. J Mater Process Tech 201:118–122

Safdarian R, Moslemi Naeini H (2015) The effect of forming parameters on the cold roll forming of channel section. Thin Wall Struct 92:130–136

Bidabadi BS, Moslemi Naeini H, Tafti RA, Mazdak S (2015) Experimental investigation of the ovality of holes on pre-notched channel products in the cold roll forming process. J Mater Process Tech 225:213–220

Bidabadi BS, Moslemi Naeini H, Tehrani MS, Barghikar H (2016) Experimental and numerical study of bowing defects in cold roll-formed, U-channel sections. J Constr Steel Res 118:243–253

Bidabadi BS, Moslemi Naeini H, Tafti RA, Barghikar H (2016) Experimental study of bowing defects in pre-notched channel section products in the cold roll forming process. Int J Adv Manuf Technol 87:997–1011

Abeyrathna B, Rolfe B, Weiss M (2017) The effect of process and geometric parameters on longitudinal edge strain and product defects in cold roll forming. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-017-0164-x

Senanayake RS, Cole IM, Thiruvarudchelvan S (1994) The application of computational and experimental techniques to metal deformation in cold roll forming. J Mater Process Tech 45:155–160

Cockcroft MG, Latham DJ (1968) Ductility and the workability of metals. J Inst Met 96:33

Shim KH, Lee SK, Kang BS, Hwang SM (2004) Investigation on blanking of thin sheet metal using the ductile fracture criterion and its experimental verification. J Mater Process Tech. 155-156:1935–1942

Fang G, Zeng P, Lou LL (2002) Finite element simulation of the effect of clearance on the forming quality in the blanking process. J Mater Process Tech 122:249–254

Subramonian S, Altan T, Campbell C, Ciocirlan B (2013) Determination of forces in high speed blanking using FEM and experiments. J Mater Process Tech 213:2184–2190

Metallic materials-tensile testing-Part 1: Method of test at room temperature (2010) General Administration of Quality Supervision, Inspection and Quarantine of PR China, Standardization Administration of the PR China

MSC. Marc, volume B: Element Library. USA: MSC Software Corporation (2013)

Coefficient of friction. http://www.engineershandbook.com/Tables/frictioncoefficients.htm

Deform 3D, V6.0, Appendix F: Fracture with Element Deletion and Damage

Wang XJ, Tu HD (1994) Leng wan xing gang sheng chan ji ying yong. Metallurgical Industry Press, Beijing (in Chinese)

Funding

This work was supported by the National Natural Science Foundation of China [grant number 51475247], the Science and Technology Project of Zhejiang Province [grant number 2016C31018], the Natural Science Foundation of Zhejiang [grant number LZ17E050001], the Natural Science Foundation of Ningbo [grant number 2016A610057], and the National Natural Science Foundation of Zhejiang [grant number Q17E050012].

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, ZX., Shu, XD., Yin, AM. et al. Experimental and numerical analysis on the forming and shearing quality of C-channel steel. Int J Adv Manuf Technol 94, 3665–3678 (2018). https://doi.org/10.1007/s00170-017-1109-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-1109-0