Abstract

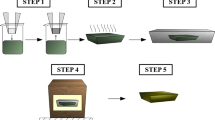

A tungsten inert gas (TIG) welding process was utilized successfully to produce a dense and hard iron aluminide coating on an aluminized plain carbon steel substrate. The aluminized surface of the steel sheets was melted using different currents in the range of 30 to 50 A. The surface and cross section of the alloyed layers were studied using optical microscopy, scanning electron microscopy, X-ray diffraction and a nano-hardness test. The results showed that the volume of the pool formed during the surface melting had a critical influence on the phases formed during the process. Forty amperes was found to be the optimum TIG current, at which a Fe-rich aluminide consisting mainly of Fe3Al formed on the steel substrate.

Similar content being viewed by others

References

Christoglou C, Voudouris N, Angelopoulos GN (2002) Formation and modelling of aluminide coatings on iron by a fluidised bed CVD process. Surf Coat Technol 155(1):51–58

Pérez FJ, Pedraza F, Hierro MP, Hou PY (2000) Adhesion properties of aluminide coatings deposited via CVD in fluidised bed reactors (CVD-FBR) on AISI 304 stainless steel. Surf Coat Technol 133:338–343

Corbin SF, Toyserkani E, Khajepour A (2003) Cladding of an Fe-aluminide coating on mild steel using pulsed laser assisted powder deposition. Mater Sci Eng A A354(1):48–57

Wang YQ, Zhang Y, Wilson DA (2010) Formation of aluminide coatings on ferritic–martensitic steels by a low-temperature pack cementation process. Surf Coat Technol 204(16–17):2737–2744

Emami M, Shahverdi HR, Hayashi S, Torkamany MJ (2013) A combined hot dip aluminizing/laser alloying treatment to produce iron-rich aluminides on alloy steel. Metall Mater Trans A 44(7):3176–3184

Zhang Y, Pint BA, Garner GW, Cooley KM, Haynes JA (2004) Effect of cycle length on the oxidation performance of iron aluminide coatings. Surf Coat Technol 188-189:35–40

Zhang Y, Pint BA, Cooley KM, Haynes JA (2005) Effect of nitrogen on the formation and oxidation behavior of iron aluminide coatings. Surf Coat Technol 200(5–6):1231–1235

Zhan ZL, He YD, Wang DR, Gao W (2006) Preparation of aluminide coatings at relatively low temperatures. Trans Nonferrous Metals Soc China 16(3):647–653

Fan P, Riddle E, Fang ZZ, Sohn HY (2008) Iron aluminide coatings by an in-situ reaction process. Surf Coat Technol 202(24):6090–6094

Masahashi N, Watanabe S, Hanada S (2001) Microstructure and oxidation behavior of low pressure plasma sprayed iron aluminides. ISIJ Int 41(9):1010–1017

Totemeier TC, Wright RN, Swank WD (2004) FeAl and Mo–Si–B intermetallic coatings prepared by thermal spraying. Intermetallics 12:1335–1344

Ji G, Elkedim O, Grosdidier T (2005) Deposition and corrosion resistance of HVOF sprayed nanocrystalline iron aluminide coatings. Surf Coat Technol 190(2–3):406–416

Tian YS, Chen CZ, Chen LX, Huo QH (2006) Microstructures and wear properties of composite coatings produced by laser alloying of Ti–6Al–4V with graphite and silicon mixed powders. Mater Lett 60(1):109–113

Majumdar JD, Mordike BL, Manna I (2000) Friction and wear behavior of Ti following laser surface alloying with Si, Al and Si+ Al. Wear 242(1):18–27

Cheol J, Lee S (2004) Correlation of microstructure with hardness and fracture properties of (TiC,SiC)/Ti–6Al–4V surface composites fabricated by high-energy electron-beam irradiation. Surf Coat Technol 179(2–3):340–348

Euh K, Lee J, Lee S, Koo Y, Kim NJ (2001) Microstructural modification and hardness improvement in boride/Ti–6Al–4V surface-alloyed materials fabricated by high-energy electron beam irradiation. Scr Mater 45(1):1–6

Monfared A, Kokabi AH, Asgari S (2013) Microstructural studies and wear assessments of Ti/TiC surface composite coatings on commercial pure Ti produced by titanium cored wires and TIG process. Mater Chem Phys 137(3):959–966

Ghadami F, Heydarzadeh Sohi M, Ghadami S (2015) Effect of TIG surface melting on structure and wear properties of air plasma-sprayed WC–Co coatings. Surf Coat Technol 261:108–113

Amirsadeghi A, Sohi MH, Bozorg SF (2008) Effects of TIG surface melting and chromium surface alloying on microstructure, hardness and wear resistance of ADI. J Iron Steel Res Int 15(4):86–94

Mridha S, Ong HS, Poh LS, Cheang P (2001) Intermetallic coatings produced by TIG surface melting. J Mater Process Technol 113(1):516–520

Hayes RW, Jeng YL, Lavernia EJ, Wolfenstine J (1995) Preliminary characterization of the room temperature fracture behavior of monolithic and composite FeAl 3-Fe 2 Al 5. Scr Metall Mater 32(3):433–437

Shahverdi HR, Ghomashchi MR, Shabestari S, Hejazi J (2002) Microstructural analysis of interfacial reaction between molten aluminium and solid iron. J Mater Process Technol 124(3):345–352

Brandes EA, Brook GB (1999) Smithells metals reference book, Seventh edn. Butterworth-Heinemann, Oxford

Kou S (2003) Welding metallurgy, 2nd edn. Wiley, Hoboken, New Jersey

Yajiang L, Yonglan Z, Yuxian L (1995) Characteristics of phase constitution in the Fe-Al alloy layer of calorized steel pipe. J Mater Sci 30:2635–2639

Yuan T, Kou S, Luo Z (2016) Grain refining by ultrasonic stirring of the weld pool. Acta Mater 106:144–154

Bahrami A, Helenbrook B, Valentine D, Aidun D (2016) Fluid flow and mixing in linear GTA welding of dissimilar ferrous alloys. Int J Heat Mass Transf 93:729–741

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Omranian Mohammadi, P., Raiszadeh, R. & Shahverdi, H. Formation of iron aluminide coatings on plain carbon steel by TIG process. Int J Adv Manuf Technol 96, 1655–1663 (2018). https://doi.org/10.1007/s00170-017-0797-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0797-9