Abstract

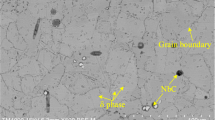

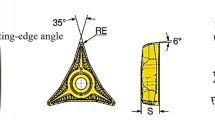

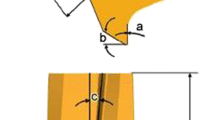

Machining titanium alloy Ti-6Al-4V is a challenging task since tool flank wear adversely affects surface integrity. Quantitative effects of predetermined tool flank wear values (VB) on the surface integrity were investigated through the orthogonal dry cutting of Ti-6Al-4V. Experimental results indicated that three-dimensional (3D) average surface roughness increased with the VB ranging from 0 to 0.2 mm but decreased at VB = 0.3 mm. Given the effects of rubbing and ironing enhanced, surface material burning and plastic flows emerged on the machined surface at VB = 0.3 mm. Not only the plastic deformation layer became deeper but also the grains were greatly distorted with the increase of tool flank wear. When machined by using the tool at VB = 0.3 mm, the β phase of Ti-6Al-4V decreased near the machined surface layer than that of using the fresh tool. Besides, the depth of work-harden layer increased from 20 to 60 μm with the VB increasing from 0 to 0.3 mm. The softened layer was generated near the machined surface by using the tool at VB = 0.3 mm. In addition, the residual compressive stresses of the machined surface had the trend of decreasing. Experimental results indicated that the VB less than 0.2 mm was the most suitable condition for better surface integrity during orthogonal dry cutting of Ti-6Al-4V. This study aims at providing experimental data for optimizing the processing parameters and improving the surface integrity of Ti-6Al-4V.

Similar content being viewed by others

References

Ezugwu EO (2005) Key improvements in the machining of difficult-to-cut aerospace super alloys. Int J Mach Tools Manuf 45(12):1353–1367

Geetha M, Singh AK, Asokamani R, Gogia AK (2009) Ti based biomaterials, the ultimate choice for orthopaedic implants—a review. Prog Mater Sci 54(3):397–425

Le Guéhennec L, Soueidan A, Layrolle P, Amouriq Y (2007) Surface treatments of titanium dental implants for rapid osseointegration. Dent Mater 23(7):844–854

Mandal N, Doloi B, Mondal B, Das R (2011) Optimization of flank wear using zirconia toughened alumina (ZTA) cutting tool: Taguchi method and regression analysis. Measurement 44(10):2149–2155

Ulutan D, Ozel T (2011) Machining induced surface integrity in titanium and nickel alloys: a review. Int J Mach Tools Manuf 51(3):250–280

Bermingham MJ, Kirsch J, Sun S, Palanisamy S, Dargusch MS (2011) New observations on tool life, cutting forces and chip morphology in cryogenic machining Ti-6Al-4V. Int J Mach Tools Manuf 51(6):500–511

Rahim EA, Sasahara H (2011) Investigation of tool wear and surface integrity on MQL machining of Ti-6AL-4V using biodegradable oil. Proc Inst Mech Eng B-J Eng Ma 225(9):1505–1511

Smithey DW, Kapoor SG, DeVor RE (2001) A new mechanistic model for predicting worn tool cutting forces. Mach Sci Technol 5(1):23–42

Yan L, Yang W, Jin H, Wang Z (2012) Analytical modeling of the effect of the tool flank wear width on the residual stress distribution. Mach Sci Technol 16(2):265–286

Zhang G, To S, Zhang S (2016) Relationships of tool wear characteristics to cutting mechanics, chip formation, and surface quality in ultra-precision fly cutting. Int J Adv Manuf Technol 83(1–4):133–144

Che-Haron CH, Jawaid A (2005) The effect of machining on surface integrity of titanium alloy Ti–6% Al–4% V. J Mater Process Technol 166(2):188–192

Yang HC, Chen ZT, Zhou ZT (2015) Influence of cutting speed and tool wear on the surface integrity of the titanium alloy Ti-1023 during milling. Int J Adv Manuf Technol 78(5–8):1113–1126

Ginting A, Nouari M (2009) Surface integrity of dry machined titanium alloys. Int J Mach Tools Manuf 49(3):325–332

Yao CF, Tan L, Ren JX, Lin Q, Liang YS (2014) Surface integrity and fatigue behavior for high-speed milling Ti-10V-2Fe-3Al titanium alloy. J Fail Anal Prev 14(1):102–112

Gong Y, Sun Y, Wen X, Wang C, Gao Q (2016) Experimental study on surface integrity of Ti-6Al-4V machined by LS-WEDM. Int J Adv Manuf Technol 88(1–4):197–207

Rao B, Dandekar CR, Shin YC (2011) An experimental and numerical study on the face milling of Ti-6Al-4V alloy: tool performance and surface integrity. J Mater Process Technol 211(2):294–304

Ducobu F, Arrazola PJ, Rivière-Lorphèvre E, Filippi E (2015) Finite element prediction of the tool wear influence in Ti6Al4V machining. Procedia CIRP 31:124–129

Lei S, Shin YC, Incropera FP (2000) Deformation mechanisms and constitutive modeling for silicon nitride undergoing laser-assisted machining. Int J Mach Tools Manuf 40(15):2213–2233

Li W, Guo YB, Barkey ME, Jordon JB (2014) Effect tool wear during end milling on the surface integrity and fatigue life of Inconel 718. Procedia CIRP 14:546–551

Rotella G, Dillon OW Jr, Umbrello D, Settineri L, Jawahir IS (2014) The effects of cooling conditions on surface integrity in machining of Ti6Al4V alloy. Int J Adv Manuf Technol 71(1–4):47–55

Nouari M, Makich H (2014) On the physics of machining titanium alloys: interactions between cutting parameters, microstructure and tool wear. Metals 4(3):335–358

Wang W, Wang M, Jie Z, Sun F, Huang D (2008) Research on the microstructure and wear resistance of titanium alloy structural members repaired by laser cladding. Opt Laser Eng 46(11):810–816

Abdel-Hady M, Hinoshita K, Morinaga M (2006) General approach to phase stability and elastic properties of β-type Ti-alloys using electronic parameters. Scripta Mater 55(5):477–480

Zhu D, Zhang X, Ding H (2013) Tool wear characteristics in machining of nickel-based superalloys. Int J Mach Tools Manuf 64:60–77

Chen L, El-Wardany TI, Harris WC (2004) Modelling the effects of flank wear land and chip formation on residual stresses. CIRP Ann-Manuf Technol 53(1):95–98

Masmiati N, Sarhan AAD, Hassan MAN, Hamdi M (2016) Optimization of cutting conditions for minimum residual stress, cutting force and surface roughness in end milling of S50C medium carbon steel. Measurement 86:253–265

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liang, X., Liu, Z. Experimental investigations on effects of tool flank wear on surface integrity during orthogonal dry cutting of Ti-6Al-4V. Int J Adv Manuf Technol 93, 1617–1626 (2017). https://doi.org/10.1007/s00170-017-0654-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0654-x