Abstract

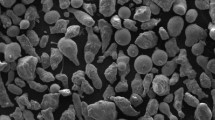

A method of coating aluminum powder with Nylon-12 via a dissolution-precipitation process to prevent hydrolysis reaction in gel casting was introduced in this study. Aluminum powder additive was adopted to facilitate the synthesis of mullite via Al-SiO2 reaction which could help to improve the high-temperature strength of Al2O3-based ceramic molds. However, the aluminum powder would have hydrolysis reaction and affect the rheological properties of the slurry. While adding the aluminum powder that was treated by corroding oxidation film and coated with Nylon-12, the slurry could finish the gel casting process. The coated aluminum almost had no impact on the rheology property of the slurry, as the viscosities of the slurries with different diameters of coated aluminum additive were all under 1 Pa s. The microstructures and phase compositions of the sintered ceramic samples were investigated by scanning electron microscopy (SEM) and X-ray diffraction (XRD), respectively. Effects of coated aluminum powder additive on the high-temperature strength of Al2O3-based ceramic containing nano-SiO2 and MgO were investigated. The bending strength of the ceramic mold at 1500 °C peaked at 20.88 MPa with 1 μm coated aluminum powder additive. Finally, a porous Al2O3-based ceramic mold was fabricated with adoption of this method and successfully applied to cast a turbine blade, indicating that the high-temperature strength of the ceramic mold could meet the casting requirements.

Similar content being viewed by others

References

Cay H, Xu H, Li QZ (2013) Mechanical behavior of porous magnesium/alumina composites with high strength and low density. Mater Sci Technol 574:137–142

Sako EY, Braulio MAL, Pandolfelli VC (2012) The corrosion resistance of microsilica-containing Al2O3-MgO and Al2O3-spinel castables. Ceram Int 38:4783–4789

Wu HH, Li DC, Chen XJ, Sun B, Xu DY (2010) Rapid casting of turbine blades with abnormal film cooling holes using integral ceramic casting molds. Int J Adv Manuf Tech 50(1–4):13–19

Lu ZL, Lu F, Cao JW, Li DC (2013) Fabricating hollow turbine blades using short carbon fiber-reinforced SiC composite. Int J Adv Manuf Tech 69(1–4):417–425

Wang X, Pan D, Xu Q, He M, Chen SW, Yu F, Li RF (2014) Synthesis of ordered mesoporous alumina with high thermal stability using aluminum nitrate as precursor. Mater Lett 135:35–38

Yen HC, Tang HH (2012) Study on direct fabrication of ceramic shell mold with slurry-based ceramic laser fusion and ceramic laser sintering. Int J Adv Manuf Tech 60(9–12):1009–1015

Zhang LF, Olhero S, Jose F (2016) Thermo-mechanical and high temperature dielectric properties of cordierite-mullite-alumina ceramic. Ceram Int 42:16897–16905

Lu ZL, Fan YX, Miao K, Jing H, Li DC (2014) Effects of adding aluminum oxide or zirconium oxide fibers on ceramic molds for casting hollow turbine blades. Int J Adv Manuf Tech 72(5–8):873–880

Pereira D, Biasibetti GRS, Camerini RV (2014) Sintering of mullite by different methods. Mater Manuf Process 29:391–396

Bushlya V, Zhou JM, Avdovic P, Stahl JE (2013) Wear mechanisms of silicon carbide-whisker-reinforced alumina (Al2O3-SiCw) cutting tools when high-speed machining aged alloy 718. Int J Adv Manuf Tech 68(5–8):1083–1093

Shao H, Liang K, Peng F (2004) Crystallization kinetics of MgO-Al2O3–SiO2 glass-ceramics. Ceram Int 30:927–930

Chen M, Wang N, Liu W (2007) Preparation and properties of alumina–magnesia precast block for ladle lining. Mater Lett 61:3388–3390

Chotard T, Soro J, Lemercier H, Huger M, Gault C (2008) High temperature characterisation of cordierite–mullite refractory by ultrasonic means. J Eur Ceram Soc 28:2129–2135

Wang C, Wang HJ, Fan XY, Zhou J, Xia HY, Fan JP (2016) Fabrication of dense beta-Si3N4-based ceramic coating on porous Si3N4 ceramic. J Eur Ceram Soc 35:1743–1750

Tsukuma K, Ueda K, Matsushita K, Shimada K (1985) High-temperature strength and fracture toughness of Y2O3-partially-stabilized ZrO2/Al2O3 composites. J Am Ceram Soc 68:56–58

Kupp ER, Kochawattana S, Lee SH, Misture S, Messing GL (2014) Particle size effects on yttrium aluminum garnet (YAG) phase formation by solid-state reaction. J Mater Res 29:2303–2311

Murayama Y, Hanada S, Lee JH (2004) Microstructure and high-temperature strength of directionally solidified Al2O3/YAG/ZrO2 eutectic composite. Mater Trans 45:303–306

