Abstract

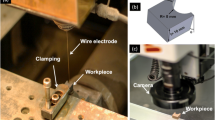

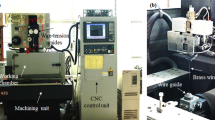

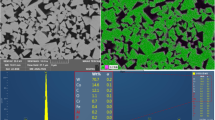

Tungsten carbide-cobalt composite (WC-Co) is commonly considered a difficult to machine material due to its very high hardness. High strength and wear resistance make WC-Co a preferred material for manufacturing of tools, dies, and molds, etc. All such applications require complex shapes to be machined including curved features. The present study is carried out to evaluate the potential of wire electric discharge machining (WEDM) to fabricate concave and convex curved profiles of different radii in WC-Co. Taguchi design of experiments technique has been employed to investigate the influence of six control variables including open circuit voltage, pulse-on time, pulse-off time, servo voltage, wire tension, and dielectric pressure, on two response characteristics namely radius of concave profile and radius of convex profile. The analysis of variance (ANOVA) has been performed to identify the significant parameters affecting the performance measures. Regression models have also been developed for both profiles to predict the radii of curved profiles against any combination of machining parameters. It has been observed that machining performance in terms of overcut and undercut depends on the geometry to be machined. However, proposed combinations of machining parameters could effectively reduce undercut/overcut of the profiles to 10 μm. Moreover, scanning electron microscopy has been performed in order to visualize recast layer, micro-cracks, and micro-chipping caused by WEDM process.

Similar content being viewed by others

References

Merklein M, Andreas K, Engel U (2011) Influence of machining process on residual stresses in the surface of cemented carbides. Procedia Engineering 19:252–257

Lin D, Xu J, Shan Z, Chung ST, Park SJ (2015) Fabrication of WC-Co cutting tool by powder injection molding. Int J Precis Eng Manuf 16(7):1435–1439

Assarzadeh S, Ghoreishi M (2013) Statistical modeling and optimization of process parameters in electro-discharge machining of cobalt-bonded tungsten carbide composite (WC/6% Co). Procedia CIRP 6:463–468

Jahan MP, Rahman M, Wong YS (2011) A review on the conventional and micro-electrodischarge machining of tungsten carbide. Int J Mach Tools Manuf 51(12):837–885

Liu K, Li XP (2001) Ductile cutting of tungsten carbide. J Mater Process Technol 113:348–354

Liu K, Li XP, Rahman M, Liu XD (2004) A study of the cutting modes in the grooving of tungsten carbide. Int J Adv Manuf Technol 24:321–326

Mahdavinejad RA, Mahdavinejad A (2005) ED machining of WC-Co. J Mater Process Technol 163:637–643

Jangra K, Groover S, Aggarwal A (2012) Optimization of multi machining characteristics in WEDM of WC-5.3% Co composite using integrated approach of Taguchi, GRA and entropy method. Front Mech Eng 7(3):288–299

Ahmed N, Darwish S, Alahmari AM (2016) Laser ablation and laser-hybrid ablation processes: a review. Mater Manuf Process 31(9):1121–1142

Levy GN, Wertheim R (1988) EDM-machining of sintered carbide compacting dies. CIRP Annals - Manufacturing Technolgy 37(1):175–178

Lauwers B, Kruth JP, Eeraerts W (2005) Wear behaviour and tool life of wire-EDM-ed and ground carbide punches. CIRP Annals - Manufacturing Technolgy 54(1):163–166

Kim CH, Kruth JP (2001) Influence of the electrical conductivity of dielectric on WEDM of sintered carbide. KSME Int J 15(12):1676–1682

Jangra K, Groover S, Chan FTS, Aggarwal A (2011) Digraph and matrix method to evaluate the machinability of tungsten carbide composite with wire EDM. Int J Adv Manuf Technol 56:959–974

Shayan AV, Afza RA, Teimouri R (2013) Parametric study along with selection of optimal solutions in dry wire cut machining of cemented tungsten carbide (WC-Co). J Manuf Process 15(4):644–658

