Abstract

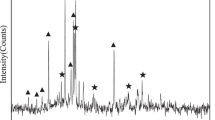

As a result of the increasing global demand for refined copper, the reserves of primary sources of copper have been decreasing at a tremendously fast rate; which thus makes secondary copper processing an ever-increasing importance within the global copper industry. Copper smelter dust (CSD) is a potential secondary source of copper that is produced during copper pyrometallurgy. The significant amount of copper value these CSDs often plays host to prompts the need to develop processes to meaningfully remove sulfur and other associated impurities from it, prior to subsequent treatment in the copper recovery process. Hence, this present work carried out a thermal analysis and kinetic study on the oxidative roasting process of copper smelter dust under non-isothermal condition in air using DSC-TGA equipment. The non-isothermal experiments were carried out at heating rates of 5, 10, 15, and 20 °C/min, from room temperature up to 1000 °C. The intermediate phases formed in each stage of the oxidative roasting of the CSD were identified. After the first weight loss step, sulfate compounds were mainly formed in the second stage, and approximately 48% of sulfur contained in the metallurgical waste was removed. In the third stage, the sulfur removal reaction was carried out; the rest of sulfur was nearly removed in this stage. Kinetics of the third stage was analyzed from the dynamic DSC-TGA data by means of Coats and Redfern equation. The nucleation and growth model yielded a satisfactory fit to these experimental data.

Similar content being viewed by others

References

Reuter M, van Schaik A (2008) Thermodynamic metrics for measuring the “sustainability” of design for recycling. JOM 60(8):39–46

European Commission (2009) European dioxin inventory—secondary copper production [online]. Available from: <http://ec.europa.eu/environment/dioxin/pdf/stage1/seccopper.pdf> [Accessed 23 February 2011] Umer, Asim, et al. “Selection of a suitable method for the synthesis of copper nanoparticles.” Nano 7.05 (2012): 1230005

Wang JB, Hung CH, Hung CH, Chang-Chien GP (2009) Polychlorinated dibenzo-p-dioxin and dibenzofuran emissions from an industrial park clustered with metallurgical industries. J Hazard Mater 161(2):800–807

Montenegro V, Sano H, Fujisawa T (2008) Recirculation of Chilean copper smelting dust with high arsenic content to the smelting process. Mater Trans 49(9):2112–2118

Regulation, E.C., 1999. No 1907/2006 of the European Parliament and of the Council of 18 December 2006, concerning the Registration. Evaluation, Authorisation and Restriction of Chemicals (REACH), establishing a European Chemicals Agency, amending Directive, 45, pp.1-849

Neveling, U. (2011) Palabora mining company annual report on ambient air quality monitoring

Qiang L, Pinto IS, Youcai Z (2014) Sequential stepwise recovery of selected metals from flue dusts of secondary copper smelting. J Clean Prod 84:663–670

Wu JY, Chang FC, Wang HP, Tsai MJ, Ko CH, Chen CC (2015) Selective leaching process for the recovery of copper and zinc oxide from copper-containing dust. Environ Technol 36(23):2952–2958

Pinto IS, Soares HM (2012) Selective leaching of molybdenum from spent hydrodesulphurisation catalysts using ultrasound and microwave methods. Hydrometallurgy 129:19–25

Pinto IS, Soares HM (2013) Recovery of molybdates from an alkaline leachate of spent hydrodesulphurisation catalyst–proposal of a nearly-closed process. J Clean Prod 52:481–487

Bakhtiari F, Atashi H, Zivdar M, Bagheri SS (2008) Continuous copper recovery from a smelter’s dust in stirred tank reactors. Int J Miner Process 86(1):50–57

Bakhtiari F, Zivdar M, Atashi H, Bagheri SS (2008) Bioleaching of copper from smelter dust in a series of airlift bioreactors. Hydrometallurgy 90(1):40–45

Alguacil FJ, Garcia-Diaz I, Lopez F, Rodriguez O (2015) Recycling of copper flue dust via leaching-solvent extraction processing. Desalin Water Treat 56(5):1202–1207

Chen Y, Liao T, Li G, Chen B, Shi X (2012) Recovery of bismuth and arsenic from copper smelter flue dusts after copper and zinc extraction. Miner Eng 39:23–28

Xu ZF, Qiang LI, Nie HP (2010) Pressure leaching technique of smelter dust with high-copper and high-arsenic. Trans Nonferrous Metals Soc China 20:s176–s181

Vítková M, Ettler V, Hyks J, Astrup T, Kříbek B (2011) Leaching of metals from copper smelter flue dust (Mufulira, Zambian Copperbelt). Appl Geochem 26:S263–S266

Vakylabad AB, Schaffie M, Ranjbar M, Manafi Z, Darezereshki E (2012) Bio-processing of copper from combined smelter dust and flotation concentrate: a comparative study on the stirred tank and airlift reactors. J Hazard Mater 241:197–206

Bakhtiari F, Darezereshki E (2011) One-step synthesis of tenorite (CuO) nano-particles from Cu4(SO4)(OH)6 by direct thermal-decomposition method. Mater Lett 65(2):171–174

Prasad S, Pandey BD (1998) Alternative processes for treatment of chalcopyrite—a review. Miner Eng 11(8):763–781

Leiter KL, LEWIS J, Porter WH, Wadsworth ME (1960) Sulfating of cuprous sulfide and cuprous oxide. Trans Metall Soc AIME 218(3):519–525

Ingraham TR (1965) Thermodynamics of the thermal decomposition of cupric sulfate and cupric oxysulfate. Trans Metall Soc AIME 233(2):359–362

Kubaschewski, O., Alcock, C.B. and Spencer, P.J. (1993) Materials thermodynamics

National Research Council (US) Chemical Sciences Roundtable (1999) Recent Advances in Computational Thermochemistry and Challenges for the Future

Khalafalla SE, Shah ID (1970) Oxidative roasting of covellite with minimal retardation from the CuO CuSO4 film. Metall Trans 1(8):2151–2156

Shah ID, Khalafalla SE (1971) Kinetics and mechanism of the conversion of covellite (CuS) to digenite (Cu1. 8S). Metall Trans 2(9):2637–2643

Mitovski A, Štrbac N, Manasijević D, Sokić M, Daković A, Živković D, Balanović L (2015) Thermal analysis and kinetics of the chalcopyrite-pyrite concentrate oxidation process. Meta 54(2):311–314

Kim BS, Kim EY, Kim CK, Lee HI, Sohn JS (2008) Kinetics of oxidative roasting of complex copper concentrate. Mater Trans 49(5):n1192–n1198

SANS (2005) South African National Standard: ambient air quality–limits for common pollutants

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Okanigbe, D.O., Popoola, A.P.I. & Adeleke, A.A. Thermal analysis and kinetics of the oxidative roasting process of a copper smelter dust. Int J Adv Manuf Technol 94, 2393–2400 (2018). https://doi.org/10.1007/s00170-017-0789-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0789-9