Kocjan A, Cesnovar M, Vengust D, Kosmac T, Dakskobler A (2016) Translucent yttria-and silica-doped mullite ceramics with anisotropic grains produced by spark plasma sintering. J Am Ceram Soc 99:3090–3096

Iftekhar S, Grins J, Gunawidjaja PN, Eden M (2011) Glass formation and structure–property–composition relations of the RE2O3-Al2O3-SiO2 (RE = La, Y, Lu, Sc) systems. J Am Ceram Soc 94:2429–2435

Herrmann M, Lippmann W, Hurtado A (2014) Y2O3–Al2O3–SiO2-based glass-ceramic fillers for the laser-supported joining of SiC. J Eur Ceram Soc 34:1935–1948

Zhou QQ, Liang XP, Wang J, Wang H, Chen P, Zhang D, Yang SM, Li JX (2015) Preparation of active aluminum-coated basalt fiber mat for defluoridation from drinking water. J Sol-Gel Sci Technol 78:331–338

Mao XJ, Shimai SZ, Dong MJ, Wang SW (2007) Gel casting of alumina using epoxy resin as a gelling agent. J Am Ceram Soc 90:986–988

Kim Y, Hwang W (2015) Wettability modified aluminum surface for a potential antifungal surface. Mater Lett 161:234–239

Colin S, Richard J, Ian R (2000) The influence of particle size distribution on the processing of food. J Food Eng 51:201–208

Qi C, Zheng Y, Cao L, Gao J, Wan Y (2015) Preparation and performance of sol-gel-derived alumina film modified by stearic acid. J Sol-Gel Sci Technol 78:641–646

Manojkumar PA, Gandhi AS, Kamaraj M, Tyagi AK (2014) Sliding wear behavior of alumina coatings prepared from mechanically milled powders. Wear 313:11–18

Hu B, Yao MW, Xiao RH, Chen JW, Yao X (2014) Optical properties of amorphous Al2O3 thin films prepared by a sol-gel process. Ceram Int 40:14133–14139

Yan CZ, Hao L, Xu L, Shi YS (2011) Preparation, characterisation and processing of carbon fibre/polyamide-12 composites for selective laser sintering. Compos Sci Technol 71:1834–1841

Piotter V, Mueller T, Plewa K, Prokop J, Ritzhaupt-Kleissl H-J, Hausselt J (2010) Manufacturing of complex-shaped ceramic components by micropowder injection molding. Int J Adv Manuf Technol 46:131–134

Cheah CM, Chua CK, Lee CW, Feng C, Totong K (2005) Rapid prototyping and tooling techniques: a review of applications for rapid investment casting. Int J Adv Manuf Technol 25(3):308–320

Chua CK, Feng C, Lee CW, Ang GQ (2005) Rapid investment casting: direct and indirect approaches via model maker II. Int J Adv Manuf Technol 25(1–2):26–32

Raja V, Zhang SJ, Garside J, Ryall C, Wimpenny D (2006) Rapid and cost-effective manufacturing of high integrity aerospace components. Int J Adv Manuf Technol 27(7):759–777

Miao K, Lu ZL, Cao JW, Zhang H, Li DC (2015) Effect of polydimethylsiloxane on the mid-temperature strength of gelcast Al2O3 ceramic part. Mater Des 89:810–814

Jones DEG, Brousseau P, Fouchard RC, Turcotte AM, Kwok QSM (2000) Thermal characterization of passivated nanometer size aluminum powders. J Therm Anal Calorim 61:805–818

Velamakanni BV, Lunge FF (1991) Effect of interparticle potentials and sedimentation on particle packing density of bimodal particle distributions during pressure filtration. J Am Ceram Soc 74:166–172

Wu SX, Claussen N (1991) Fabrication and properties of low-shrinkage reaction-bonded Mullite. J Am Ceram Soc 74:2460–2463

Leo S, Tallon C, Franks GV (2014) Aqueous and nonaqueous colloidal processing of difficult-to-densify ceramics: suspension rheology particle packing. J Am Ceram Soc 97:3807–3817

Guo L, Yang J, Feng YB, Qiu T, Chen B, Wan W (2016) Preparation and properties of AlN ceramic suspension for non-aqueous gel casting. Ceram Int 42:8066–8071

Wu HH, Li DC, Tang YP, Sun B, Xu DY (2009) Gelcasting of alumina based ceramic cores containing yttria for single crystal and directional solidification blades. Adv Appl Ceram 108:406–411

Chen XJ, Li DC, Wu HH, Tang YP, Zhao L (2011) Analysis of ceramic shell cracking in stereolithography-based rapid casting of turbine blade. Int J Adv Manuf Technol 55(5–8):447–455

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lu, Z., Chen, Y., Miao, K. et al. Microstructures and high-temperature strength of gel-casting Al2O3-based ceramic molds with coated aluminum additive. Int J Adv Manuf Technol 94, 845–854 (2018). https://doi.org/10.1007/s00170-017-0930-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0930-9