Singha A, Pal SK, Saha P (2008) Soft computing models based prediction of cutting speed and surface roughness in wire electro-discharge machining of tungsten carbide cobalt composite. Int J Adv Manuf Technol 39(1–2):74–84

Jangra K, Grover S, Aggarwal A (2011) Digraph and matrix method for the performance evaluation of carbide compacting die manufactured by wire EDM. Int J Adv Manuf Technol 54:579–591

Muthuraman V, Ramakrishnan R (2012) Multi parametric optimization of WC-Co composites using desirability approach. Procedia Eng 38:3381–3390

Yan MT, Lai YP (2007) Surface quality improvement of wire-EDM using a fine-finish power supply. Int J Mach Tools Manuf 47:1686–1694

Yan MT, Liu YT (2009) Design, analysis and experimental study of a high-frequency power supply for finish cut of wire-EDM. Int J Mach Tools Manuf 49(10):793–796

Shah A, Mufti NA, Rakwal D, Bamberg E (2011) Material removal rate, kerf, and surface roughness of tungsten carbide machined with wire electrical discharge machining. J Mater Eng Perform 20(1):71–76

Sanchez JA, De Lacalle LNL, Lamikiz A (2004) A computer-aided system for the optimization of the accuracy of the wire electro-discharge machining process. Int J Comput Integr Manuf 17(5):413–420

Conde A, Sanchez JA, Plaza S, Ramos JM (2016) On the influence of wire-lag on the WEDM of low-radius free-form geometries. Procedia CIRP 42:274–279

Firouzabadi HA, Parvizian J, Abdullah A (2015) Improving accuracy of curved corners in wire EDM successive cutting. Int J Adv Manuf Technol 76:447–459

Kechagias J (2007) An experimental investigation of the surface roughness of parts produced by LOM process. Rapid Prototyp J 13(1):17–22

Jangra KK (2015) An experimental study for multi-pass cutting operation in wire electrical discharge machining of WC-5.3% Co composite. Int J Adv Manuf Technol 76:971–982

Yan BH, Tsai HC, Huang FY, Lee LC (2005) Examination of wire electrical discharge machining of Al2O3p/6061Al composites. Int J Mach Tools Manuf 45:251–259

Patil NG, Brahmankar PK (2010) Some studies into wire electro-discharge machining of alumina particulate-reinforced aluminum matrix composites. Int J Adv Manuf Technol 48:537–555

Kumar A, Kumar V, Kumar J (2013) Multi-response optimization of process parameters based on response surface methodology for pure titanium using WEDM process. Int J Adv Manuf Technol 68:2645–2668

Plaza S, Ortega N, Sanchez JA, Pombo I, Mendikute A (2008) Original models for the prediction of angular error in wire-EDM taper-cutting. Int J Adv Manuf Technol 44(5–6):529–538

Ikram A, Mufti NA, Saleem MQ, Khan AR (2013) Parametric optimization for surface roughness, kerf and MRR in wire electrical discharge machining (WEDM) using Taguchi design of experiment. J Mech Sci Technol 27(7):2133–2141

Alahmari AM, Darwish S, Ahmed N (2016) Laser beam micro-milling (LBMM) of selected aerospace alloys. Int J Adv Manuf Technol 86(9–12):2411–2431

Azam M, Jahanzaib M, Abbasi JA, Abbas M, Wasim A, Hussain S (2016) Parametric analysis of recast layer formation in wire-cut EDM of HSLA steel. Int J Adv Manuf Technol 87:713–722

Lee SH, Li X (2003) Study of the surface integrity of the machined workpiece in the EDM of tungsten carbide. J Mater Process Technol 139:315–321

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Naveed, R., Mufti, N.A., Mughal, M.P. et al. Machining of curved profiles on tungsten carbide-cobalt composite using wire electric discharge process. Int J Adv Manuf Technol 93, 1367–1378 (2017). https://doi.org/10.1007/s00170-017-0592-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0592-7