Abstract

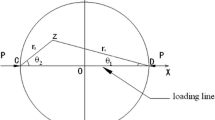

In this paper, an upper-bound analysis is developed to model the rod extrusion process of the strain hardening materials. A velocity field, including radial and angular velocity components, is assumed in the deformation zone. This field permits to predict the possible formation of a central burst. The strain rate levels were calculated in each region of billet to apply strain hardening effect in the presented central bursting criterion. The presented criterion is compared with FEM simulation data and the experimental data of the published papers. The results show that the central bursting defects are affected primarily by the strain hardening exponent. So that by increasing the strain hardening exponent, the possibility of the central bursting defects and the relative extrusion pressure is being decreased. Based on the obtained criterion, the diagram is presented for the safe zones in a wide range of process variables.

Similar content being viewed by others

References

Avitzur B (1968) Metal forming; processes and analysis. McGraw-Hill, New York

Lim LG, Dunne FPE (1996) Modelling central bursting in the extrusion of particulate reinforced metal matrix composite materials. Int J Mach Tools Manuf 37:901–915

Avitzur B (1968) Analysis of central bursting defects in extrusion and wire drawing. ASME J Eng Ind 90(1):79–90

Plancak M, Vilotic D, Kacmarcik I (2014) Stress state in forward cold extrusion. J Technol Plastic 39(1):21–27

Ragab AR, Samy SN, Saleh CAR (2005) Prediction of central bursting in drawing and extrusion of metals. ASME J Manuf Sci Eng 127:698–702

Choi S, Lee YS, Oh HK (1998) Ductile fracture in axisymmetric extrusion. J Mater Process Technol 74:263–267

Aravas N (1986) The analysis of void growth that leads to central burst during extrusion. J Mech Phys Solids 34:55–79

Reddy NV, Dixit PM, Lal GK (2000) Ductile fracture criteria and its prediction in axisymmetric drawing. Int J Mach Tools Manuf 40:95–111

Gurney FJ, DePierre V (1974) The influence of the interface conditions on the plastic deformation region and the resultant product integrity in extrusion. ASME J Eng Ind 96:912–916

Parghazeh A, Haghighat H (2016) Prediction of central bursting defects in rod extrusion process with upper bound analysis method. Trans Nonferrous Metals Soc China 26:2892–2899

Ayada M, Higashino T, Mori K (1987) Central bursting in extrusion of inhomogeneous materials. Adv Technol Plastic 1:553–558

Zimerman Z, Avitzur B (1970) Analysis of the effect of strain hardening on central bursting defects in drawing and extrusion. ASME J Eng Ind 92(1):135–145

Moritoki H (1991) The criterion for central bursting and its occurence in drawing and extrusion under plane strain. Int J Plast 7:713–731

Wu S, Li M (1992) Analysis of the central cavity of axisymmetric forward extrusion by upper bound approach. J Mater Eng Perform 1:409–414

Alberti N, Barcellona A, Masnata A, Micari F (1993) Central bursting defects in drawing and extrusion: numerical and ultrasonic evaluation. CIRP Ann Manuf Technol 42:269–272

Reddy NV, Dixit PM, Lal GK (1996) Central bursting and optimal die profile for axisymmetric extrusion. ASME J Manuf Sci Eng 118:579–584

Moritoki H, Okuyama E (1998) Prediction of central bursting in extrusion. J Mater Process Technol 80-81:579–584

Ko DC, Kim BM (2000) The prediction of central burst defects in extrusion and wire drawing. J Mater Process Technol 102:19–24

Saanouni K, Mariage JF, Cherouat A, Lestriez P (2004) Numerical prediction of discontinuous central bursting in axisymmetric forward extrusion by continuum damage mechanics. Comput Struct 82:2309–2332

McVeigh C, Liu WK (2006) Prediction of central bursting during axisymmetric cold extrusion of a metal alloy containing particles. Int J Solids Struct 43:3087–3105

Soyarslan C, Tekkaya AE (2009) Prevention of internal cracks in forward extrusion by means of counter pressure: a numerical treatise. Steel Res Int 80:671–679

Sebek F, Kubik P, Petruska J (2015) Prediction of central bursting in the process forward extrusion using the uncoupled ductile failure models. Adv Mater Process Technol 1(1–2):43–48

Hosseini SH, Sedighi M, Mosayebnezhad J (2016) Numerical and experimental investigation of central cavity formation in aluminum during forward extrusion process. J Mech Sci Technol 30(5):1951–1956

Ebrahimi R, Reihanian M, Kanaani M, Moshksar MM (2008) An upper-bound analysis of the tube extrusion process. J Mater Process Technol 199(1–3):214–220

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Haghighat, H., Parghazeh, A. An investigation into the effect of strain hardening on the central bursting defects in rod extrusion process. Int J Adv Manuf Technol 93, 1127–1137 (2017). https://doi.org/10.1007/s00170-017-0577-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0577-6